Preparation method of EPS foam product

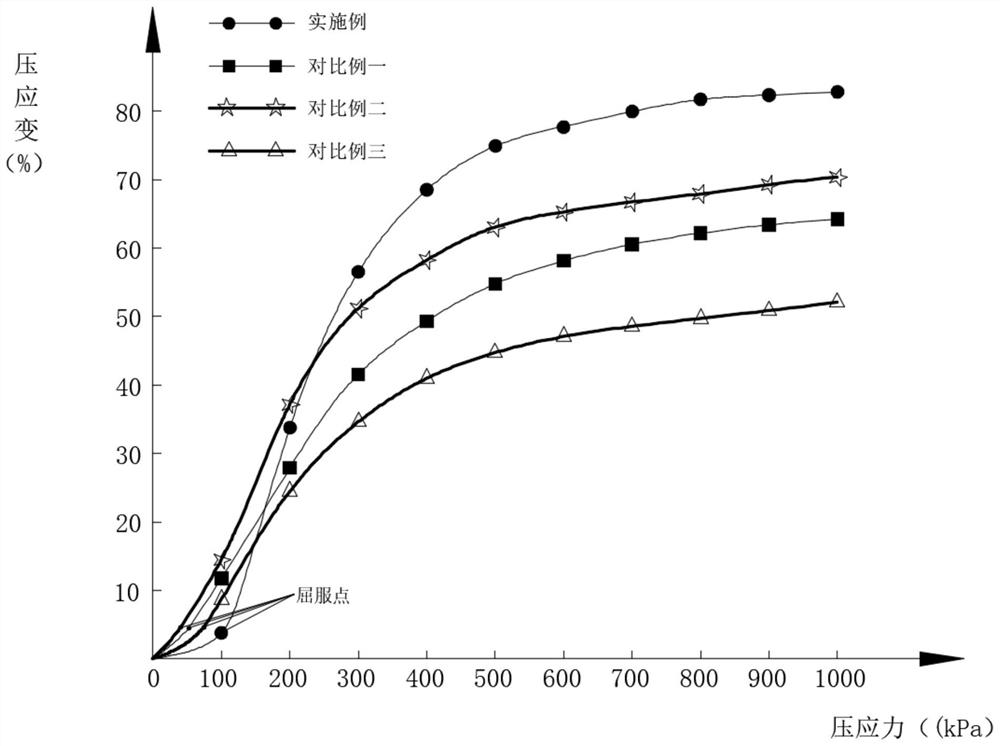

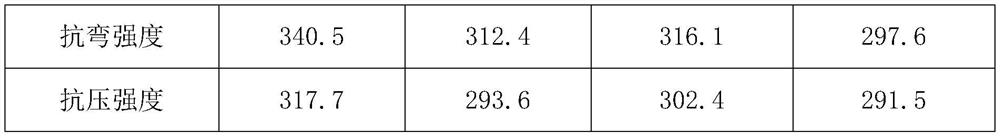

A foam and product technology, applied in the field of EPS foam product preparation, can solve the problems of poor elastic deformation ability, poor tensile, shear and bending resistance, etc., and achieves strong elastic deformation ability, large linear elastic variation range, unbreakable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In an embodiment of the present invention, a method for preparing EPS foam products comprises the following components: 60-70 parts of polystyrene particles, 20-25 parts of benzene, 60-70 parts of absolute ethanol, 20-22 parts of ethylene glycol Diethyl ether, 8-10 parts of soluble pentane and 5-6 parts of brominated polystyrene, the preparation method comprises the following steps:

[0023] S1. Foaming: 60-70 parts of polystyrene particles, 20-25 parts of benzene, 60-70 parts of absolute ethanol, 20-22 parts of ethylene glycol ether, 8-10 parts of soluble pentane and 5-6 parts After the brominated polystyrene is uniformly mixed, it is fed into the foaming machine for heating and foaming to make it expand, and the density reaches the set density to obtain the mixture;

[0024] S2, ripening: the inside of the mixture obtained in the step S1 is infiltrated by air, and the internal and external pressure of the mixture is kept in balance;

[0025] S3. Forming: Fill the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| yield point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com