A kind of manufacturing method of extra thick steel plate

A manufacturing method and technology of extra-thick steel plates, which are applied in the field of metal plate manufacturing technology, can solve the problems of products that cannot meet the actual production requirements, large equipment investment, and high production costs, and achieve the goals of overcoming internal porosity and shrinkage cavities, increasing production, and shortening the cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

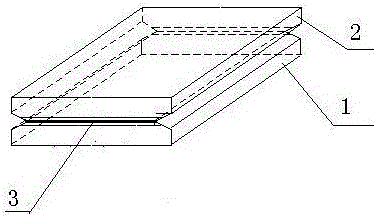

[0040] Two Q345B continuous casting slabs with approximately the same size are selected as the base plate, and their specifications are both: 210mm×1630 mm×2570 mm (thickness×width×length).

[0041] Use a planer to remove the iron oxide scale on the surface to be compounded of the two blanks, open the ring groove, and use a grinder to grind the surface to be compounded of the base material 1 and compound material 2, and control the surface roughness to 6.3 μm; rinse and polish with clean water On the surface to be composited, remove surface impurities, and then use a mixed solution of 65% acetone and 35% ethanol to clean the surface to be composited of substrate 1 and composite material 2 once, and dry it with cool wind.

[0042] Sprinkle the magnesium powder 3 with a particle size of 1250 mesh on the surface of the base material 1 to be compounded, spread evenly with a brush, and control the thickness of the magnesium powder 3 to 1.5mm.

[0043] After the composite material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com