A Forming Technology of FRP Reinforced Polymer High Pressure Pipeline

A molding process and high-pressure pipeline technology, applied in the field of pipelines, can solve the problems of reinforced concrete pipelines that require a lot of manpower and material resources, limited pressure bearing performance, and corrosion of concrete pipelines, so as to avoid potential hazards and chronic persecution, fast curing speed, and resistance to cracks extended effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

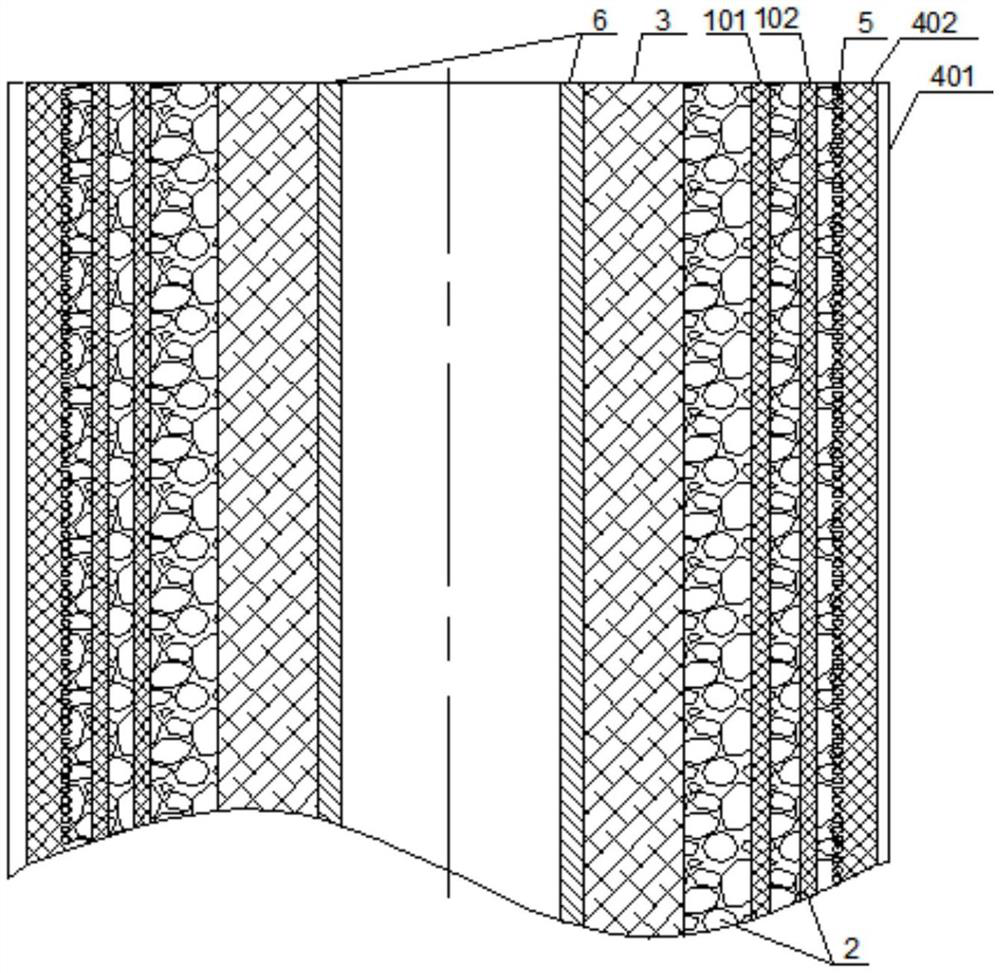

[0034] Example 1, such as figure 1 As shown, the structure of the FRP pipeline includes an inner lining layer 6, an FRP pipe 3, a polymer concrete layer 2 with a skeleton net 101 and a reinforcement net 102, a bonding reinforcement layer 5 composed of quartz sand, and a fabric resin from the inside to the outside. layer 402 and gel coat resin layer 401, the FRP pipe 3 is the inner tank of the integral pipe, and the FRP pipe is prefabricated by the winding molding process, and two methods of fixed-length winding or continuous winding are adopted. The two methods use the same lay-up and lay-up structure As follows: one layer of surface felt cross-wound two layers of glass fiber yarn, impregnated with food-grade resin, thickness 1.5-2.5mm, and then hoop-wrapped 2-4 layers of glass fiber yarn, impregnated with reinforcing resin, thickness 2.5-3.5mm. Based on the above structure and process, the specific operation steps of the FRP reinforced polymer high pressure pipeline forming p...

Embodiment 2

[0055] Example 2 is a different implementation from Example 1, wherein the raw materials for the preparation of polymer concrete include 93% aggregate, resin binders, and additives totaling 7% by mass percentage, and the aggregate includes a mass ratio of 20:30:12:12:5:3 1-3 mesh quartz sand, 5-8 mesh quartz sand, 15-25 mesh quartz sand, 40-60 mesh quartz sand, 80-110 mesh quartz sand, 150- 200 mesh quartz sand, auxiliary agent is the curing agent accounting for 1.7% of resin binder, 0.27% accelerator, 1.3% coupling agent, 0.024% polymerization inhibitor.

Embodiment 3

[0056] Example 3 is a different implementation from the above two examples, wherein the raw materials for the preparation of polymer concrete include 92.5% of aggregate, 7.5% of resin binders and auxiliary agents in total, and the aggregate includes 1.5-2 mesh quartz sand, 6-7 mesh quartz sand, 18-23 mesh quartz sand, 45-55 mesh quartz sand, 90-100 mesh quartz sand with a mass ratio of 30:40:16:16:10:8 180-230 mesh quartz sand, additives are 1.5% curing agent, 0.2% accelerator, 1% coupling agent, 0.02% polymerization inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com