Non-magnetic vermicular graphite cast iron material

A technology of vermicular graphite cast iron and weight percentage, applied in the field of cast iron materials, can solve the problems of loss of the properties of non-magnetic materials, easy decomposition and oxidation of the structure, poor machining performance, etc., to expand the scope of application, without heat treatment, reduce The effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

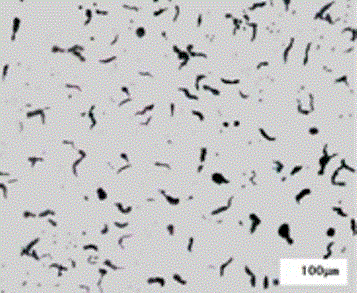

Image

Examples

Embodiment 1

[0028]A non-magnetic vermicular graphite cast iron material, the weight percentage of each component is: C2.8%, Si4.2%, Ni5.0%, Mn8.0%, Cu4.0%, Al0.4%, Mg (residual) 0.01-0.018%, Re (residual) 0.01-0.02%, the total amount of impurities (S, P, etc.) ≤ 0.2%, and the rest is Fe. Its concrete preparation steps are:

[0029] (1) Ingredients The raw materials used mainly include primary iron (Z18), steel scrap (45 # ), electrolytic nickel (Ni99.50), ferromanganese (65FeMn), ferrosilicon (75FeSi), electrolytic copper (1 # ), etc., the ratio of raw materials is determined according to the above-mentioned non-magnetic vermicular graphite cast iron material composition requirements. Among them, Si / Mn=0.52-0.59, Ni / Mn=0.5-0.63, Cu / Mn=0.47-0.5, and the silicon content in the original molten iron is 3.2%.

[0030] (2) Melting According to the material ratio in the previous step, put the material into the intermediate frequency electric furnace for smelting, and the temperature of the fu...

Embodiment 2

[0036] A non-magnetic vermicular graphite cast iron material, the weight percentage of each component is: C2.9%, Si4.0%, Ni4.5%, Mn7.5%, Cu3.6%, Al0.5%, Mg (residual) 0.01-0.018%, Re (residual) 0.01-0.02%, the total amount of impurities (S, P, etc.) ≤ 0.2%, and the rest is Fe. Its concrete preparation steps are:

[0037] (1) Ingredients The raw materials used mainly include primary iron (Z18), steel scrap (45 # ), electrolytic nickel (Ni99.50), ferromanganese (65FeMn), ferrosilicon (75FeSi), electrolytic copper (1 # ), pure aluminum (5052), vermicular agent (FeSiMgRe), etc., the ratio of raw materials is determined according to the above-mentioned non-magnetic vermicular graphite cast iron material composition requirements. Among them, Si / Mn=0.52-0.59, Ni / Mn=0.5-0.63, Cu / Mn=0.47-0.5, and the silicon content in the original molten iron is 3.0%.

[0038] (2) Melting According to the material ratio in the previous step, put the material into the intermediate frequency electric...

Embodiment 3

[0044] A non-magnetic vermicular graphite cast iron material, the weight percentage of each component is: C3.0%, Si3.8%, Ni4.0%, Mn7.0%, Cu3.4%, Al0.55%, Mg (residual) 0.01-0.018%, Re (residual) 0.01-0.02%, the total amount of impurities (S, P, etc.) ≤ 0.2%, and the rest is Fe. Its concrete preparation steps are:

[0045] (1) Ingredients The raw materials used mainly include primary iron (Z18), steel scrap (45 # ), electrolytic nickel (Ni99.50), ferromanganese (65FeMn), ferrosilicon (75FeSi), electrolytic copper (1 # ), pure aluminum (5052), vermicular agent (FeSiMgRe), etc., the ratio of raw materials is determined according to the above-mentioned non-magnetic vermicular graphite cast iron material composition requirements. Among them, Si / Mn=0.52-0.59, Ni / Mn=0.5-0.63, Cu / Mn=0.47-0.5, and the silicon content in the original molten iron is 2.8%.

[0046] (2) Melting According to the material ratio in the previous step, put the material into the intermediate frequency electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com