High-viscosity modified asphalt mixture and application thereof

A technology of modified asphalt and mixture, applied in the field of pavement construction, can solve the problem of not considering the shear resistance of the cover, and achieve the effect of expanding the suitable construction temperature, good fluidity and prolonging the life expectancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

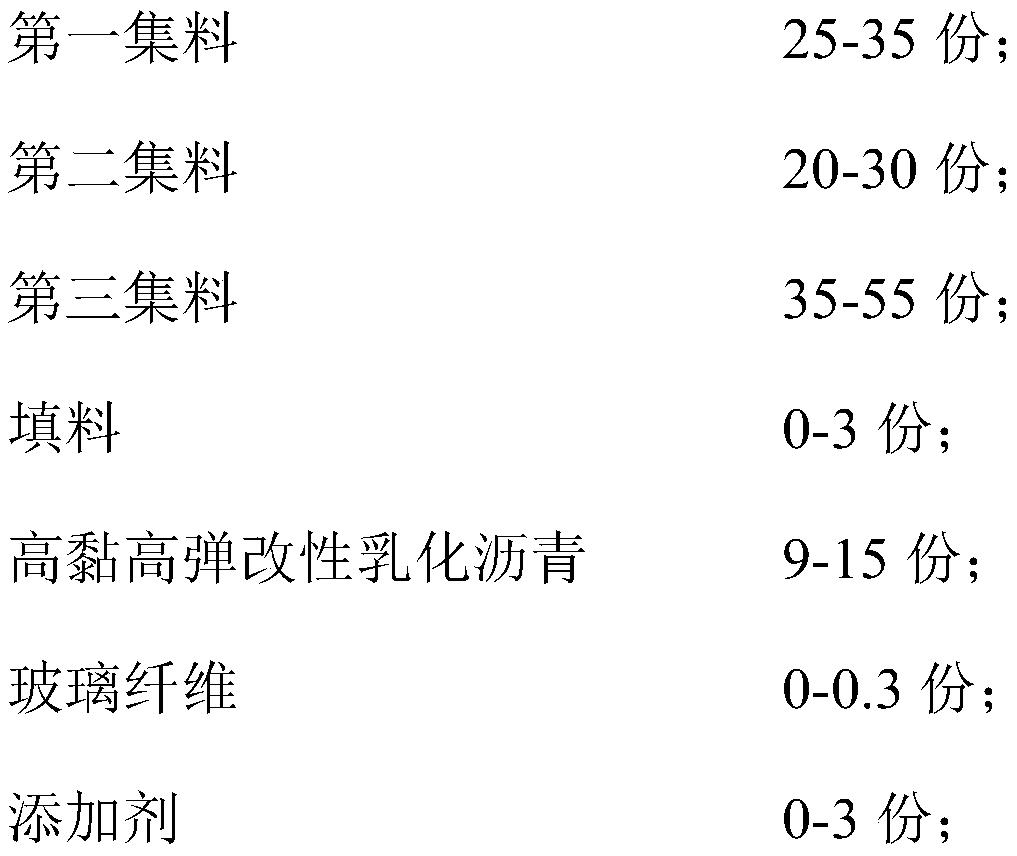

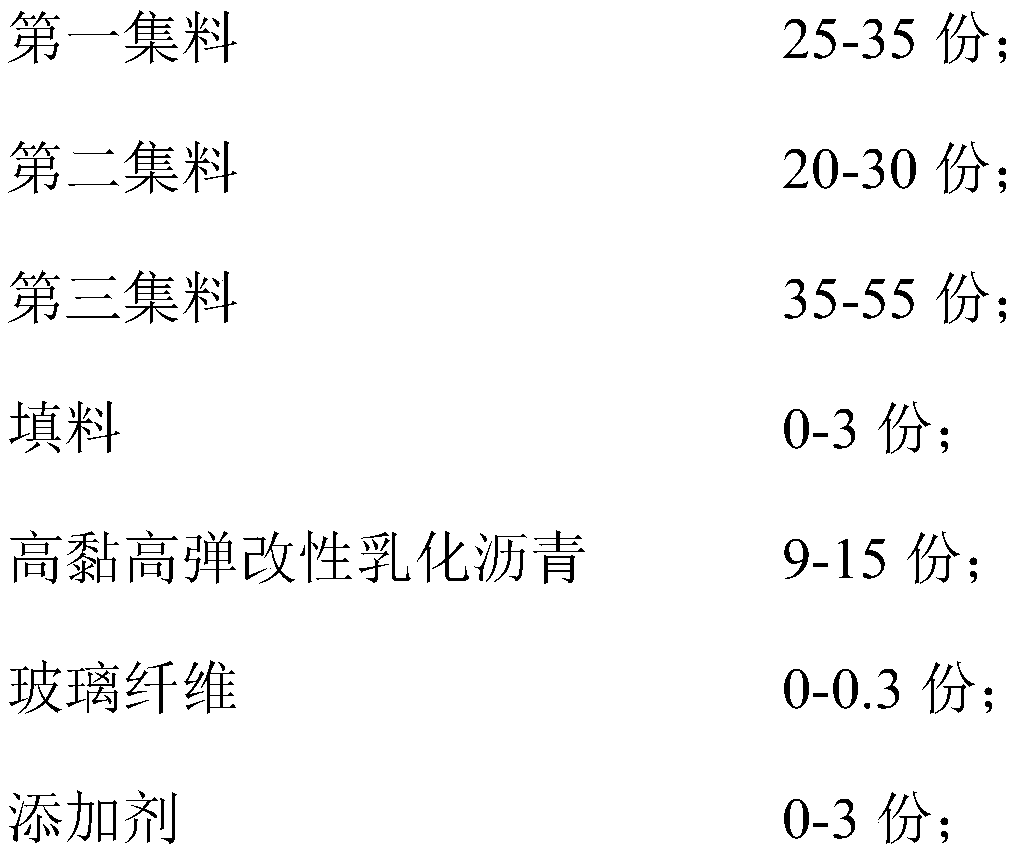

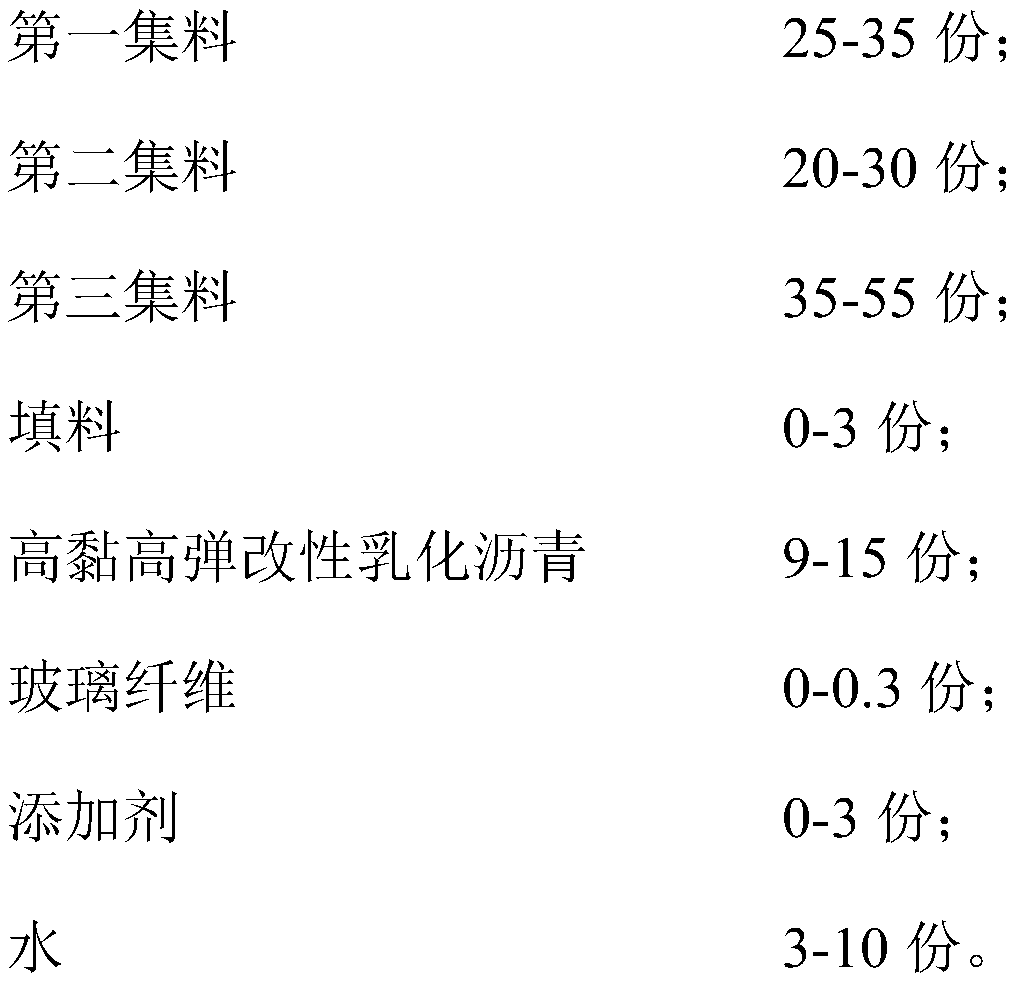

[0059] For the high-viscosity modified asphalt mixture of Examples 1-3, the components are as shown in Table 1 in parts by weight:

[0060] Component parts by weight of Table 1 Embodiment 1-3

[0061]

[0062]

[0063] The special gradation of the particle size distribution of the first aggregate, the second aggregate and the third aggregate is shown in Table 2:

[0064] Table 2 Special grading of aggregates

[0065]

[0066] The mass percentage of SBS modifier and tackifier in the high-viscosity and high-elasticity modified emulsified asphalt is shown in Table 3:

[0067] Table 3 Amount of SBS modifier and tackifier (%)

[0068]

[0069] The rest of the features are the same as the specific implementation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com