Synthesis method for 1-chloro-1-acetyl cyclopropane

A synthesis method and technology of acetylcyclopropane, which is applied in the field of synthesis of 1-chloro-1-acetylcyclopropane, can solve the problems of difficulty in large-scale industrial production, production risk control, many raw materials, low yield, etc., and achieve improved Yield, high product purity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

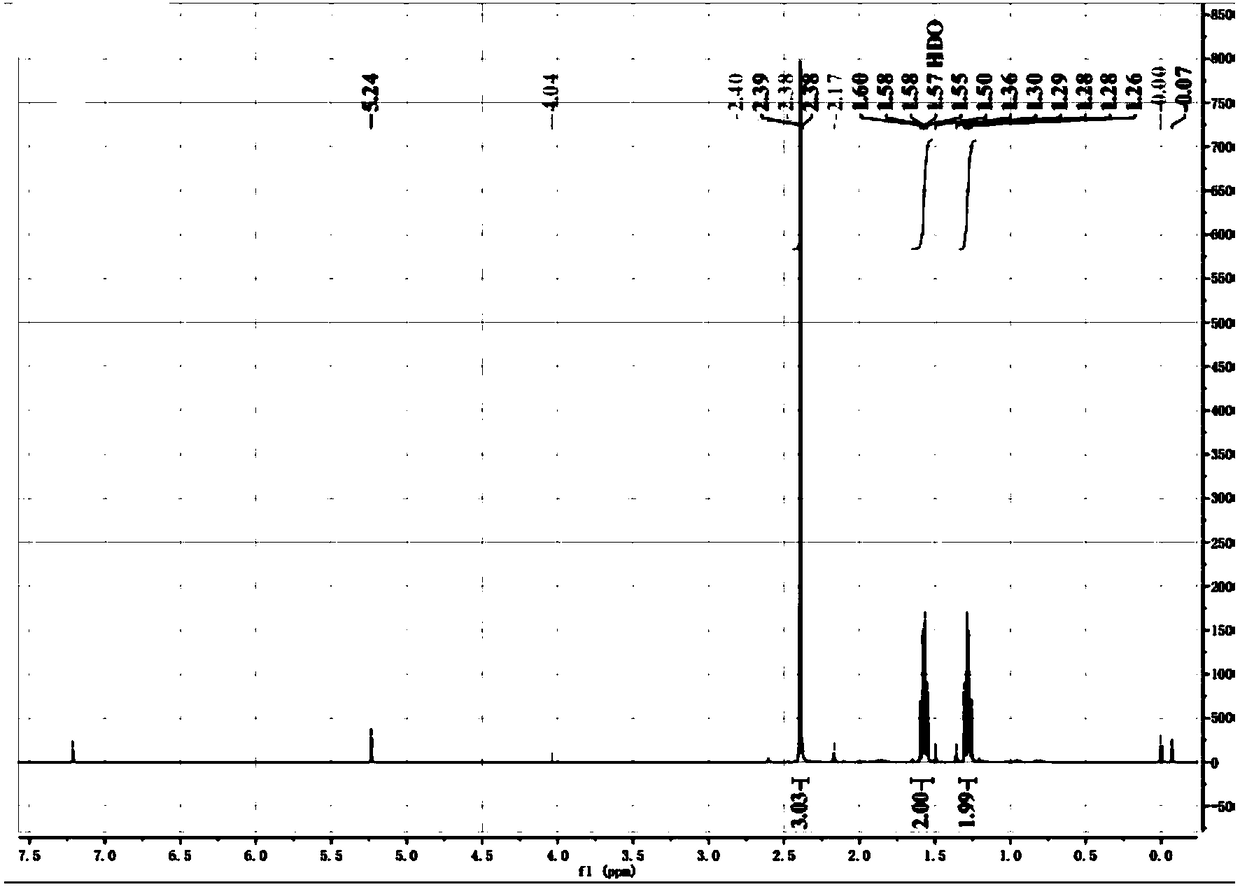

Image

Examples

Embodiment 1

[0019] Add 240 g (1.2 mol) of 20% aqueous sodium hydroxide solution and 155 g of 6# solvent oil into a 1000 mL four-neck flask. Add 2.2g (0.01mol) of 15-crown-5 to the reaction system, raise the temperature of the reaction system to 25°C, add 155g (1mol) of 3,5-dichloro-2-pentanone dropwise at this temperature, and control the reaction volume at 50°C. The dropwise addition time is about 1h. After the dropwise addition, keep warm at 50°C for 1.5h. After the reaction is lowered to room temperature, separate the liquids. Wash the oil phase with 100g of water to obtain 275g of the oil phase. After drying, distill to obtain 1-chloro-1 - 110 g of acetylcyclopropane, the normalized purity detected by GC is 99%, and the calculated yield is 92.28%.

Embodiment 2

[0021] Add 400 g (2 mol) of 20% aqueous sodium hydroxide solution and 465 g of 120# solvent oil into a 1000 mL four-neck flask. Add 13.25g (0.05mol) of 18-crown-6 to the reaction system, raise the temperature of the reaction system to 80°C, add 155g (1mol) of 3,5-dichloro-2-pentanone dropwise at this temperature, and control the reaction volume at 50°C. The dropping time is about 5 hours. After the dropping is completed, keep warm at 50°C for 1.5 hours. After the reaction is cooled to room temperature, separate the liquids and wash the oil phase with 100g of water to obtain 580g of the oil phase. After drying, use GC to detect the normalized purity It was 99%, and the content of the organic layer was quantitatively analyzed, and the converted yield was 95.3%.

Embodiment 3

[0023] Add 260 g (1.3 mol) of 20% aqueous sodium hydroxide solution and 155 g of 200# solvent oil into a 1000 mL four-neck flask. Add 3.52g (0.02mol) of 12-crown-4 to the reaction system, raise the temperature of the reaction system to 25°C, add 155g (1mol) of 3,5-dichloro-2-pentanone dropwise at this temperature, and control the reaction volume at 50°C. The dropping time is about 1.5h. After the dropping, keep warm at 50°C for 1.5h. After the reaction is lowered to room temperature, separate the liquids. Wash the oil phase with 100g of water to obtain 280g of the oil phase. After drying, use GC to detect and normalize The purity is 99%, the content of the organic layer is quantitatively analyzed, and the converted yield is 94.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com