Method for improving quality of bottom layer of oriented silicon steel

A technology for improving the quality of oriented silicon steel, which is applied in the field of improving the quality of the bottom layer of oriented silicon steel, can solve the problems of unstable quality of the bottom layer of oriented silicon steel, and achieve the effects of perfecting secondary recrystallization, promoting oxidation, and strengthening inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

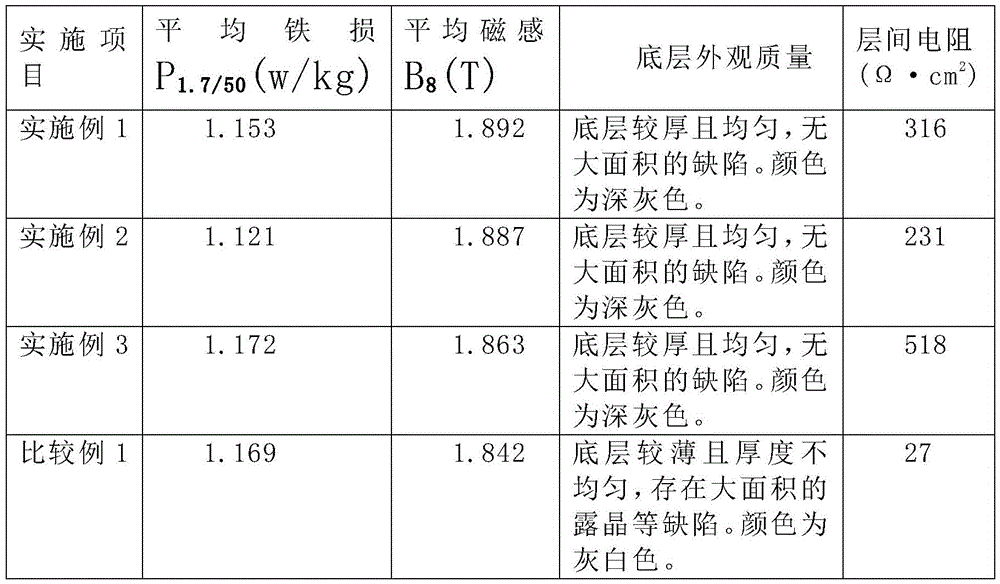

Examples

Embodiment 1

[0028] 1. In the chemical composition of the billet, the contents (percentage by weight) of the chemical elements that affect the quality of the bottom layer are: Als: 0.019%, Als / N=2.0; Sn: 0.055%; Sb: 0.02%; Cr: 0.02%; V: 0.002%; Cu: 0.51%.

[0029] 2. After steelmaking, continuous casting slab, hot rolling and other processes, the steel plate is pickled in hydrochloric acid, and then the steel plate is brushed with a wire brush roller with a diameter of 300mm, a diameter of brush wire of 0.5mm, and a speed of 1000rpm. The surface is polished to completely remove the internal oxide layer on the surface of the steel plate.

[0030] 3. The steel plate is subjected to continuous decarburization annealing after the first cold rolling, and continuous recovery annealing after the second cold rolling. Before the continuous annealing, the steel plate is degreased and cleaned with ultrasonic waves. The ultrasonic cleaning solution is 1.5% sodium hydroxide solution, and Add 0.5% sodi...

Embodiment 2

[0035] 1. In the chemical composition of the billet, the contents (percentage by weight) of the chemical elements that affect the quality of the bottom layer are: Als: 0.018%, Als / N=2.0; Sn: 0.055%; Sb: 0.02%; Cr: 0.02%; V: 0.002%; Cu: 0.51%.

[0036] 2. After steelmaking, continuous casting slab, hot rolling and other processes, the steel plate is pickled in hydrochloric acid, and then the steel plate is brushed with a wire brush roller with a diameter of 300mm, a diameter of brush wire of 0.5mm, and a speed of 1000rpm. The surface is polished to completely remove the internal oxide layer on the surface of the steel plate.

[0037] 3. The steel plate is subjected to continuous decarburization annealing after the first cold rolling, and continuous recovery annealing after the second cold rolling. Before the continuous annealing, the steel plate is degreased and cleaned with ultrasonic waves. The ultrasonic cleaning solution is 1.5% sodium hydroxide solution, and Add 1.5% sodi...

Embodiment 3

[0042] 1. In the chemical composition of the billet, the contents (percentage by weight) of the chemical elements that affect the quality of the bottom layer are: Als: 0.018%, Als / N = 2.1; Sn: 0.03%; Sb: 0.03%; Cr: 0.01%; V: 0.002%; Cu: 0.58%.

[0043] 2. After steelmaking, continuous casting slab, hot rolling and other processes, the steel plate is pickled in hydrochloric acid, and then the steel plate is brushed with a wire brush roller with a diameter of 250mm, a brush wire diameter of 0.8mm, and a speed of 1000rpm. The surface is polished to completely remove the internal oxide layer on the surface of the steel plate.

[0044] 3. The steel plate is subjected to continuous decarburization annealing after the first cold rolling, and continuous recovery annealing after the second cold rolling. Before continuous annealing, the steel plate is degreased and cleaned with ultrasonic waves. The ultrasonic cleaning solution is 3% sodium hydroxide solution, and Add 2% sodium silicat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com