Anti-skinning unshaped refractory material made of magnesium aluminate spinel used for cement kiln and preparation method and application of anti-skinning unshaped refractory material

A magnesia-aluminum spinel and refractory technology, which is applied in the field of magnesia-aluminum spinel anti-skinning amorphous refractories and its preparation, can solve problems such as poor anti-skin performance, and achieve excellent anti-skin resistance, Low thermal expansion coefficient and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0039] Example 1-3, Preparation and detection of magnesia-alumina spinel anti-skinning amorphous refractories for cement kilns

[0040] 1. Preparation of magnesia-alumina spinel anti-skinning amorphous refractories for cement kilns

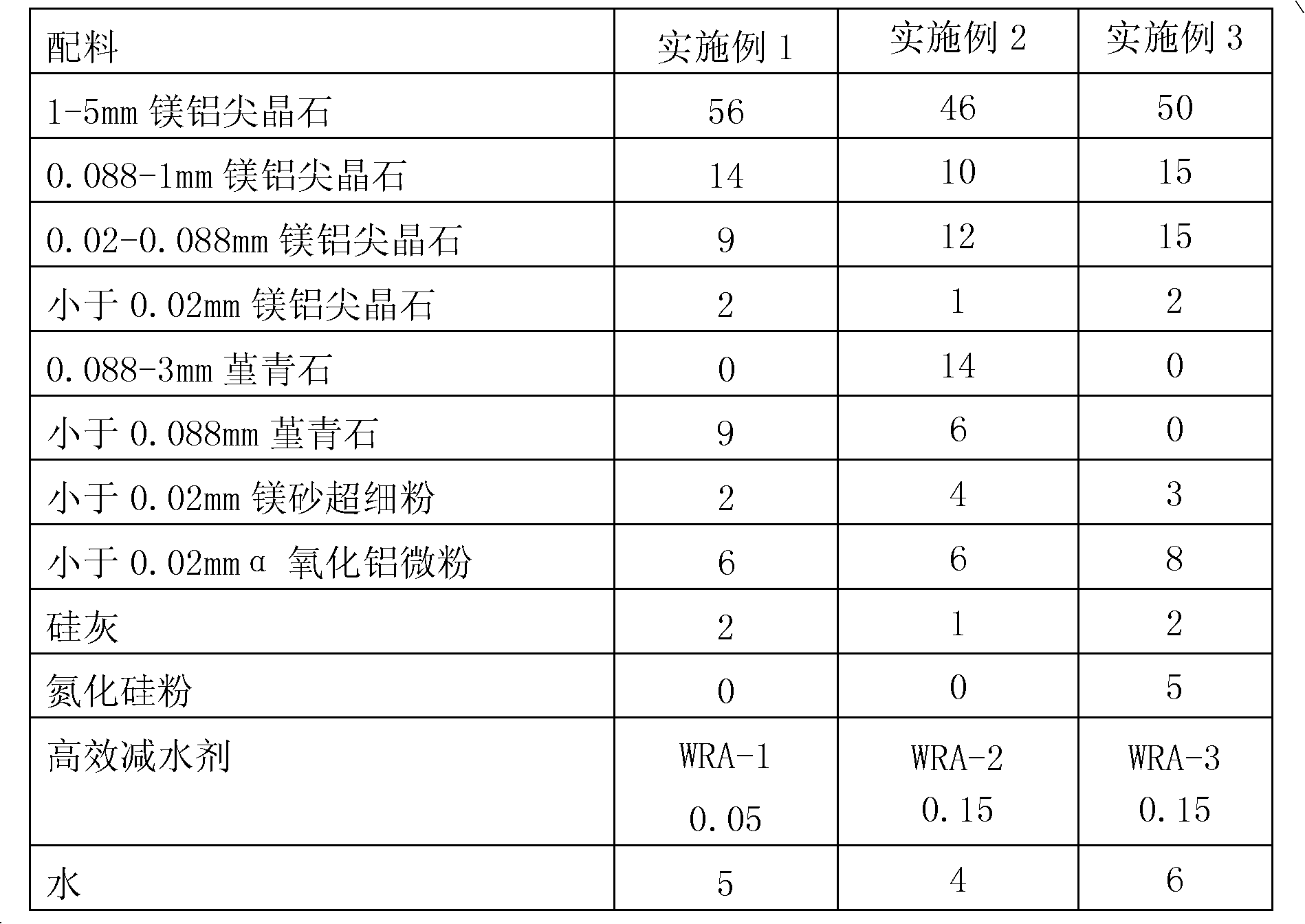

[0041] The formula of embodiment 1-3 cement kiln of the present invention uses magnesia-aluminum spinel anti-skinning amorphous refractory material as shown in table 1:

[0042] Table 1 Formula of magnesia-alumina spinel anti-skinning monolithic refractories for cement kilns (unit: kg)

[0043]

[0044] The preparation method of the magnesia-alumina spinel anti-skinning amorphous refractory material for cement kiln of embodiment 1-3 comprises the following steps:

[0045] 1) Take the raw materials according to the formula shown in Table 1;

[0046] 2) Mixing the raw materials to obtain the magnesia-alumina spinel anti-skinning amorphous refractory material for cement kilns.

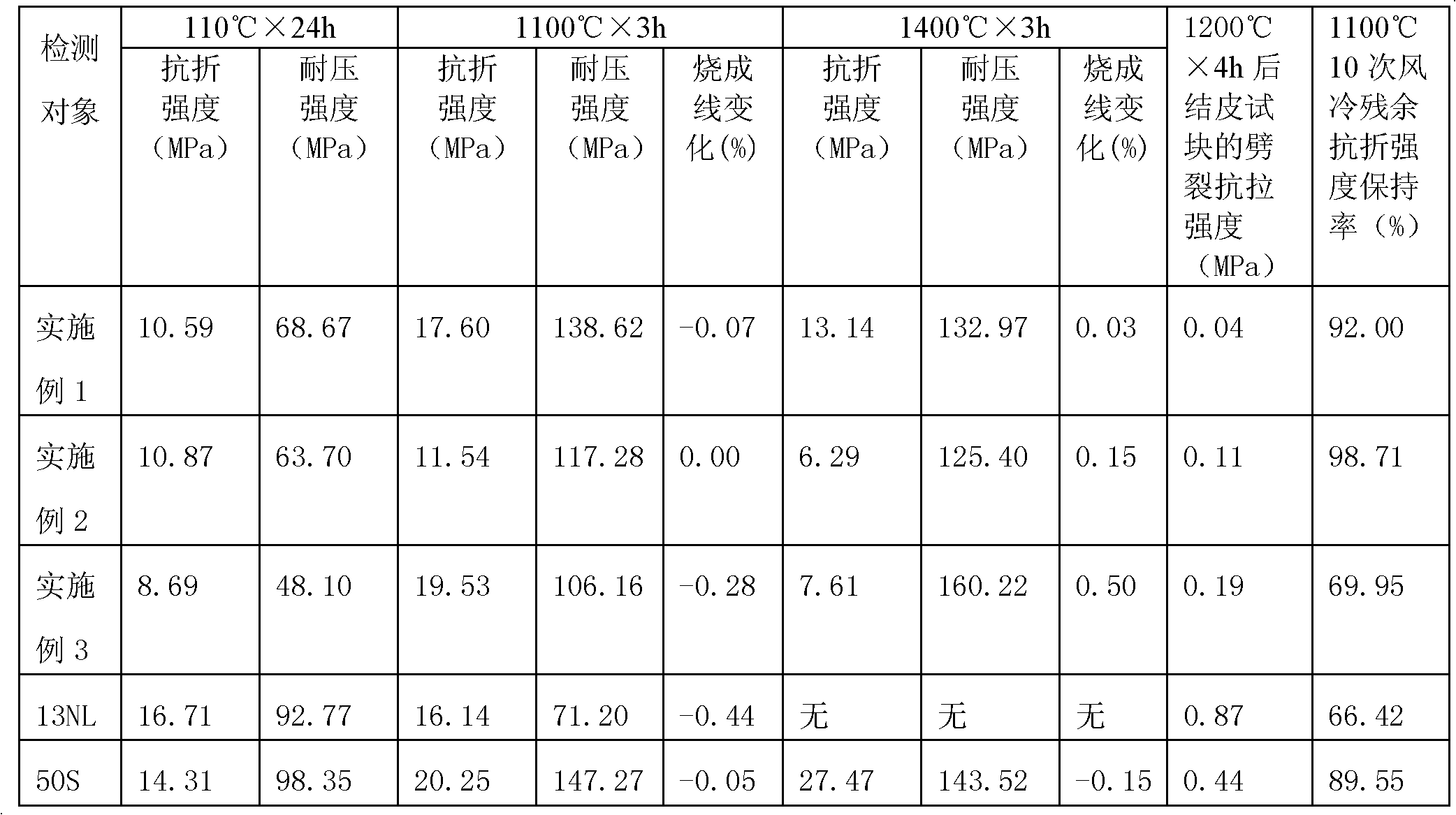

[0047] 2. Performance testing of magnesia aluminum spinel anti-ski...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com