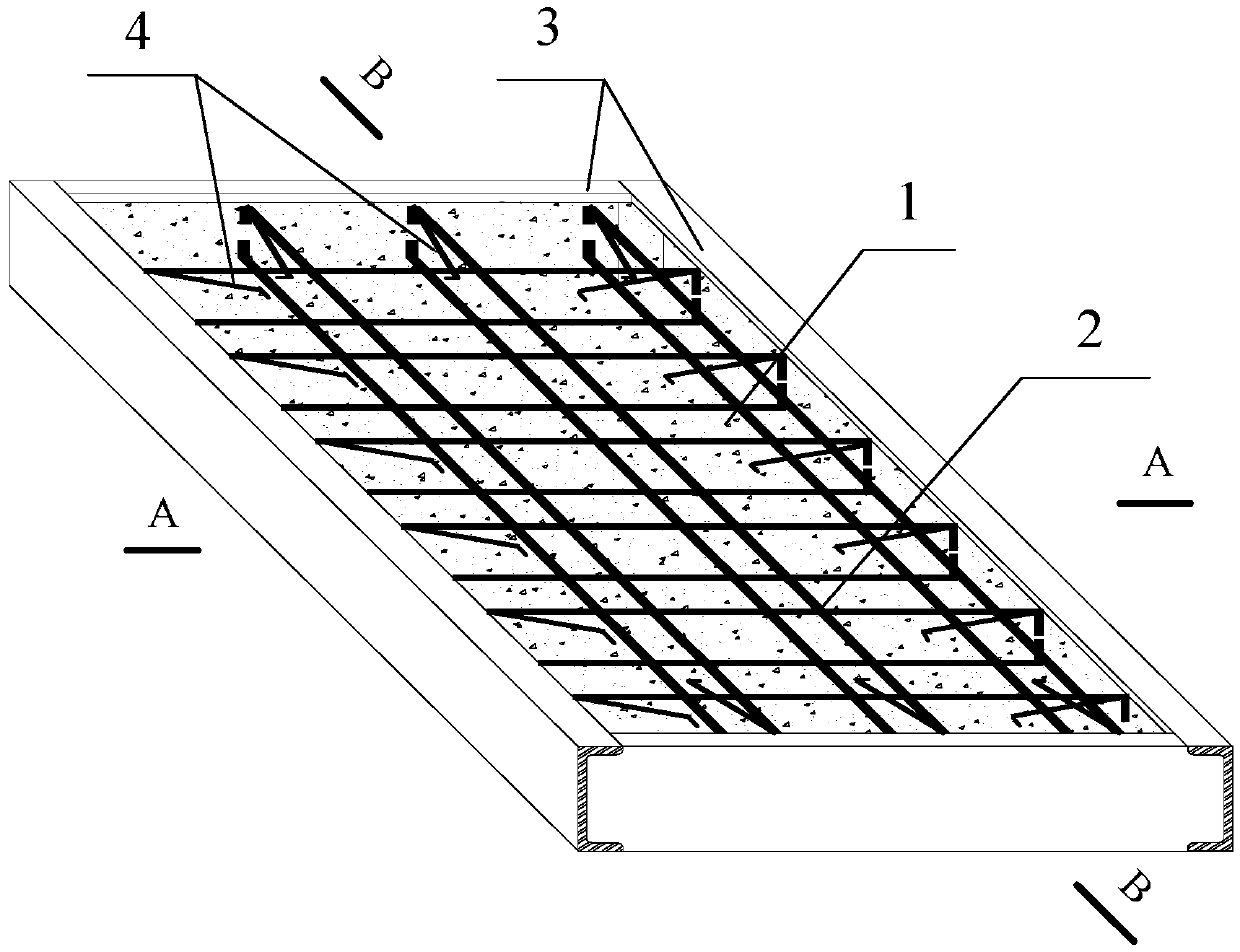

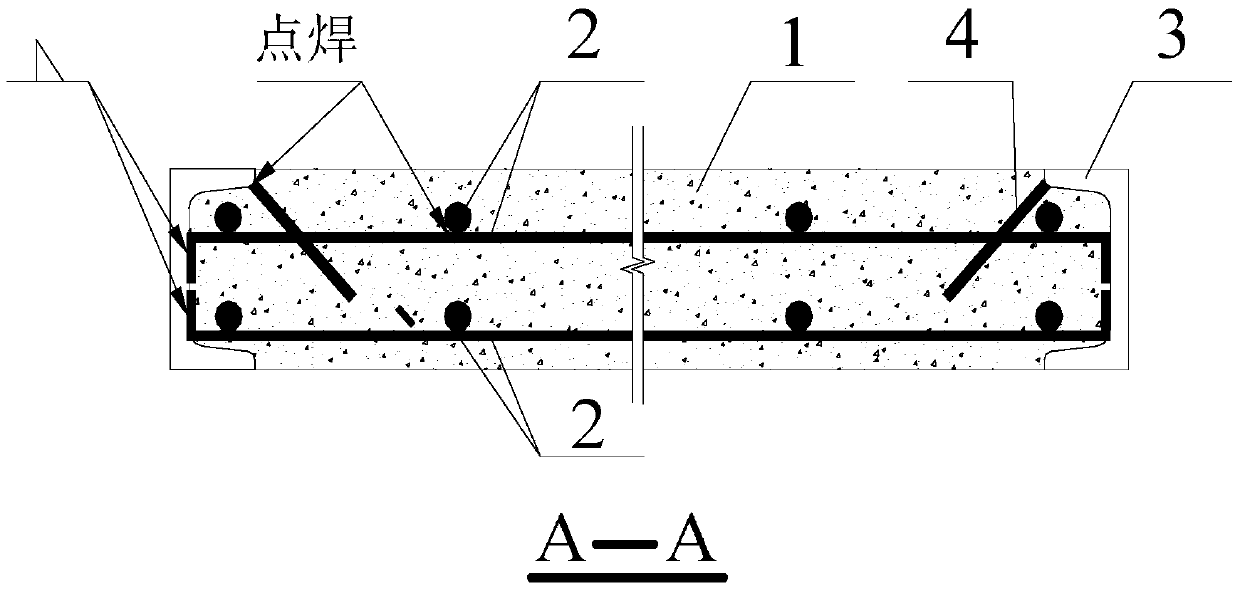

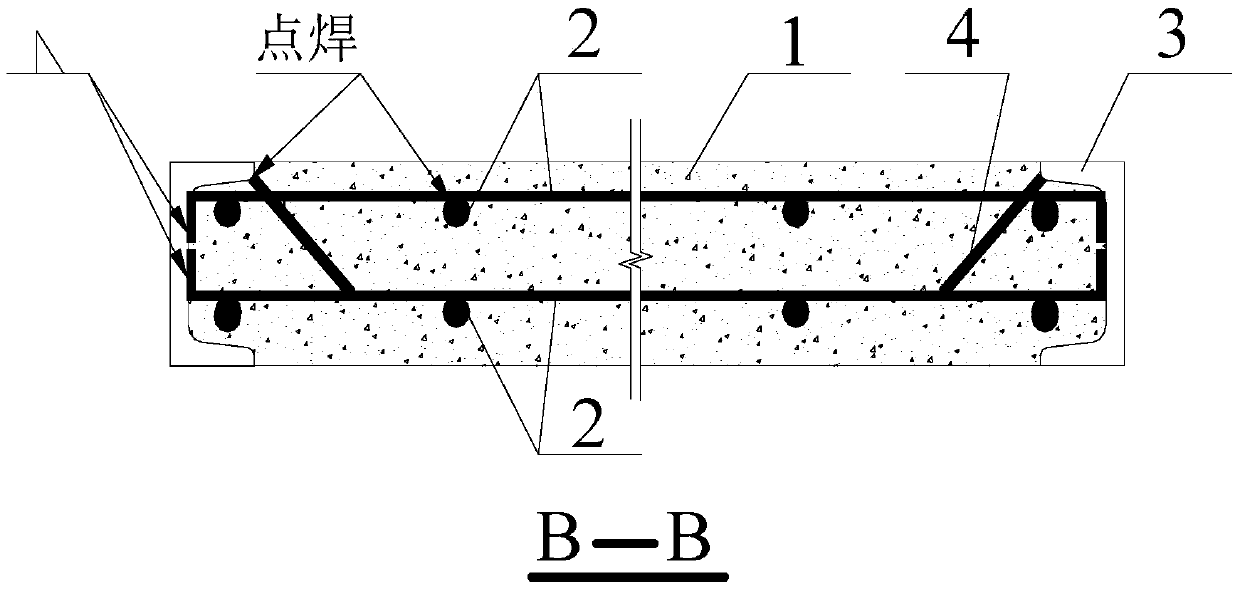

A reinforced concrete slab with shear reinforcement channel steel frame around it

A technology for reinforced concrete slabs and channel steel frames, which is applied in building materials and other directions, can solve the problems of reduced slab structure integrity and bearing capacity, restricting the speed of assembly and construction of steel structure systems, and lack of tight connection between profiled steel and concrete. The effect of crack development, improved flexural and overall performance, and faster building construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0022] Such as figure 1 , figure 2 , image 3 As shown, the concrete slab of the present invention comprises concrete 1, double-layer steel mesh 2, channel steel frame 3 and shear reinforcement 4, selects suitable type channel steel according to design requirements, and is processed and welded into channel steel frame 3, then according to the design specification, Select the steel bar type and intercept the steel bar, and bend straight hooks of equal length on the same side at both ends of the steel bar. The vertical and horizontal steel bars are spot welded at the intersection to form a steel bar mesh, and the ends of the surrounding steel bars are welded to the inner belly of the channel steel frame 3. On the board, a double-layer reinforcement mesh 2 is formed. figure 2 with image 3 The vertical and horizontal spacing of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com