As-cast pearlite ductile iron material for crankshaft, and preparation method of the same

A pearlite sphere and as-cast technology, which is applied in the field of casting materials, can solve the problems of increased supercooling of molten iron, loss of toughness, and high strength, and achieves the effect of easy operation and stable as-cast material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

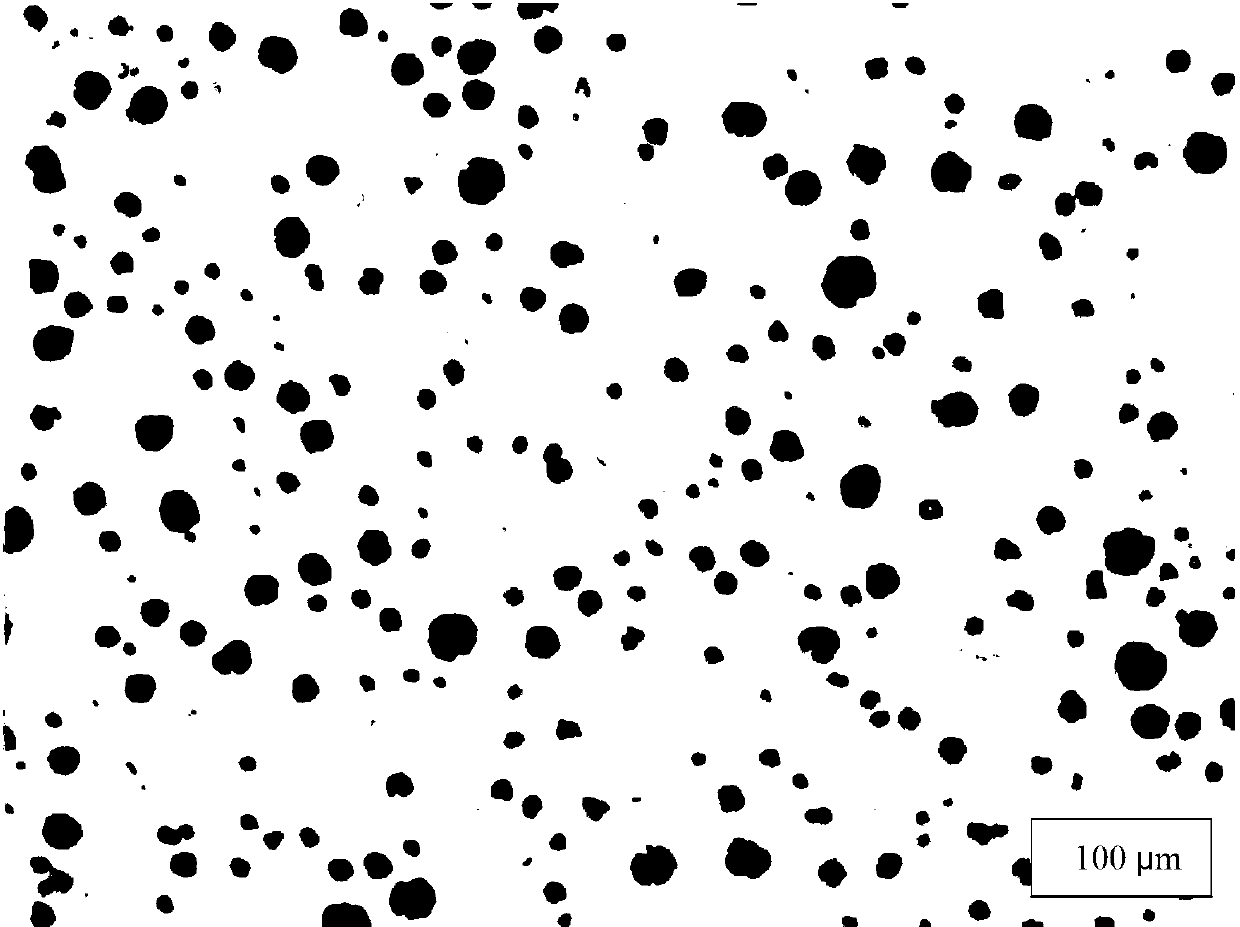

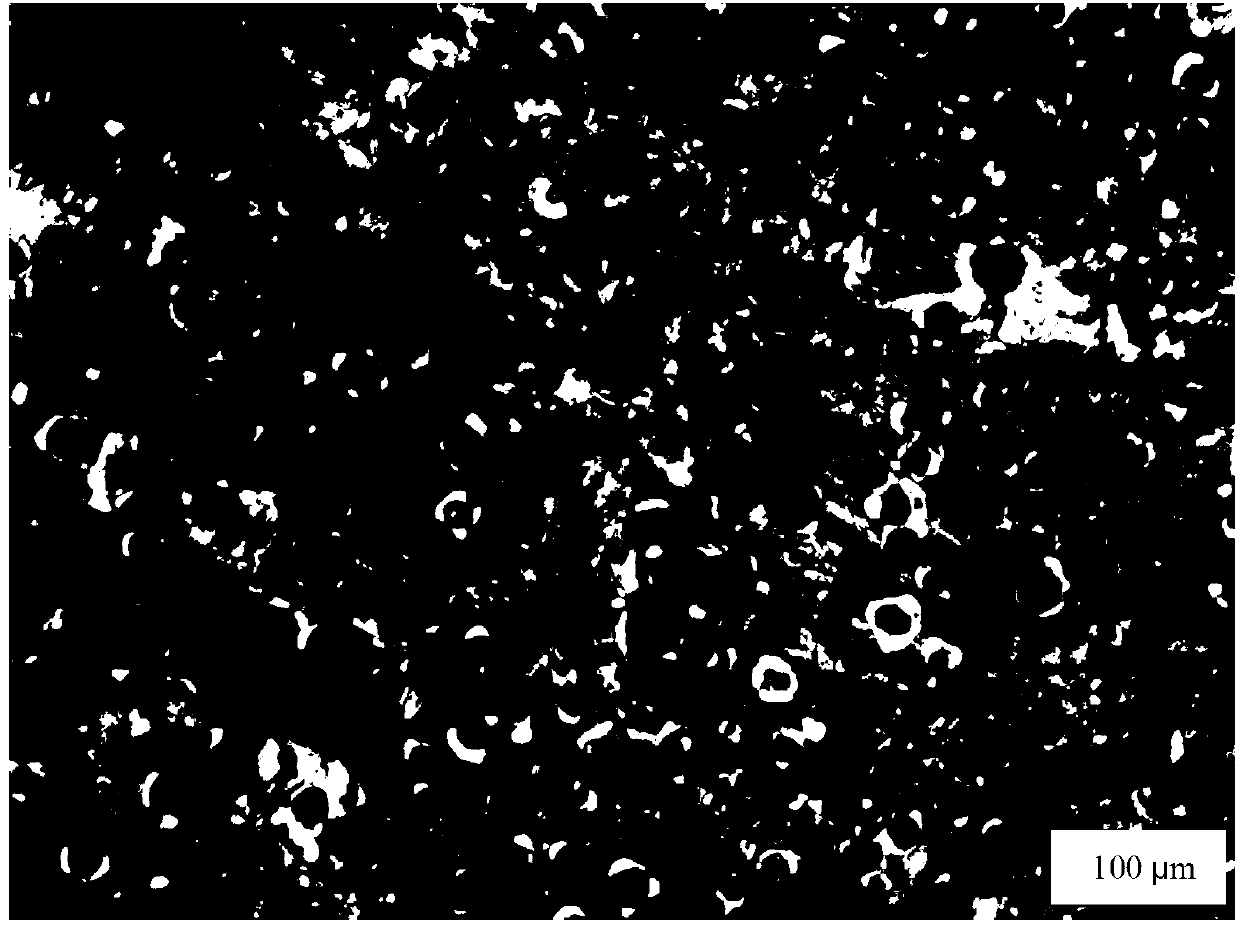

Image

Examples

Embodiment 1

[0035] A kind of as-cast pearlitic ductile iron material for crankshaft was prepared, the chemical composition mass percent was: C: 3.42%, Si: 2.27%, Mn: 0.16%, S: 0.009%, P: 0.026%, Cu: 0.92%, Sn : 0.013%, Mg: 0.035%, and the rest is Fe.

[0036] Preparation:

[0037] The first step is to use Q10 pig iron, recycled material, and scrap steel. The ratio of the three is: pig iron 300kg, recycled material 1200kg, and scrap steel 1500kg; smelting in an intermediate frequency electric furnace and adding a low-sulfur recarburizer (among them, the mass of carbon is 100kg) The sulfur content is greater than 99%, the mass percentage of sulfur is less than 0.05%; the particle size is 0.5-5mm) the amount of carbon is added in the furnace, and the melting temperature is 1505 °C;

[0038] The second step is to sample and detect the molten iron in the intermediate frequency induction furnace during the smelting process. The sampling and detection process is as follows: scoop a spoonful of ...

Embodiment 2

[0045] In this example, the chemical composition mass percentages are: C: 3.74%, Si: 2.58%, Mn: 0.34%, S: 0.008%, P: 0.027%, Cu: 1.08%, Sn: 0.029%, Mg: 0.047% , the rest is Fe; 900kg of Q10 pig iron, 1500kg of returned charge, 600kg of scrap steel, the addition of rare earth magnesium ferrosilicon nodulizer is 1.3% of the weight of the molten iron, and the rest of the content steps are the same as in Example 1.

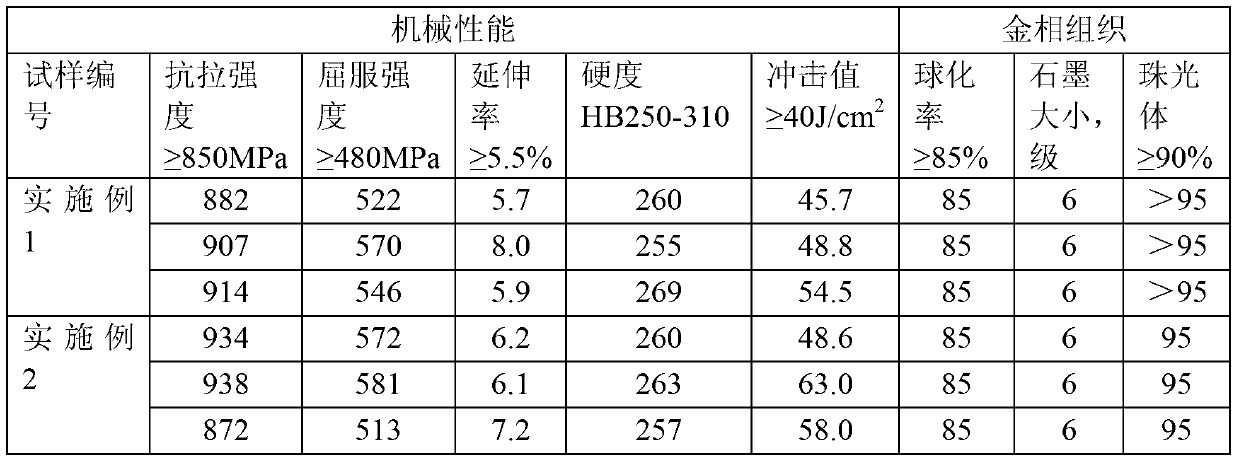

[0046] The material testing results are shown in Table 1.

Embodiment 3

[0048] In this example, the chemical composition mass percentages are: C: 3.59%, Si: 2.46%, Mn: 0.26%, S: 0.007%, P: 0.026%, Cu: 0.99%, Sn: 0.022%, Mg: 0.041% , the rest is Fe; Q10 pig iron 450kg, furnace charge 1350kg, steel scrap 1200kg, rare earth magnesium ferrosilicon nodulizer addition 1.25%, the rest of the content steps are the same as in Example 1.

[0049] The material testing results are shown in Table 1.

[0050] Table 1

[0051]

[0052]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com