Preparation method and product of deep sea fish skin collagen polypeptide peeling mask

A technology for washing facial masks and collagen polypeptides, which is applied in skin care preparations, cosmetic preparations, dressing preparations, etc., which can solve problems such as environmental pollution, discarding, and waste of resources, and achieve economic benefits, increase added value, and speed up production. The effect of decomposition and exclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The preparation method of the deep-sea fish skin collagen polypeptide washing mask provided by the invention comprises the following steps:

[0052] (1). Preparation of raw materials

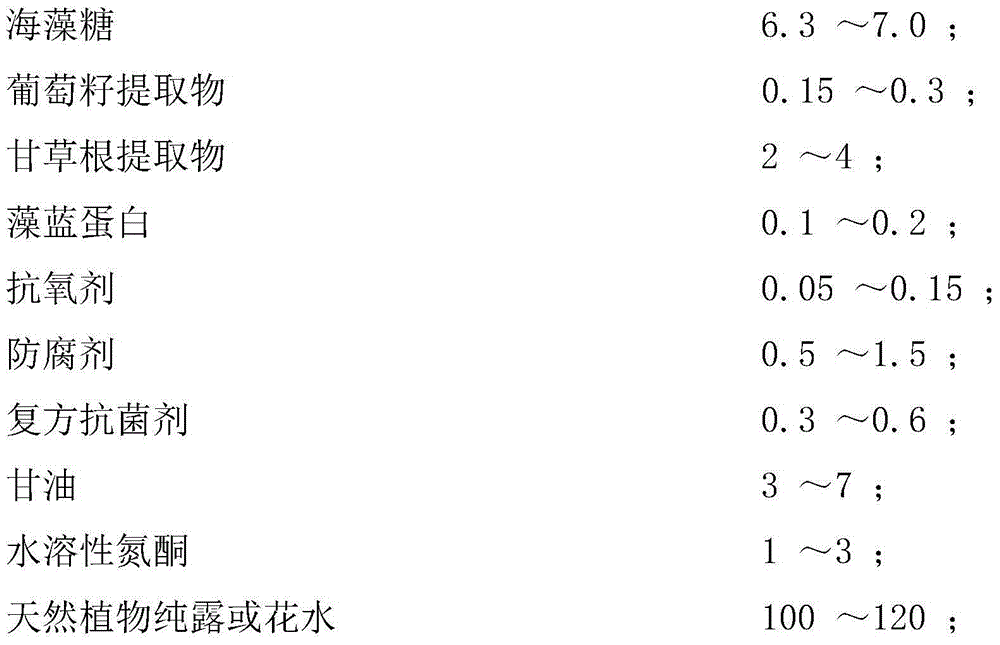

[0053] Prepare the following raw materials according to the following parts by weight:

[0054]

[0055] (2). Preparation of intermediate product A solution

[0056] Add the arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol prepared in step (1) to the natural plant hydrosol or flower water in parts by weight: 48 to 52, heat and stir, and heat to the temperature 60℃~70℃; the stirring speed is 100r / min~150r / min, until the arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol are completely dissolved, then cool to 20℃~30℃ to obtain the intermediate product A solution, standby;

[0057] (3). Preparation of intermediate product B solution

[0058] Add the fish skin collagen polypeptide and trehalose prepared in step (1) to natural plant pure dew...

Embodiment 2

[0081] The preparation method of the deep-sea fish skin collagen polypeptide washing mask provided by this embodiment and the deep-sea fish skin collagen polypeptide washing mask product thereof are basically the same as in Example 1, except that:

[0082] The preparation method of deep-sea fish skin collagen polypeptide washing mask comprises the following steps:

[0083] (1). Preparation of raw materials

[0084] Prepare the following raw materials according to the following parts by weight:

[0085]

[0086]

[0087] (2). Preparation of intermediate product A solution

[0088] Arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol prepared in step (1) are added to natural plant pure dew or flower water with parts by weight of 48, heated and stirred, and heated to a temperature of 60 ℃; the stirring speed is 120r / min, until the arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol are completely dissolved, then cool to 20 ℃ to obt...

Embodiment 3

[0108] The preparation method of the deep-sea fish skin collagen polypeptide washing mask provided in this example and the deep-sea fish skin collagen polypeptide washing mask are basically the same as those in Examples 1 and 2, except that:

[0109] The preparation method of deep-sea fish skin collagen polypeptide washing mask comprises the following steps:

[0110] (1). Preparation of raw materials

[0111] Prepare the following raw materials according to the following parts by weight:

[0112]

[0113]

[0114] (2). Preparation of intermediate product A solution

[0115] Arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol prepared in step (1) are added to natural plant pure dew or flower water with parts by weight of 50, heated and stirred, and heated to a temperature of 65 ℃; the stirring speed is 120r / min, until the arbutin, hydroxyethyl cellulose, sodium alginate and polyethylene glycol are completely dissolved, then cool to 20 ℃ to obtain th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com