Wear-resisting, high-toughness and high-strength excavator bucket tooth and manufacturing method thereof

A technology for excavator bucket teeth and a manufacturing method, which is applied to earth moving machines/shovels, construction, etc., can solve problems such as the inability to meet the high toughness requirements of excavator bucket teeth, achieve a simple and efficient manufacturing method, and increase graphite balls. Number, strength and toughness enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

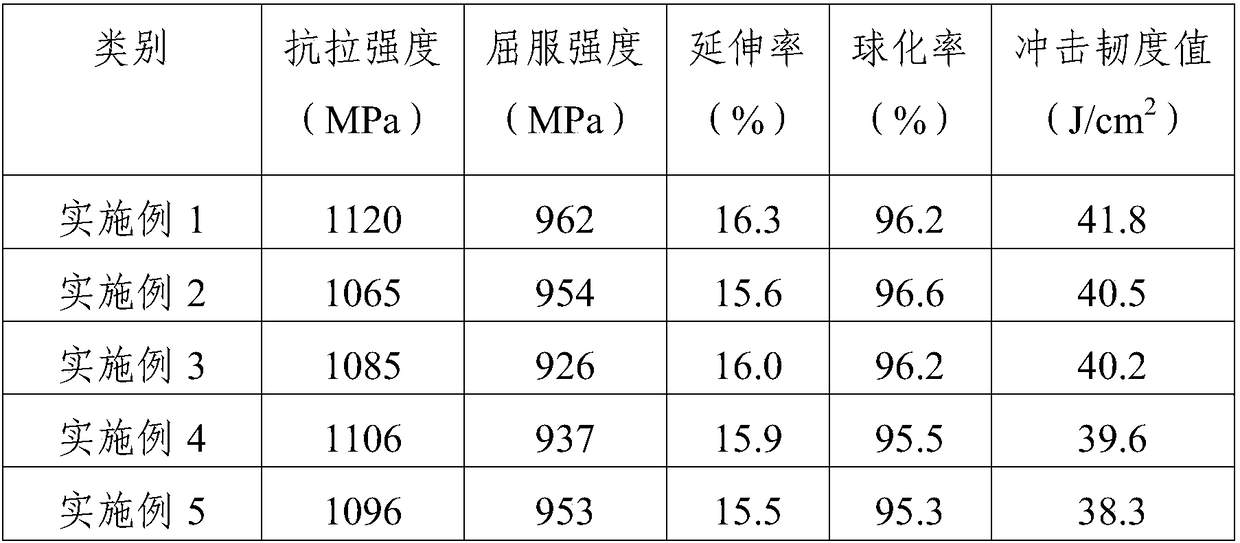

Examples

Embodiment 1

[0022] A wear-resistant, high-toughness, and high-strength excavator bucket tooth, the weight percentage of each element composition is: C: 3.65%, Si: 2.42%, Mn: 0.81%, Mg: 0.32%, Cu: 1.32%, Cr: 0.41 %, Ce: 0.08%, Mo: 0.09%, Te: 0.18%, Y: 0.07%, Nd: 0.018%, P≤0.02%, S≤0.02%, and the balance is Fe.

[0023] The method for manufacturing the above-mentioned wear-resistant, high-toughness, and high-strength excavator bucket teeth includes the following steps:

[0024] (1) After batching, each raw material is added to an intermediate frequency induction furnace for smelting. During the smelting process, the temperature of the molten iron is guaranteed to be 1550°C to obtain a molten iron with qualified chemical composition, and then static slag removal treatment is carried out;

[0025] (2) Mix cerium oxide with 0.12% of the total weight of molten iron and rare earth magnesium alloy nodulizer with 1.25% of the total weight of molten iron and add it into the nodulizer bag, and cover...

Embodiment 2

[0030] A wear-resistant, high-toughness, and high-strength excavator bucket tooth, the weight percentage of each element composition is: C: 3.9%, Si: 2.5%, Mn: 0.9%, Mg: 0.4%, Cu: 1.5%, Cr: 0.35 %, Ce: 0.1%, Mo: 0.09%, Te: 0.25%, Y: 0.06%, Nd: 0.01%, P≤0.02%, S≤0.02%, and the balance is Fe.

[0031] The method for manufacturing the above-mentioned wear-resistant, high-toughness, and high-strength excavator bucket teeth includes the following steps:

[0032] (1) After batching, each raw material is added to an intermediate frequency induction furnace for smelting. During the smelting process, the temperature of the molten iron is guaranteed to be 1580°C, and the molten iron with qualified chemical composition is obtained, and then static slag removal is carried out;

[0033] (2) Mix cerium oxide with 0.15% of the total weight of the molten iron and a rare earth magnesium alloy nodulizer with a total weight of 1.12% of the molten iron, and then add it to the nodulizer bag, and c...

Embodiment 3

[0038] A wear-resistant, high-toughness, and high-strength excavator bucket tooth, the weight percentage of each element composition is: C: 3.76%, Si: 2.3%, Mn: 0.65%, Mg: 0.2%, Cu: 1.2%, Cr: 0.5 %, Ce: 0.06%, Mo: 0.05%, Te: 0.1%, Y: 0.05%, Nd: 0.008%, P≤0.02%, S≤0.02%, and the balance is Fe.

[0039] The method for manufacturing the above-mentioned wear-resistant, high-toughness, and high-strength excavator bucket teeth includes the following steps:

[0040] (1) After batching, each raw material is added to an intermediate frequency induction furnace for smelting. During the smelting process, the temperature of the molten iron is guaranteed to be 1520°C, and the molten iron with qualified chemical composition is obtained, and then static slag removal is carried out;

[0041] (2) Mix cerium oxide with 0.12% of the total weight of molten iron and rare earth magnesium alloy nodulizer with 1.1% of the total weight of molten iron and add it into the nodulizer bag, and cover a laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com