Steam-curing-free early-strength steel fiber concrete pipe segment and preparation method thereof

A steel fiber concrete and steam-free curing technology, which is applied in the field of concrete segments, can solve the problems of high energy consumption and achieve the effects of fast setting and hardening, simplified curing methods, and shortened curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the above-mentioned steam-free, early-strength steel fiber concrete segment comprises the following steps:

[0025] Step 1. Pour the fine aggregate, coarse aggregate, and end-hook steel fiber into the mixing pot and dry mix for 30s~60s to stir evenly;

[0026] Step 2. Pour the formula quantity of ordinary Portland cement, rapid hardening sulphoaluminate cement, fly ash and slag into the mixing pot, add the formula quantity of water and polycarboxylate water reducer and wet mix for 2 to 3 minutes. Formed concrete;

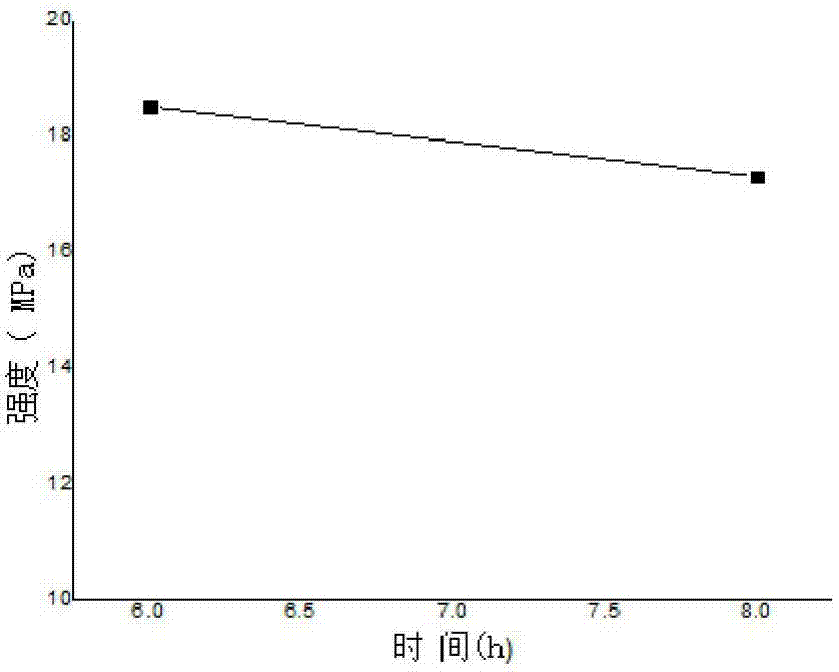

[0027] Step 3: Pour the formed concrete into the mold, vibrate and compact it; release the mold after curing for 6h-8h under natural conditions; then immerse in saturated calcium hydroxide solution at 20°C for 24h, take out the natural curing for 28d, and obtain the non-steaming Yang, early strength steel fiber reinforced concrete segments.

Embodiment 1

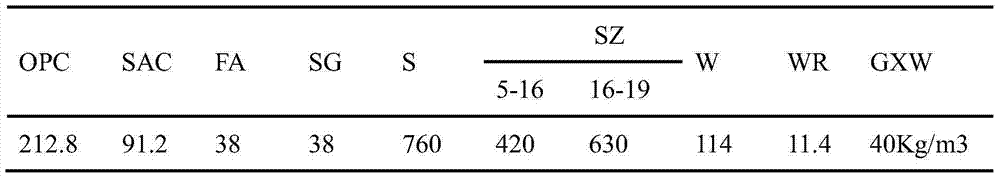

[0032] 1. Raw material and mix ratio

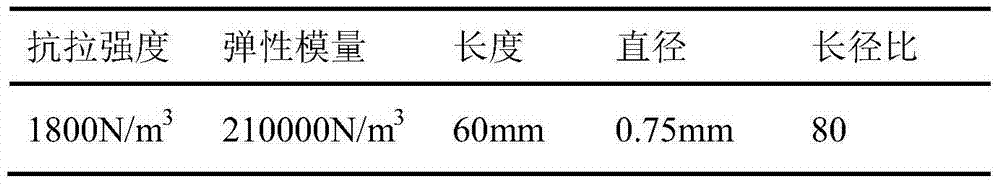

[0033] The raw materials are Ordinary Portland Cement (OPC), Rapid Hardening Sulphoaluminate Cement (SAC), Fly Ash (FA), Slag (SG), Fine Aggregate (S), Coarse Aggregate (SZ), Water (W), polycarboxylate water reducer (WR), end hook steel fiber (GXW), the mix ratio design is shown in Table 2.

[0034] Table 2 (Unit: Kg / m 3 )

[0035]

[0036] 2. Preparation method:

[0037] 1) Pour the fine aggregate, coarse aggregate, and end-hook steel fiber into the mixing pot, and dry mix for 30 seconds to mix evenly;

[0038] 2) Pour ordinary Portland cement, rapid hardening sulphoaluminate cement, fly ash, and slag into the mixing pot, add water and polycarboxylate water reducer in the prescribed amount, and mix for 180 seconds to form concrete ;

[0039]3) Pour the formed concrete into the mold, vibrate and compact, release the mold after curing for 6h-8h under natural conditions, then immerse in saturated calcium hydroxide solution at 20°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com