Patents

Literature

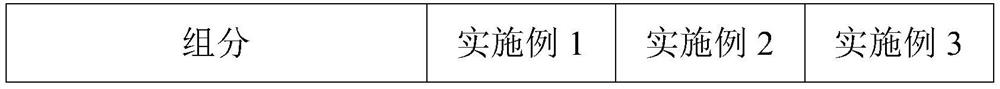

33results about How to "Shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing abrasive compact with improved properties

InactiveUS6132675AImproved abrasionImprove stabilityUltra-high pressure processesCeramic shaping apparatusPolycrystalline diamondCarbide

Metal carbide supported polycrystalline diamond (PCD) compacts having improved abrasion / impact resistance properties and a method for making the same under high temperature / high pressure (HT / HP) processing conditions. The PCD compact is characterized as having a mixture of submicron sized diamond particles and large sized diamond particles.

Owner:DIAMOND INNOVATIONS INC

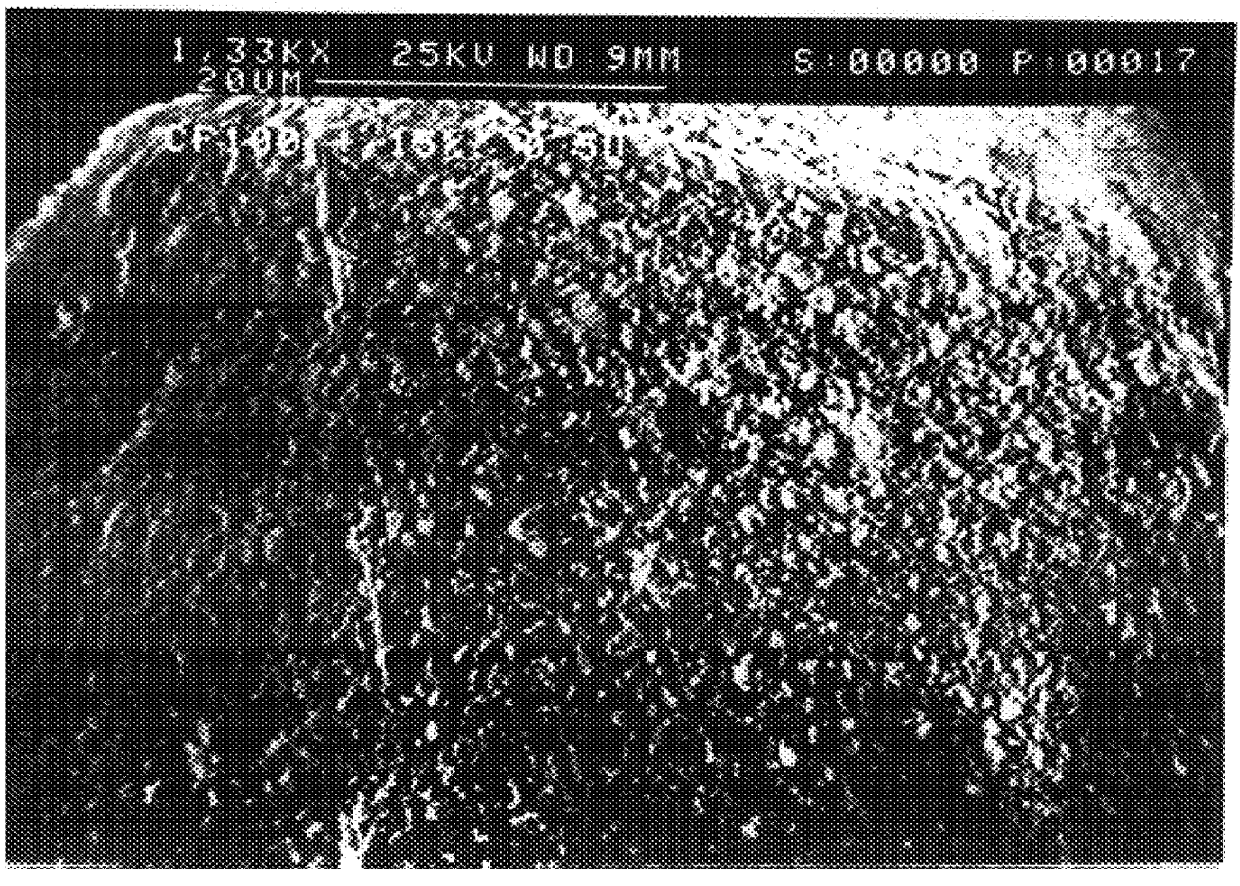

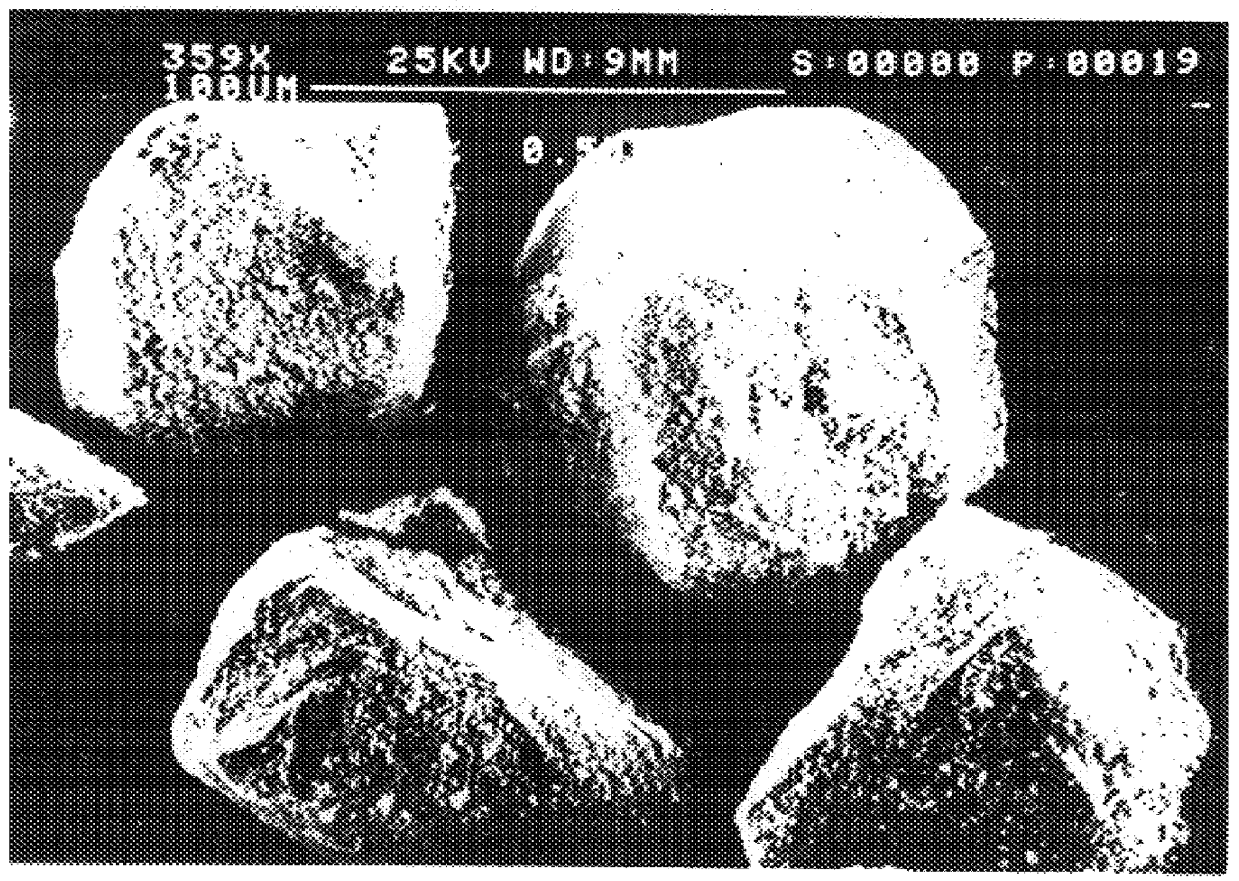

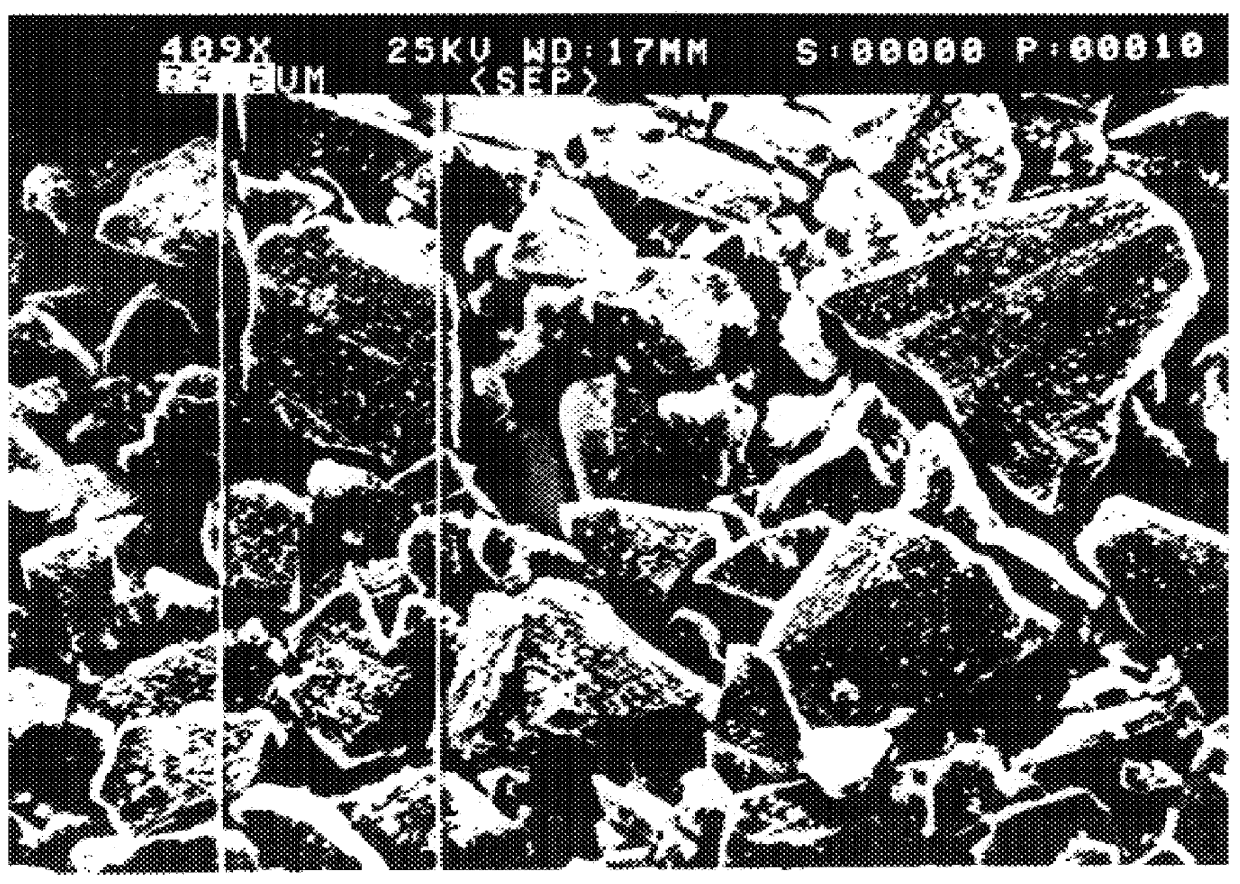

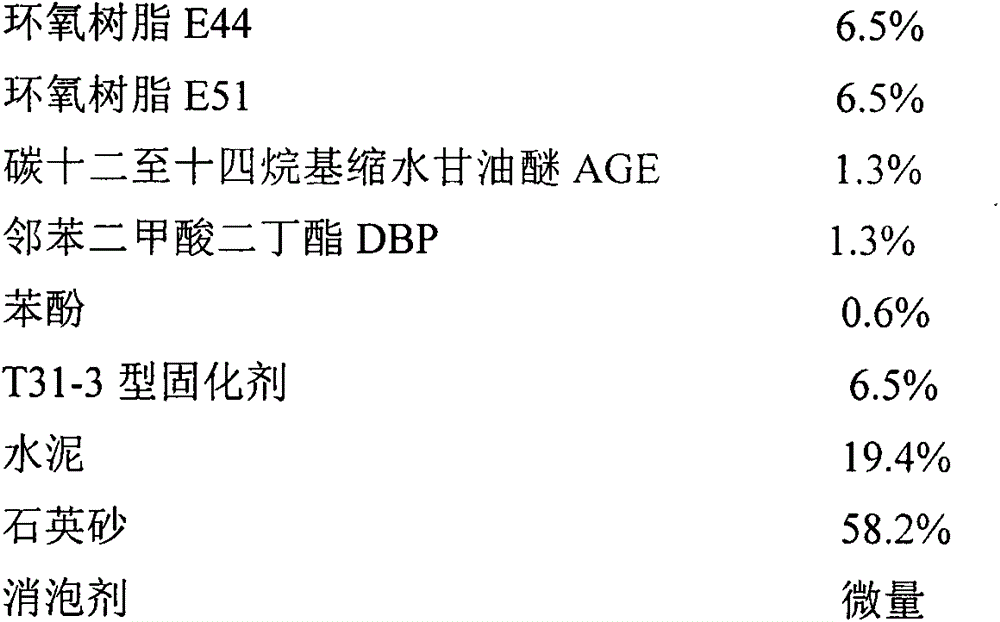

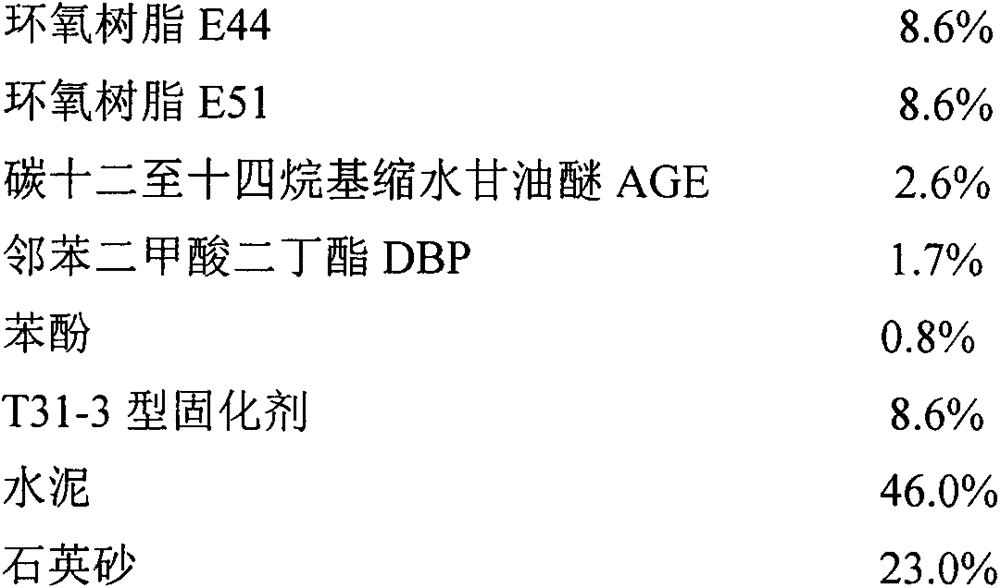

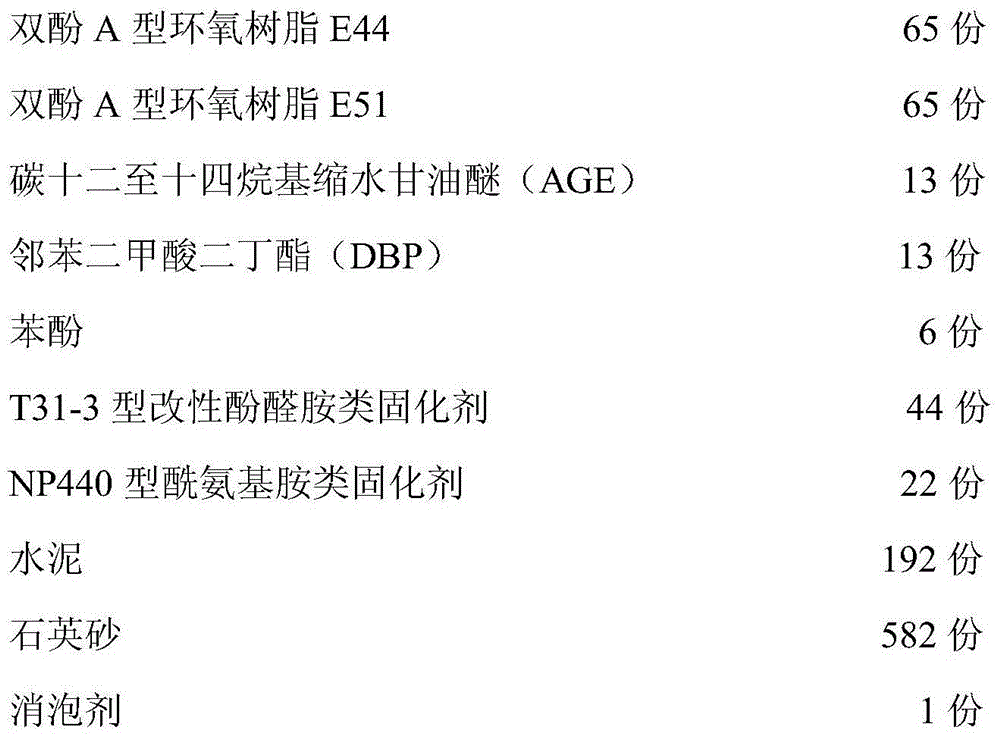

Preparation method of epoxy mortar for filling ocean oil and gas pipeline

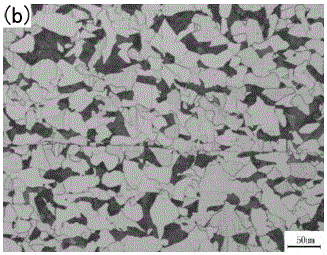

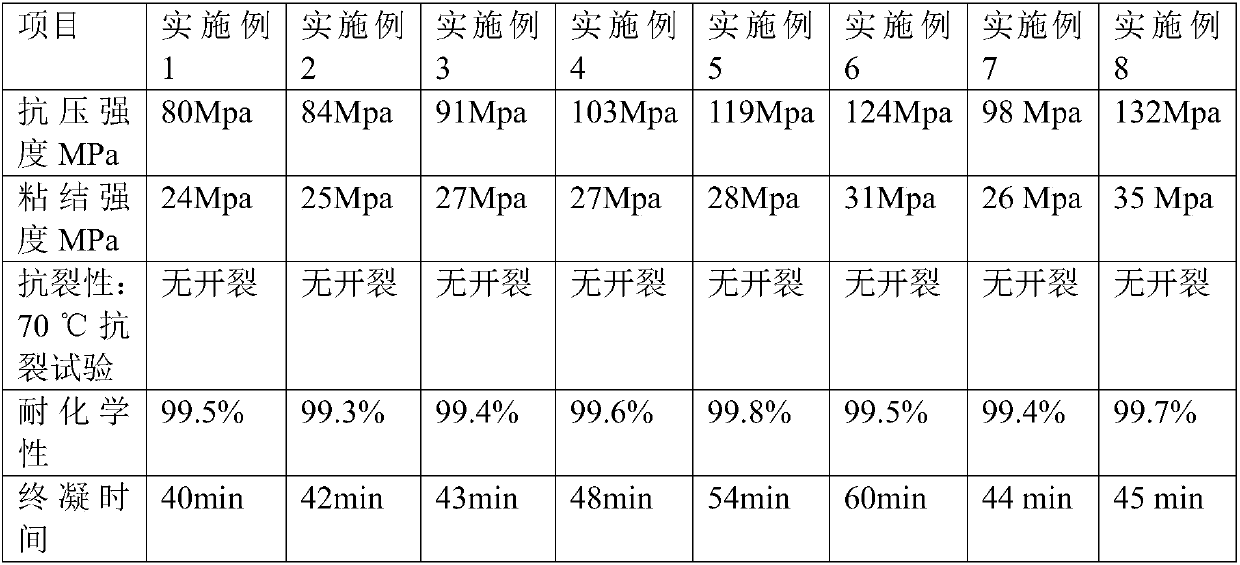

InactiveCN103819144ASimple preparation processMeet the replacement requirementsShock resistanceSeawater

The invention belongs to the technical field of application of polymer mortar and particularly relates to a preparation method of epoxy mortar for filling an ocean oil and gas pipeline. The epoxymortar consists of a component A, a component B and a component C, wherein the component A is prepared by defoaming after blending epoxy resin, a reactive diluent, a plasticizer, an accelerator and pigments according to the proper proportion and; the component B is a special underwater T31-3 type curing agent; the component C is aggregate formed by mixing cement with quartz sand according to a certain proportion. When the epoxymortar is used for construction, the component A is heated to 30-50DEG C and stirred to homogeneousphase, and then the component A and the component B are mixed according to certain proportion and uniformly stirred; the component C is subsequently added into the mixture for uniformly blending to obtain an epoxymortar mixture for filling the ocean oil and gas pipeline. The mortar mixture is simple in preparation process; the prepared mixture has the advantages of high curing speed and strong cohesiveness as well as excellent compress and shock resistance and seawater corrosion resistance. The mortar mixture can be used for filling and strengthening an anode protection anticorrosive structure of the ocean oil and gas pipelines.

Owner:TIANJIN UNIV OF SCI & TECH +1

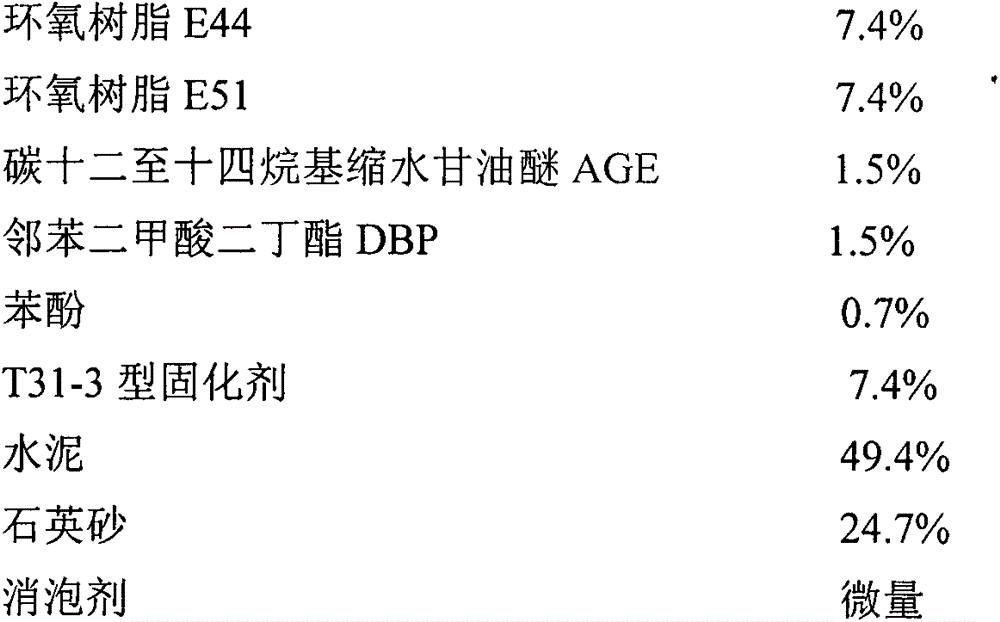

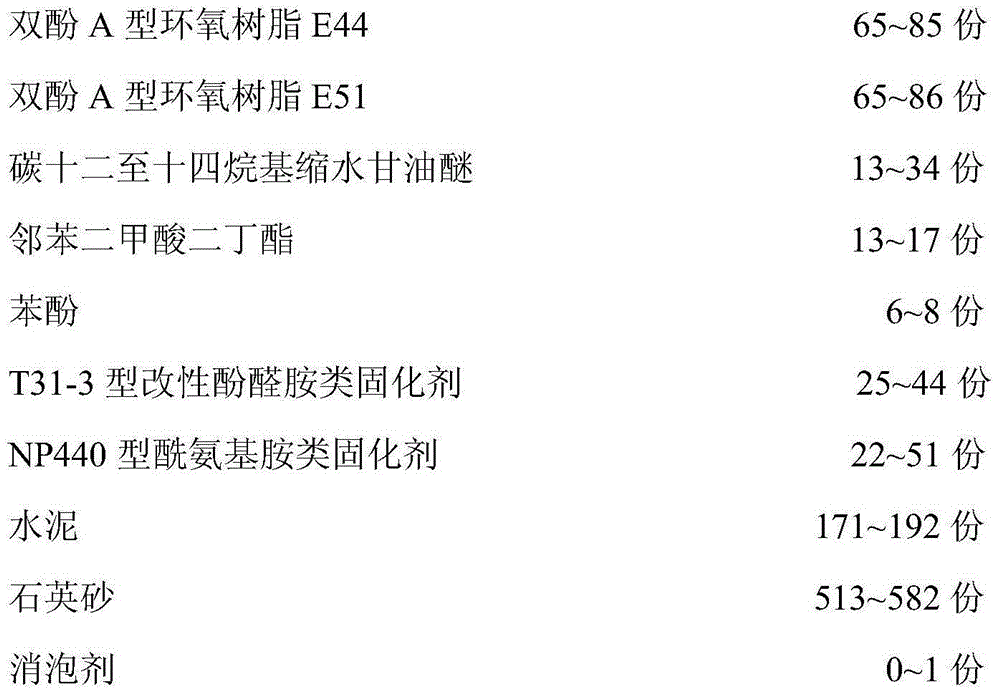

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

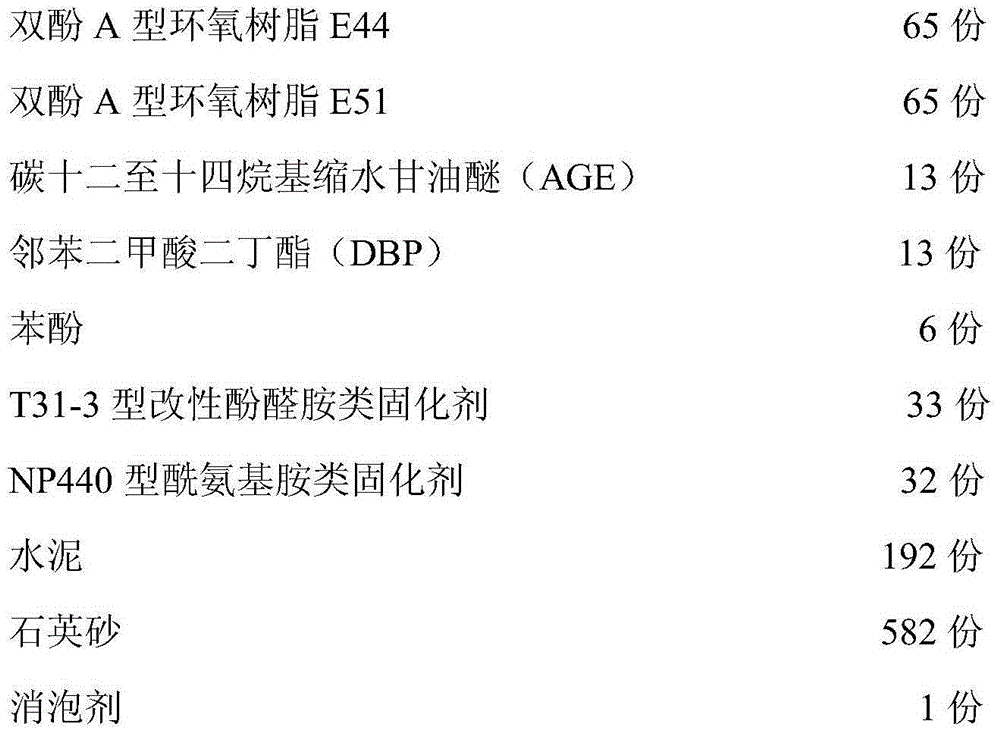

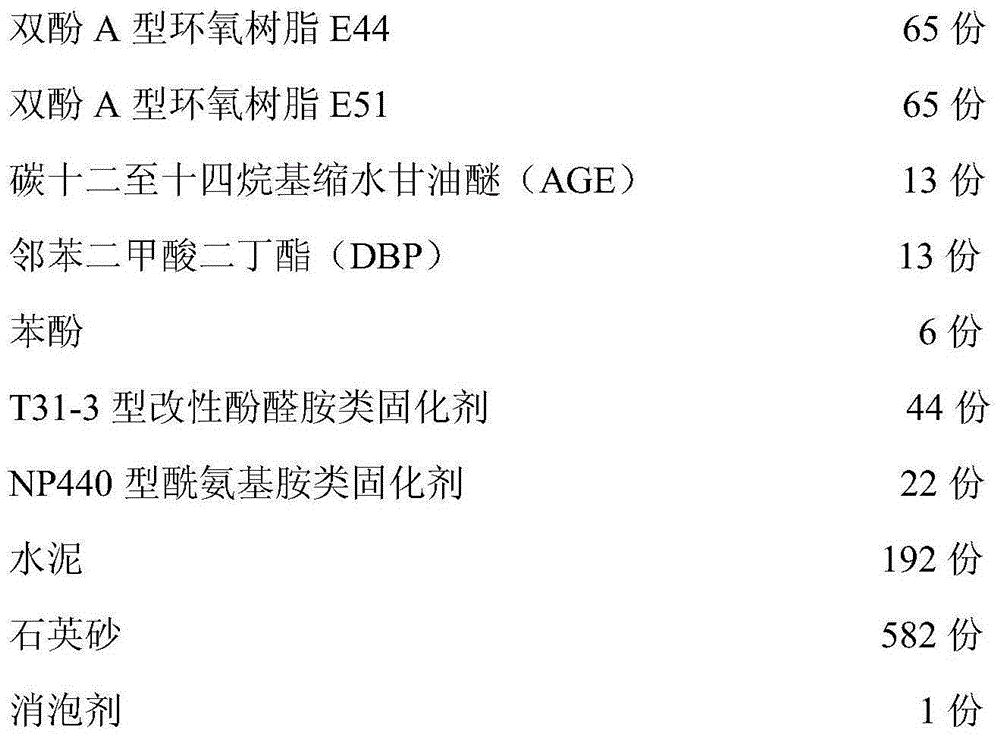

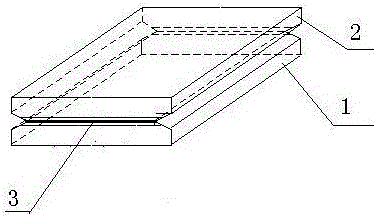

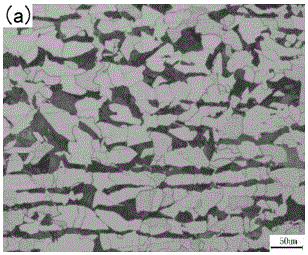

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

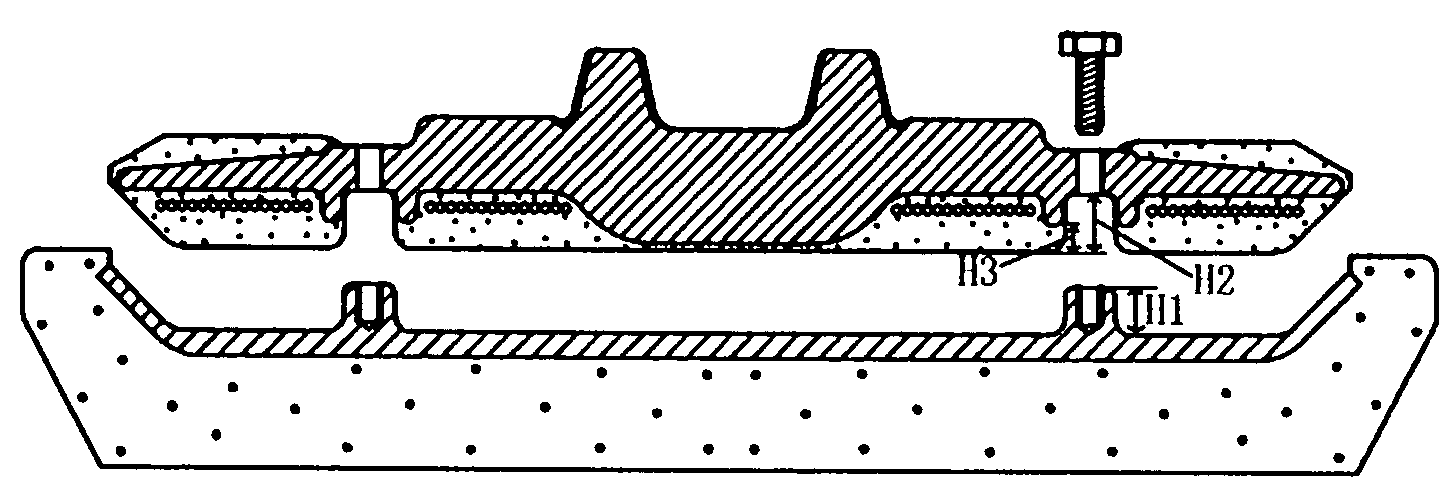

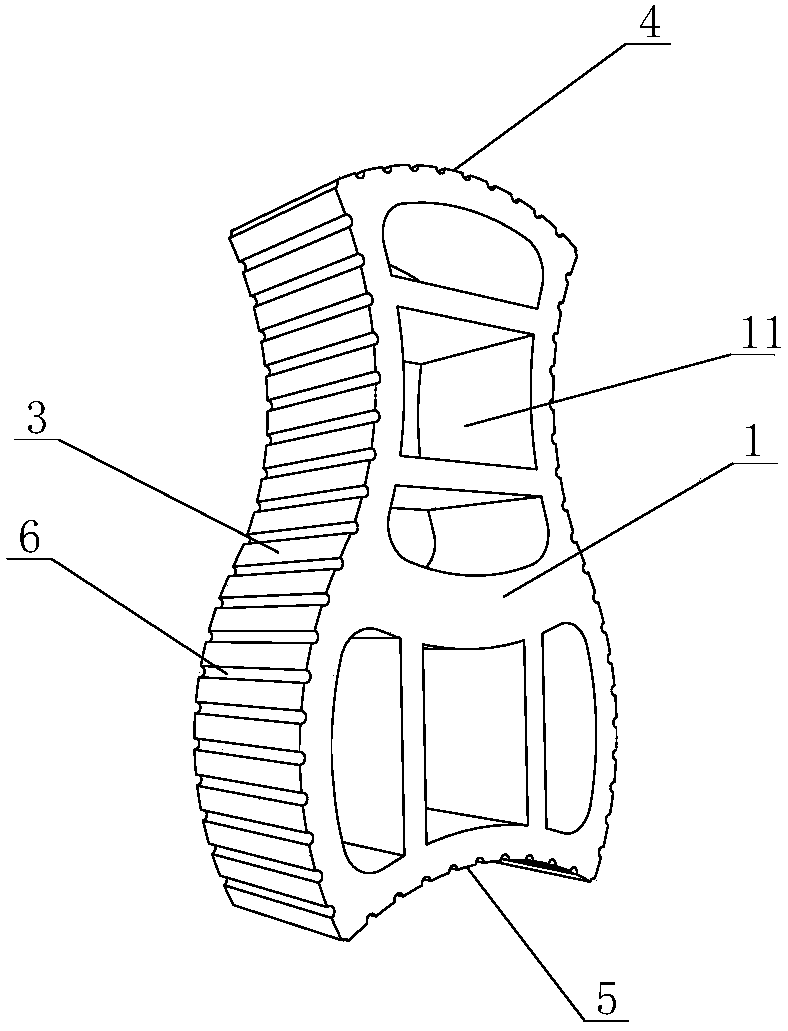

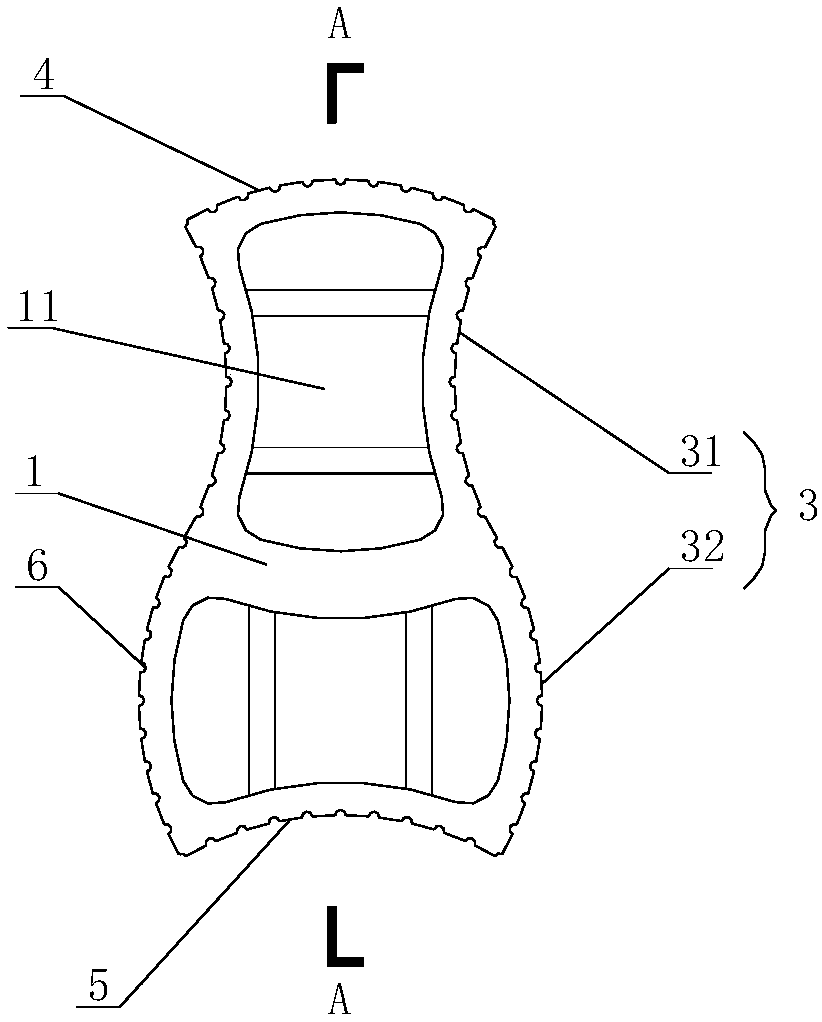

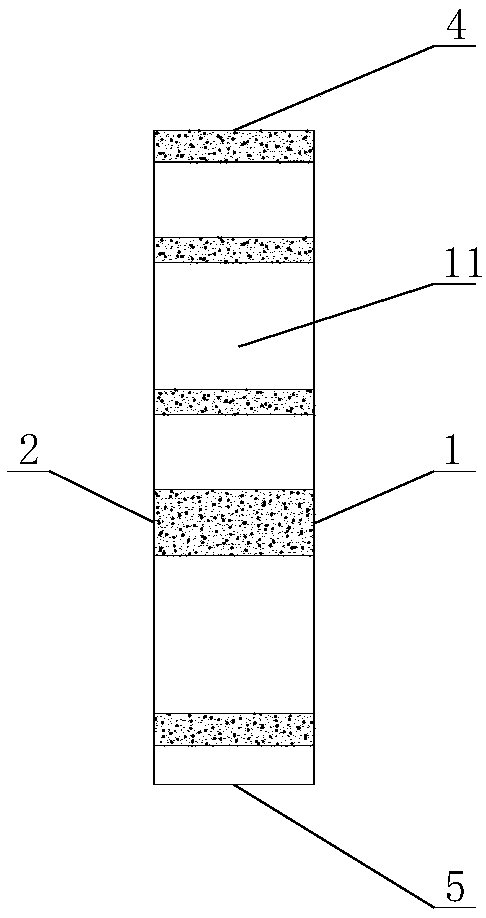

Detachable crawler

ActiveUS7377601B2Increased durabilityAvoid noiseDrill bitsConveyorsEngineeringMechanical engineering

A detachable crawler (1, 20) capable of increasing the durability thereof on a rubber belt part (4) body side, wherein each of a metal core (6) and a track shoe (21) of a detachable pad (5) is formed so that tightening force in a specific range (approx. 4.90 to 78.5 MPa per unit area) can be applied to a rubber elastic body (4a) including a tensile reinforcing layer (2) sandwiched between a core bar (3) in the rubber belt part (4) and the metal core (6) or steel track shoe (21) of the detachable paid (5).

Owner:FUKUYAMA GOMU KOGYO

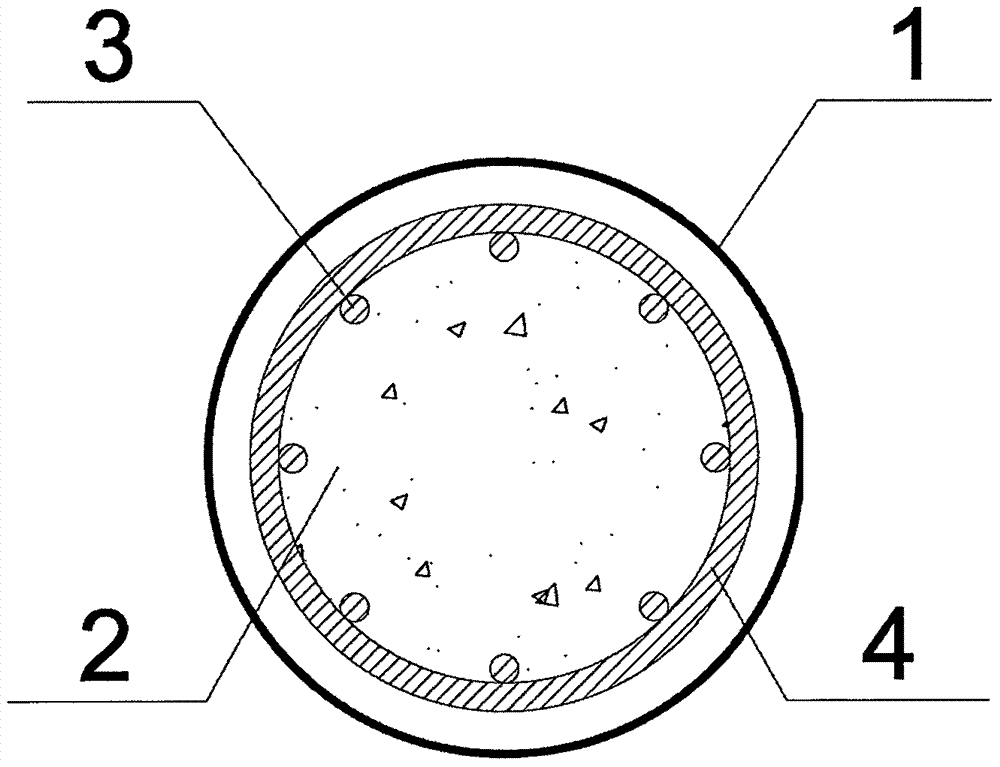

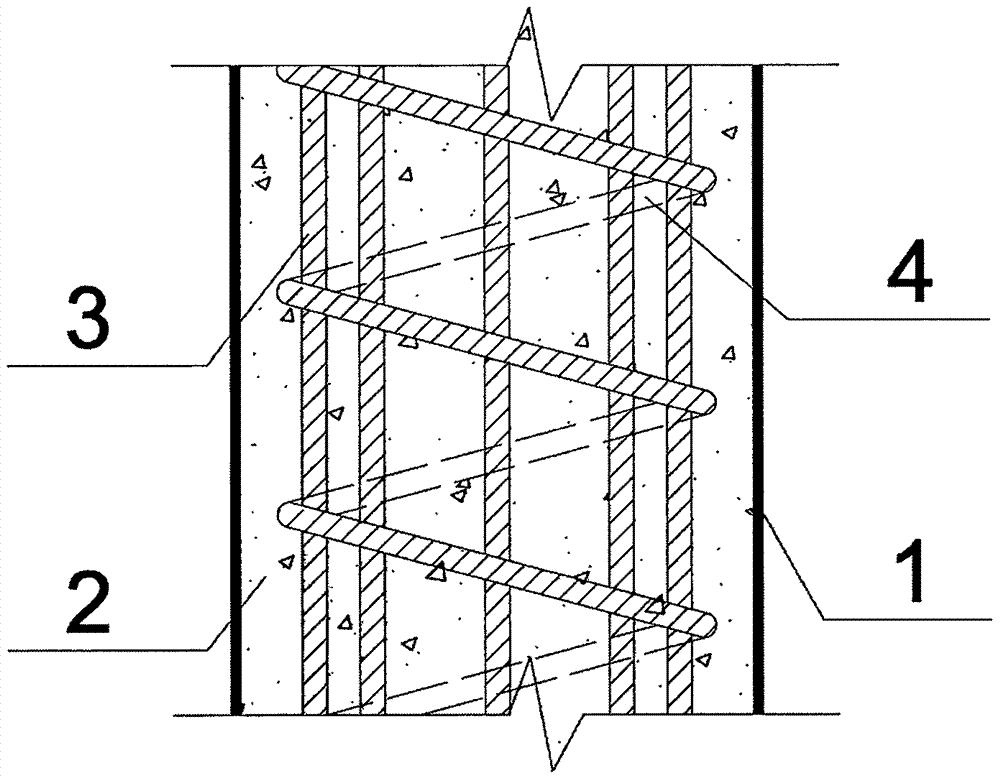

Pre-stress FRP bush-FRP rib sea sand seawater expansion concrete combination column

PendingCN107503470AIncrease profitIncrease the range of axial ultimate bearing capacityStrutsBridge structural detailsEcological environmentPre stress

The present invention relates to the field of building, bridge and harbor engineering, and provides a pre-stress FRP bush-FRP rib sea sand seawater expansion concrete combination column, which comprises an external FRP bush and internal FRP rib sea sand seawater expansion concrete, wherein the FRP bush wraps the sea sand seawater expansion concrete, self-stress is generated in the FRP bush and the concrete through the expansion of the concrete and the restriction of the FRP, uniformly distributed FRP longitudinal ribs are arranged on the periphery close to the sea sand seawater expansion concrete combination column, and penetrate through the sea sand seawater expansion concrete from top to bottom, and FRP spiral stirrups are bound around the FRP longitudinal ribs from the outer side along a top-to-bottom direction of the combination column according to the same interval and the same spiral angle. According to the present invention, the pre-tensile stress is generated in the FRP bush through the micro-expansion of the expanded concrete so as to effectively improve the axial limit bearing force of the combination column; and the river sand is replaced by the sea sand, the fresh water is replaced by the seawater, and the steel bar is replaced by the FRP rib, such that the performance of the combination column is improved, the limitation of the application of the sea sand seawater in the practical engineering is broken through, and the positive effect is provided in the protection of the ecological environment.

Owner:GUANGDONG UNIV OF TECH

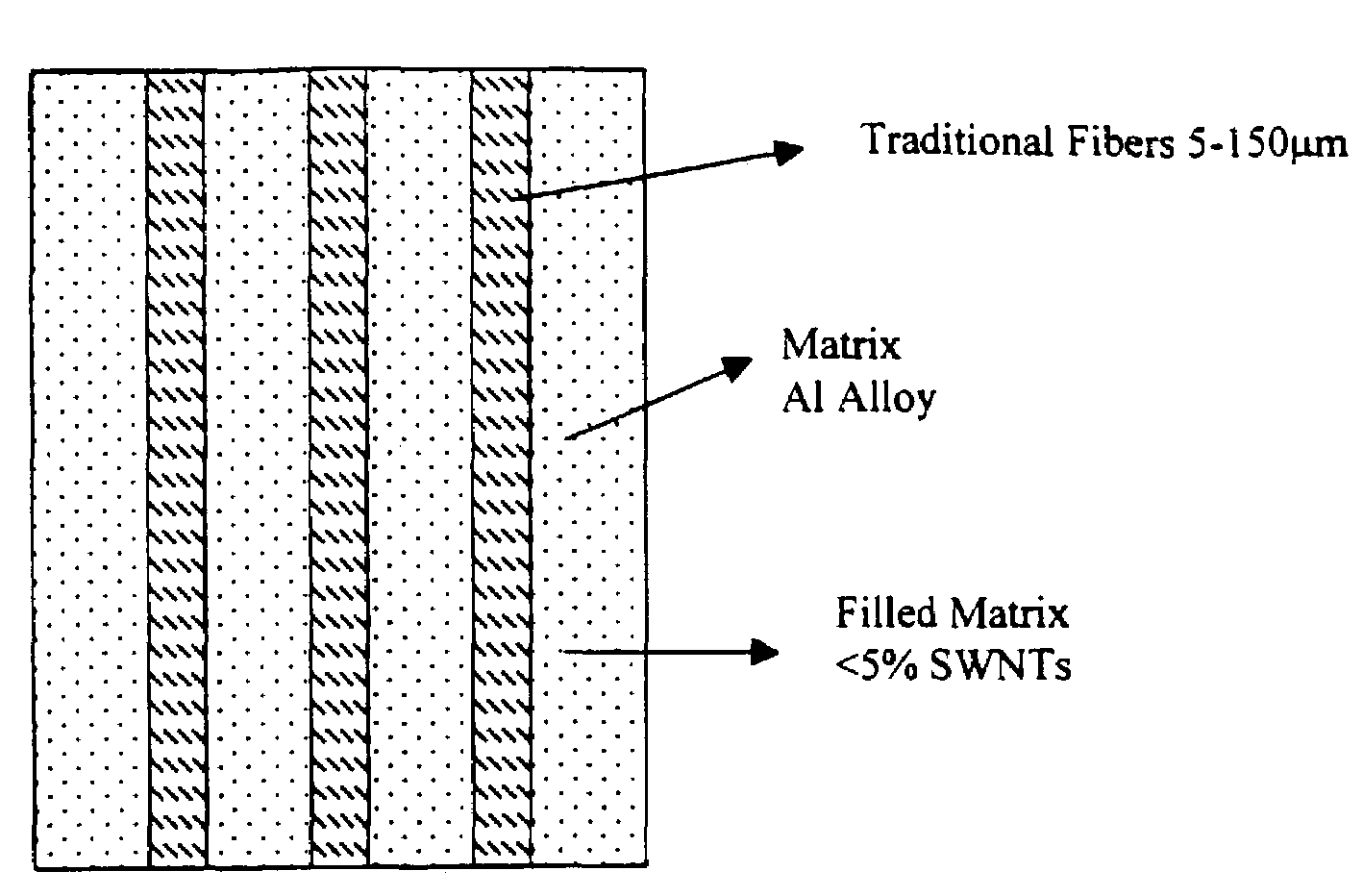

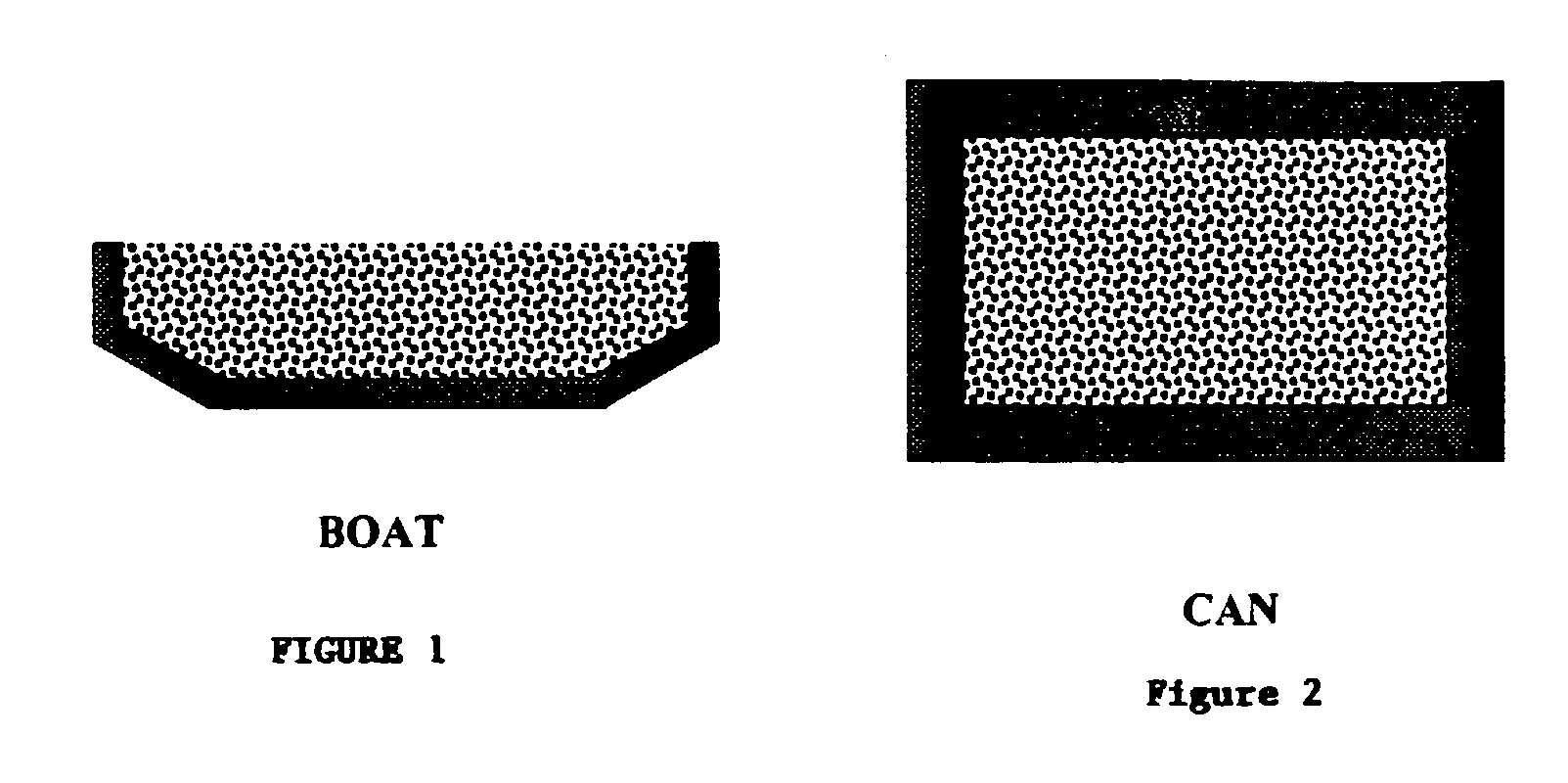

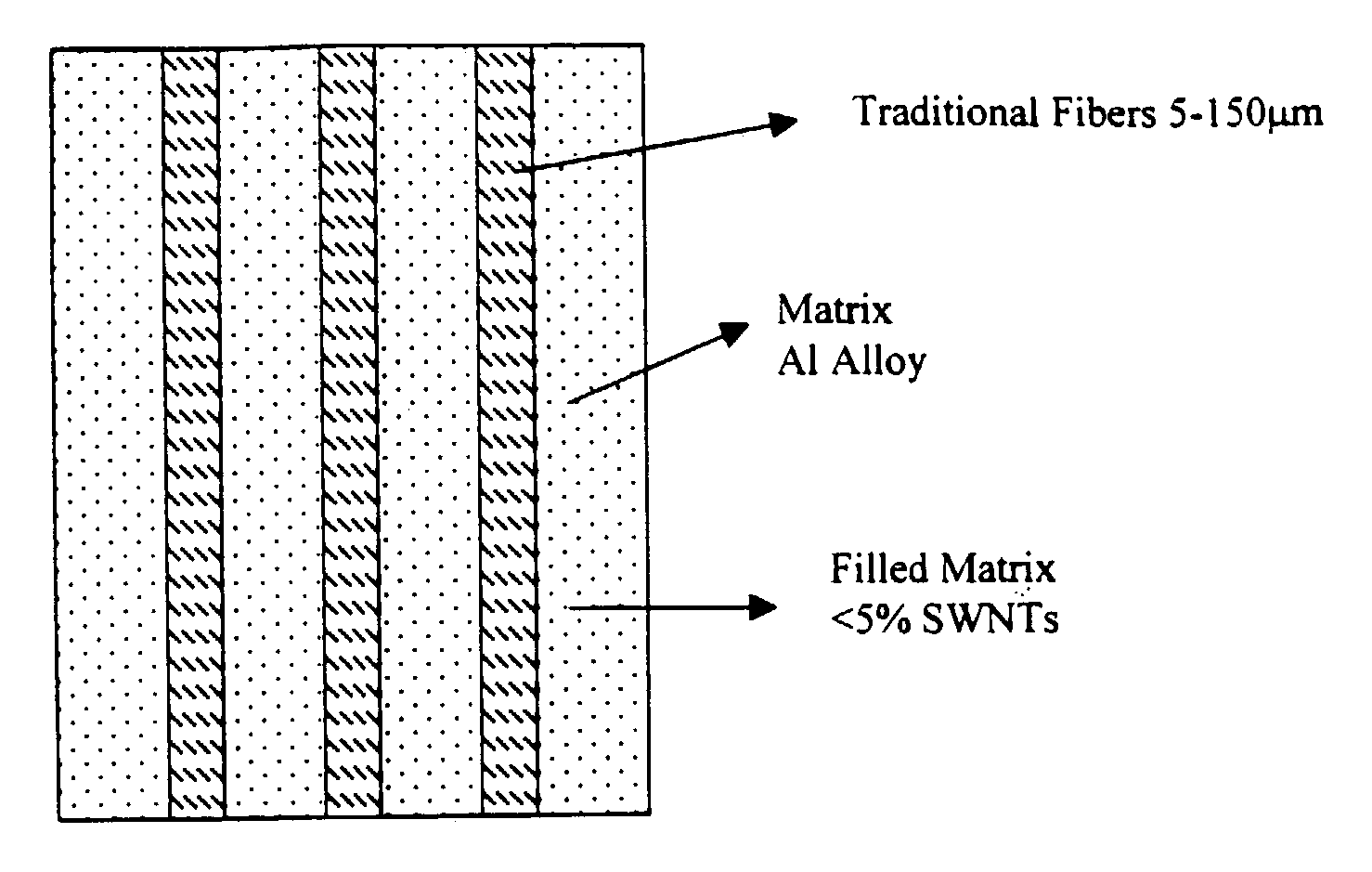

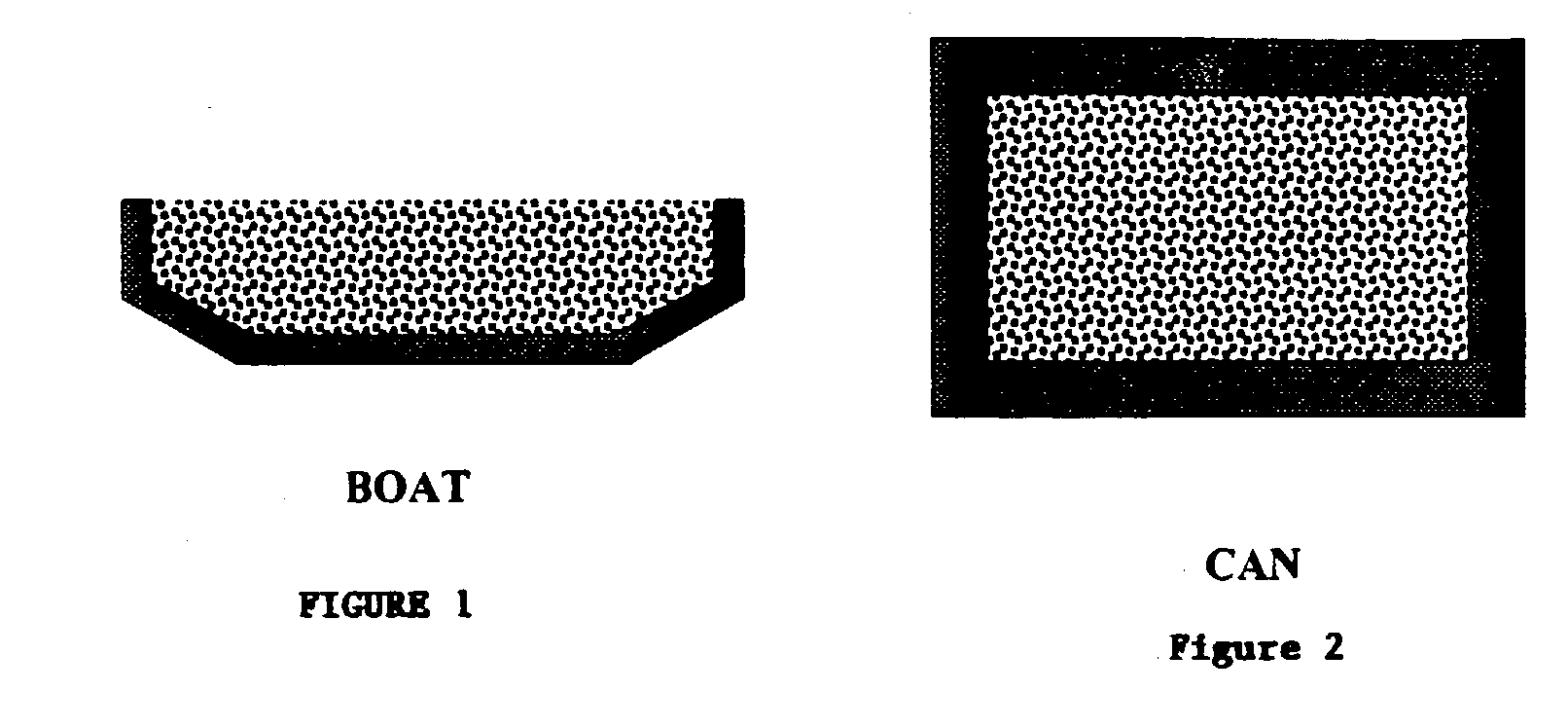

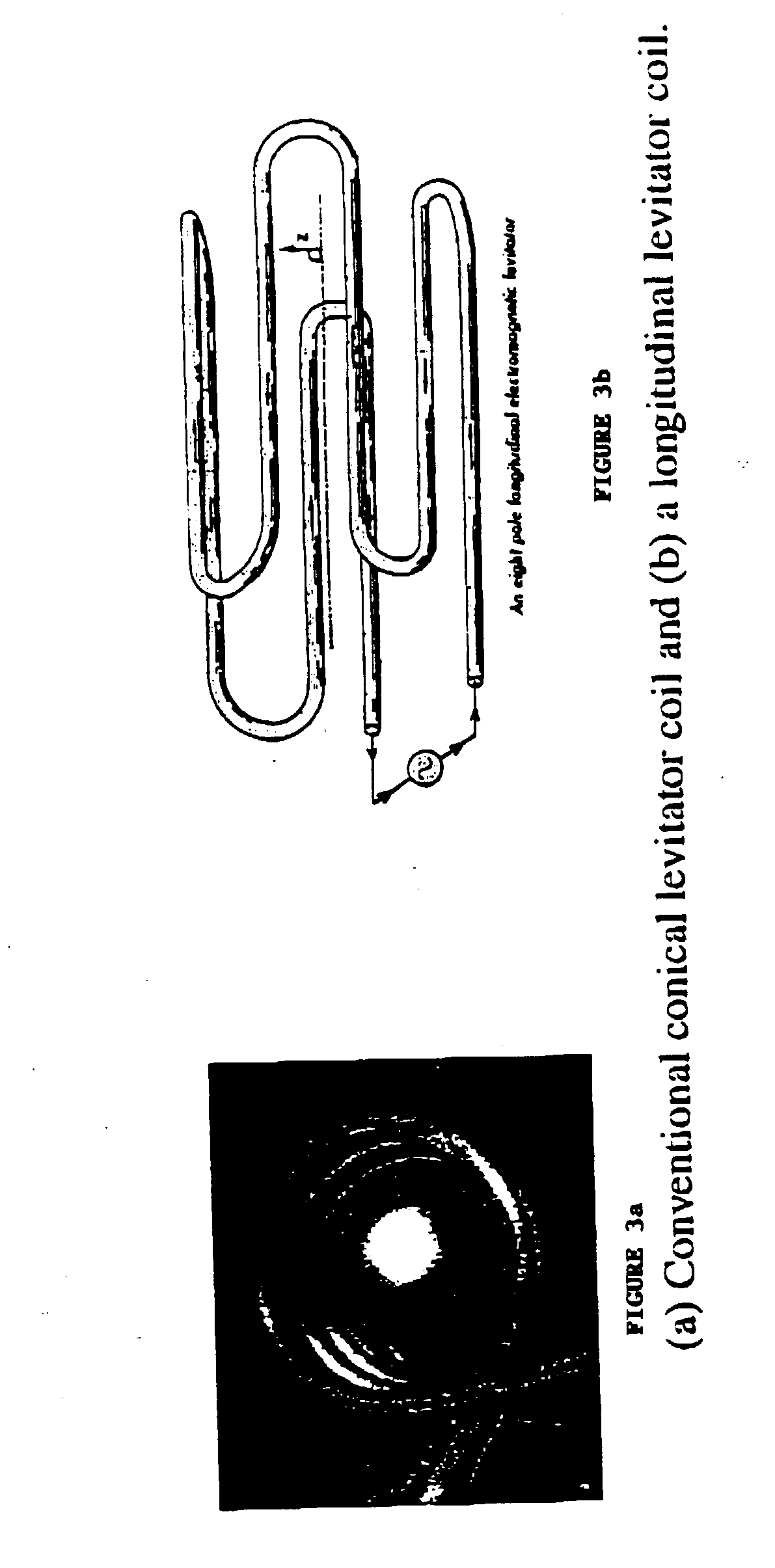

Containerless mixing of metals and polymers with fullerenes and nanofibers to produce reinforced advanced materials

The present invention relates to fullerene, nanotube, or nanofiber filled metals and polymers. This invention stems from a cross-disciplinary combination of electromagnetic and acoustic processing and property enhancement of materials through fullerene or nanofiber additives. Containerless processing (CP) in the form of electromagnetic field enduced and / or acoustic mixing leads to controlled dispersion of fullerenes, nanotubes, or nanofibers in various matrices. The invention provides methods of mixing that highly disperse and align the fullerenes, nanotubes, or nanofibers within the matrices of metals and polymers. The invention provides new compositions of matter and multifunctional materials based on processing, composition, and degree of in situ processing.

Owner:WILLIAM MARSH RIDE UNIV

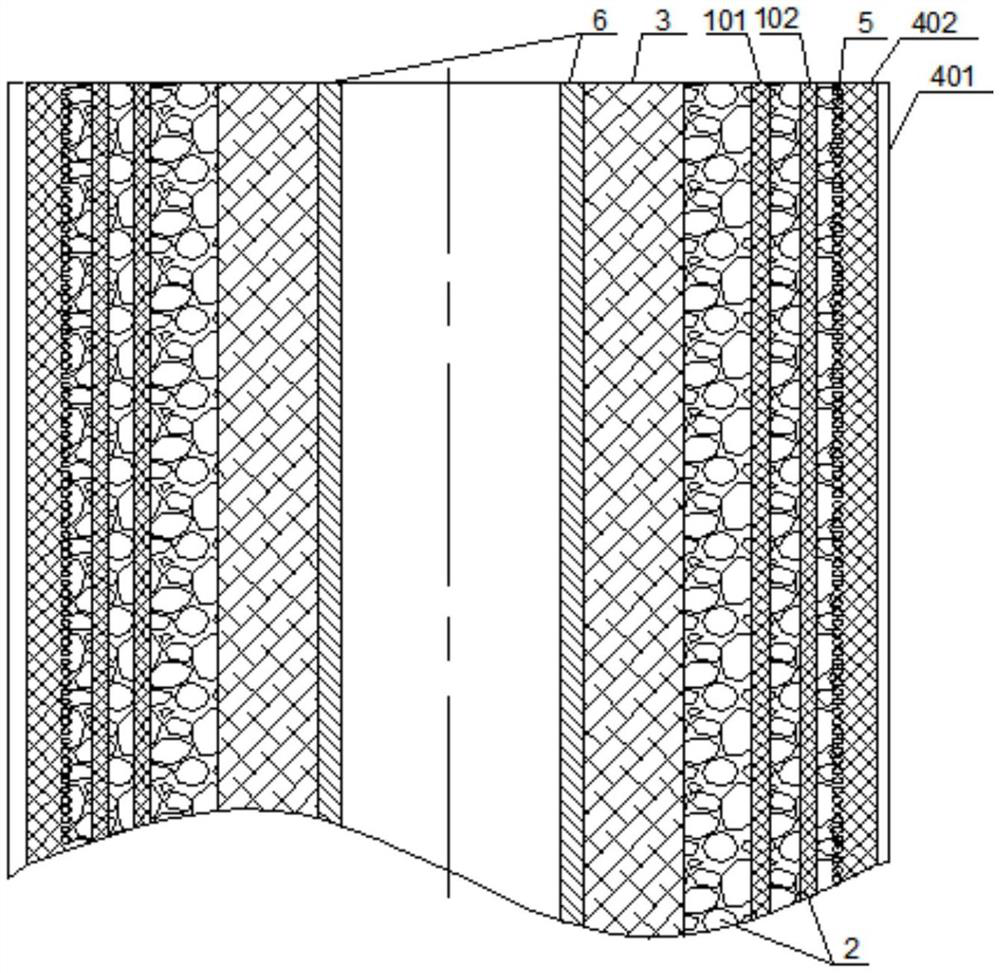

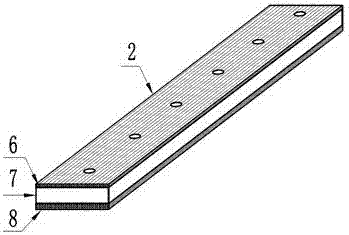

Polymer-reinforced prestressed concrete cylinder pipe molding technology

ActiveCN107599273AImprove mixing uniformityImprove compactnessTubular articlesPre treatmentWork in process

The invention provides a polymer-reinforced prestressed concrete cylinder pipe molding technology, and belongs to the technical field of pipeline manufacturing. The polymer-reinforced prestressed concrete cylinder pipe molding technology comprises the following steps that (1) manufacturing of a lining mold is conducted, wherein circumferential prestressed wires are wound around a concrete pipe core with a steel cylinder, a PCCP semi-finished product is formed and directly serves as the lining mold, and a reinforcing net is prefabricated in the concrete pipe core; (2) pretreatment of an outer mold is conducted, wherein a release agent coats the inner wall of the outer mold; and (3) construction of a pouring structure is conducted, wherein the lining mold, the reinforcing net and the outer mold are combined in sequence from inside to outside so as to form the pouring structure, polymer concrete is poured into the pouring structure, the outer mold is removed after molding is accomplished,and therefore a polymer-reinforced prestressed concrete cylinder pipeline is obtained. The polymer-reinforced prestressed concrete cylinder pipe molding technology is simple, and the manufactured polymer-reinforced prestressed concrete cylinder pipeline is excellent in performance and has the advantages of being high in sealing performance, strength and anti-permeability and resistant to corrosion.

Owner:江苏致乐管业科技有限公司

Containerless mixing of metals and polymers with fullerenes and nanofibers to produce reinforced advanced materials

The present invention relates to fullerene, nanotube, or nanofiber filled metals and polymers. This invention stems from a cross-disciplinary combination of electromagnetic and acoustic processing and property enhancement of materials through fullerene or nanofiber additives. Containerless processing (CP) in the form of electromagnetic field enduced and / or acoustic mixing leads to controlled dispersion of fullerenes, nanotubes, or nanofibers in various matrices. The invention provides methods of mixing that highly disperse and align the fullerenes, nanotubes, or nanofibers within the matrices of metals and polymers. The invention provides new compositions of matter and multifunctional materials based on processing, composition, and degree of in situ processing.

Owner:WILLIAM MARSH RIDE UNIV

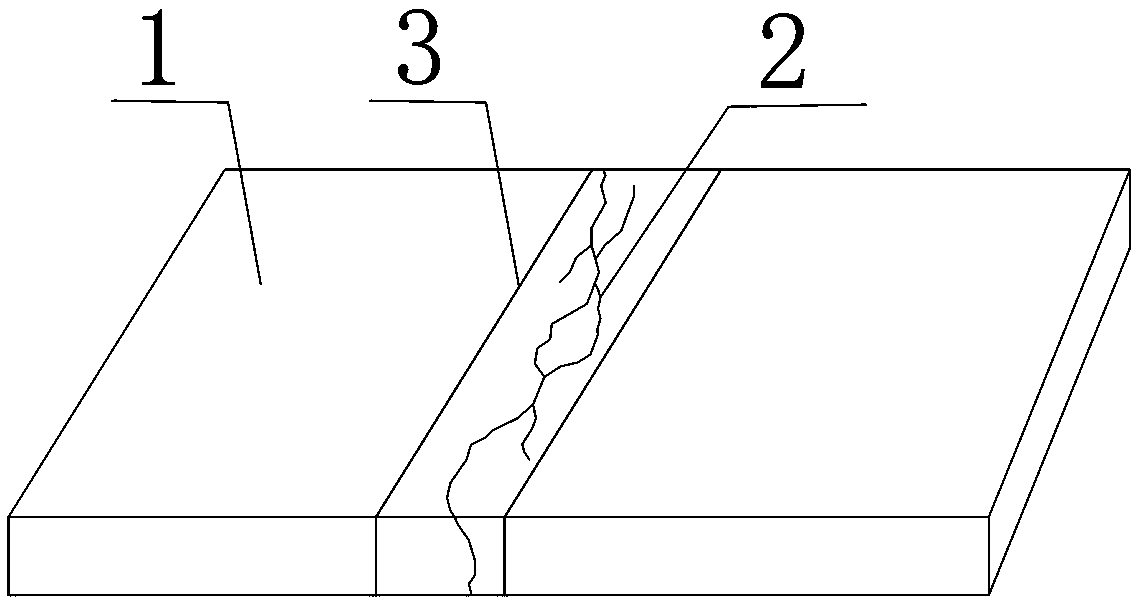

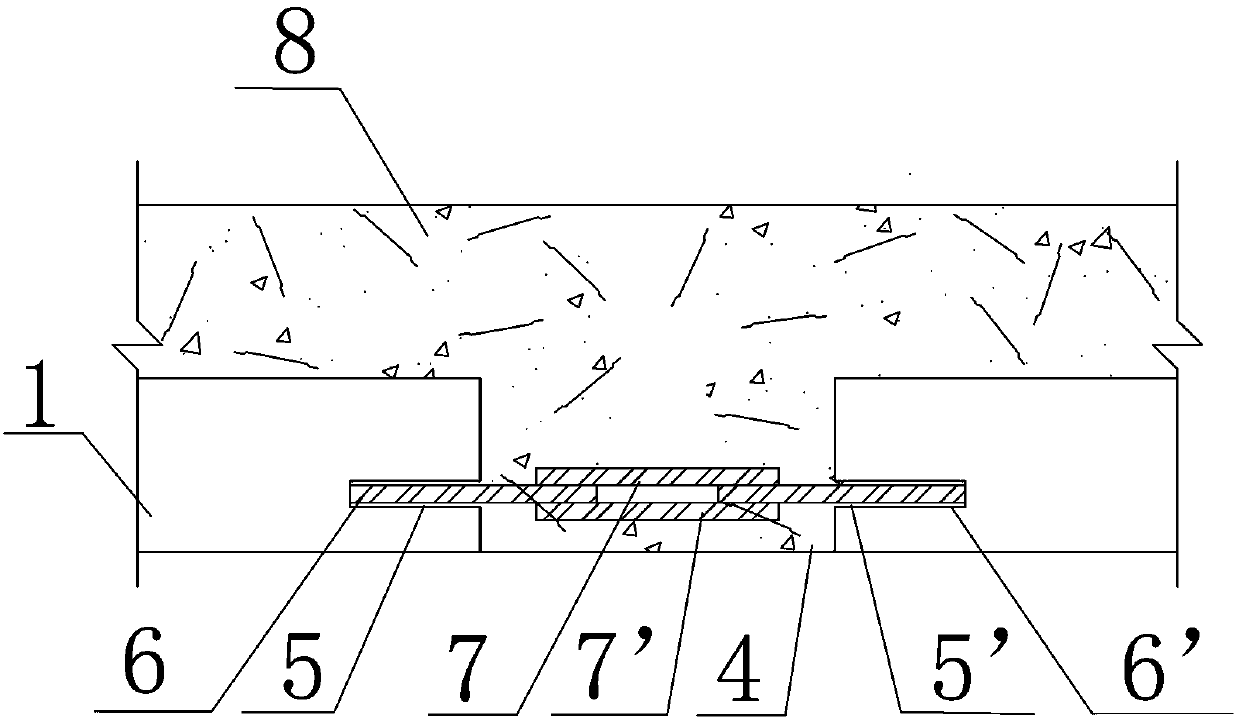

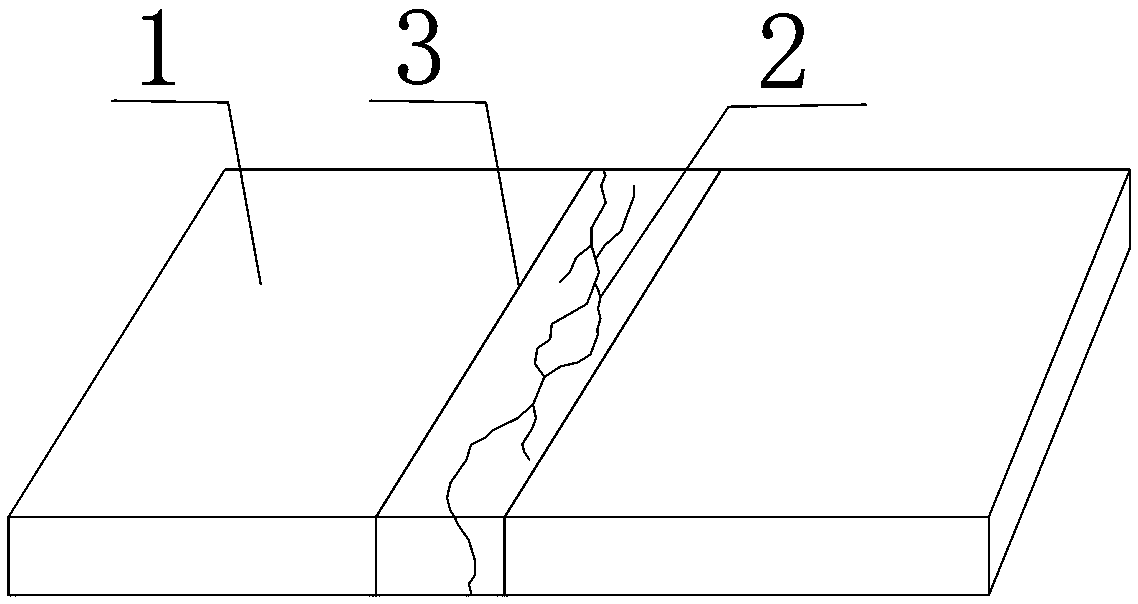

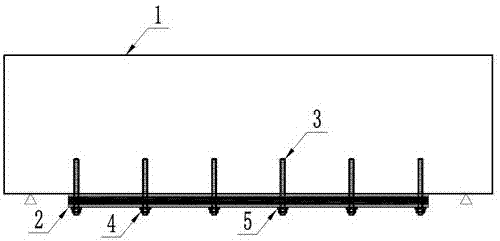

Damaged concrete pavement panel reinforcing structure and method

InactiveCN105507109ASmall shrinkage deformationImprove tensile propertiesPaving detailsWork performanceRoad surface

The invention provides a damaged concrete pavement panel reinforcing structure and method. The structure comprises a concrete pavement panel, the concrete pavement panel is provided with a reinforcing groove, a plurality of pairs of horizontal steel bar embedding holes are formed in the two walls of the reinforcing groove, and horizontal steel bars are fixedly arranged in the horizontal steel bar embedding holes; a steel fiber reinforced concrete blanket is fixedly poured over the concrete pavement panel. The method comprises the steps of 1, conducting surface debristling; 2, making the reinforcing groove and drilling the plurality of pairs of horizontal steel bar embedding holes; 3, embedding the horizontal steel bars; 4, pouring steel fiber reinforced concrete to form the steel fiber reinforced concrete blanket. By combining the horizontal steel bars with steel fiber reinforced concrete, new cement concrete and old cement concrete cooperation work performance is improved, the bearing capacity of the concrete pavement panel reinforcing area is improved, and the service life and maintenance cycle of a road are prolonged.

Owner:ZHENGZHOU UNIV

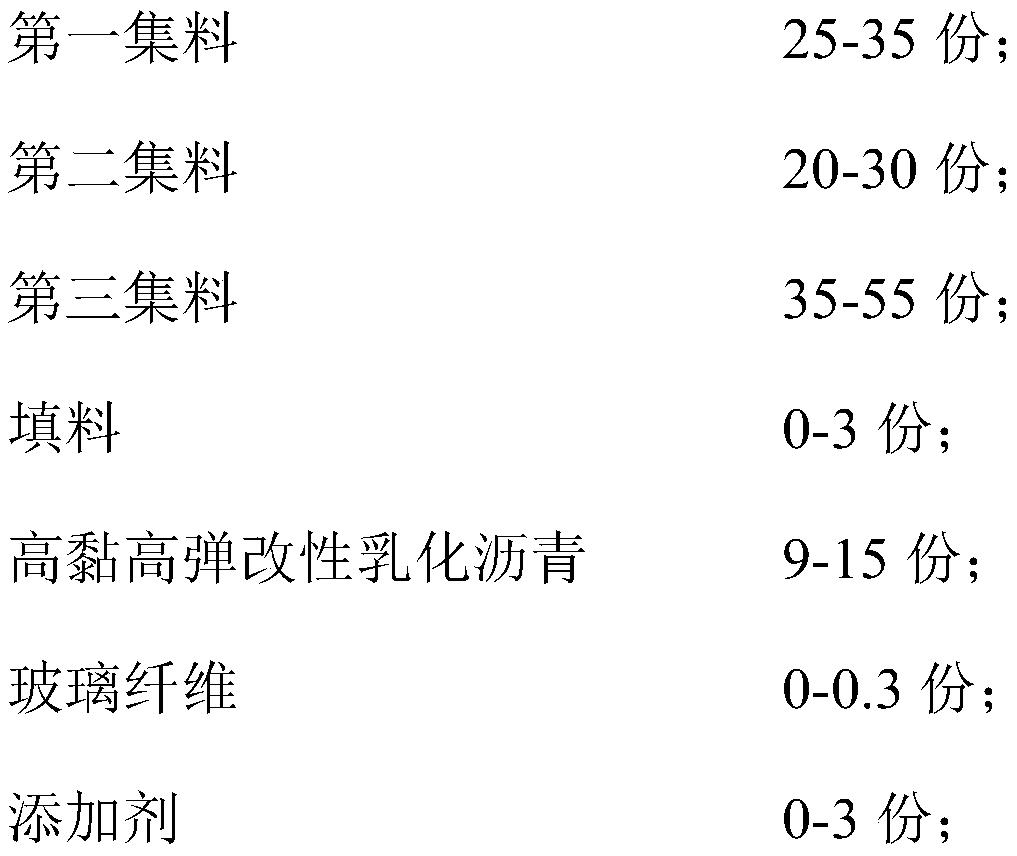

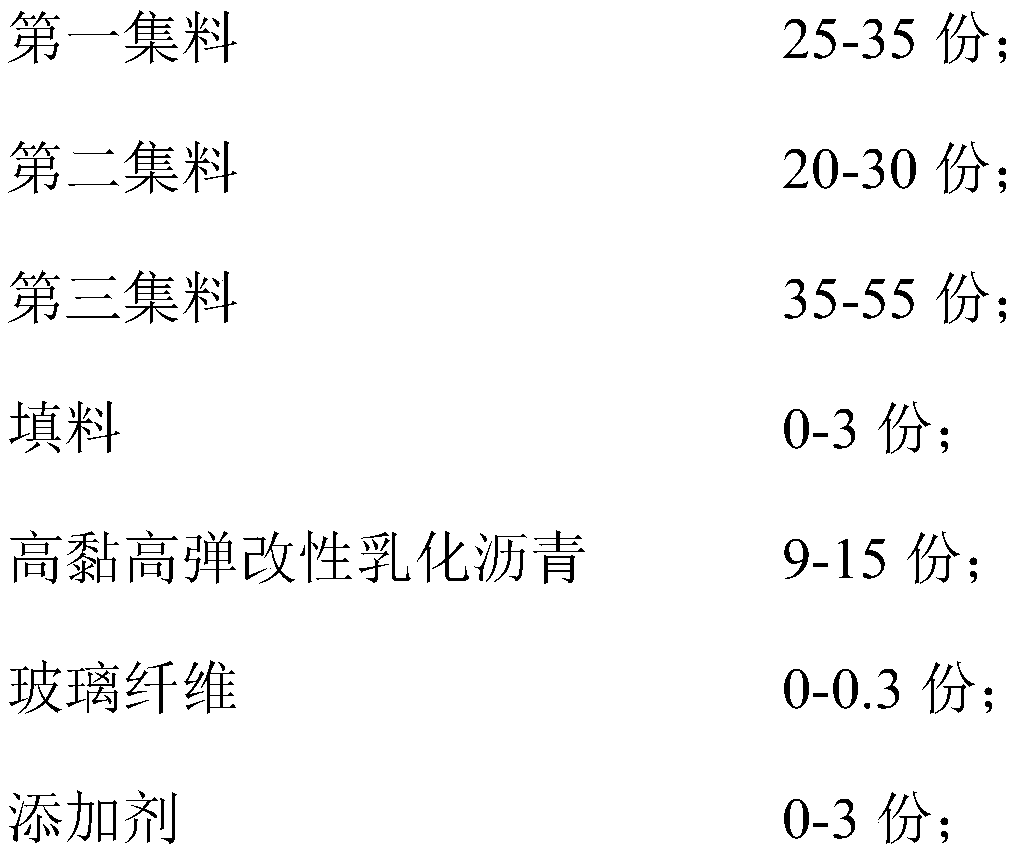

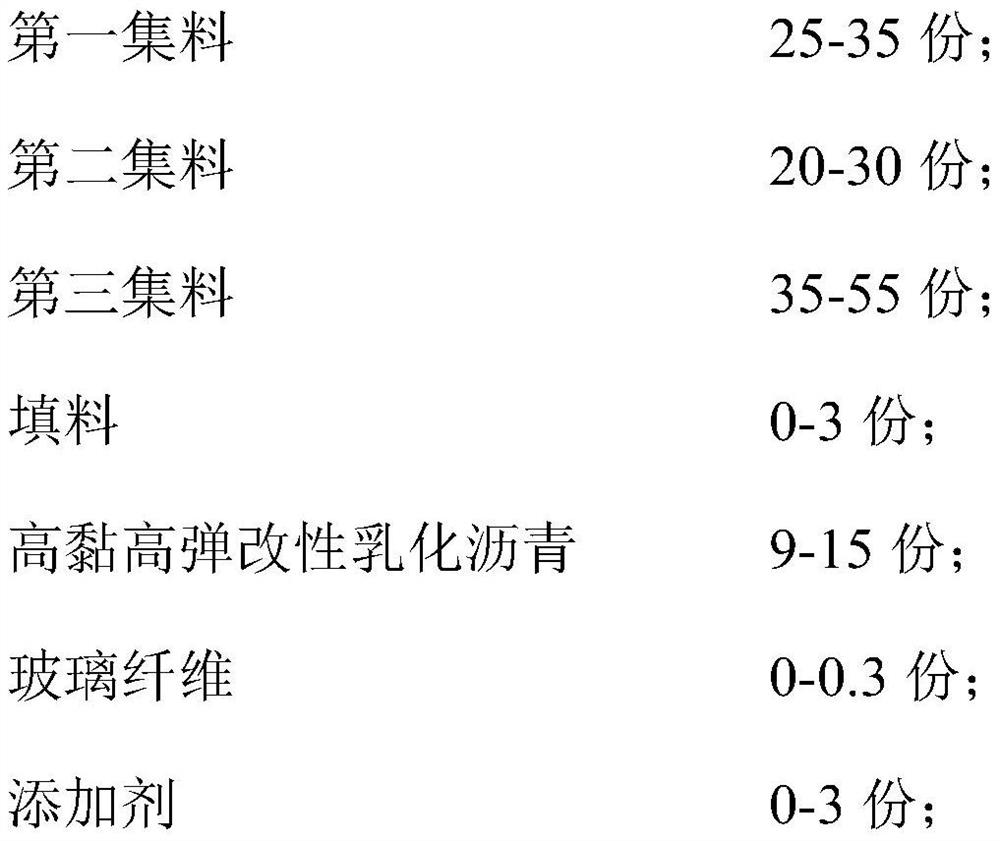

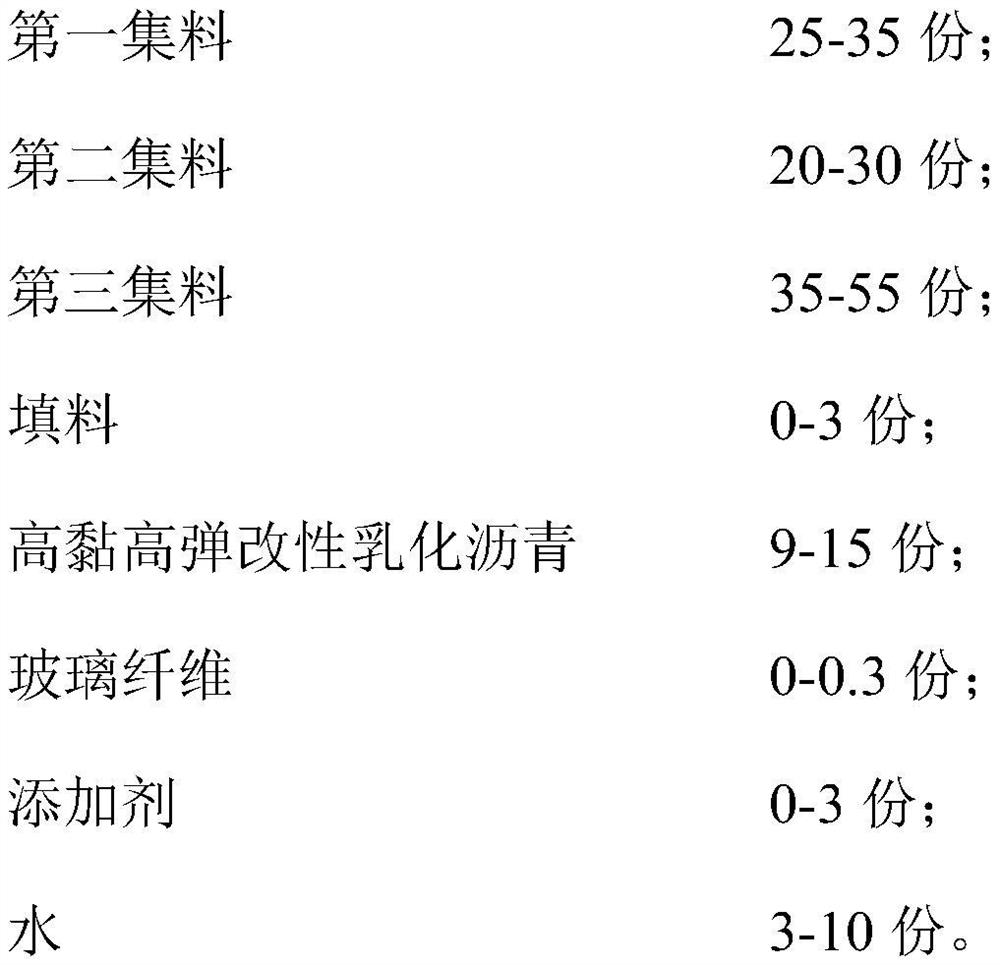

High-viscosity modified asphalt mixture and application thereof

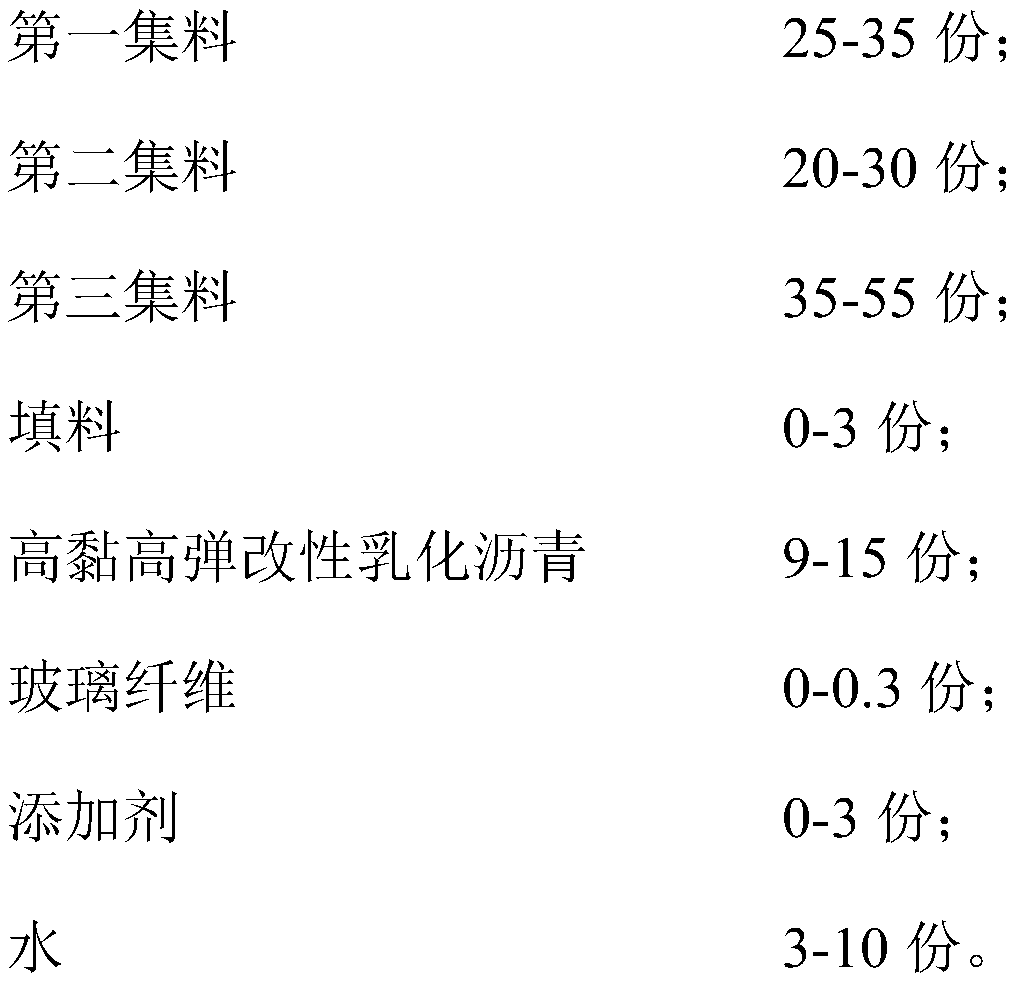

The invention discloses a high-viscosity modified asphalt mixture and application thereof. The high-viscosity modified asphalt mixture comprises the following components in parts by weight: 25-35 parts of a first aggregate; 20 to 30 parts of a second aggregate; 35 to 55 parts of a third aggregate; 0-3 parts of a filler; 9-15 parts of high-viscosity and high-elasticity modified emulsified asphalt;0 to 0.3 part of glass fiber and 0-3 parts of an additive; the application of the high-viscosity modified asphalt mixture is as follows: the high-viscosity modified asphalt mixture is paved and then automatically flows to form a pavement overlay, and the high-viscosity modified asphalt mixture is a thin slurry mixture, is good in fluidity, and can intrude into asphalt pavement cracks, so that asphalt pavement cracks are repaired, and new cracks on an asphalt pavement can be effectively inhibited.

Owner:广州市北二环交通科技有限公司

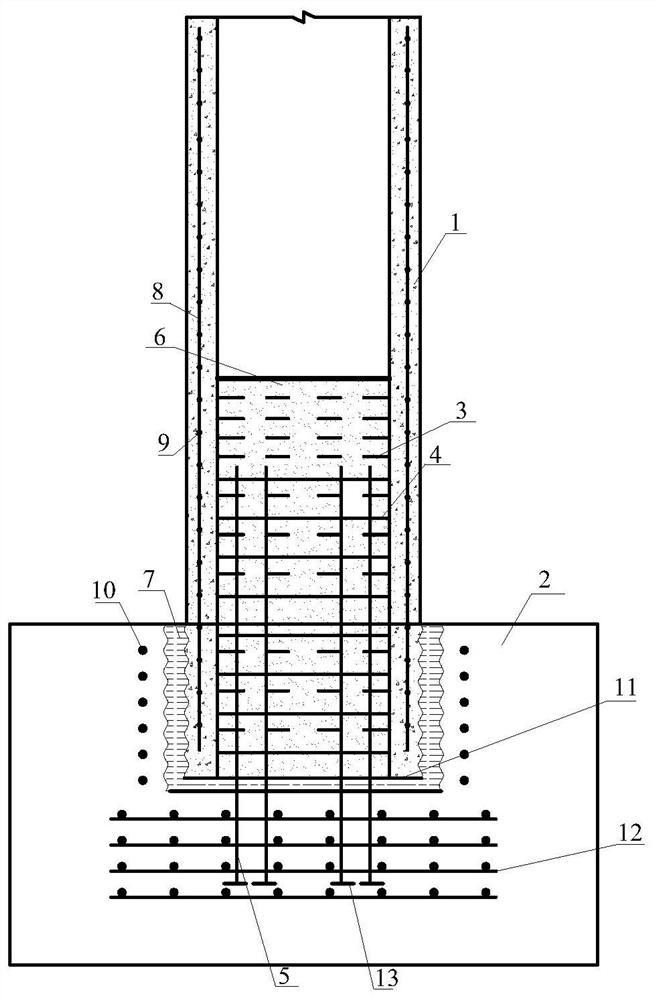

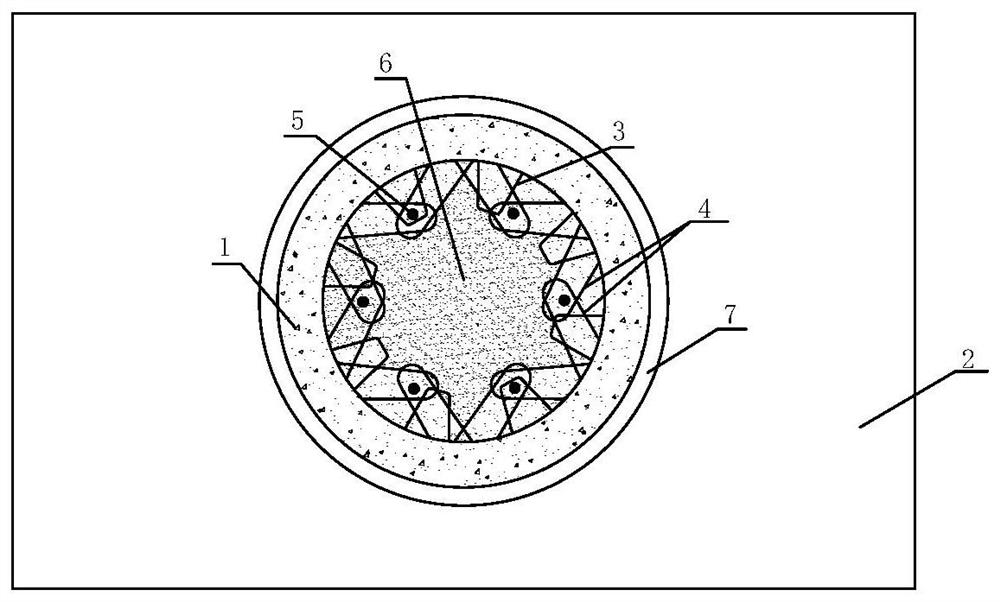

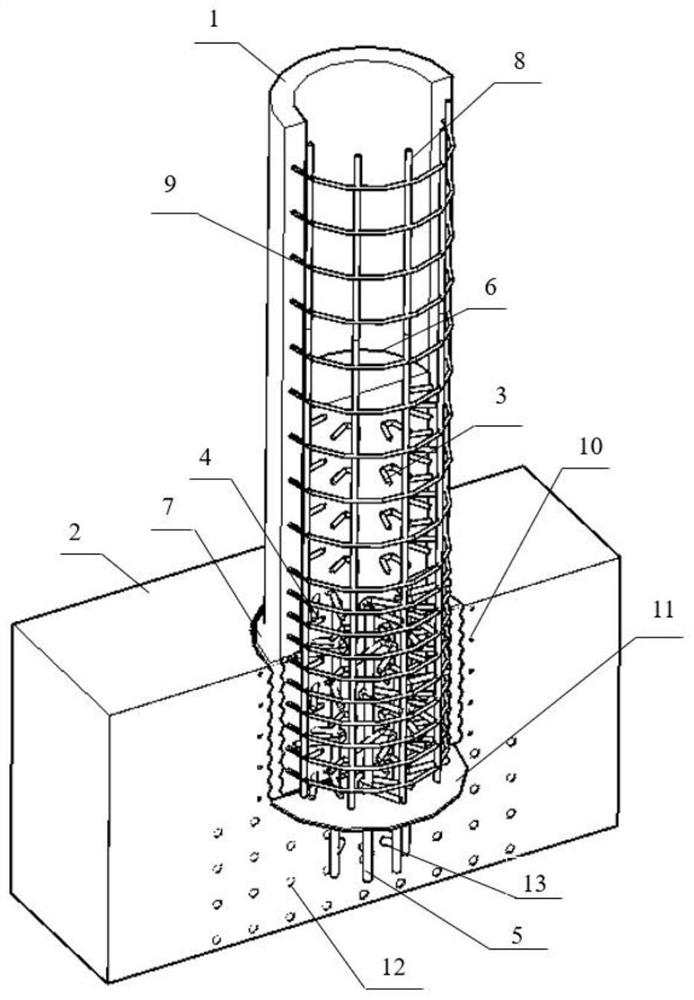

Connecting method and structure of socket and embedded steel bar combined prefabricated hollow pier-bearing platform

InactiveCN112761176AEasy to makeReduce pollutionBridge structural detailsFoundation engineeringEarthquake resistanceMesh reinforcement

The invention discloses a connecting method and structure of a socket and embedded steel bar combined prefabricated hollow pier-bearing platform. The structure comprises a prefabricated hollow pier column, a prefabricated bearing platform, core filling concrete and a high-performance grouting material; the prefabricated hollow pier column is composed of pier column longitudinal bars, pier column stirrups, small U-shaped bars and large U-shaped bars, and the outer surface of the pier column at the connecting position of the bottom and a socket groove is in a corrugated shape; the prefabricated bearing platform is composed of connecting steel bars, bearing platform stirrups, the socket groove and a steel bar net; the surface of the inner wall of the socket groove is corrugated; and the connecting steel bars are common steel bars, and anchor heads are arranged at the ends. In order to guarantee the connecting strength of the prefabricated hollow pier column and the bearing platform, the structural integrity of the pier column and the bearing platform is enhanced through a socket and spigot joint mode and a pre-embedded connecting steel bar combined connection method. By prefabricating important components such as the bridge pier column and the bearing platform, rapid construction is achieved, the construction quality is guaranteed, meanwhile, the construction progress is accelerated, the socket depth is reduced, the good stress performance of the overall structure is guaranteed, and the requirement for the anti-seismic performance of a bridge is met.

Owner:BEIJING UNIV OF TECH

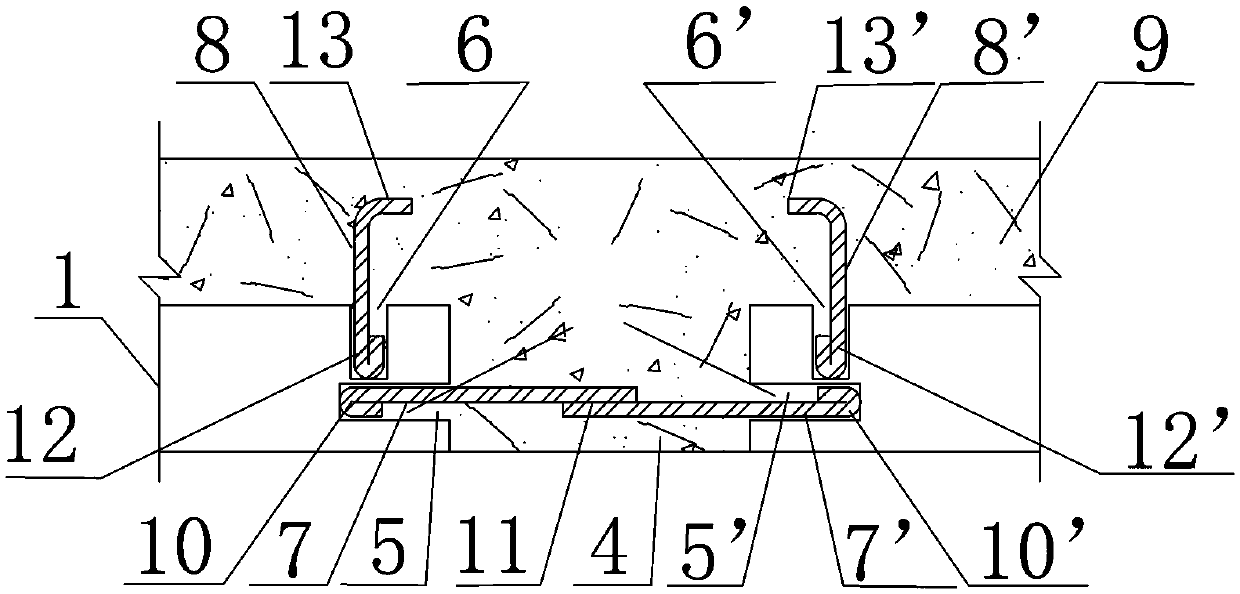

Reinforcing structure and method for damaged concrete pavement panel

InactiveCN105507110AImprove the anchoring effectEffective anchoringPaving detailsRoad surfaceFace sheet

The invention provides a reinforcing structure and method for a damaged concrete pavement panel. The reinforcing structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, a reinforcing groove, multiple pairs of horizontal rebar embedding holes, and vertical rebar embedding holes. The horizontal rib embedding holes are formed in the two groove walls of the reinforcing groove, and the vertical rib embedding holes are formed in the concrete pavement panel. Horizontal rebars are fixedly arranged in the horizontal rebar embedding holes, vertical rebars are fixedly arranged in the vertical rebar embedding holes, and a steel fiber reinforced concrete cover is poured and fixed to the concrete pavement panel. The reinforcing method for the damaged concrete pavement panel includes the following steps that 1, surface planing is conducted; 2, the reinforcing groove is formed, and the multiple pairs of horizontal rebar embedding holes and the multiple pairs of vertical rebar embedding holes are drilled; 3, construction glue is poured, and the horizontal rebars and the vertical rebars are embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover. The bearing capacity of the concrete pavement panel is increased, the service life and the maintenance period of a road are prolonged, and the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

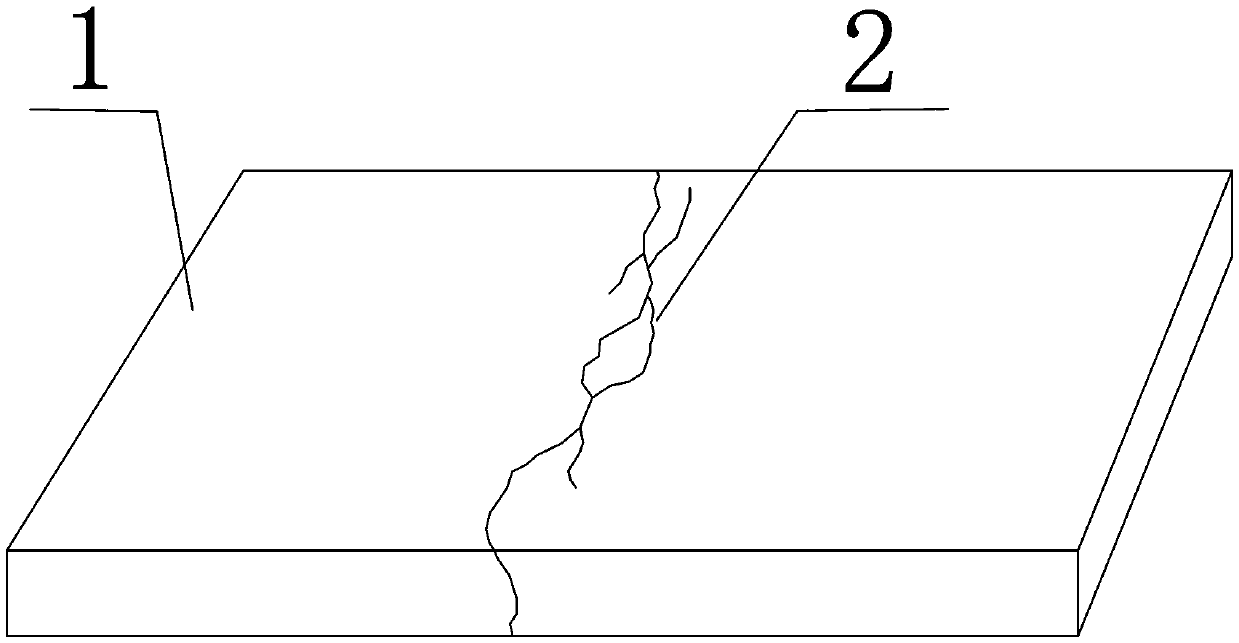

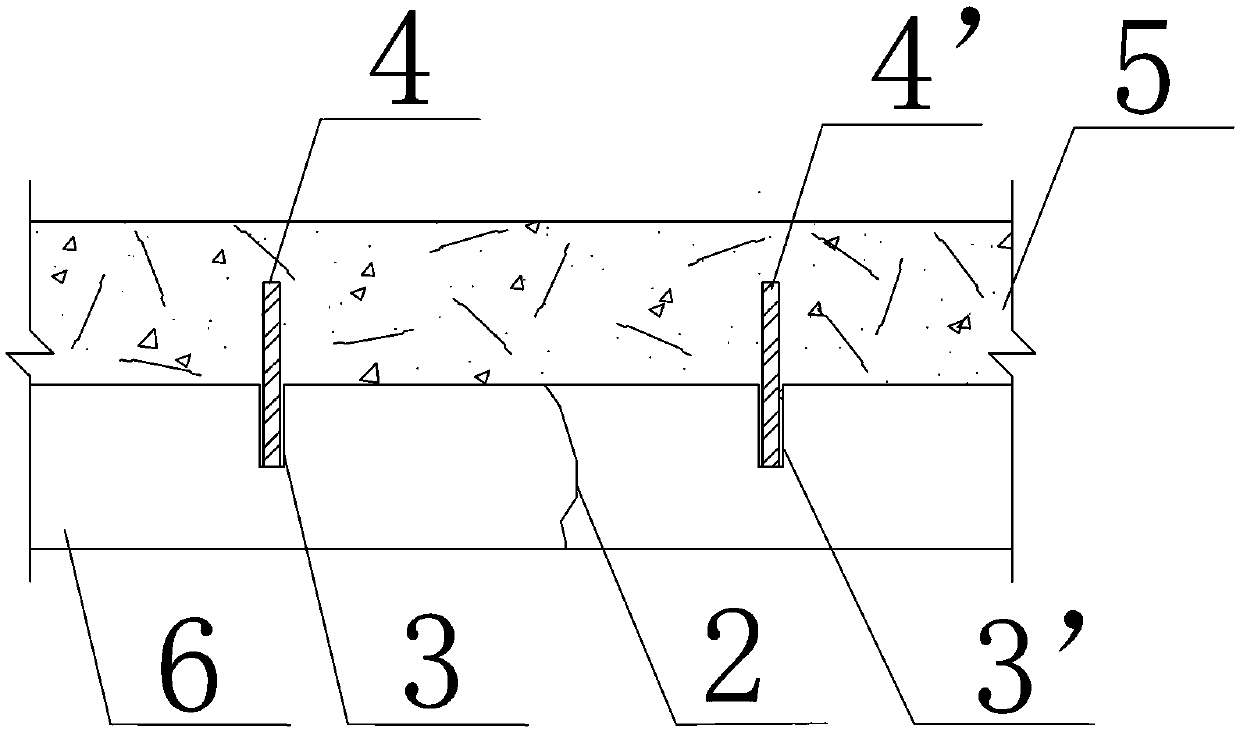

Restoration structure and method for damaged concrete pavement panel

InactiveCN105507111AImprove wear resistanceImprove bending resistanceIn situ pavingsPaving detailsRestoration methodRoad surface

The invention provides a restoration structure and method for a damaged concrete pavement panel. The restoration structure for the damaged concrete pavement panel comprises the concrete pavement panel with the planed surface, multiple pairs of rebar embedding holes, rebars and a steel fiber reinforced concrete cover. The rebar embedding holes are formed in the two sides of a broken slab crack in pairs and distributed in the extension direction of the broken slab crack. The rebars are vertically inserted and fixed into the rebar embedding holes in a binding mode. The steel fiber concrete cover is poured and fixed to the concrete pavement panel. The restoration method for the damaged concrete pavement panel includes the steps that 1, planing is conducted; 2, the multiple pairs of rebar embedding holes are drilled; 3, construction glue is poured into the rebar embedding holes, and the rebars are vertically embedded; 4, steel fiber reinforced concrete is poured to form the steel fiber reinforced concrete cover, and finally the restoration structure for the damaged concrete pavement panel is formed. According to the restoration structure and method for the damaged concrete pavement panel, the service life and the maintenance period of a road are prolonged, and meanwhile the long-term use cost is reduced.

Owner:ZHENGZHOU UNIV

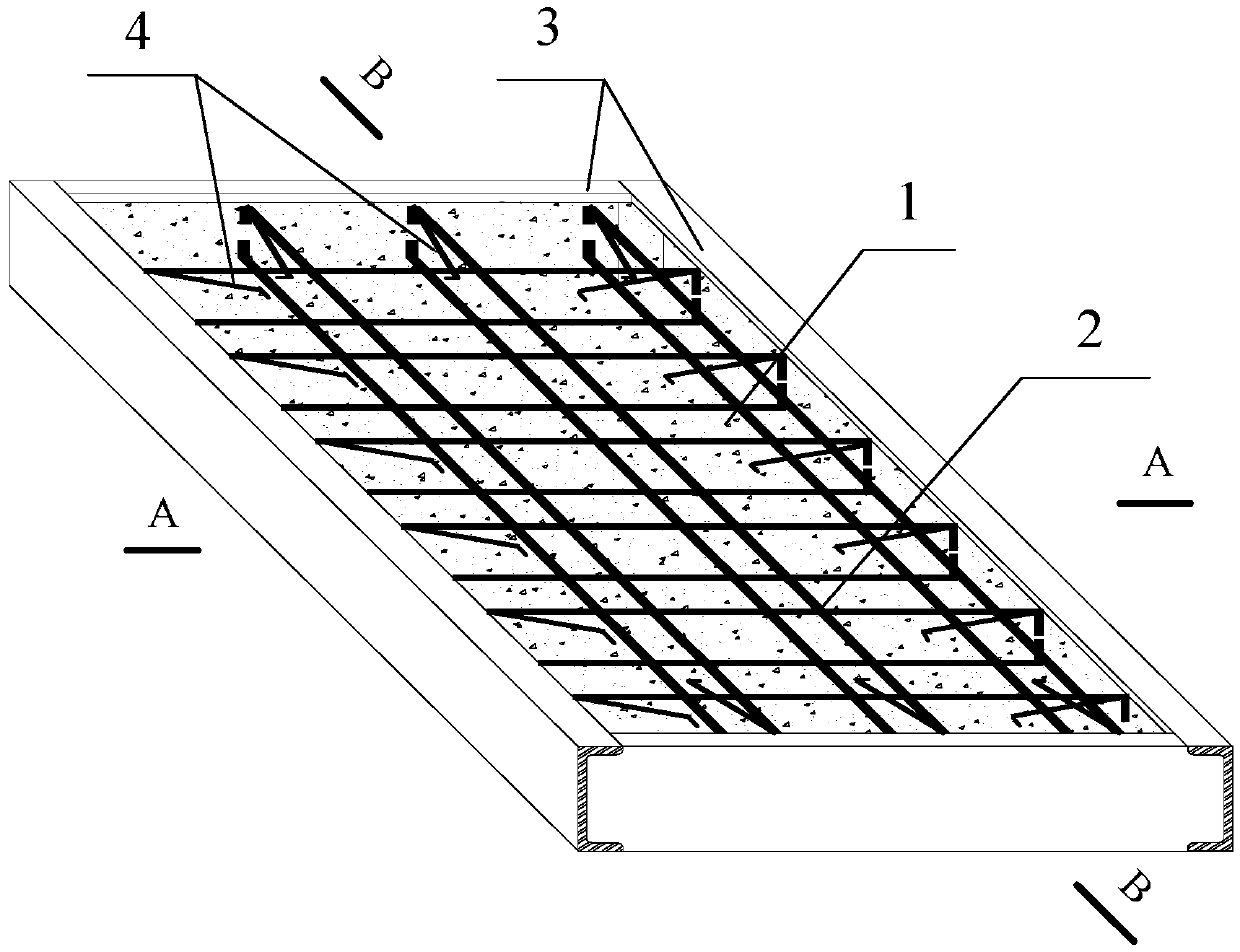

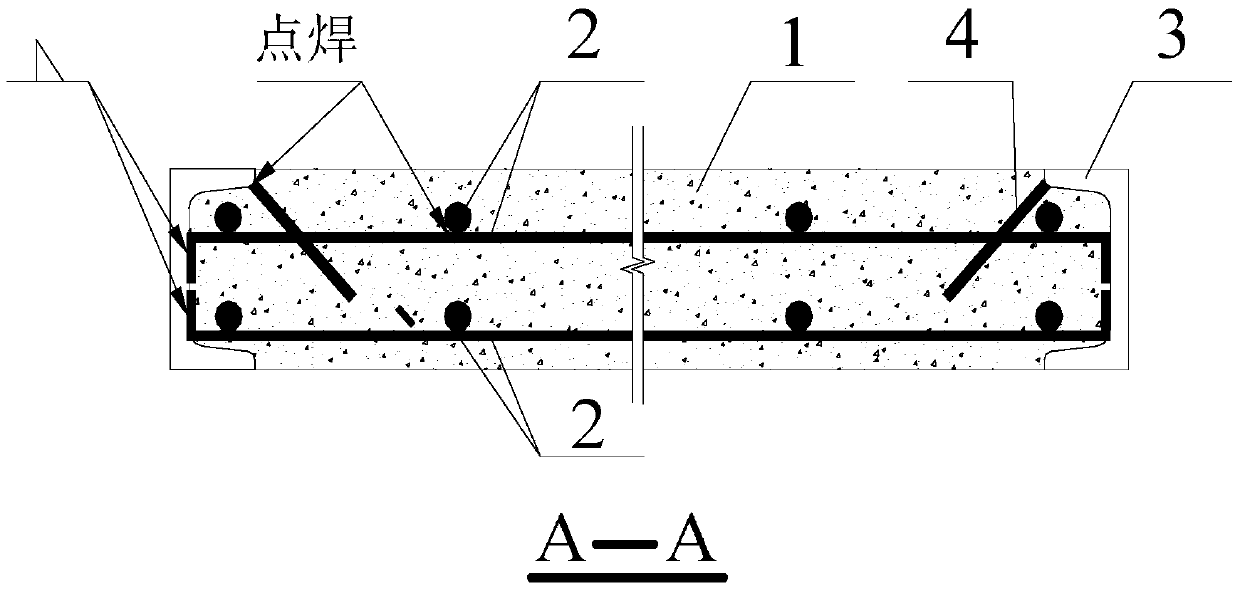

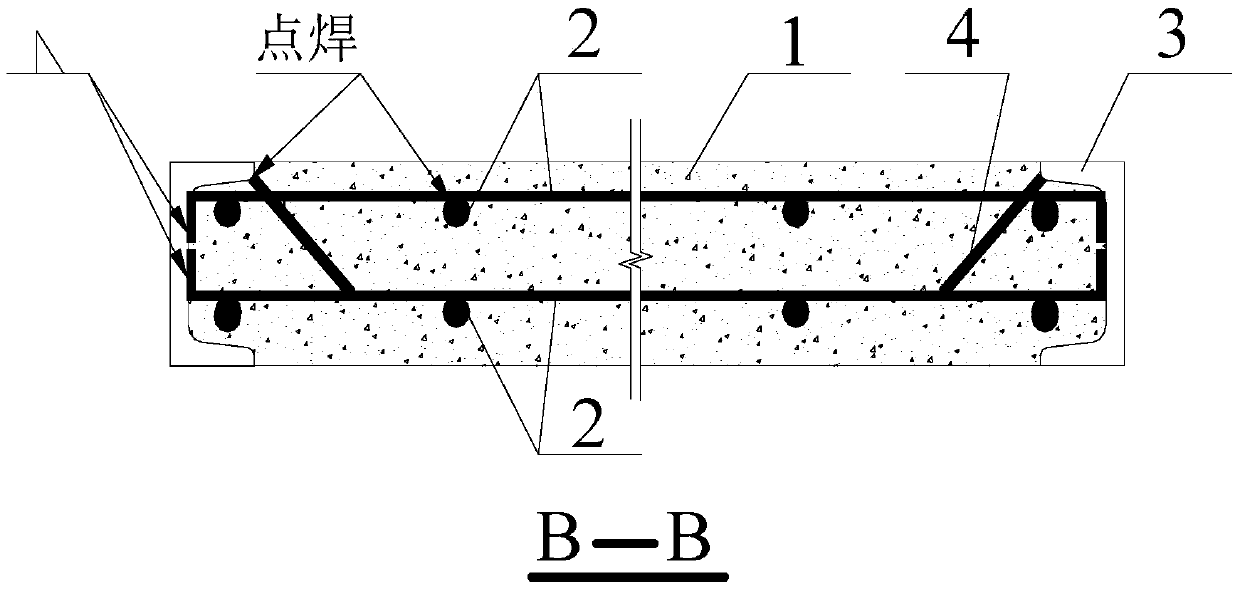

A reinforced concrete slab with shear reinforcement channel steel frame around it

ActiveCN103758275BSimple structureEasy to manufactureConstruction materialFloor slabMesh reinforcement

The invention discloses a reinforced concrete plate with a shear reinforcement steel channel frame at the periphery, and belongs to the field of building materials. The reinforced concrete plate comprises concrete, a dual-layer steel mesh reinforcement, steel channel and shear reinforcements, wherein the steel channel is welded to form the frame; the shear reinforcements are spot welded on the steel channel, form angles of 45 degrees together with the plane of the plate, and are positioned at the inner side edge of a steel channel opening corresponding to the end part of a reinforcing steel bar of the upper-layer steel mesh reinforcement; the steel mesh reinforcement comprises longitudinal reinforcements and transverse reinforcements which are arranged at intervals in a uniform staggered manner; the longitudinal reinforcements and transverse reinforcements are arranged at equal intervals; the steel mesh reinforcement serves as the framework of the plate and is arranged in the thickness direction of the plate in a layering manner; the periphery of the steel mesh reinforcement is welded to the steel channel frame, and the middle is wrapped with concrete. The reinforced concrete plate disclosed by the invention is simple in structure, convenient to manufacture, and excellent in bending resistance, shear resistance, and anti-seismic property, can realize standardized and industrial production of floor slabs, and has an important significance in realizing the industrial production target of steel structure buildings.

Owner:MAANSHAN LANXIN ENVIRONMENTAL PROTECTION TECH CO LTD

Integrated flower pool type ecological soil blocking building block and assembly type soil blocking wall

PendingCN108442403AGood overall stabilitySave templateArtificial islandsUnderwater structuresBuilding materialEngineering

The invention discloses an integrated flower pool type ecological soil blocking building block and an assembly type soil blocking wall, and relates to the technical field of building materials. The soil blocking building block comprises an integrated block body, the integrated block body comprises a first top surface, a first bottom surface, a front side surface, a rear side surface, a left side surface and a right side surface, and the front side surface of the integrated type block body is a first arc-shaped convex surface; the rear side surface of the integrated type block body is a first arc-shaped concave surface; the left side surface and the right side surface of the integrated type block body are correspondingly provided with symmetrically arranged wave surfaces, the front sectionsof the wave surfaces are concave sections, and the rear sections of the wave surfaces are protruding sections; the first arc-shaped convex surface can be matched with the first arc-shaped concave surface and can also be matched with the concave sections; the protruding section can be matched with the first arc-shaped concave surface and can also be matched with the concave sections; and at leastone first through hole penetrating through the first top surface and the first bottom surface is formed in the integrated type block body.

Owner:湖北和利康博生态科技有限公司

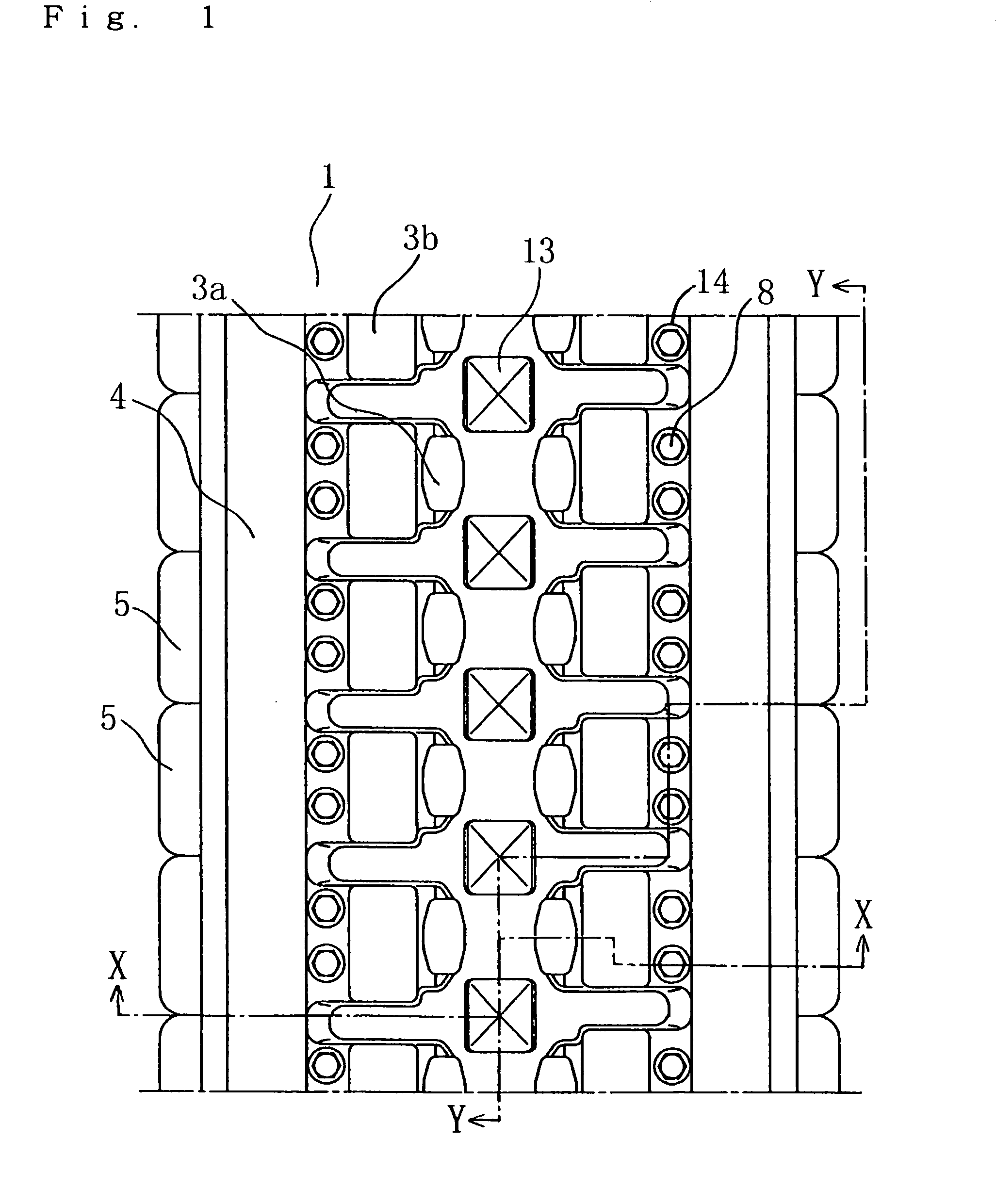

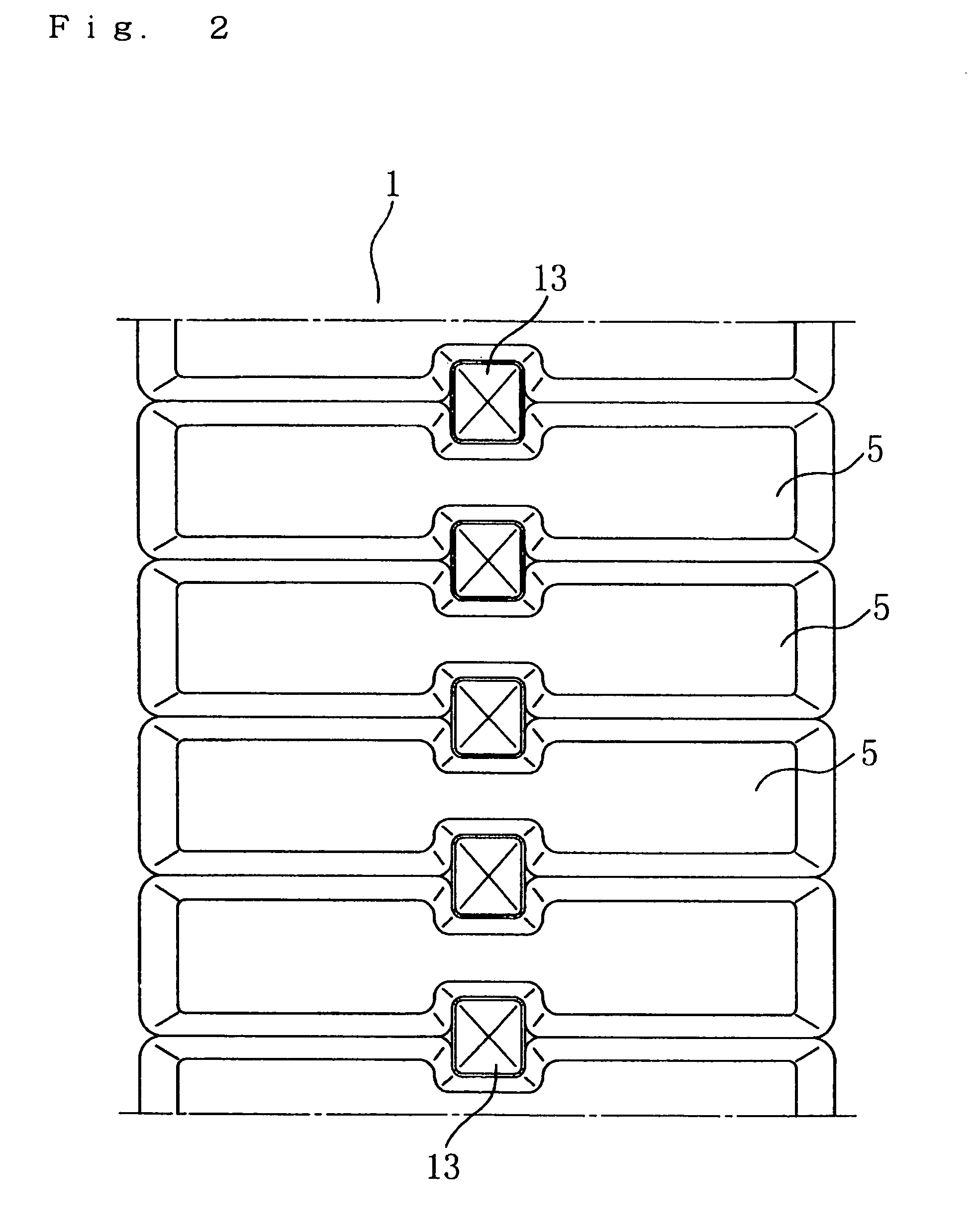

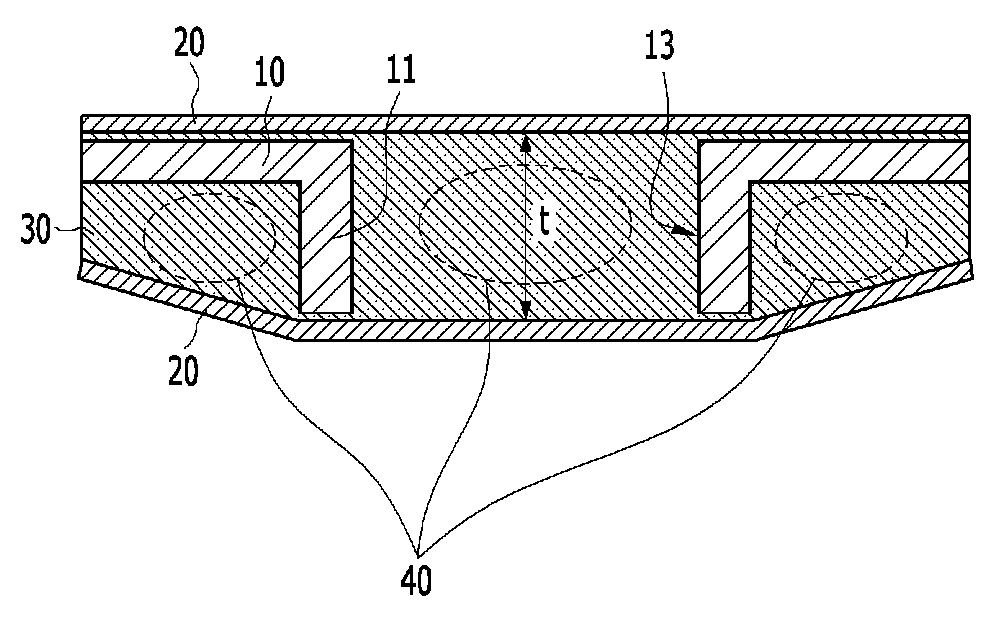

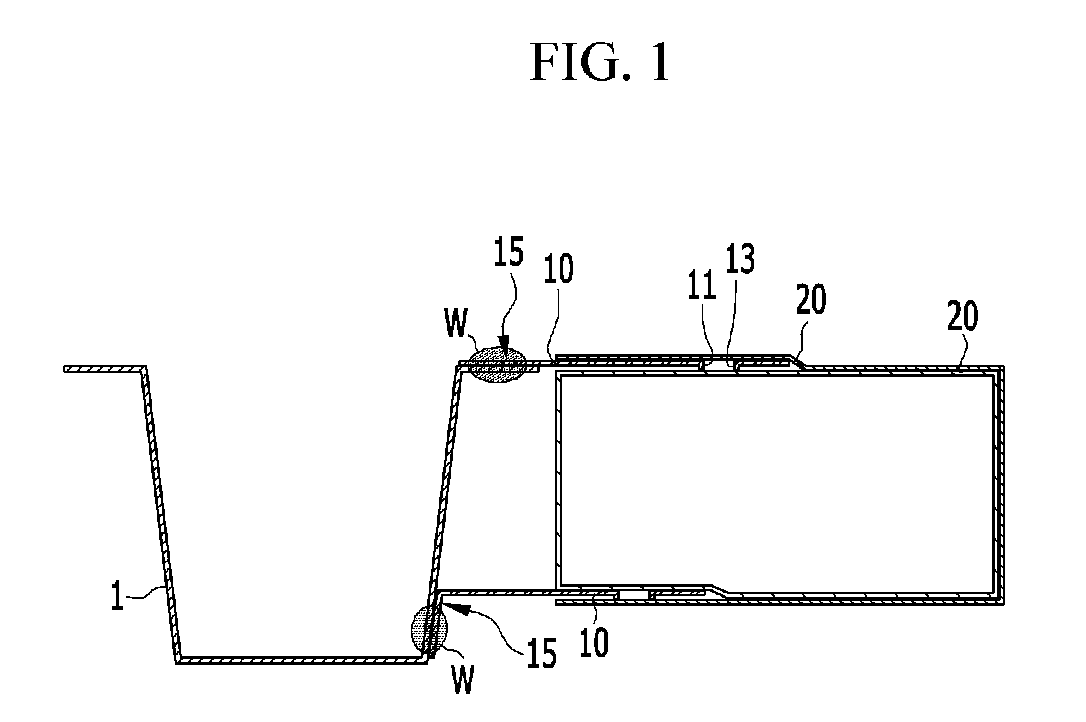

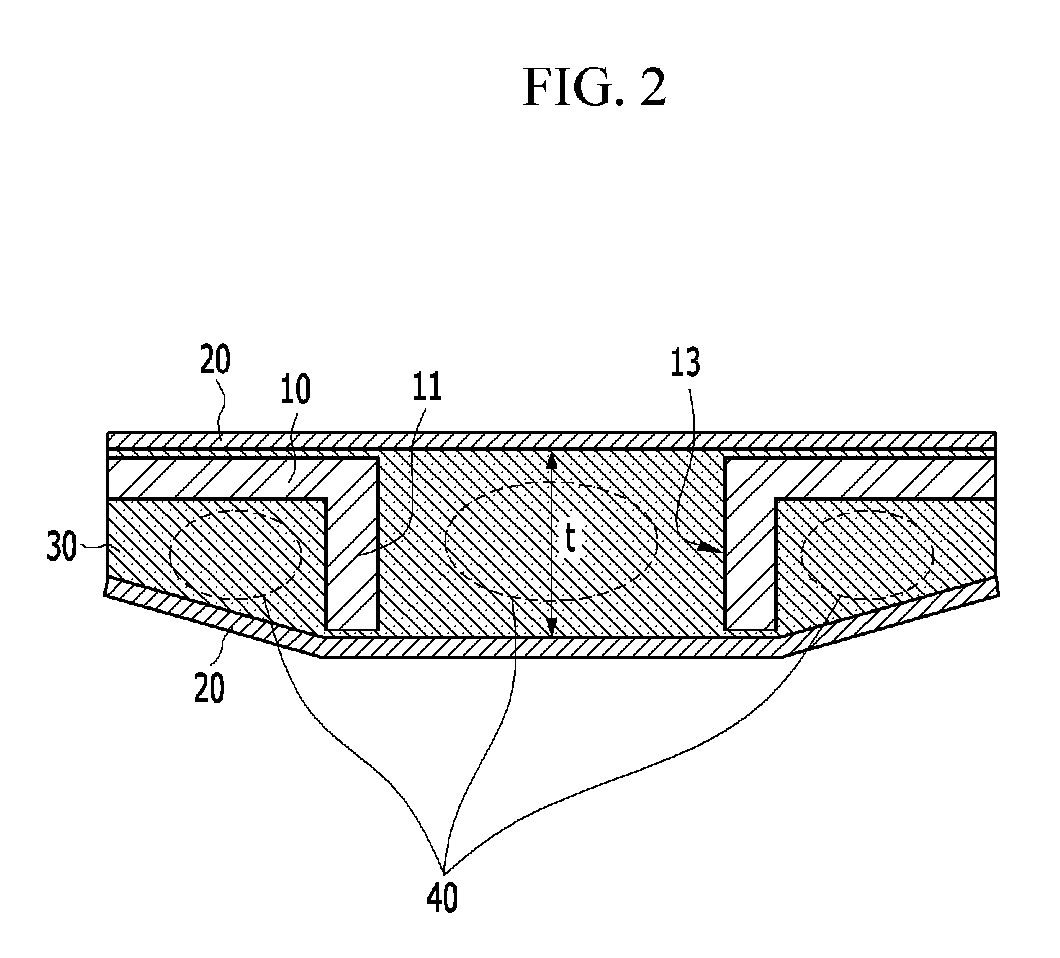

Composite material with insert-molded attachment steel

ActiveUS20170313030A1Increased shear strengthIncreasing the thicknessSynthetic resin layered productsVehicle sub-unit featuresFiberMetallurgy

A composite material with an insert-molded attachment steel is provided. The composite material includes a plurality of burring apertures, each of which has a flange in one direction on the attachment steel and is inserted between fibers. A resin is then introduced between the fibers in each burring aperture and external to the flange.

Owner:HYUNDAI MOTOR CO LTD

Molding process of polymer concrete pipeline

The invention discloses a molding process of a polymer concrete pipeline, and belongs to the technical field of pipeline manufacturing. The polymer concrete pipeline comprises an inner lining mould and an outer mould. The molding process comprises the following steps: A, firstly, spraying a layer of mould discharging agent on an outer wall of the inner lining mould, then spraying a fabric resin gel coat layer on a surface of the mould discharging agent, and spraying and scattering quartz sand particles; B, firstly, spraying the layer of mould discharging agent on an inner wall of the outer mould, then spraying a pure resin gel coat layer or the fabric resin gel coat layer on the surface of the mould discharging agent, and curing and spraying and scattering adhesive particles; C, sequentially mounting the inner lining mould, a steel mesh skeleton, a reinforced net and an outer mould in a sleeving manner from inside to outside to form a casting structure; D, casting polymer concrete into the casting structure, and removing the inner lining mould and the outer mould after solidification and molding so as to obtain the polymer concrete pipeline. The molding process of the polymer concrete pipeline disclosed by the invention is simple in process, and the prepared polymer concrete pipeline has excellent performance of all aspects, and has the advantages of high sealing property, high strength, high impermeability, corrosion resistance and the like.

Owner:义乌市超强管业有限公司

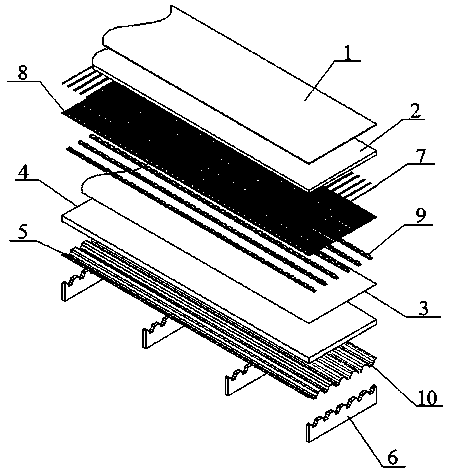

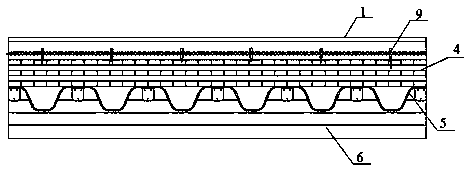

A COCS combine bridge deck structure

PendingCN109024268AStrong shock absorption and shock resistanceHigh strengthBridge structural detailsClimate change adaptationStress concentrationSheet steel

The invention discloses an A COCS combine bridge deck structure which comprises an asphalt abrasion layer, a UHPFRC layer, a Waterproof layer, CLT top board, a corrugated sheet steel board and a diaphragm board, all of which are orderly arrayed from the top to the bottom. The UHPFRC layer is provided with a ribbed reinforcing steel mesh, the asphalt abrasion layer is laid on the surface of the UHPFRC layer, the waterproof layer is laid on the surface of the CLT top plate, and the UHPFRC layer is connected with the CLT top plate through a shear connector. A CLT top board, the c corrugated sheet steel board and the UHPFRC layer are combined organically, A PZ-type shear connector and a screw connector are used to effectively combine that parts, The advantages of each material are further brought into play to avoid the welding connection of the traditional structure, to overcome the problem of stress concentration at the vulnerable position caused by the number and collection of the structural weld seams, to improve the fatigue resistance of the orthotropic plate, to improve the integrity of the assembled building, to facilitate the manufacture and installation, to be simple in maintenance and to be low in production cost.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Production process for casting core mold part based on lost foam technology

PendingCN113385638AHarden fastReduce the temperatureFoundry mouldsFoundry coresSurface roughnessMaterial consumption

The invention discloses a production process for casting a core mold part based on a lost foam technology. The production process comprises the following steps of A, preparing a core mold model; b, preparing a core model cluster; c, pretreatment of model casting, specifically, burying the core model cluster into a sand box, compacting molding sand in the sand box, covering the molding sand with a plastic film, and performing primary vacuumizing treatment on the sand box to enable the interior of the sand box to be in a negative pressure state; d, casting; and e, post-treatment of model casting, specifically, uncovering the plastic film on the sand box, carrying out secondary vacuumizing on the interior of the sand box, taking out a fully cooled core mold casting from the sand box, and carrying out size and shape finish machining treatment to obtain the core mold part. The core mold part manufactured through the production process has the advantages of being high in size precision and low in surface roughness, the production process is simple, the production cost is greatly reduced, material consumption is low, and production process has high popularization value in the field of core mold part casting.

Owner:INNER MONGOLIA UNIV OF TECH

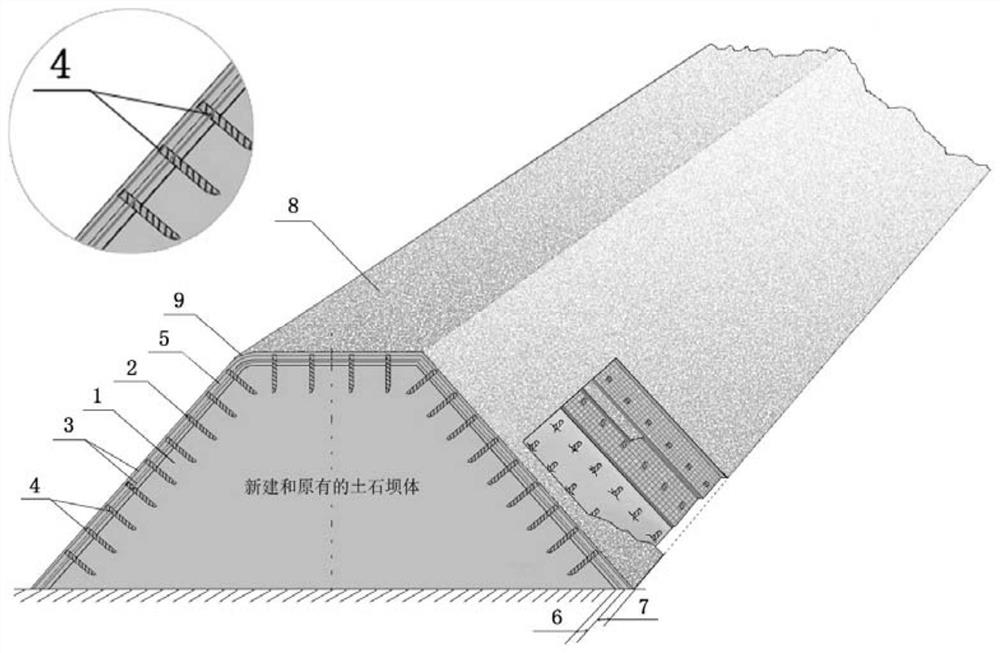

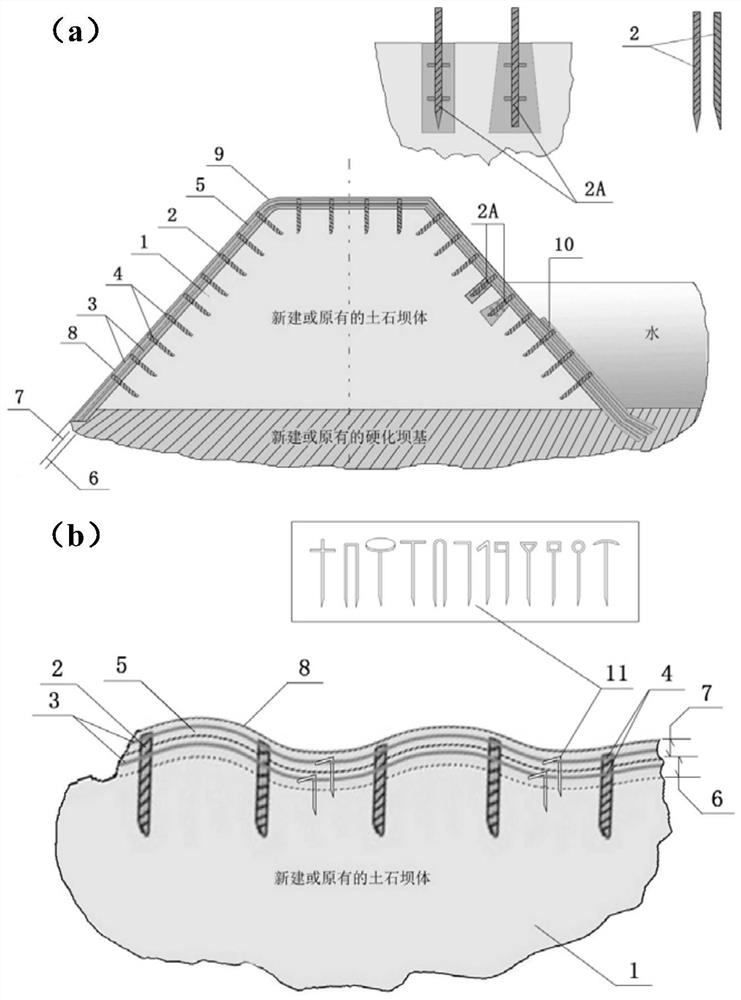

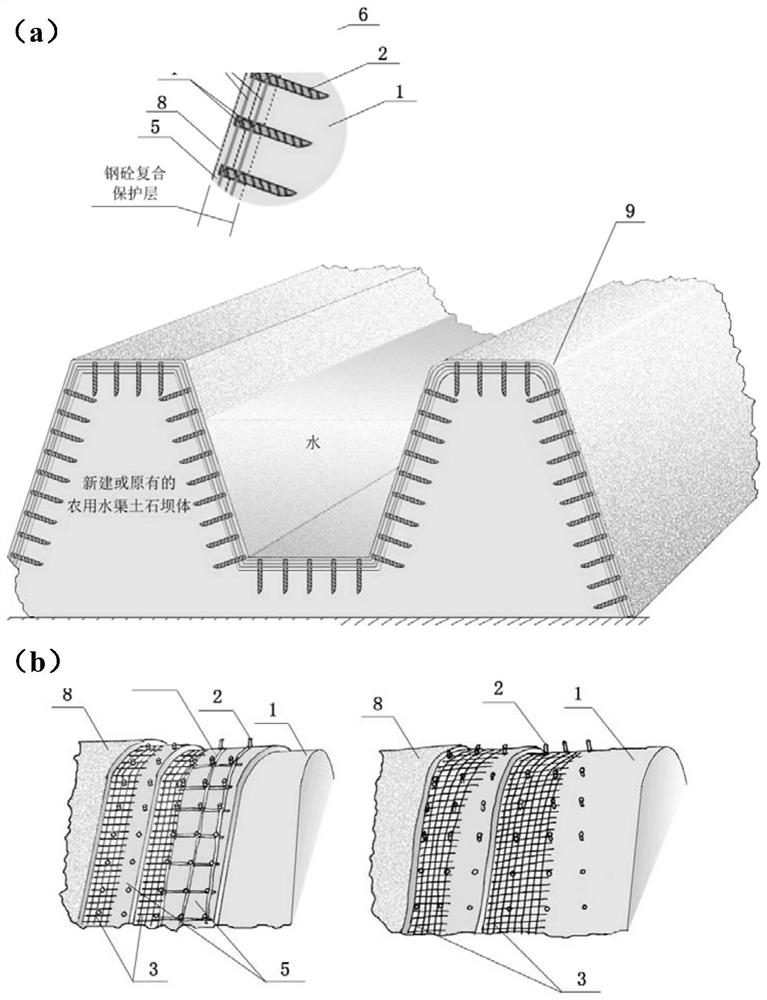

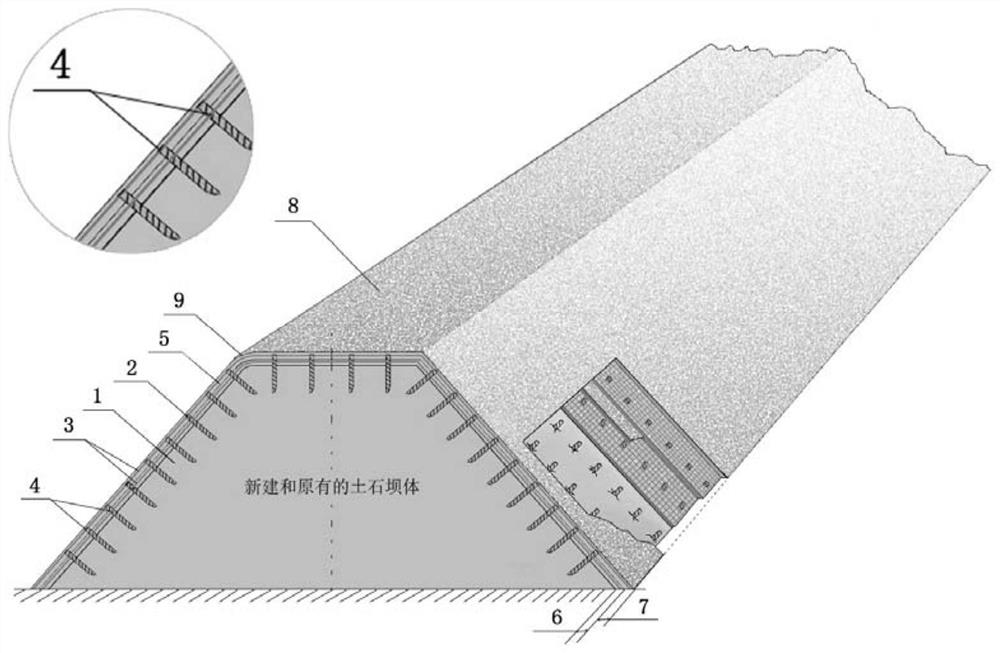

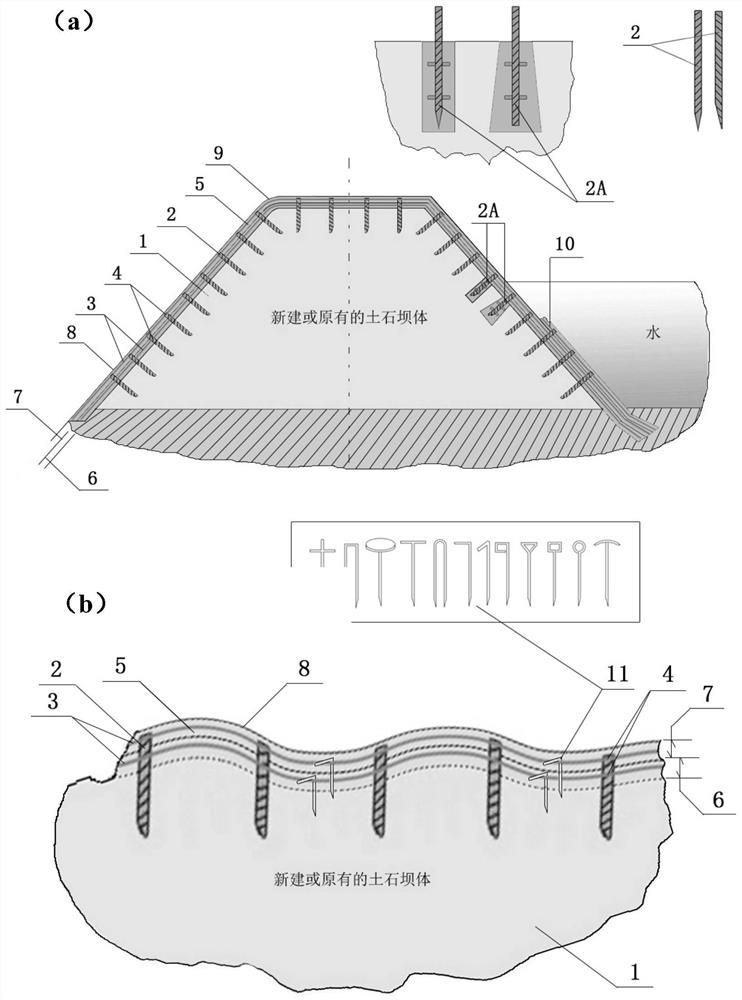

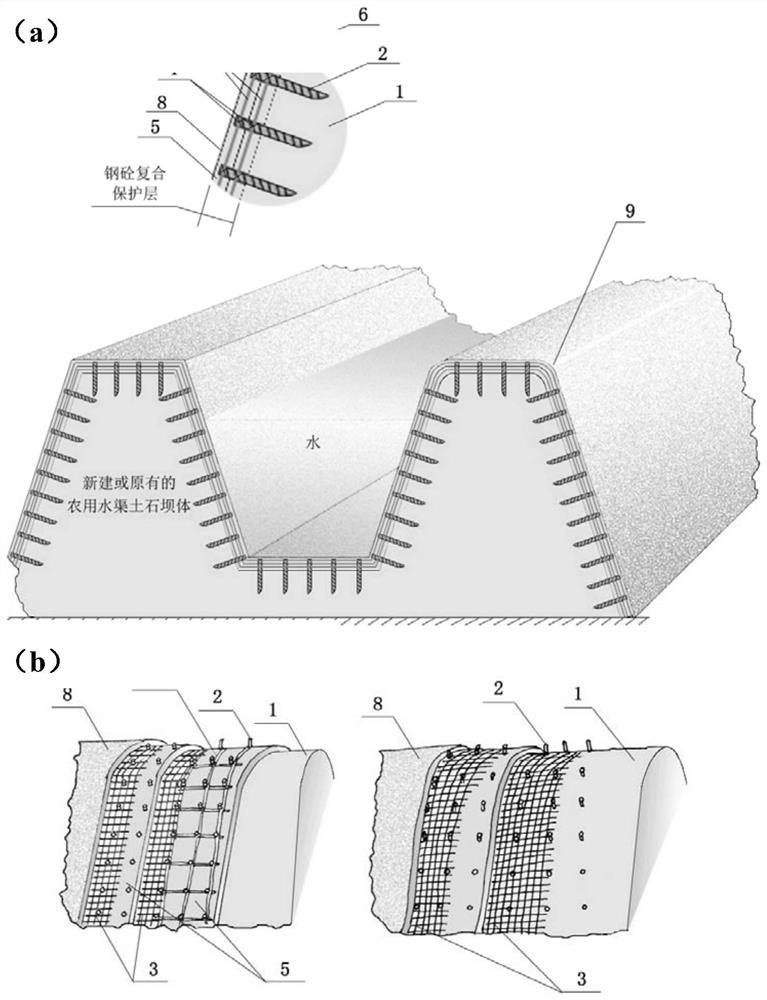

Reinforcing and Reconstruction Device for Whole-body Baotuan Dam and Earth-rock Dam

ActiveCN112575745BShear strengthGood flexural resistanceClimate change adaptationEarth-fill damsSoil scienceStructural engineering

Owner:张柏祥 +1

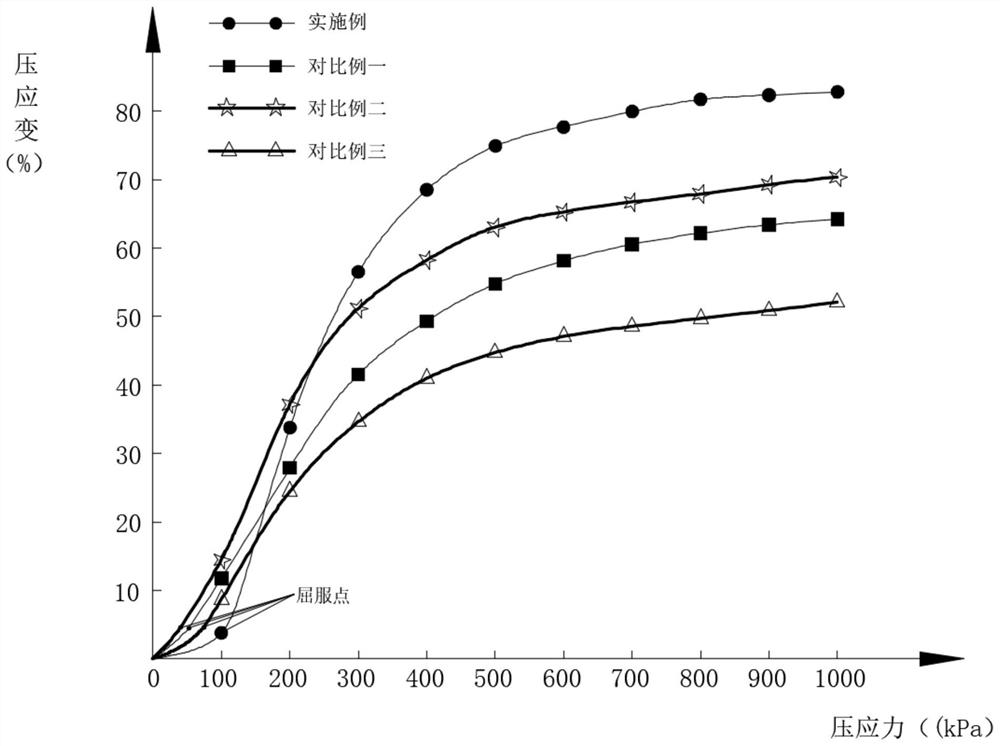

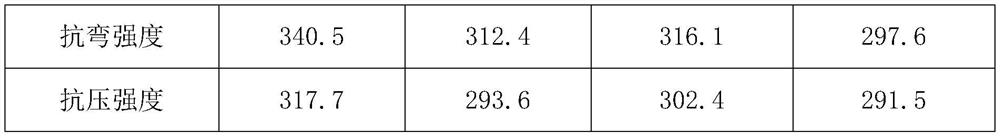

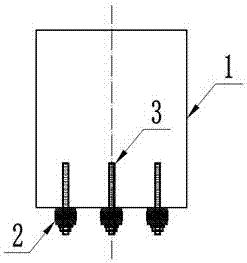

Whole-body huddling dam and earth-rock dam body reinforcing and reconstructing device and construction method

ActiveCN112575745AShear strengthGood flexural resistanceClimate change adaptationEarth-fill damsStructural engineeringConcrete composites

The invention discloses a whole-body huddling dam and earth-rock dam body reinforcing and reconstructing device and a construction method. The device comprises an earth-rock dam body, implanted steelpiles and a steel-concrete composite layer, wherein the implanted steel piles are densely distributed on the earth-rock dam body at different points, one end of each implanted steel pile is driven into the earth-rock dam body, the other end of each implanted steel pile is left on the surface of the dam body, the steel-concrete composite layer comprises gravel concrete and an anti-cracking steel mesh, the anti-cracking steel mesh covers the surface of the dam body and is fixed with the implanted steel piles, and the gravel concrete fills and covers the anti-cracking steel mesh. According to thedevice, the earth-rock dam body which maintains the stability of the dam body just by means of the friction cohesion characteristic and the self-weight compactness among original earth-rock sand-stone particles in the past and resists and prevents water pressure leakage, scouring and damage, the implanted steel piles and the steel-concrete composite layer form a full-body huddling structure, thefull-body clustering structure is formed in the mode that many chopsticks are combined, force is gathered and clustered, a firm dam similar to a rock mountain as a whole is formed, the shear resistance, the fracture resistance and the impact resistance of the dam are greatly improved, qualitative leap is achieved, and the dam can be seamless, has few seams and is attractive in surface.

Owner:张柏祥 +1

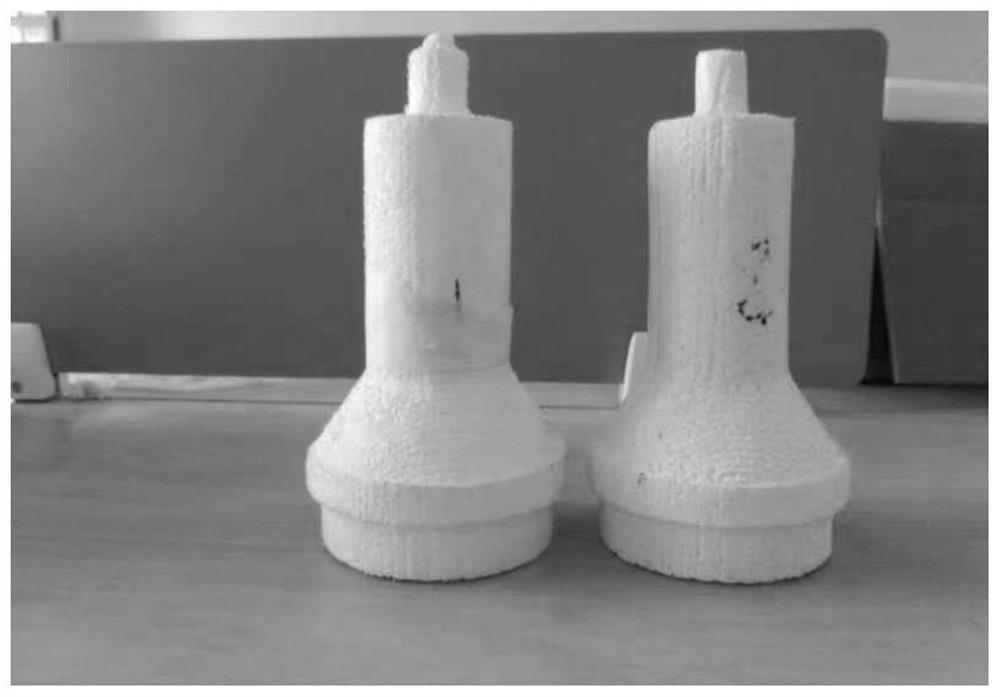

Preparation method of EPS foam product

The invention relates to the technical field of EPS foam production, and discloses a preparation method of an EPS foam product. The EPS foam product comprises the following components: 60-70 parts of polystyrene particles, 20-25 parts of benzene, 60-70 parts of absolute ethyl alcohol, 20-22 parts of glycol ether, 8-10 parts of soluble pentane and 5-6 parts of brominated polystyrene. The preparation method comprises the following steps: S1, foaming; S2, curing; S3, forming; and S4, cutting. The material is composed of the polystyrene particles, the benzene, the absolute ethyl alcohol, the glycol ether, the soluble pentane and the brominated polystyrene, the polystyrene particles are composed of sodium dodecyl benzene sulfonate, polyvinyl alcohol, calcium phosphate, styrene, auxiliaries and calcium carbonate, and therefore, the product has excellent tensile resistance, shear resistance, bending resistance and compression resistance; and in the using process of the product, the product is not easy to damage due to external force, long in service life, large in linear elasticity change range, good in elastic property and capable of bearing large pressure.

Owner:青岛荣发保温材料有限公司

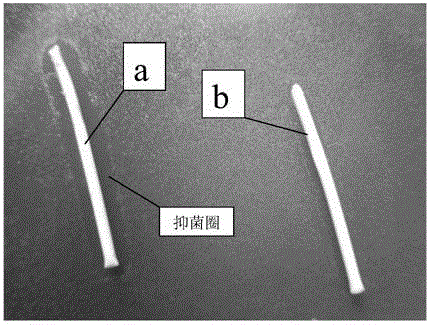

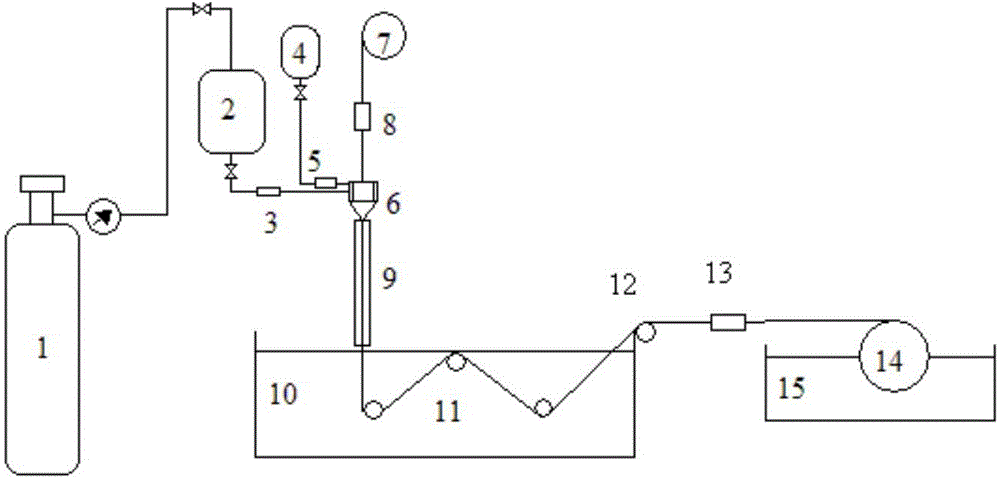

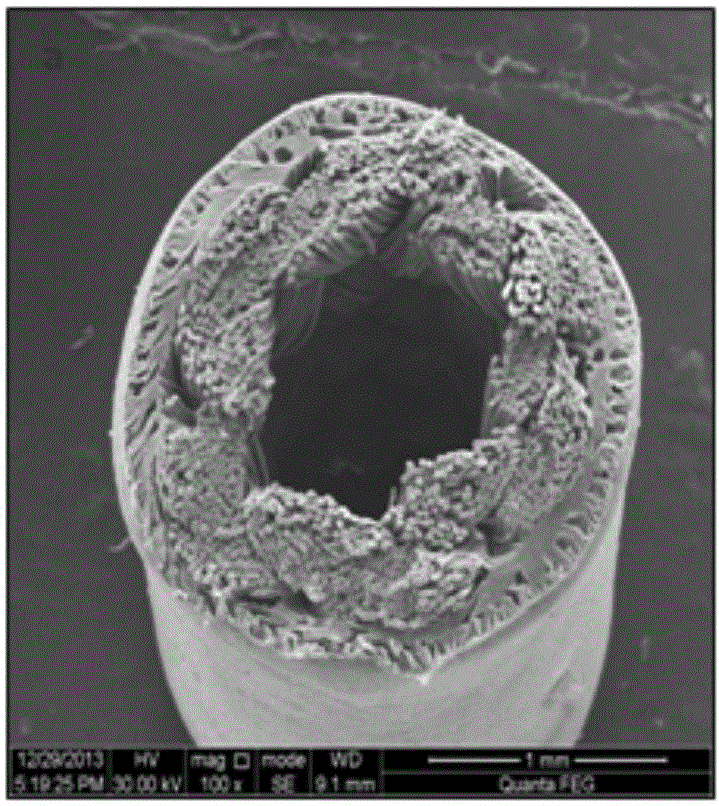

A kind of preparation method of pvc hollow fiber membrane with bacteriostasis

ActiveCN103933867BReduce manufacturing costImprove mechanical propertiesSemi-permeable membranesPolyesterPolymer science

The invention provides a preparation method of a PVC (polyvinyl chloride) hollow fiber film with antibacterial performance. The preparation method comprises the following steps: under an ultrasonic condition, dissolving and dispersing silver nanoparticles in a solvent for dissolving polyvinyl chloride; adding polyvinyl chloride, a pore-forming agent and Tween-80 into a spinning pot with a solvent and stirring under a sealing condition; vacuumizing, standing and defoaming; filtering out impurities to obtain a film casting solution; injecting the film casting solution into a spinneret by a metering pump and simultaneously introducing polyester yarn threads into the spinneret by traction, allowing the polyester yarn threads to flow out together with the film casting solution, and evenly applying the film casting liquid to the outer surfaces of the polyester yarn threads of a support layer; and performing a phase inversion process in a coagulating bath, thereby obtaining the reinforced hollow fiber film with antibacterial performance. The hollow fiber film has the characteristics of bacteria inhibiting capability, high strength, high flux and low price.

Owner:HARBIN ENG UNIV

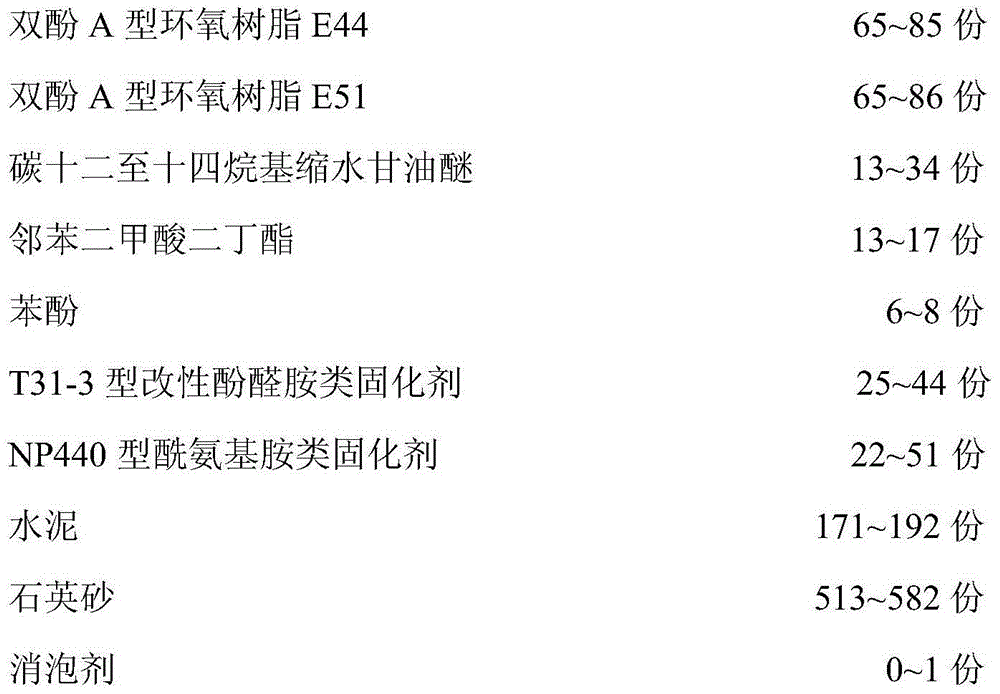

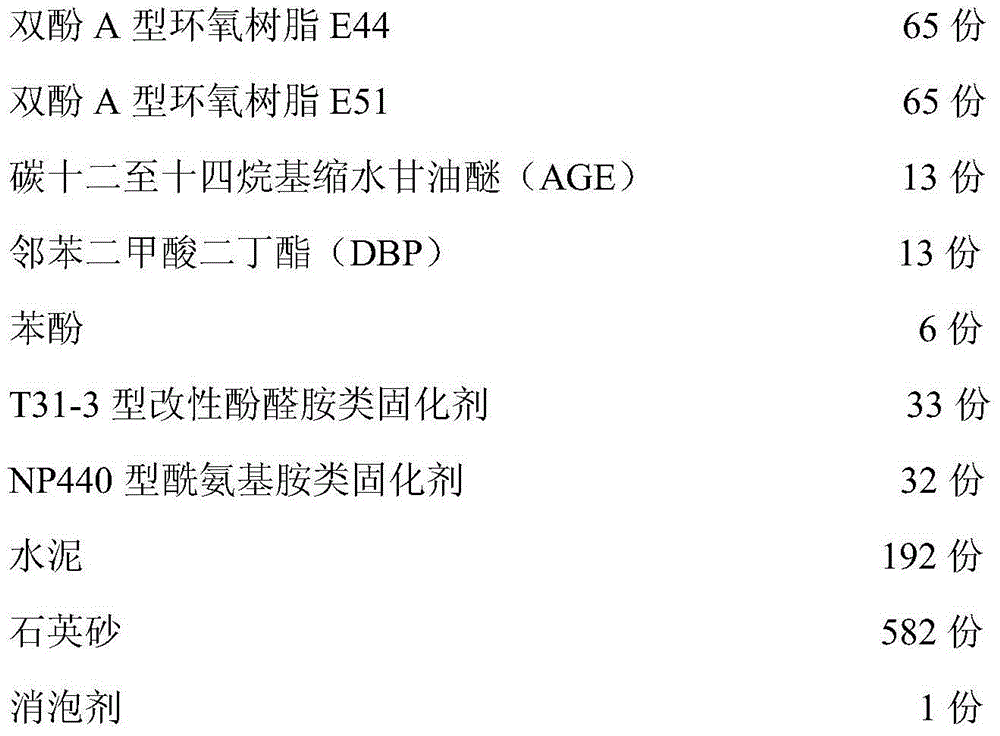

A kind of epoxy mortar for offshore oil and gas pipeline repair and preparation method thereof

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

A kind of manufacturing method of extra thick steel plate

A method for manufacturing an extra-thick steel plate, belonging to the technical field of sheet metal manufacturing technology, is used to manufacture extra-thick steel plates with a thickness of more than 100mm. The surface of the base material and composite material to be compounded is processed flat and smooth, and then sprinkled with magnesium powder with a particle size of 1250 mesh, stacked symmetrically, and welded to obtain a composite billet. The composite billet is heated in a furnace and rolled. In the hot rolling process In order to realize the metallurgical bonding between the base material and the composite material interface, the extra-thick steel plate with excellent performance can be obtained. The present invention improves the current technical means for producing extra-thick steel plates, greatly reduces the technical difficulty of making extra-thick steel plates, significantly reduces production costs, can greatly increase the output of extra-thick steel plates, and has the advantages of simple process, High efficiency, less investment, low cost, good internal product quality and so on.

Owner:HEBEI IRON AND STEEL

Polymer concrete pipeline material

The invention relates to a polymer concrete pipeline material and belongs to the technical field of polymer concrete. The polymer concrete pipeline material is prepared from the ingredients in percentage by mass: 92% to 93.5% of aggregates and 6.5% to 8% of resin binder and auxiliaries, wherein the aggregates comprise quartz sand with the grain size of 3 / 8 to 4 meshes, quartz sand with the grain size of 4 to 10 meshes, quartz sand with the grain size of 10 to 30 meshes, quartz sand with the grain size of 30 to 70 meshes, quartz sand with the grain size of 70 to 120 meshes and quartz sand withthe grain size of 120 to 250 meshes, which are in the mass ratio of (20 to 30): (30 to 40): (12 to 16): (12 to 16): (5 to 10): (3 to 8). According to the polymer concrete pipeline material disclosed by the invention, through the matching and designing among the ingredients, the prepared polymer concrete material is low in cost, long in service life and excellent in comprehensive performance and isenvironmentally friendly, corrosion-resistant, pressure-proof and cold-resistant.

Owner:山东省呈祥电工电气有限公司

A Forming Technology of FRP Reinforced Polymer High Pressure Pipeline

ActiveCN109352884BImprove mixing uniformitySimple structureTubular articlesGlass fiberPolymer science

The invention relates to a molding process of FRP-reinforced polymer high-pressure pipelines. The molding process uses FRP pipes as inner molds and cooperates with outer molds to form a pouring space for polymer concrete. After molding, the outer molds are removed to obtain glass-steel-reinforced polymerization For high-pressure pipelines, the molding process goes through three steps: external mold pretreatment, pouring structure construction, and pouring molding. The FRP reinforced polymer high-pressure pipelines are made of inner lining, FRP pipe, skeleton net and reinforcement from inside to outside. The polymer concrete layer, bonding reinforcement layer, fabric resin layer and gel coat resin layer of the net, the formed pipe not only has a good anti-corrosion effect on the surface, but also has a high hoop tensile strength and can withstand high water pressure. During use, it is not easy to crack, breakage and other damage phenomena, and the maintenance cost in the later period is low, which can save a lot of manpower and material resources.

Owner:山东土大力管道工程有限公司

Forming Technology of Polymer Reinforced Prestressed Steel Cylindrical Concrete Pipe

ActiveCN107599273BSimple structureImprove mixing uniformityTubular articlesPre stressPolymer concrete

The invention provides a polymer-reinforced prestressed concrete cylinder pipe molding technology, and belongs to the technical field of pipeline manufacturing. The polymer-reinforced prestressed concrete cylinder pipe molding technology comprises the following steps that (1) manufacturing of a lining mold is conducted, wherein circumferential prestressed wires are wound around a concrete pipe core with a steel cylinder, a PCCP semi-finished product is formed and directly serves as the lining mold, and a reinforcing net is prefabricated in the concrete pipe core; (2) pretreatment of an outer mold is conducted, wherein a release agent coats the inner wall of the outer mold; and (3) construction of a pouring structure is conducted, wherein the lining mold, the reinforcing net and the outer mold are combined in sequence from inside to outside so as to form the pouring structure, polymer concrete is poured into the pouring structure, the outer mold is removed after molding is accomplished,and therefore a polymer-reinforced prestressed concrete cylinder pipeline is obtained. The polymer-reinforced prestressed concrete cylinder pipe molding technology is simple, and the manufactured polymer-reinforced prestressed concrete cylinder pipeline is excellent in performance and has the advantages of being high in sealing performance, strength and anti-permeability and resistant to corrosion.

Owner:江苏致乐管业科技有限公司

Fiber thin plate-steel composite reinforced rc structure and its method and application

ActiveCN105863288BExcellent deformation coordination performanceFree sizeBuilding repairsSteel platesDuctility

The invention discloses a fiber sheet-steel plate combination reinforced RC structure and a method and application thereof. A fiber sheet-steel plate combined plate is of a three-layer structure, the inner layer in contact with concrete is a low-elasticity-modulus high-strength glass fiber sheet or an aramid fiber sheet or a basalt fiber sheet, the middle layer is a steel plate, and the outer layer is an intermediate-elasticity-modulus or high-elasticity-modulus carbon fiber sheet. A method for preparing and reinforcing an RC structure of the combined plate comprises the steps that the fiber sheet and the steel plate as well as the fiber sheet and the concrete are bonded through epoxy resin super-strong glue, and anchoring is conducted through bolts embedded in the RC structure. The RC structure is reinforced through the combination reinforcing method, the bearing capacity, the rigidity and the ductility of an original structure can be substantially improved, and the RC structure is good in deformation coordinated property, resistant to corrosion, cracking, fatigue and impact, and durable.

Owner:SOUTH CHINA UNIV OF TECH

A high-viscosity modified asphalt mixture and its application

The invention discloses a high-viscosity modified asphalt mixture and an application thereof. The high-viscosity modified asphalt mixture comprises components in parts by weight: 25-35 parts of the first aggregate; 20-30 parts of the second aggregate; 35-55 parts of the third aggregate; 0-3 parts of filler; 9-15 parts of high-viscosity and high-elasticity modified emulsified asphalt; 0-0.3 parts of glass fiber; 0-3 parts of additives; application of high-viscosity modified asphalt mixture In order to pave the high-viscosity modified asphalt mixture and form it into a pavement overlay by self-flowing; the high-viscosity modified asphalt mixture is a slurry mixture with good fluidity and can invade the cracks in the asphalt pavement surface, thereby repairing the cracks in the asphalt pavement surface , can effectively inhibit new cracks in asphalt pavement.

Owner:广州市北二环交通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com