Restoration structure and method for damaged concrete pavement panel

A technology for concrete pavement and repairing structure, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, and can solve the problems of high long-term use cost, short service life, and large deformation of newly built cement concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

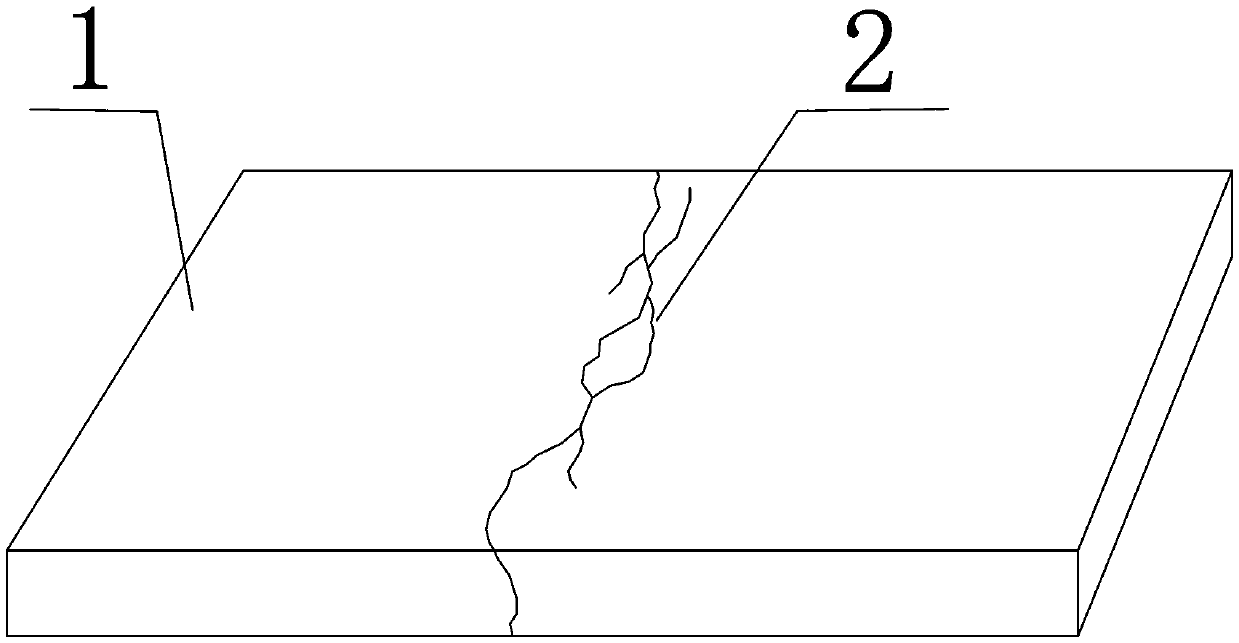

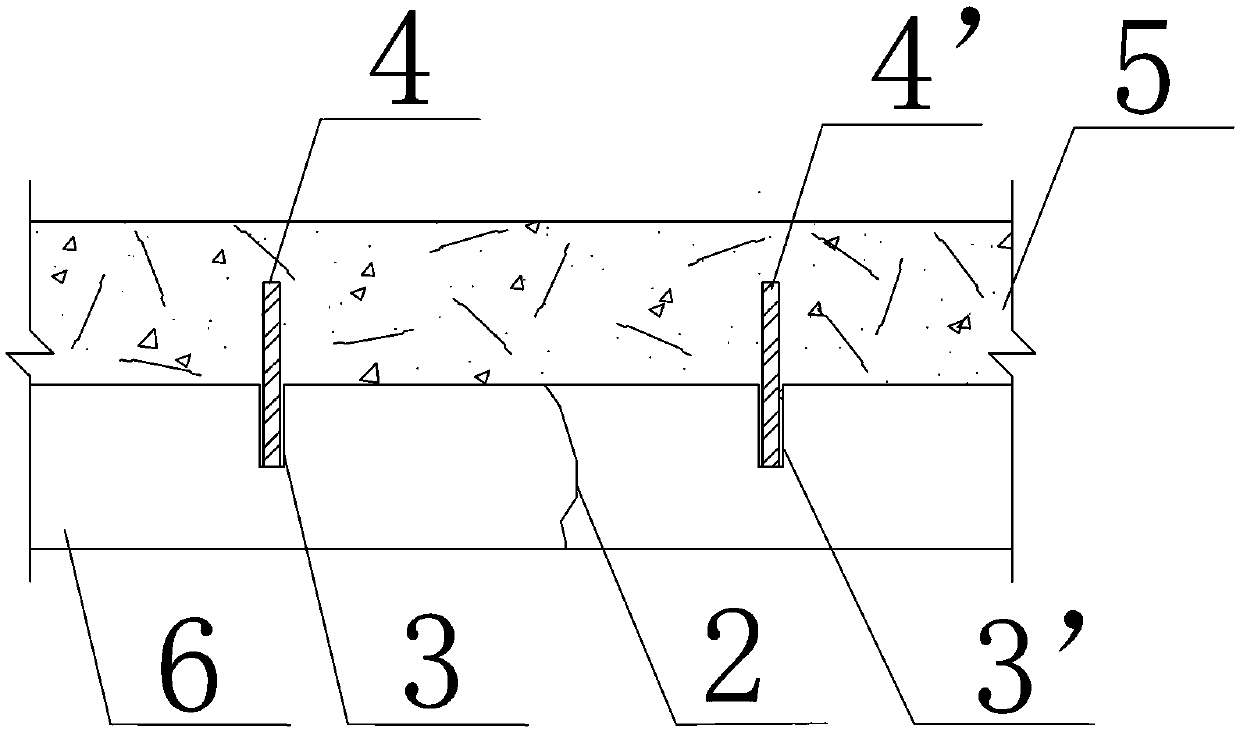

[0026] Examples such as figure 1 , figure 2 As shown, the repair structure of the damaged concrete pavement panel includes a concrete pavement panel 6 planed on the surface, a plurality of pairs of reinforcement holes 3 arranged in pairs on both sides of the broken plate crack 2 and distributed along the extending direction of the broken plate crack 2, 3', inserting vertically and bonding and fixing the steel bars 4, 4' in the reinforcement holes 3, 3' and pouring and fixing the steel fiber concrete overlay 5 on the concrete pavement panel 6, the steel bars The top of 4, 4' is higher than the upper surface of the concrete pavement panel 6 and lower than the upper surface of the steel fiber concrete overlay 5, and the depth of the groove formed by the concrete pavement panel 6 due to surface planing is less than Or equal to 1 / 4 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com