A kind of preparation method of vermicular graphite cast iron braking material

A brake material, technology of vermicular graphite cast iron, applied in the field of preparation of vermicular graphite cast iron brake material, can solve the problem of material shaping reduction, achieve stable creep rate, stable quality, and ensure the effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

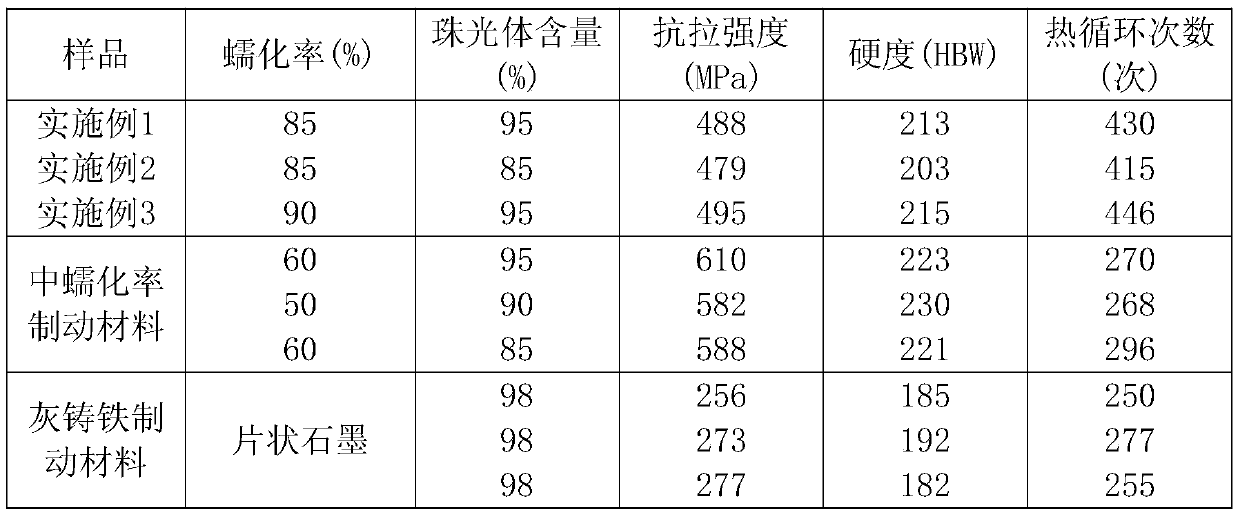

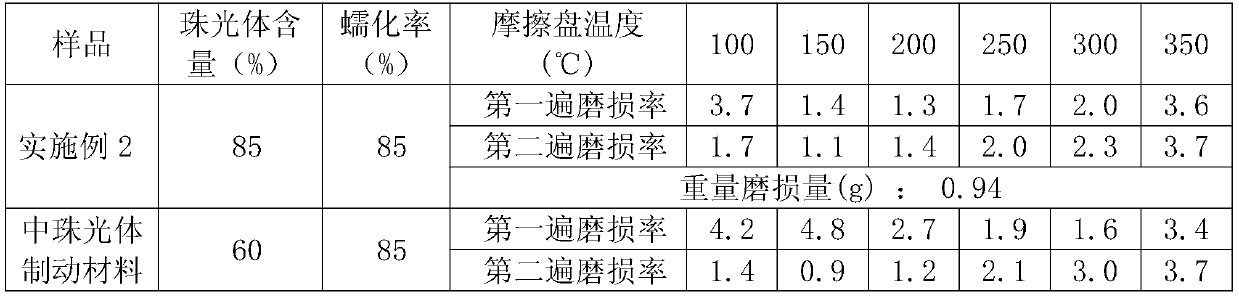

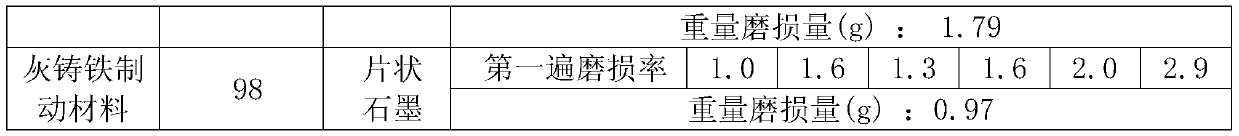

Examples

preparation example Construction

[0021] A preparation method of vermicular graphite cast iron brake material, comprising the following steps in sequence:

[0022] Pre-treatment of vermicularization: first put the molten iron obtained from smelting into the vermicularization treatment bag for scalding, then pour the vermicularization agent into the bottom of the vermicularization treatment bag for compaction, and cover and compact with inoculants and iron plates in turn , wherein, the mass percentage content of the S element in the molten iron is less than 0.015%, the described vermicular agent is a rare earth magnesium titanium vermicular agent, and its raw material composition and mass percentage content are: Re 6%-12%, Mg 5%- 10%, Ti 5%~10%, Si 40%~50%, Ca<4%, the balance is Fe and unavoidable impurities, and the mass ratio of the vermicular agent, inoculant, and molten iron is 0.4%~0.7% :0.3%~0.5%: 1;

[0023] Vermicularization treatment: Divide the molten iron after scalding into two parts, and then quic...

Embodiment 1

[0039] A preparation method of vermicular graphite cast iron brake material, comprising the following steps in sequence:

[0040] Pre-treatment of vermicularization: first add Sn and Cu to the bottom of the vermicularization treatment bag, then put the molten iron obtained by smelting in the intermediate frequency furnace into the vermicularization treatment bag for scalding, and then pour the vermiserative agent into the vermicularization treatment bag Compact the bottom, and cover and compact with inoculants and iron plates successively, wherein the mass ratio of Sn, Cu, and molten iron is 0.1%:0.6%:1, and the mass percentage content of S element in the molten iron is 0.01 %, the content of active oxygen in molten iron is 0.0062%, and the vermicular agent is a rare earth magnesium titanium vermicular agent, and its raw material composition and mass percentage content are: Re 10%, Mg 8%, Ti 8%, Si 45%, Ca 3%, balance is Fe and unavoidable impurity, described inoculant is 75Si...

Embodiment 2

[0044] Step is with embodiment 1, and difference is:

[0045] In the pre-treatment step of vermicularization, the mass ratio of Sn, Cu, and molten iron is 0.07%:0.7%:1, and the raw material composition and mass percentage content of the vermicularizing agent are: Re 6%, Mg 5%, Ti 5% , Si 50%, Ca 3%, the balance is Fe and unavoidable impurities, and the mass ratio of vermicular agent, inoculant, and molten iron is 0.7%:0.3%:1.

[0046] In the vermisification treatment step, the standing time is 1min, and the temperature after the vermisification of molten iron is 1550°C;

[0047] In the pouring inoculation treatment step, the pouring temperature is 1430° C., and the mass ratio of the inoculant to the molten iron is 0.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com