Pre-stress FRP bush-FRP rib sea sand seawater expansion concrete combination column

A technology of expansive concrete and composite columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of restricting the use of FRP sleeves due to constraints, and achieve the effects of saving the amount of stirrups, protecting the ecological environment, and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

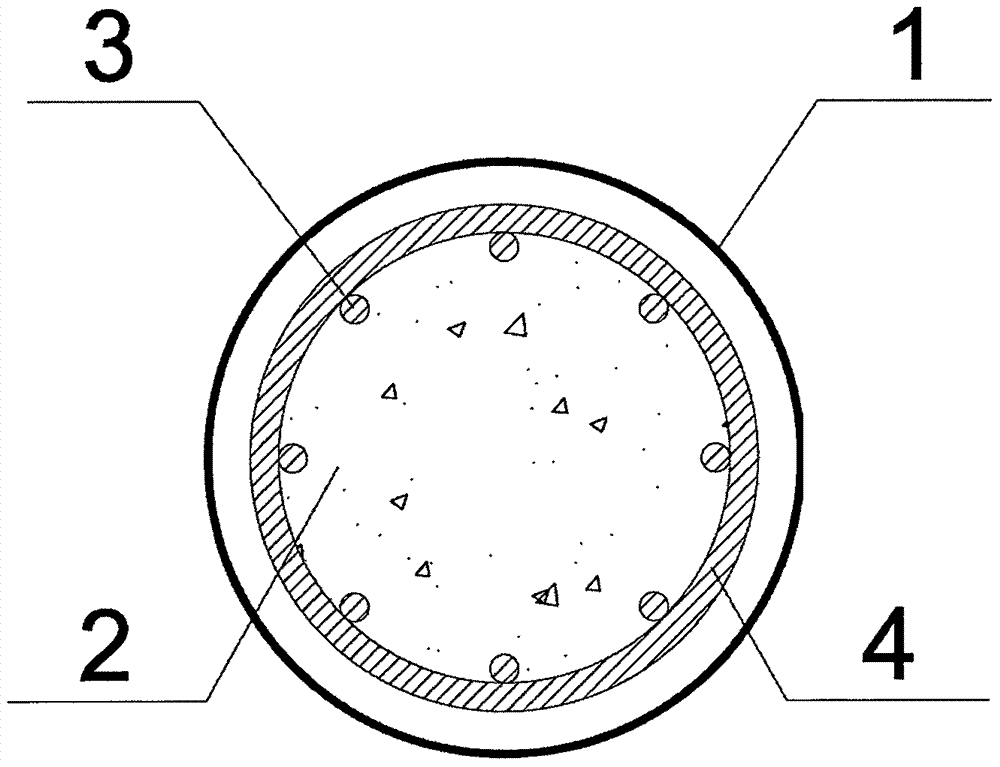

[0019] Such as figure 1 As shown, a prestressed FRP sleeve FRP bar sea sand seawater expansive concrete composite column includes an external FRP sleeve 1 and an internal sea sand seawater expansive concrete 2, and the FRP sleeve 1 combines sea sand and seawater expansive concrete 2 Wrapping, the expansion of concrete and the constraints of FRP generate prestress in the FRP sleeve and concrete, and the cross-section of the prestressed FRP sleeve FRP reinforcement sea sand seawater expansion concrete composite column is selected from one of circular, rectangular or square The FRP sleeve 1 is selected from a CFRP sleeve, a GFRP sleeve, a BFRP sleeve or an AFRP sleeve.

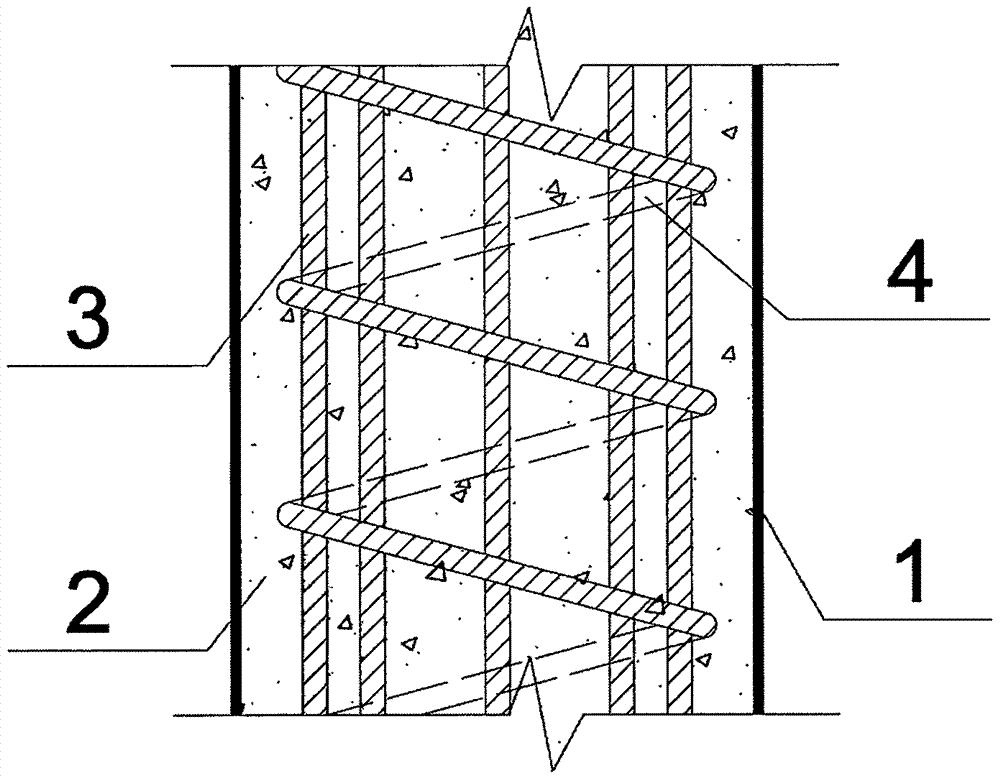

[0020] Such as figure 1 with figure 2 As shown, evenly distributed FRP longitudinal bars 3 are placed around the sea-sand and sea-water expansive concrete 2, and run through the sea-sand and sea-water expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com