Polymer concrete pipeline material

A polymer and pipeline technology, applied in the field of polymer concrete, can solve the problems of unable to further reduce the resin content, curb the development of PC, and poor durability, so as to prevent water from entering the structure, improve insulation performance and anti-corrosion performance, and improve compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

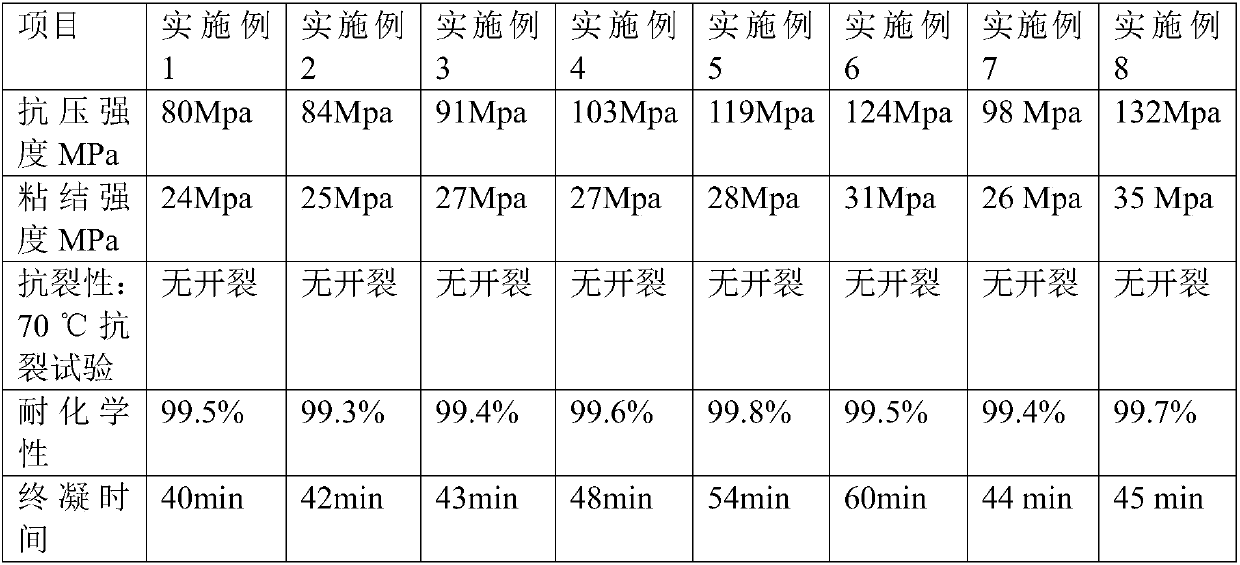

Examples

Embodiment 1

[0027] A polymer concrete pipeline material, in terms of mass percentage, comprising 92.8% of aggregate, 7.2% of resin binder and auxiliary agent in total, and the aggregate comprises 25:35:14:14:7:5 mass ratio 3 / 8-4 mesh quartz sand, 4 mesh < particle size ≤ 10 mesh quartz sand, 10 mesh < particle size ≤ 30 mesh quartz sand, 30 mesh < particle size ≤ 70 mesh quartz sand, 70 mesh < particle size ≤ 120 mesh Quartz sand, 120 mesh < particle size ≤ 250 mesh quartz sand.

[0028] Among them, the auxiliary agent is 1.5% curing agent, 0.3% accelerator, 1.5% coupling agent, 0.025% polymerization inhibitor and 3% flame retardant, which account for 1.5% of the resin adhesive.

[0029] Among them, the parameters of each component of the aggregate are controlled as follows: moisture content ≤ 0.2%, mud content ≤ 0.5%, silicon content ≥ 90%, acid resistance ≥ 95%, and the texture is hard and round.

[0030] The resin binder used in the present invention is a resin binder treated with sty...

Embodiment 2

[0039] A polymer concrete pipeline material, in terms of mass percentage, including 92% of aggregate, 8% of resin binder and auxiliary agent in total, and the aggregate includes a mass ratio of 20:30:12:12:5:3 1-3 mesh quartz sand, 5-8 mesh quartz sand, 15-25 mesh quartz sand, 40-60 mesh quartz sand, 80-110 mesh quartz sand, 150-200 mesh quartz sand.

[0040] Among them, the auxiliary agent is a curing agent accounting for 1.7% of the resin adhesive, 0.27% accelerator, 1.3% coupling agent, 0.024% polymerization inhibitor, and 4% flame retardant.

[0041] Among them, the parameters of each component of the aggregate are controlled as follows: moisture content ≤ 0.2%, mud content ≤ 0.5%, silicon content ≥ 90%, acid resistance ≥ 95%, and the texture is hard and round.

[0042] The resin binder used in the present invention is a resin binder treated with styrene. Due to the high viscosity and poor fluidity of the resin, the styrene treatment reduces the viscosity of the resin and ...

Embodiment 3

[0051] A polymer concrete pipeline material, which comprises 92.5% of aggregate, 7.5% of resin binder and auxiliary agent in total in terms of mass percentage, and the aggregate comprises 30:40:16:16:10:8 mass ratio 1.5-2 mesh quartz sand, 6-7 mesh quartz sand, 18-23 mesh quartz sand, 45-55 mesh quartz sand, 90-100 mesh quartz sand, 180-230 mesh quartz sand.

[0052] Among them, the auxiliary agent is a curing agent accounting for 1.5% of the resin adhesive, 0.2% accelerator, 1% coupling agent, 0.02% polymerization inhibitor, and 5% flame retardant.

[0053] Among them, the parameters of each component of the aggregate are controlled as follows: moisture content ≤ 0.2%, mud content ≤ 0.5%, silicon content ≥ 90%, acid resistance ≥ 95%, and the texture is hard and round.

[0054] The resin binder used in the present invention is a resin binder treated with styrene. Due to the high viscosity and poor fluidity of the resin, the styrene treatment reduces the viscosity of the resin ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com