Smelting method of high strength vermicular iron

A high-strength, vermicular iron technology, applied in the field of iron smelting, can solve the problem of no smelting method, and achieve the effects of easy pouring temperature, small temperature drop, and stable creep rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

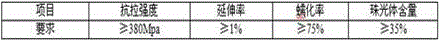

Examples

Embodiment 1

[0025] Embodiment 1: produce vermicular iron according to the following specific steps

[0026] (1) Ingredients: Add the weighed charge to the 1T intermediate frequency furnace. The charge is composed of returned charge, scrap steel and pig iron, and the returned charge accounts for 30% of the total charge;

[0027] (2) Melting: power transmission to melt the charge, fully stir the molten pool after the charge is melted, take samples for analysis and discharge slag, add ferrosilicon, ferromanganese, ferromolybdenum and copper alloy to adjust the chemical composition of molten iron, the chemical composition of molten iron is controlled as: carbon 3.3 %, silicon 2.2%, manganese 0.60%, phosphorus ≤0.07%, sulfur ≤0.05%, chromium 0.95%, copper 0.50%, molybdenum 0.20%, titanium ≤0.19%, magnesium 0.010%, RE 0.010%, and the rest is iron;

[0028] (3) Vermicularization: 0.45% of the amount of molten iron is placed in the vermisification ladle, and 3 / 5 of the molten iron in the ladle is...

Embodiment 2

[0031] Embodiment 2: produce vermicular iron according to the following specific steps

[0032] (1) Ingredients: Add the weighed charge to the 1T intermediate frequency furnace. The charge is composed of returned charge, scrap steel and pig iron, and the returned charge accounts for 30% of the total charge;

[0033] (2) Melting: power transmission to melt the charge, fully stir the molten pool after the charge is melted, take samples for analysis and release slag, add ferrosilicon, ferromanganese, ferromolybdenum and copper alloy to adjust the chemical composition of molten iron, the chemical composition of molten iron is controlled as follows: carbon 3.5 %, silicon 2.4%, manganese 0.70%, phosphorus ≤0.07%, sulfur ≤0.05%, chromium 0.97%, copper 0.60%, molybdenum 0.24%, titanium ≤0.19%, magnesium 0.020%, RE 0.020%, and the rest is iron;

[0034] (3) Vermisification: 0.50% of the amount of vermisifying agent is placed in the vermisification ladle, 3 / 5 of the molten iron in the l...

Embodiment 3

[0037] Embodiment 3: produce vermicular iron according to the following specific steps

[0038] (1) Ingredients: Add the weighed charge to the 1T intermediate frequency furnace. The charge is composed of returned charge, scrap steel and pig iron, and the returned charge accounts for 30% of the total charge;

[0039] (2) Melting: power transmission to melt the charge, fully stir the molten pool after the charge is melted, take samples for analysis and discharge slag, add ferrosilicon, ferromanganese, ferromolybdenum and copper alloy to adjust the chemical composition of molten iron, the chemical composition of molten iron is controlled as: carbon 3.6 %, silicon 2.6%, manganese 0.80%, phosphorus ≤0.07%, sulfur ≤0.05%, chromium 0.98%, copper 0.70%, molybdenum 0.28%, titanium ≤0.19%, magnesium 0.030%, RE 0.030%, and the rest is iron;

[0040] (3) Vermisification: 0.55% of the amount of vermisifying agent is placed in the vermisification ladle, 3 / 5 of the molten iron in the ladle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com