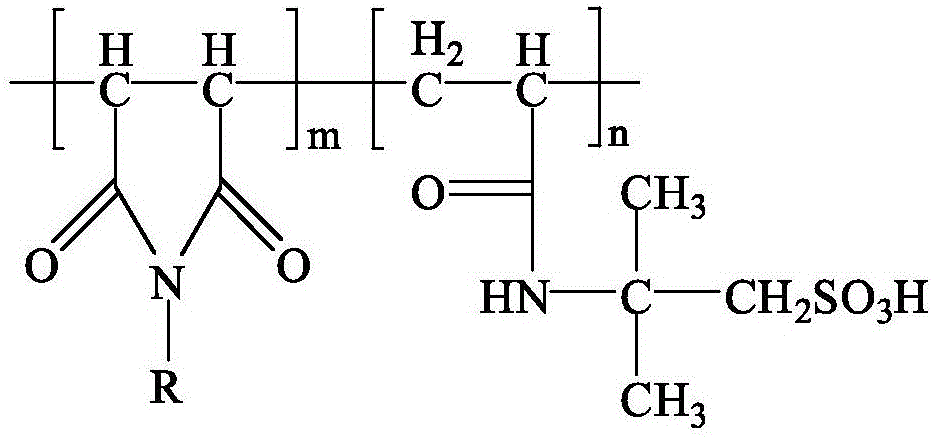

High-wax thick oil pour point depressant and preparation method thereof

A pour point depressant and heavy oil technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as poor temperature and salt resistance, high waxy heavy oil production, unsatisfactory application effects, etc., to achieve Good heat resistance and salt resistance, reduced dosage, easy to obtain, transport and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

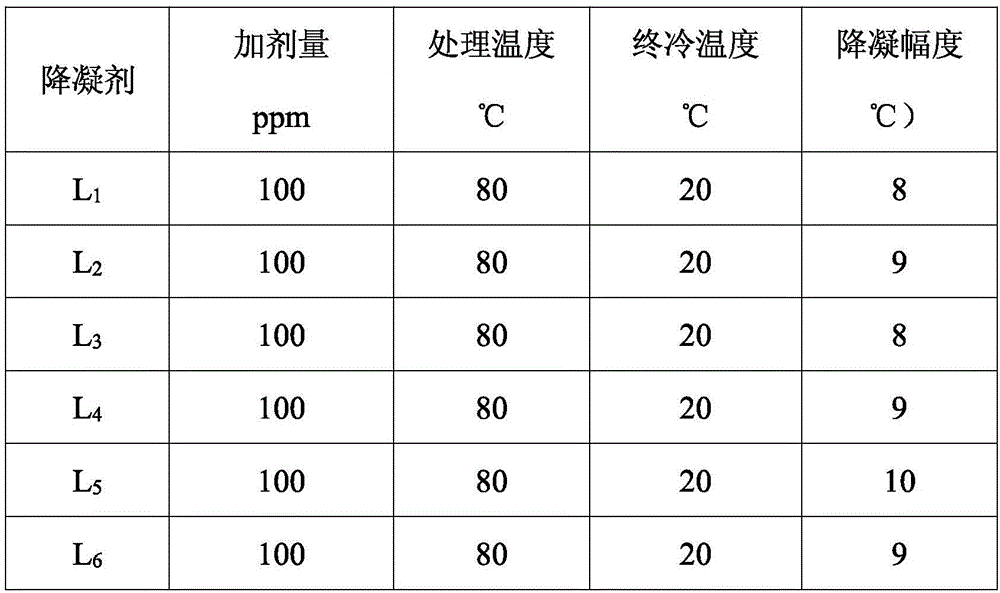

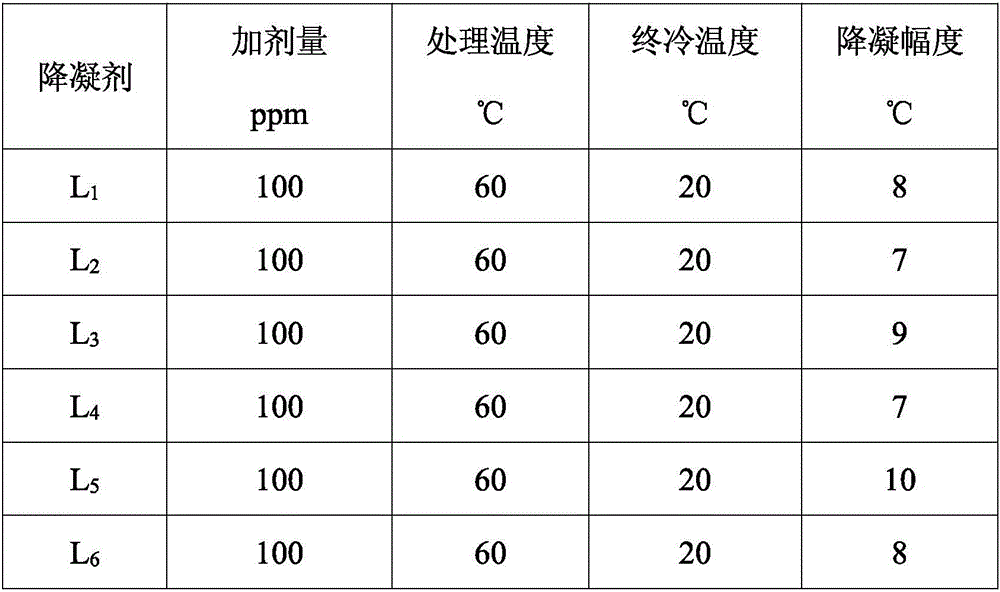

Examples

Embodiment 1

[0025] Example 1: Pour Point Depressant T 1 And its preparation method

[0026] (1) Pour point depressant T 1 The composition and components are as follows:

[0027] Maleic anhydride 0.2mol (19.61g)

[0028] 2-acrylamido-2-methylpropanesulfonic acid 0.002mol (0.41g)

[0029] (2) Pour point depressant T 1 The preparation method is as follows:

[0030] ①Put 19.82g of toluene and 19.61g of maleic anhydride into a four-necked flask, and pass N 2 Protect, heat to 30℃ and stir at 100rpm for 10min; Dissolve 0.41g 2-acrylamido-2-methylpropanesulfonic acid in 0.41gN,N-dimethylformamide, then pour it into a four-neck flask ; Dissolve 0.12g benzoyl peroxide into 1.98g toluene, place it in a constant pressure dropping funnel, and control the dropping rate to 4 drops / min. Subsequently, the stirring rate was increased to 200 rpm, the temperature was raised to 70° C., and the reaction was held at a constant temperature for 5 hours. After the reaction, 0.16 g of hydroquinone was added, the heating de...

Embodiment 2

[0034] (1) Pour point depressant T 2 The composition and components are as follows:

[0035] Maleic anhydride 0.2mol (19.61g)

[0036] 2-acrylamido-2-methylpropanesulfonic acid 0.2mol (41.45g)

[0037] (2) Pour point depressant T 2 The preparation method is as follows:

[0038] ①Add 91.59g of xylene and 19.61g of maleic anhydride into a four-necked flask, and pass N 2 Protect, heat to 30℃ and stir at 150rpm for 30min; Dissolve 41.45g 2-acrylamido-2-methylpropanesulfonic acid in 49.74g N,N-dimethylacetamide, then pour it into a four-neck flask Medium; Dissolve 1.53g of azobisisobutyronitrile into 24.42g of toluene, place it in a constant pressure dropping funnel, and control the dropping rate to 6 drops / min. Subsequently, the stirring rate was increased to 300 rpm, the temperature was increased to 90° C., and the reaction was held at a constant temperature for 10 hours. After the reaction, 0.85 g of hydroquinone was added, the heating device was turned off, and the mixture was stirred...

Embodiment 3

[0041] Example 3: Pour Point Depressant T 3 And its preparation method

[0042] (1) Pour point depressant T 3 The composition and components are as follows:

[0043] Maleic anhydride 0.2mol (19.61g)

[0044] 2-acrylamido-2-methylpropanesulfonic acid 0.01mol (2.07g)

[0045] (2) Pour point depressant T 3 The preparation method is as follows:

[0046] ① Put 28.18g of toluene and 19.61g of maleic anhydride into a four-necked flask, and pass N 2 Protect, heat to 30℃ and stir at 120rpm for 25min; Dissolve 2.07g 2-acrylamido-2-methylpropanesulfonic acid in 2.48g N,N-dimethylformamide, then pour into a four-neck flask Medium; Dissolve 0.22g azobisisobutyronitrile into 4.34g toluene, place it in a constant pressure dropping funnel, and control the dropping rate to 5 drops / min. Subsequently, the stirring rate was increased to 220 rpm, the temperature was raised to 75° C., and the reaction was held at a constant temperature for 6 hours. After the reaction, 0.22 g of hydroquinone was added, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com