Eco-concrete with compressive strength of 120-200 MPa and preparation method thereof

A technology of ecological concrete and compressive strength, applied in cement production, sustainable waste treatment, solid waste management, etc., can solve the problems of high energy consumption in cement production, backlog of industrial waste residue, environmental pollution, etc., and achieve low production energy consumption, The effect of fast setting time and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

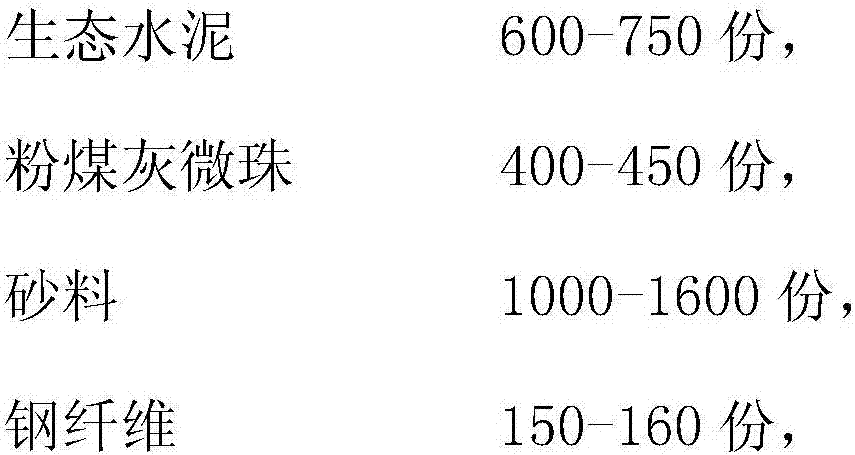

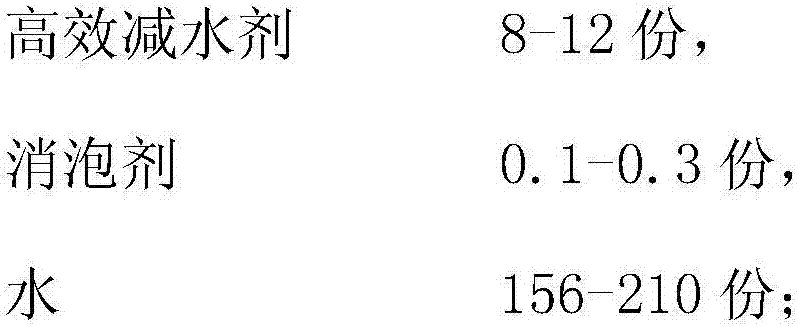

Method used

Image

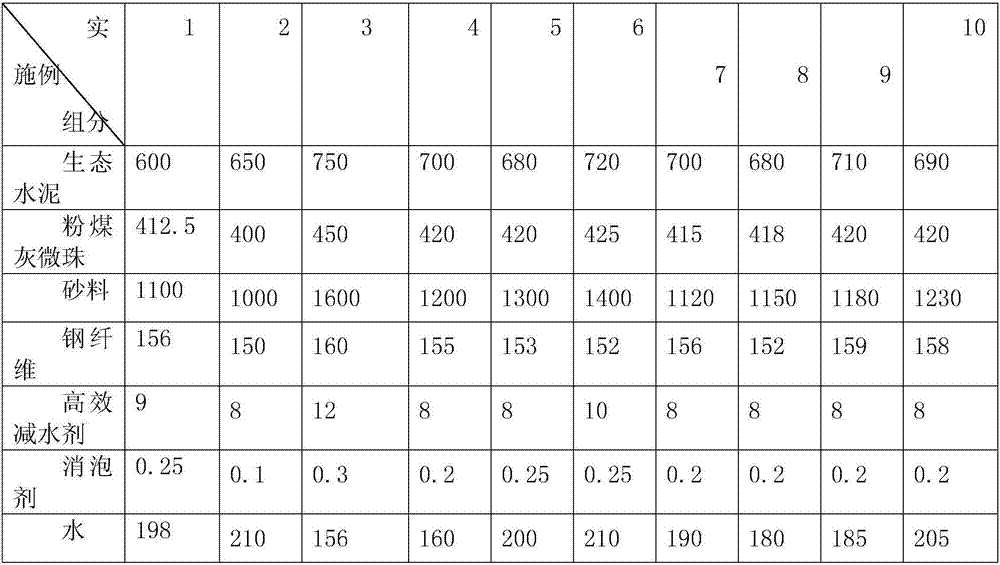

Examples

Embodiment 1

[0045] Preparation of ecological cement

[0046] According to parts by weight, clay is 60 parts, tuff is 30 parts, sodium hydroxide is 8 parts, calcium hydroxide is 2 parts, and the clay and tuff are first pulverized and then dried at 700°C. The above materials are uniformly mixed to obtain ecological cement.

Embodiment 2

[0048]Preparation of ecological cement

[0049] According to parts by weight, 20 parts of tuff, 60 parts of shale, 10 parts of dodecyltrimethylammonium chloride, and 10 parts of sodium sulfate. After the two kinds of rocks are ground, the powders are mixed and dried at 600 ° C. . The above materials are uniformly mixed to obtain ecological cement.

Embodiment 3

[0051] Preparation of ecological cement

[0052] According to parts by weight, there are 25 parts of silica fume, 60 parts of kaolin, and 15 parts of quaternary ammonium base. After the kaolin is pulverized, it is dried at 600°C. The above materials are uniformly mixed to obtain ecological cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com