Process for producing soft-state copper clad steel conductor by adopting welding cladding method

A copper-clad steel wire and copper-clad steel technology, applied in the manufacture of electrical components, circuits, cables/conductors, etc., can solve the problems of low product yield, environmental pollution, and high production costs, and achieve high conductivity, environmentally friendly processes, The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

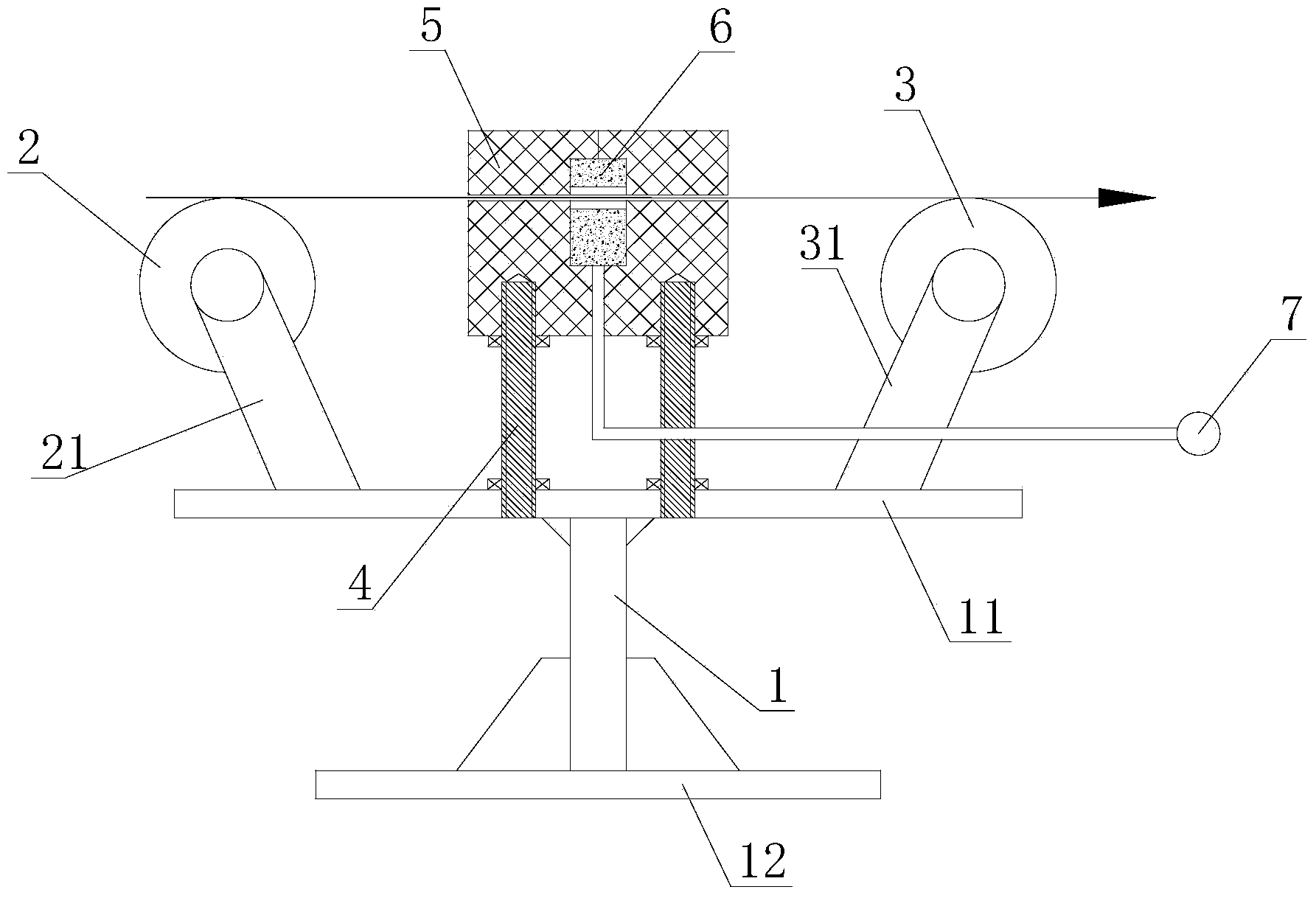

Image

Examples

Embodiment

[0027] A process for producing a soft copper-clad steel wire by a welding cladding method is characterized in that the following steps are included in sequence:

[0028] (1) Drawing, pull the steel wire with a wire diameter of 9.0-10.0mm to a wire diameter of 8.0-8.6mm;

[0029](2) Low-temperature tempering, put the drawn steel wire into a vacuum tempering furnace for low-temperature heat treatment, the tempering temperature is 420-500°C, the heating time is 1-2 hours, and the holding time is 5.5-6.5 hours; Cool the furnace for 3 hours, and then turn on the air cooler to cool it to about 260°C; eliminate the work hardening of the steel wire, improve the plasticity, and facilitate subsequent processing; at the same time, the lubricating liquid remaining on the surface of the steel wire in the previous process is carbonized at high temperature to form a loose oxide scale , easy to remove scale by subsequent pickling;

[0030] (3) pickling to remove the scale on the surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com