A kind of preparation method of pvc hollow fiber membrane with bacteriostasis

A technology of fiber membrane and bacteriostasis, which is applied in the field of preparation of high-strength PVC hollow fiber membranes, can solve the problems of being susceptible to biological contamination, poor membrane filament strength, and no bacteriostasis modification, etc., so as to improve hydrophilicity and flexibility, improve the ability to resist shear force, and improve the effect of anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

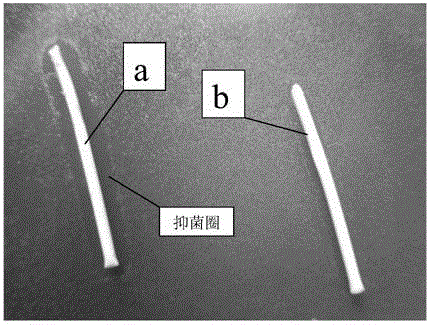

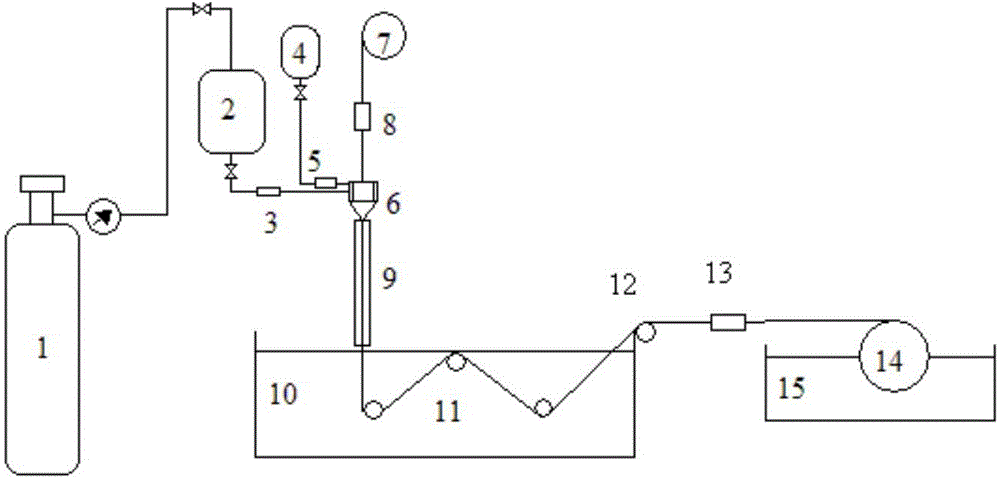

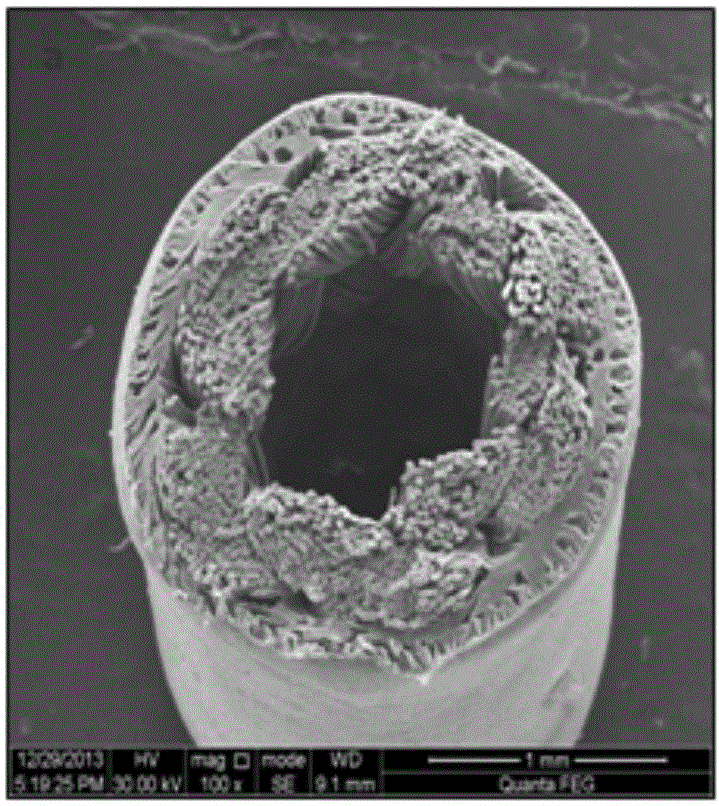

[0039] Under ultrasonic conditions, 62.5g of nano-silver particles were dissolved in 4.27KgN-N dimethylacetamide solvent and dispersed for 15min, 1Kg of PVC resin powder (after drying), 562.5g of pore-forming agent polyvinylpyrrolidone (PVP), 62.5 Slowly add gTween-80 into the spinning tank, seal the tank mouth and stir for 24 hours to form a homogeneous casting solution, then vacuum the spinning tank at a temperature of 60±1°C and a vacuum degree of -0.08MPa Stand in the environment for degassing for 24h. Adjust the nitrogen pressure of the spinning tank to 0.3 MPa. The degassed casting solution passes through the filter screen under the action of pressure to filter out impurities. The casting solution is injected into the spinneret through the metering pump. At this time, the polyester thread is also It is passed into the spinneret and flows out together with the casting solution. The casting solution is coated on the polyester thread of the support layer, and undergoes a ph...

Embodiment 2

[0042]Under ultrasonic conditions, 62.5g of nano-silver particles were dissolved in 4.27KgN-N dimethylacetamide solvent and dispersed for 15min, 1Kg of PVC resin powder (after drying), 250g of pore-forming agent polyvinylpyrrolidone (PVP), 62.5g of Tween Slowly add -80 into the spinning tank, seal the tank mouth and stir for 24 hours to form a homogeneous casting solution, then vacuum the spinning tank, and let it stand for degassing in a vacuum of -0.08MPa for 24 hours. Adjust the nitrogen pressure of the spinning tank to 0.3 MPa. The degassed casting solution passes through the filter screen under the action of pressure to filter out impurities. The casting solution is injected into the spinneret through the metering pump. At this time, the polyester thread is also It is passed into the spinneret and flows out together with the casting solution. The casting solution is coated on the polyester thread of the support layer, and undergoes a phase inversion process in the coagulat...

Embodiment 3

[0045] Under ultrasonic conditions, 62.5g of nano-silver particles were dissolved in 3.5KgN-N dimethylacetamide solvent and dispersed for 15min, 1Kg of PVC resin powder (after drying), 562.5g of pore-forming agent polyvinylpyrrolidone (PVP), 62.5 Slowly add gTween-80 into the spinning tank, seal the tank mouth and stir for 24 hours to form a homogeneous casting solution, then vacuum the spinning tank, and let it stand in a vacuum environment of -0.08MPa for 24 hours for defoaming. Adjust the nitrogen pressure of the spinning tank to 0.3 MPa. The degassed casting solution passes through the filter screen under the action of pressure to filter out impurities. The casting solution is injected into the spinneret through the metering pump. At this time, the polyester thread is also It is passed into the spinneret and flows out together with the casting solution. The casting solution is coated on the polyester thread of the support layer, and undergoes a phase inversion process in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com