Vermiculizer for preparing vermicular graphite cast iron and preparation method thereof

A technology of vermicular graphite cast iron and vermicular agent, which is applied in the field of cast iron material production, can solve the problems of unstable reaction, low vermicularization rate, and low production cost, and achieve small whitening tendency, low production cost, and good plasticity and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

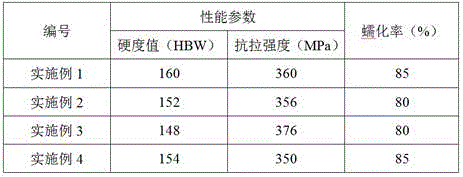

Examples

Embodiment 1

[0014] Example 1: Smelting molten iron in an intermediate frequency induction furnace, first put the pig iron into the furnace, and then add scrap steel and ferrosilicon to the furnace after it is completely melted to adjust the chemical composition of the molten iron. Out of the furnace; adopt the bottom-packing method for vermicularization treatment and inoculation treatment, select SiFe75 inoculant, the addition amount is 1% of the original molten iron, and the addition amount of the vermicular agent is 0.8% of the original molten iron, according to the mass of the element composition The fraction ratios are: 14 parts of rare earth, 40 parts of silicon, 4 parts of magnesium, iron balance and a small amount of impurity elements. The temperature of creeping treatment is 1420~1450℃, and the sample is poured after removing slag from the furnace.

Embodiment 2

[0015] Example 2: The difference between this example and Example 1 is that the used vermicular agents are respectively: 14 parts of rare earth, 40 parts of silicon, 8 parts of magnesium, iron balance and a small amount of impurity elements according to the mass fraction ratio of element components . Other steps are identical with embodiment 1.

Embodiment 3

[0016] Embodiment 3: The difference between this embodiment and embodiment 1 or embodiment 2 is that the used vermicular agent is respectively according to the mass fraction ratio of element components: 18 parts of rare earth, 38 parts of silicon, 4 parts of magnesium, iron balance and A small amount of impurity elements. Other steps are identical with embodiment 1 or embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com