Patents

Literature

121 results about "2-Pentanone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

2-Pentanone or methyl propyl ketone (MPK) is a ketone and solvent of minor importance. It is comparable to methyl ethyl ketone, but has a lower solvency and is more expensive. It occurs naturally in Nicotiana tabacum (Tobacco) and blue cheese as a metabolic product of Penicillium mold growth.

Process for preparing GAMM-hexalactone, products produced therefrom dan organoleptic uses of said products

A process for producing high yields of gamma -hexalactone and 2-pentanone from the corresponding hexanoic acid starting material is carried out with high amounts of oxygen and sugar in the presence of a mold microorganism. Fragrance compositions and foodstuff compositions are augmented and enhanced by the presence of the product compounds.

Owner:INTERNATIONAL FLAVORS & FRAGRANCES

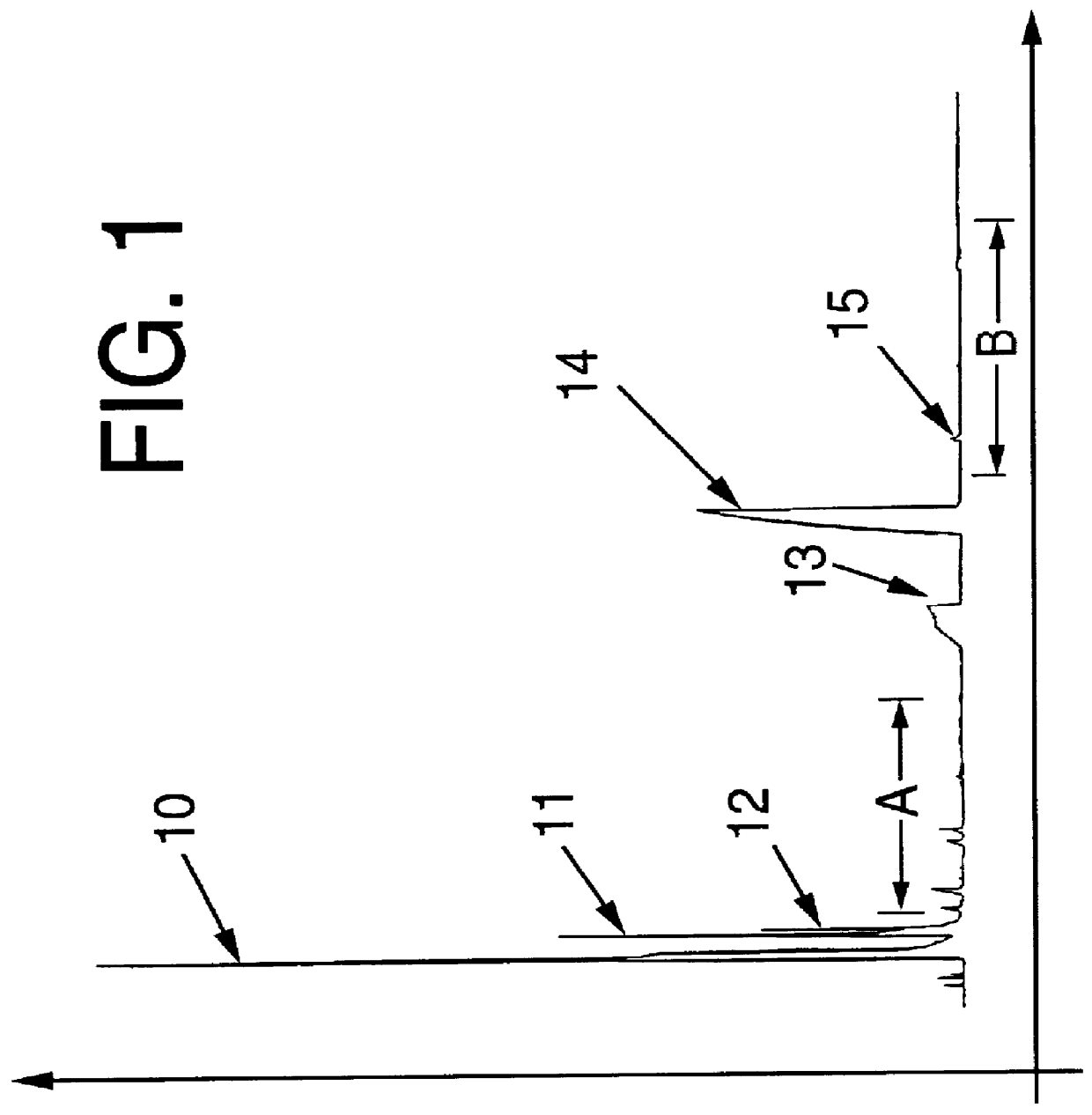

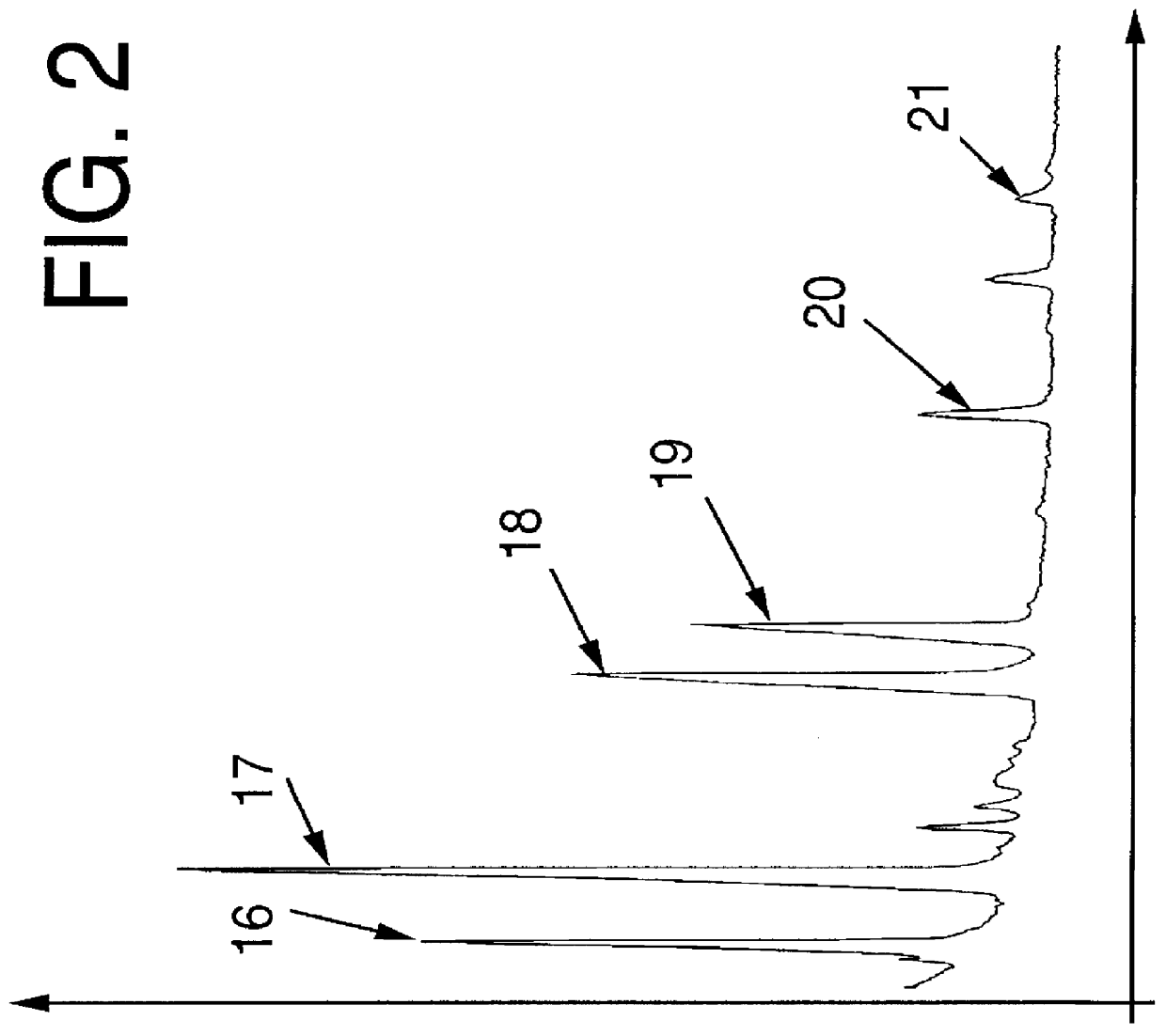

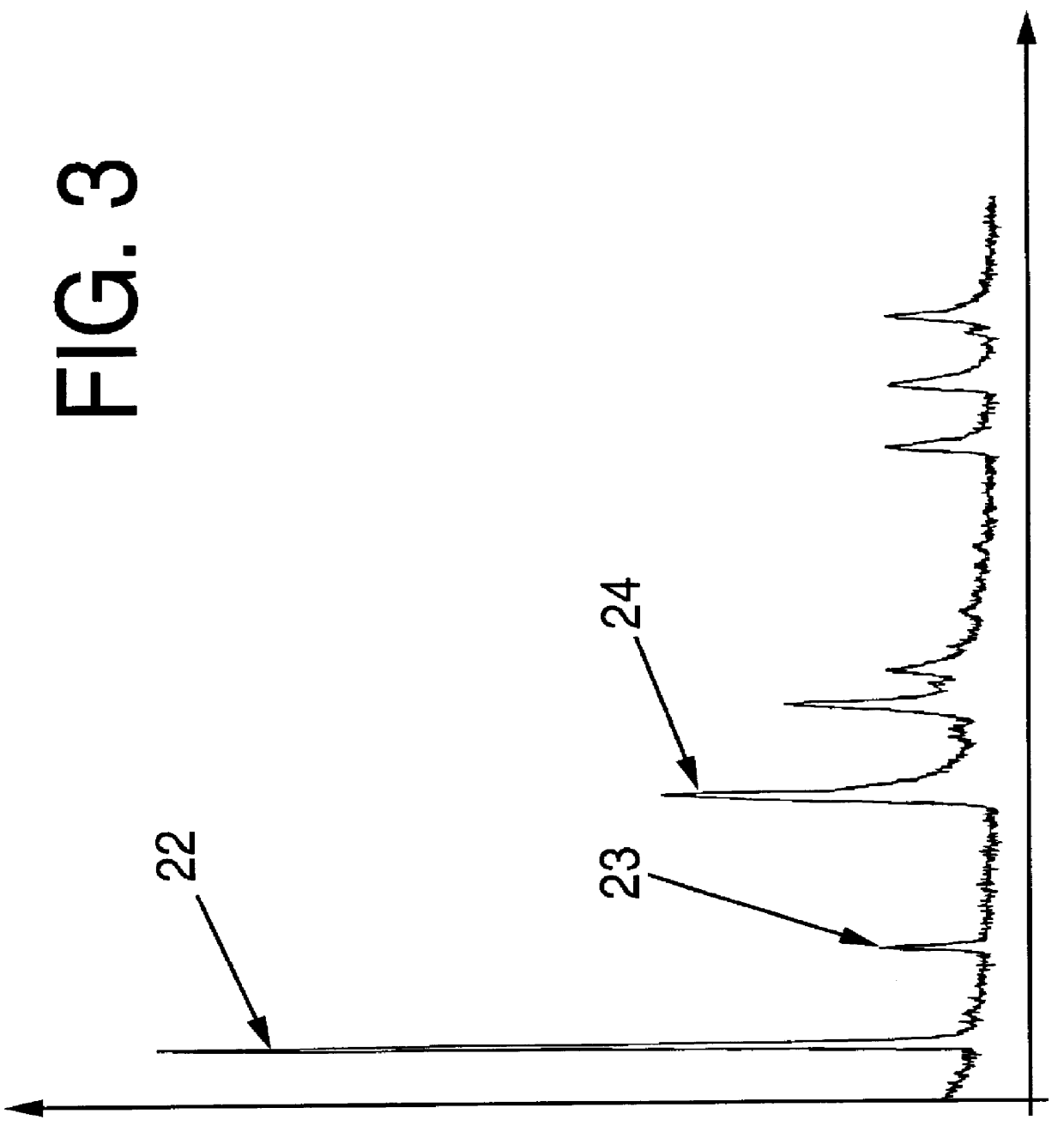

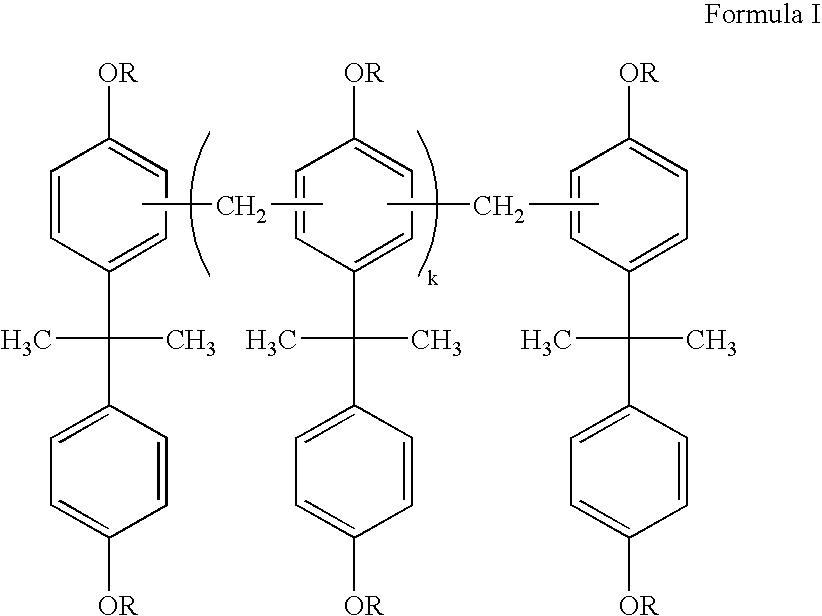

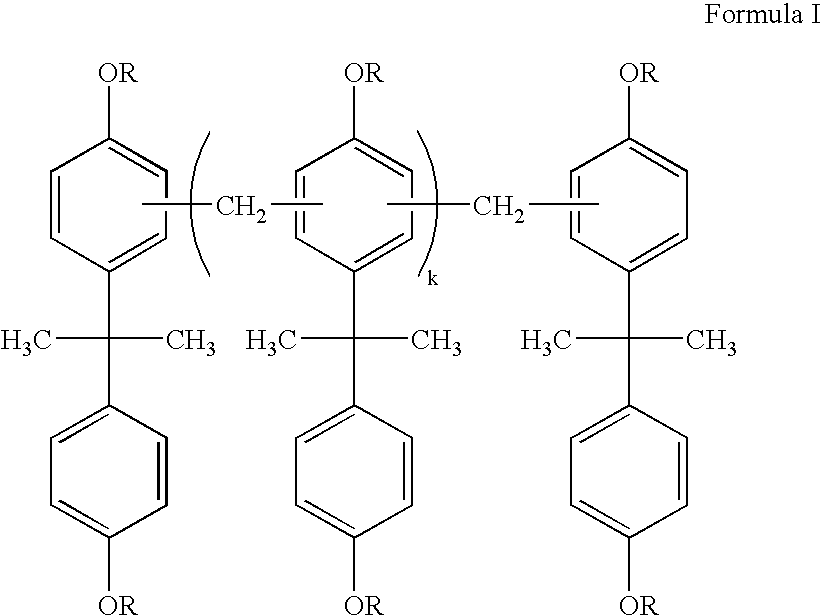

Photoimageable coating composition and composite article thereof

InactiveUS20050266335A1Photosensitive materialsPhotomechanical coating apparatusResistPhotoacid generator

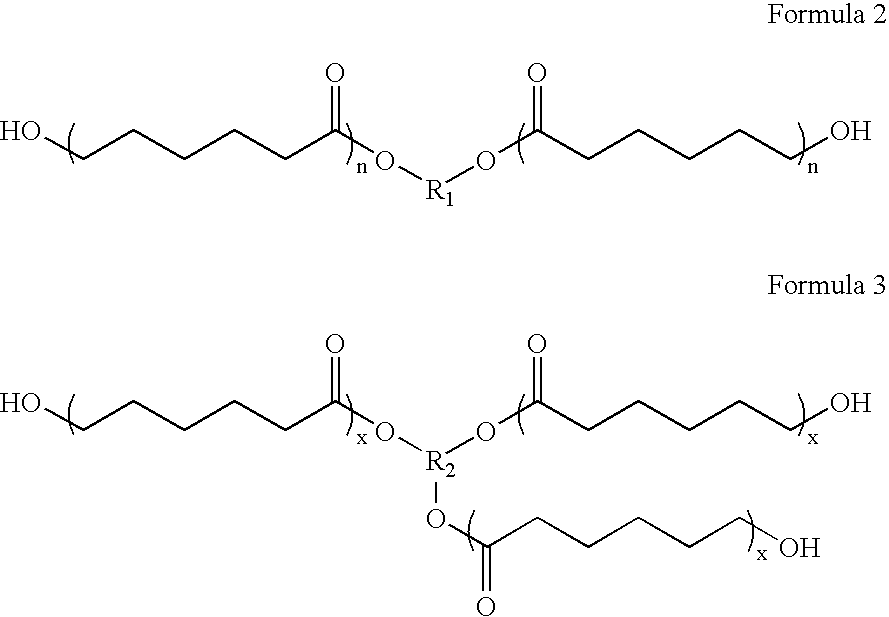

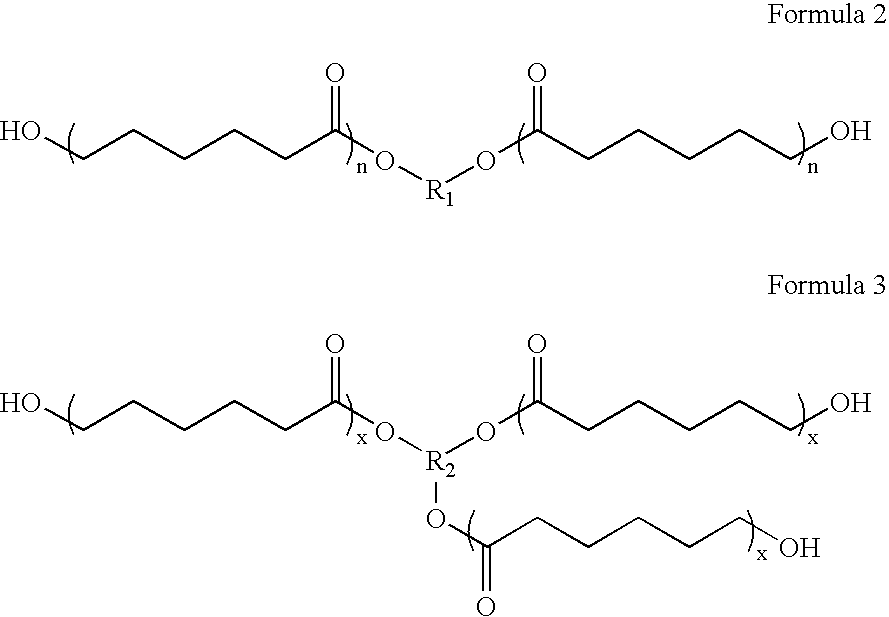

A photoimagable composition suitable for use as a negative photoresist comprising: (A) at least one epoxidized polyfunctional bisphenol A formaldehyde novolak resin; (B) at least one polycaprolactone polyol reactive diluent, wherein the amount of component (A) is from about 95% to about 75% by weight of the sum of (A) and (B) and the amount of component (B) is from about 5% to about 25% by weight of the sum of (A) and (B); (C) at least one photoacid generator in an amount from about 2.5 to about 12.5 parts per hundred parts of resin and reactive diluent, which initiates polymerization upon exposure to actinic radiation; and (D) a sufficient amount of solvent to dissolve (A), (B) and (C); wherein the solvent comprises 2-pentanone, 3-pentanone, and 1,3-dioxolane and mixtures thereof.

Owner:MICROCHEM CORP +1

Barbecue essence and production process thereof

The invention discloses a barbecue essence, which is prepared from the following raw materials: ethyl maltol, 4-hydroxyl-2,5-dimethyl-3(2H)-furanone, 2,5-dimethyl-2,5-diyhydroxyl-1,4-dithiacyclo-hexane, methyl cyclopentenotone, 2-acetylpyrazine, 2-methyl tetrahydrofuran-3-mercaptan, bis(2-methyl-3-furyl) disulfide, propyl2-methyl-3-furyl disulfide, 4-methyl-5- hydroxyethyl-thiazole, 2-methylpyrazine, 2,3,5-trimethylpyrazine, 3-methylmercaptopropionaldehyde, difurfuryl disulfide, 4-methyl-4-furfurylthio-2-pentanone, 2,4,5-trimethylthiazole, 2,4,6-triisobutyl-1,3,5-dithiazine, beta-phenylethylmercaptan, 1,6-ethanthiol, 2-pentylthiophene, furfuryl mercaptan, 4,5-dimethyl-2-isobutyl-3-thiazoline, guaiacol, delta-dodecalactone, 2,4-decadienealdehyde, trans,trans-2,4- nonadienal, anisic aldehyde, butanoic acid, acetic acid, black pepper essential oil ginger essential oil, clove oil, cassia oil and an oil-soluble solvent. The invention also discloses a barbecue essence production process.

Owner:厦门市顶味兴业香料发展有限公司

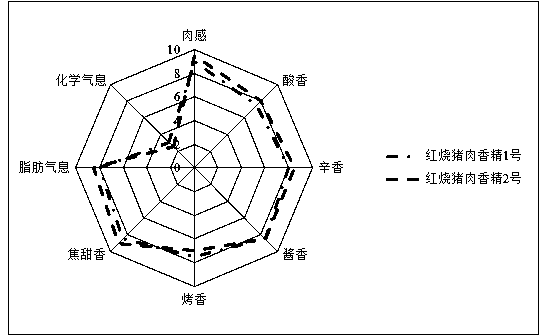

Mixed stewed pork essence and making method thereof

InactiveCN104026546AHigh concentration of fragranceRealistic aromaFood preparation2-methyl-3-furanthiolFuran

The invention discloses mixed stewed pork essence which consists of furanone, ethyl maltol, 2-acetylpyrazine, methyl cyclopentenolone, difurfuryl sulfide, 3-sulfydryl-2-butanol, 2-methyl-3-furan mercaptan, di(2-methyl-3-furan mercaptan)-disulfide, methyl(2-methyl-3-furan mercaptan)-disulfide, acetic acid, 3-sulfydryl-2-butanone, 3-propionaldehyde, thiophane-3-acetone, 2,3,5-trimethyl pyrazine, counter,counter-2,4-decadiene aldehyde, furfuryl disulfide, furfurylmercaptan, anise camphor, anisic aldehyde, pepper essential oil, 2-acetyl thiazole, delta-dodecalactone, 4-methyl-5(beta)-hydroxyethyl thiazole acetate, onion oil alcohol, 4-methyl-4-bran sulfenyl-2-pentanone and glycerol triacetate. The mixed stewed pork essence is high in biofidelity and mellow and fine in fragrance, has a good application effect and is economical and practical.

Owner:SHANGHAI INST OF TECH

Photoimageable coating composition and composite article thereof

InactiveUS7449280B2Photosensitive materialsPhotomechanical coating apparatusResistPhotoacid generator

A photoimagable composition suitable for use as a negative photoresist comprising:(A) at least one epoxidized polyfunctional bisphenol A formaldehyde novolak resin;(B) at least one polycaprolactone polyol reactive diluent, wherein the amount of component (A) is from about 95% to about 75% by weight of the sum of (A) and (B) and the amount of component (B) is from about 5% to about 25% by weight of the sum of (A) and (B);(C) at least one photoacid generator in an amount from about 2.5 to about 12.5 parts per hundred parts of resin and reactive diluent, which initiates polymerization upon exposure to actinic radiation; and(D) a sufficient amount of solvent to dissolve (A), (B) and (C);wherein the solvent comprises 2-pentanone, 3-pentanone, and 1,3-dioxolane and mixtures thereof.

Owner:MICROCHEM CORP +1

Method for synthesizing 1,2-pentanediol

InactiveCN102180769AWide variety of sourcesLow costOrganic compound preparationHydroxy compound preparationThiazoleHydrogen

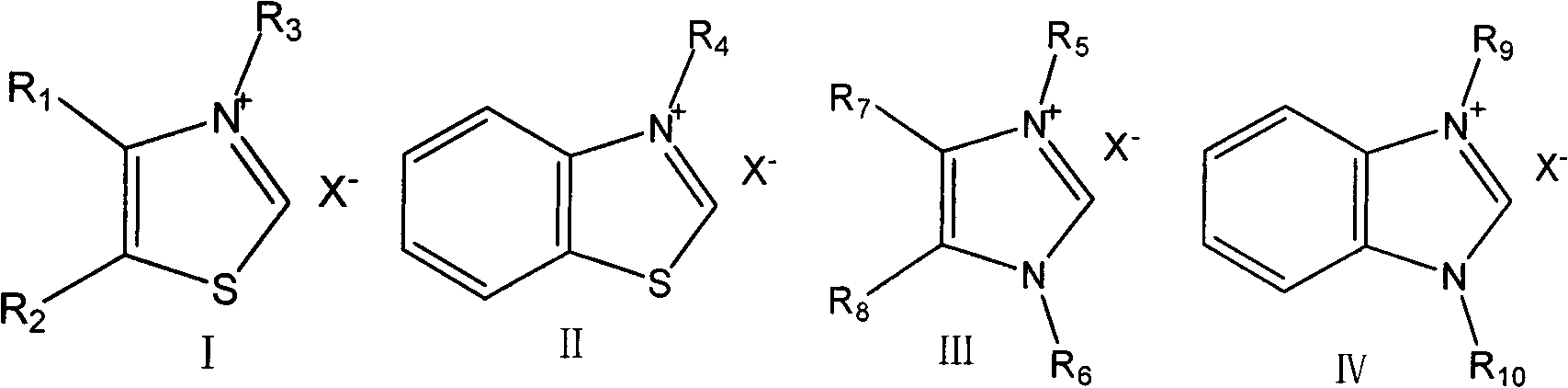

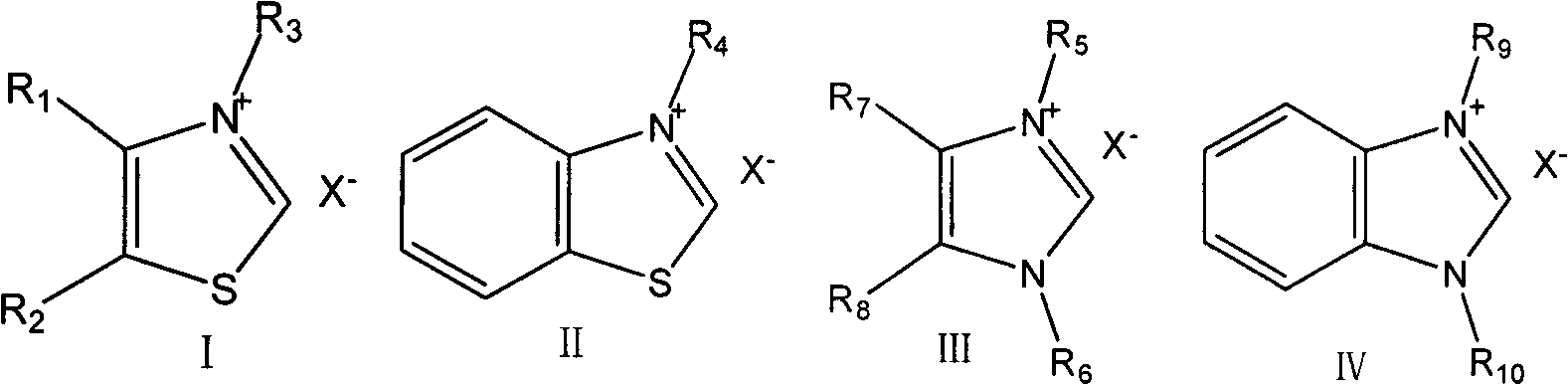

The method relates to a method for synthesizing 1,2-pentanediol. The method comprises the following steps of: 1, reacting n-butanal with paraformaldehyde in the presence of a catalyst such as thiazole salt (or imidazole salt) under the action of alkali and a solvent, and after the reaction is finished, distilling under reduced pressure to separate light fractions such as the n-butanal, the solvent and the like, and distilling again under reduced pressure of 20 mmHg to separate an intermediate product such as 1-hydroxy-2-pentanone; and 2, conducting reduction reaction of the intermediate product such as 1-hydroxy-2-pentanone with hydrogen under the action of a hydrogenation catalyst such as Pd / C, and after the reaction is finished, distilling under reduced pressure, and collecting the fraction, namely the pure 1,2-pentanediol product at the top temperature of between 95 and 100 DEG C under the condition of 20 mmHg, wherein the purity is over 98 percent and the total yield can reach 60 percent. The method has the advantages of low price of raw materials, recycled catalysts in the reactions, low production cost, environmental friendliness, mild reaction conditions and the like.

Owner:HUBEI UNIV OF TECH

Chicken meat essence

ActiveCN101288459AKeep natural propertiesImprove temperature resistanceFood preparationChicken FlavorAdditive ingredient

The invention relates to a chicken flavor, including the following ingredients according to weight percentage: 0.5-1.0 part of ethyl maltol, 0.05-0.1 part of 2-acetylpyrazine, 0.1-0.2 part of clove oil, 0.05-0.1 part of cassia oil, 0.3-0.4 part of ginger essential oil, 0.2-0.3 part of star anise oil, 0.05-0.2 part of 3-methylthio-propanal, 0.01-0.1 part of (E,E)-2,4-decadienal, 0.2-0.4 part of 4-methyl-4-furfurylthio-2-pentanone, 0.05-0.2 part of tetrahydrothiophen-3-one, 0.01-0.1 part of 2,5-dimethyl-2,5-dihydroxy-1,4-disulfocyclohexane, 0.1-0.3 part of bis(2-methyl-3-furyl)disulfide, 0.01-0.1 part of 2-furfuryl monosulfide, 0.01-0.05 part of 2-Methyl-3-tetrahydrofuranthiol solution and 96.45-98.36 parts of soy salad oil. The chicken flavor has nature stewing chicken fragrance and taste as well as good temperature tolerance.

Owner:GUANGZHOU TIANHUI FOOD

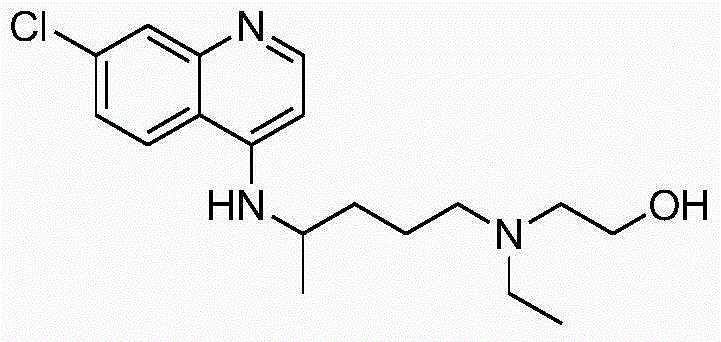

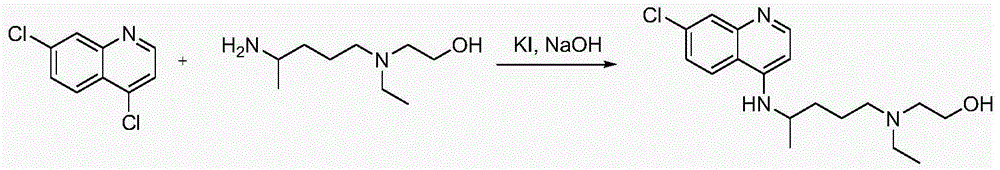

Side chain, synthesis method thereof, and method for synthesizing hydroxychloroquine sulfate from side chain

ActiveCN107266323AEasy to operateReduce the difficulty of industrial productionOrganic compound preparationAmino-hyroxy compound preparationSynthesis methodsSide chain

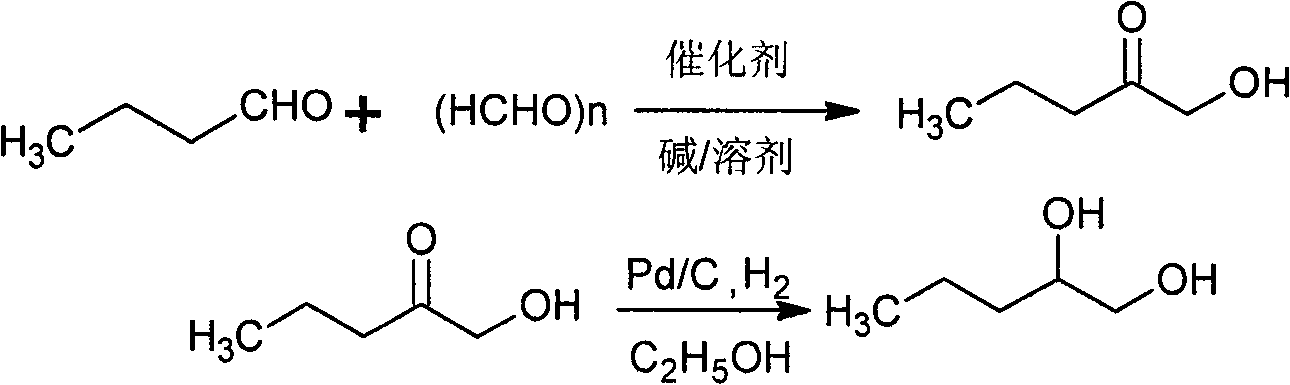

The invention discloses a side chain, a synthesis method thereof, and a method for synthesizing hydroxychloroquine sulfate from the side chain. The synthesis method of the side chain comprises the following steps: 1, condensing N-ethylethanolamine and 5-chloro-2-pentanone to obtain a condensation product; 2, esterifying the condensation product and an acetyl reagent to obtain an esterification product; 3, reducing the esterification product to obtain a reduction product; and 4, reacting the reduction product with a halogenating agent to obtain the side chain. The synthesis method of the hydroxychloroquine sulfate comprises the following steps: 1, reacting 4-amino-7-chloroquinoline with paratoluensulfonyl chloride to obtain 4-Tos-amino-7-chloroquinoline; 2, reacting the side chain with the 4-Tos-amino-7-chloroquinoline to obtain a hydroxyquine base; and 3, reacting the hydroxyquine base with sulfuric acid to obtain the hydroxychloroquine sulfate. The synthesis method of the new side chain avoids the ammonification process and the catalytic hydrogenation process, and is safe and environmentally friendly, and the hydroxychloroquine sulfate can be obtained through low-temperature condensation of the side chain, so the quality of the above products is remarkably improved, and the production flow is simplified.

Owner:宜宾莱特医药化工有限公司

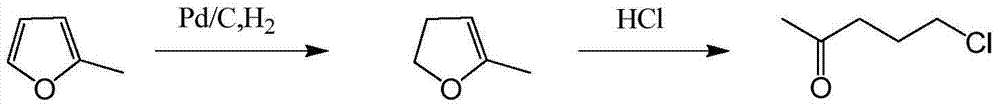

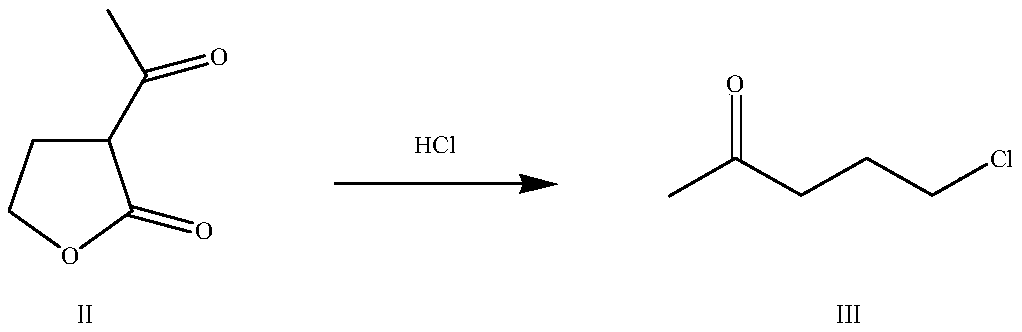

5-chloro-2-pentanone preparation method

ActiveCN103694094AEliminate the effects ofIncrease profitPreparation from heterocyclic compoundsFuranHydrogenation reaction

The present invention provides a 5-chloro-2-pentanone preparation method, which comprises that: 2-methyl furan is subjected to a hydrogenation reaction in the presence of a hydrogenation catalyst and hydrogen gas to prepare 2-methyl-4,5-dihydrofuran, and the 2-methyl-4,5-dihydrofuran and hydrochloric acid are subjected to a ring opening chlorination reaction to obtain the 5-chloro-2-pentanone. According to the present invention, 2-methyl furan is adopted as the raw material, the reaction steps are simple and easy to operate, no wastewater is generated during the production process, and environmental protection requirements are met; the hydrogenation catalyst, the distillate and the hydrochloric acid can be recycled so as to substantially reduce the production cost, and the prepared product has characteristics of high yield and high purity; and compared with the conventional process, the preparation method of the present invention has characteristics of complete elimination of influence of hydrochloric acid on the catalyst, improvement of the catalyst utilization rate, and substantial reduction of the 5-chloro-2-pentanone production cost.

Owner:JIANGSU QINGQUAN CHEM CO LTD

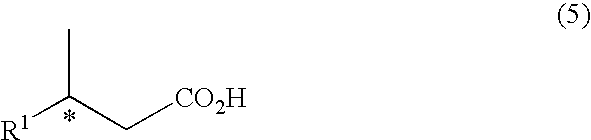

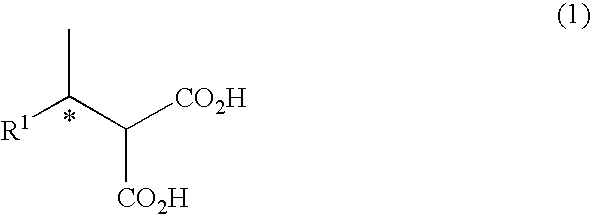

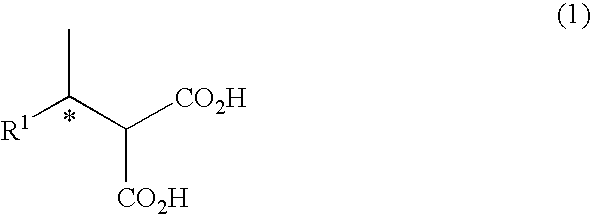

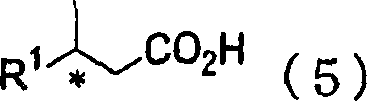

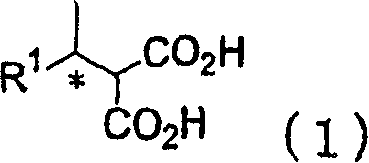

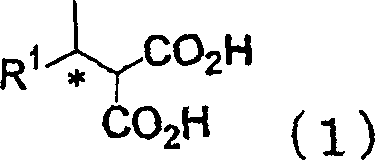

Method For Producing Alcohol and Carboxylic Acid Having Optical Activity

InactiveUS20080233621A1High optical purityProduced inexpensively and efficientlyOrganic compound preparationOrganic chemistry methodsCarboxylic acidMethyl group

It is an object of the present invention to provide an inexpensive and efficient industrial method for obtaining (S)-2-pentanol, (S)-2-hexanol, 1-methylalkyl malonic acid and 3-methyl carboxylic acid at a high optical purity. The present invention provides a method of producing (S)-2-pentanol or (S)-2-hexanol which comprises allowing certain types of microorganisms or transformed cells, a product obtained by treating said microorganisms or cells, a culture solution of said microorganisms or cells, and / or a crude purified product or purified product of a carbonyl reductase fraction obtained from said microorganisms or cells, to act on 2-pentanone or 2-hexanone.

Owner:API CORP (JP)

Preparation method of meat-flavor essence

The invention relates to a preparation method of a meat-flavor essence. The method comprises the following steps: in a reactive kettle, successively adding a sulfocompound, an amino acid mixture, reducing sugar, hydrolyzed plant protein, enzyme-dispersed animal protein and yeast extract for maillard reaction to obtain a reaction essence base; with salad oil as the solvent, successively adding zanthoxylum oil, anise oil, cinnamon oil, geranium oil and ginger oil to obtain spicy essence base; with trimethylene glycol as the solvent, successively adding 4-methyl-4-sulfydryl-2-pentanone, 4-methyl-5-ethoxyl thiazole, 2-acetylpyrazine, ethyl maltol and vanillin to obtain a meat-flavor essence base; taking the reaction essence base, the spicy essence base and the meat-flavor essence, and adding table salt, monosodium glutamate, white granulated sugar and a thickening agent, uniformly mixing, and using a homogenizer and a colloid mill to prepare a pasty essence; and stirring the prepared pasty essence under the constant temperature of 50-100 DEG C for 10-60min to obtain the finished product. The essence is more plump in flavor and more natural, and has more cooking sensation.

Owner:TIANJIN CHUNFA BIO TECH GRP

Catalyst in use for synthesizing 2-pentanone from ethanol

InactiveCN1660750AReduce the discharge of three wastesOrganic compound preparationCarbonyl compound preparationAlkaline earth metalMixed oxide

A catalyst used for synthesizing 2-pentone from ethanol is prepared from zirconium oxide, manganese oxide, zinc oxide, less noble metal (Pt, Pd, Rh, etc) and less assistant (Li, Na, K, Mg, etc) through mixing three oxides, dipping assistant, calcining, dipping noble metal, and calcining. It has high activity, selectivity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

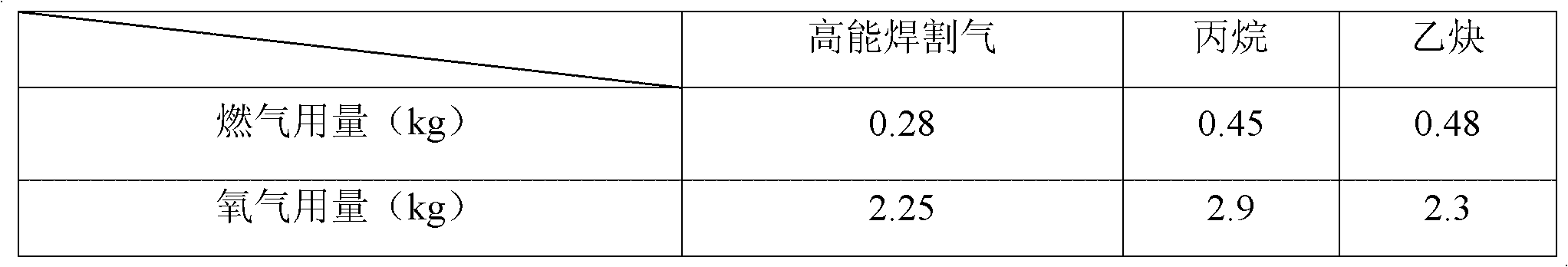

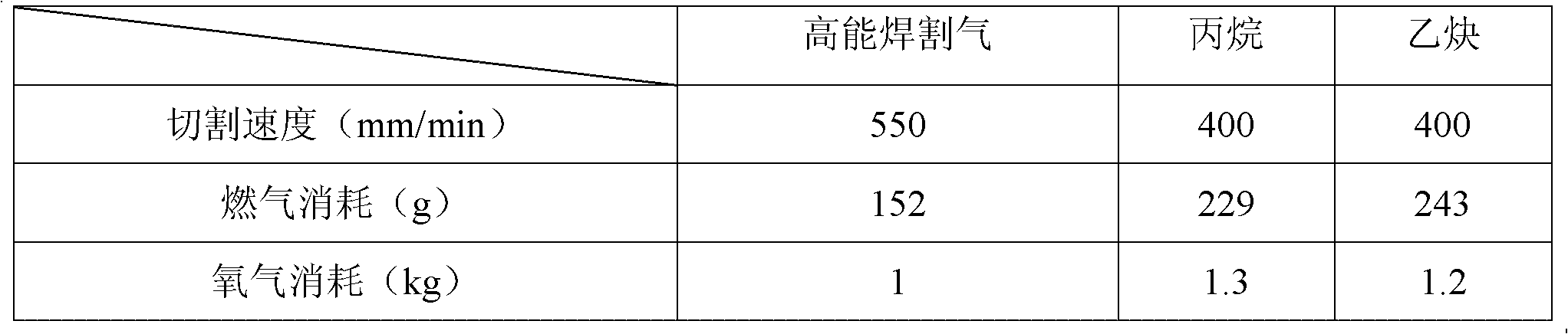

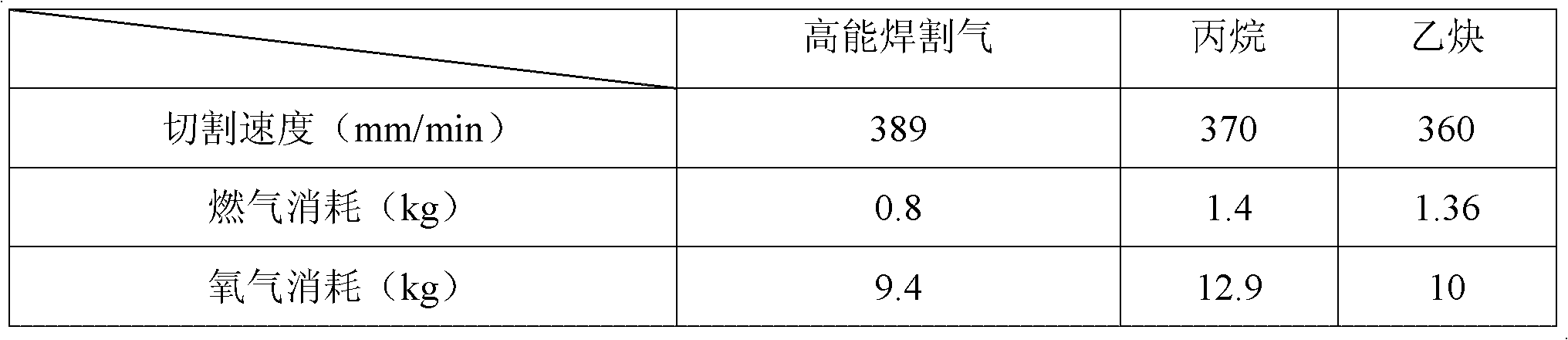

High-energy welding-cutting gas

Owner:李铁锁 +1

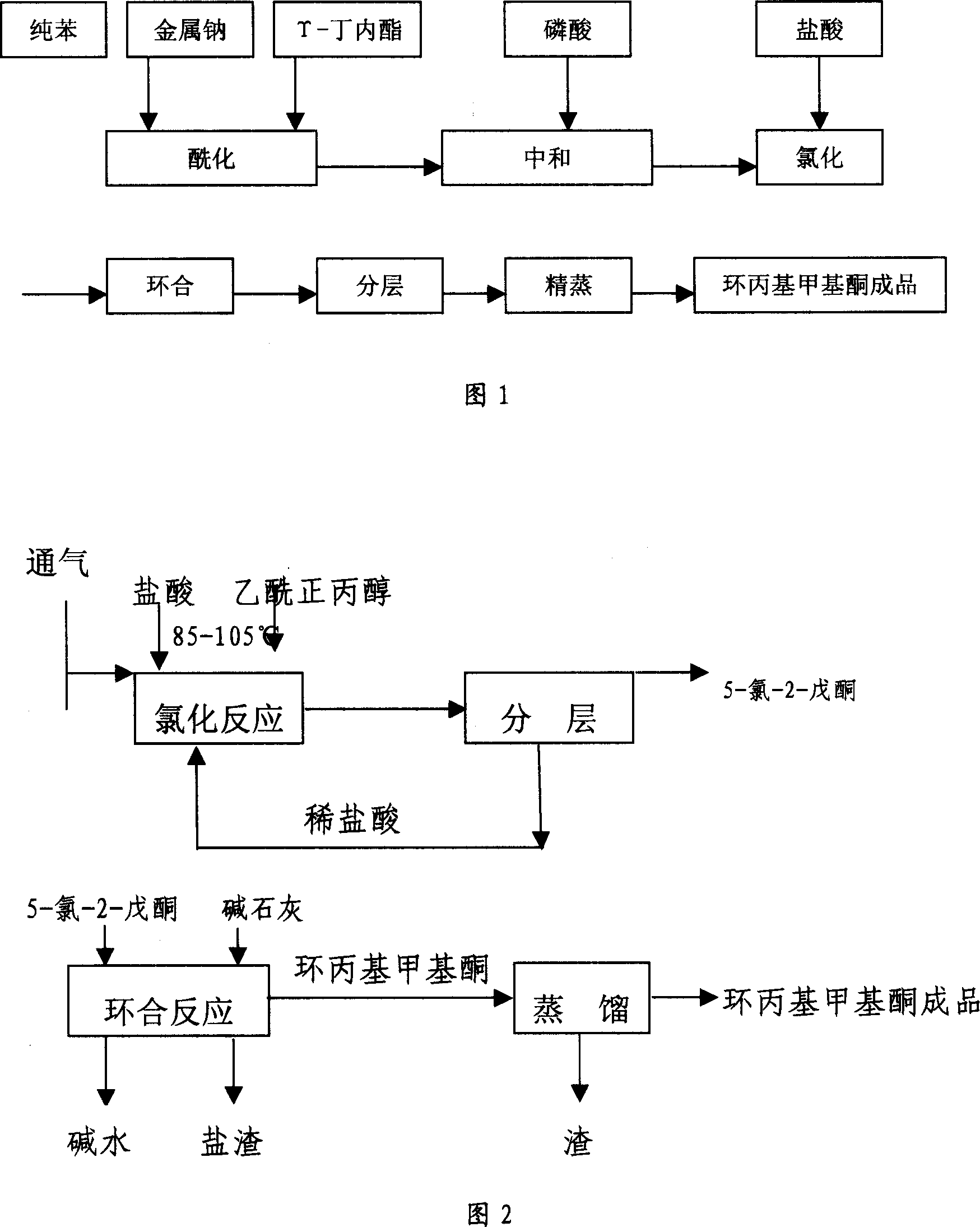

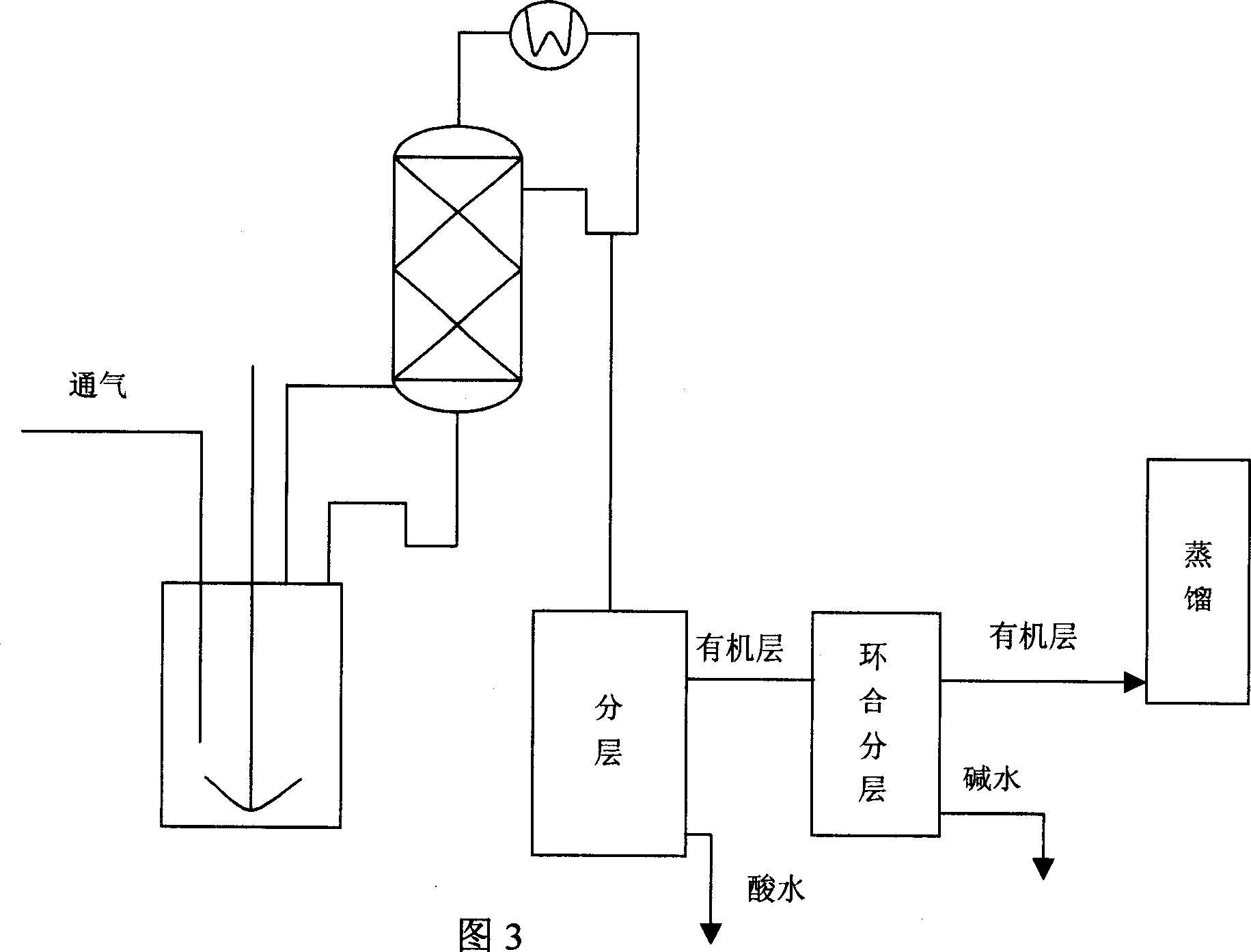

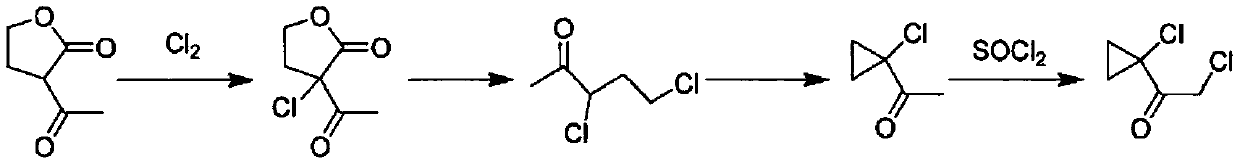

Process for preparing cyclopropyl methyl ketone

ActiveCN1994996AReduce generationIncrease profitOrganic compound preparationCarbonyl compound preparationAlcoholMethyl Ketone

The invention discloses a making method of cyclopropyl methyl ketone, which comprises the following steps: adding normal aceto propyl alcohol in the alcaine solution; chlorinating; evaporating 5-chloride-2-pentanone; adopting separating coupling technique to do ringed-reaction for 5-chloride-2-pentanone; generating cyclopropyl methyl ketone.

Owner:ANHUI JIXI COUNTY HUIHUANG CHEM

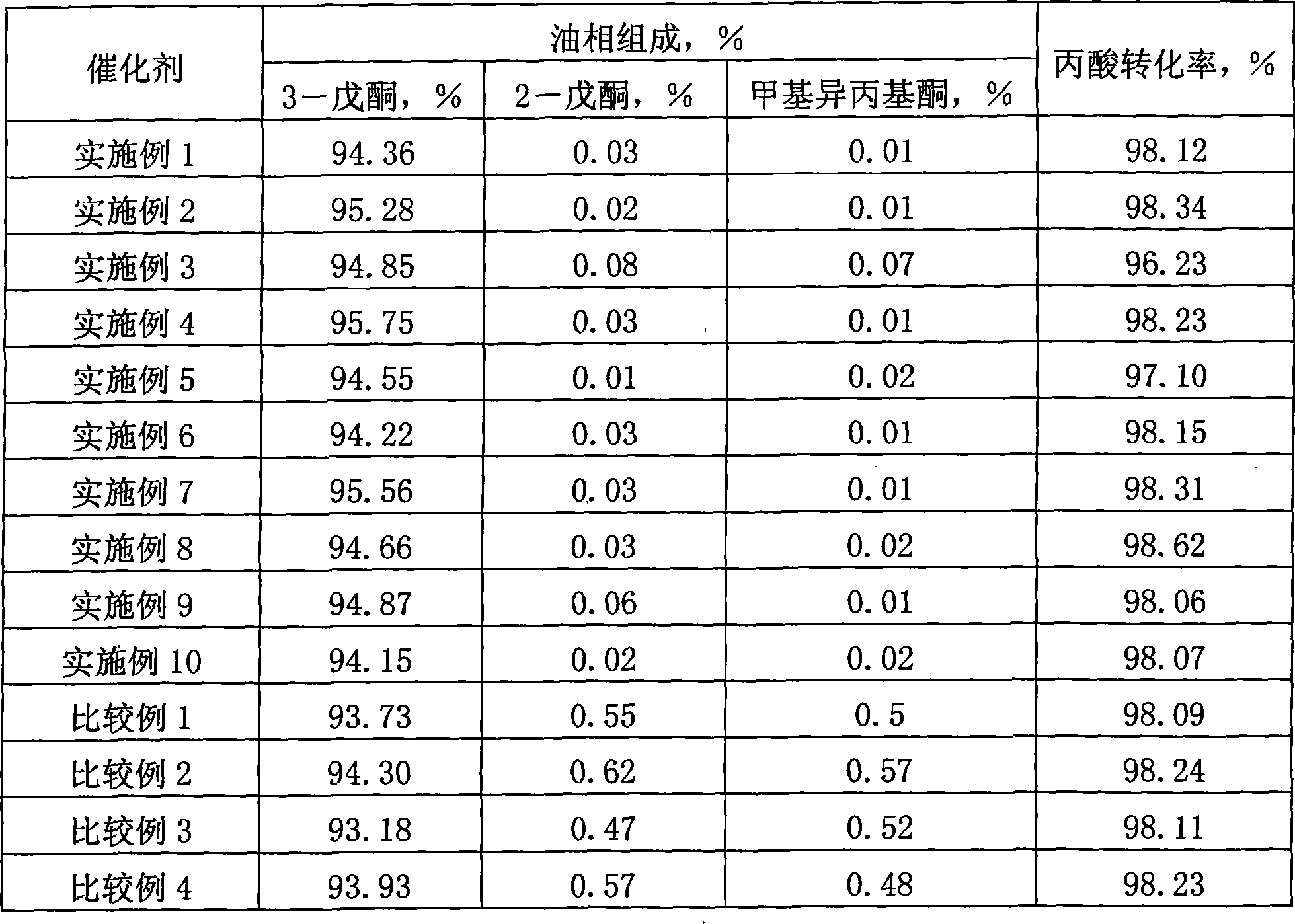

Catalyst for synthesizing 3-pentanone

InactiveCN101507919AReduce the difficulty of separationKeep aliveOrganic compound preparationCarbonyl compound preparationIsomerizationRare earth

The invention relates to a catalyst for synthesizing 3-pentanone, and belongs to the technical field of preparation of catalysts for fine chemical products. The catalyst consists of an active composition, an auxiliary agent and a carrier, wherein the active composition is one or more of lanthanum rare earth oxide and actinium rare earth oxide; the carrier is one or more of zirconia, alumina, titania and silicon dioxide; the weight ratio of the active composition to the carrier is 5-80:95-20; and the auxiliary agent is one or more alkali metals or alkaline earth oxides and is 0.1 to 5 weight percent of the total weight of the active composition and the carrier. The catalyst not only maintains the activity of the prior catalyst, but also overcomes the defects of the prior rare earth catalyst, achieves the aims of inhibiting the isomerization reaction and reducing the content of 2-pentanone and methyl isopropyl ketone in the reaction products, and greatly reduces the separation difficulty of the 3-pentanone.

Owner:YIXING ZHONGGANG FINE CHEM

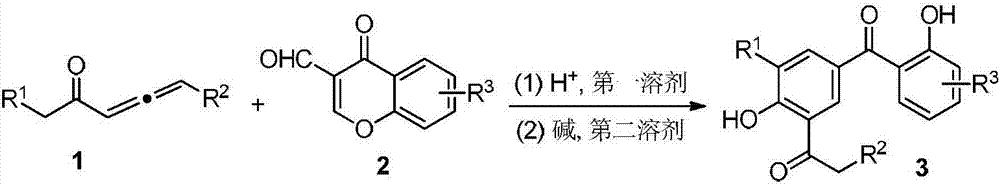

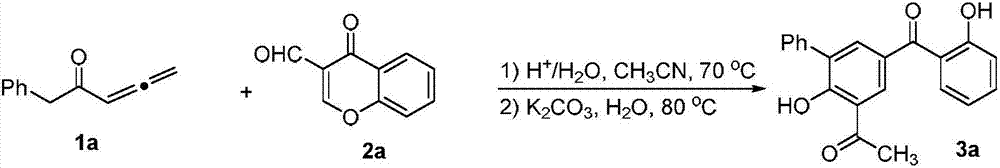

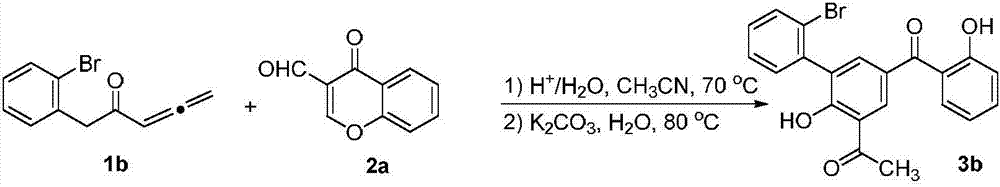

Synthesis method of 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound

ActiveCN107141207AEasy to synthesizeAtom economy is highCarbonyl compound separation/purificationPreparation from heterocyclic compoundsOrganic synthesisSolvent

The invention discloses a synthesis method of a 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound, and belongs to the technical field of organic synthesis. The key point of the technical scheme of the invention is as follows: the synthesis method of the 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound particularly comprises the following processes: disoolving a 3,4-diene-2-pentanone compound and a 3-formyl chromone compound into a first solvent, performing stirring reaction at a temperature of 50 to 80 DEG C under the acidic condition, adding a second solvent and alkali, and performing stirring reaction at 60 to 100 DEG C to prepare the 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound. The 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound is synthesized through one-pot multi-step cascade reaction of the 3,4-diene-2-pentanone compound and the 3-formyl chromone compound; the synthesis method of the 3'-acyl-2,4'-dihydroxyl diphenyl ketone compound has the advantates of simplicity and convenience in operation, mild condition, wide application range of substrates and the like, and is suitable for industrialized production.

Owner:HENAN NORMAL UNIV

Method for synthesizing 2-pentanone by usig ethanol

InactiveCN1660749AHigh activityHigh selectivityPreparation by hydrogenolysisReaction temperatureKetone

A process for synthesizing pentone from ethanol features the reaction between ethanol and catalyst K-Pd / ZrO2 / MnO / ZnO in initial gas. Its advantages are high conversion rate (100%) and selectivity. Its separation method is distilling.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

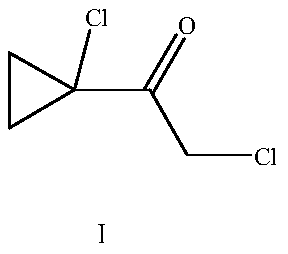

Method of preparing 1-acetyl-1-chlorocyclopropane

InactiveUS20050222451A1Preparation by hydrogen halide split-offOrganic compound preparationOrganic solventPhase-transfer catalyst

The present invention provides a method of preparing 1-acetyl-1-chlorocyclopropane from 1,3 dichloro-2-pentanone by reaction with base in the presence of a phase transfer catalyst. The reaction may be run in the presence or absence of an organic solvent and in a continuous or batch process.

Owner:BAYER CROPSCI LP +1

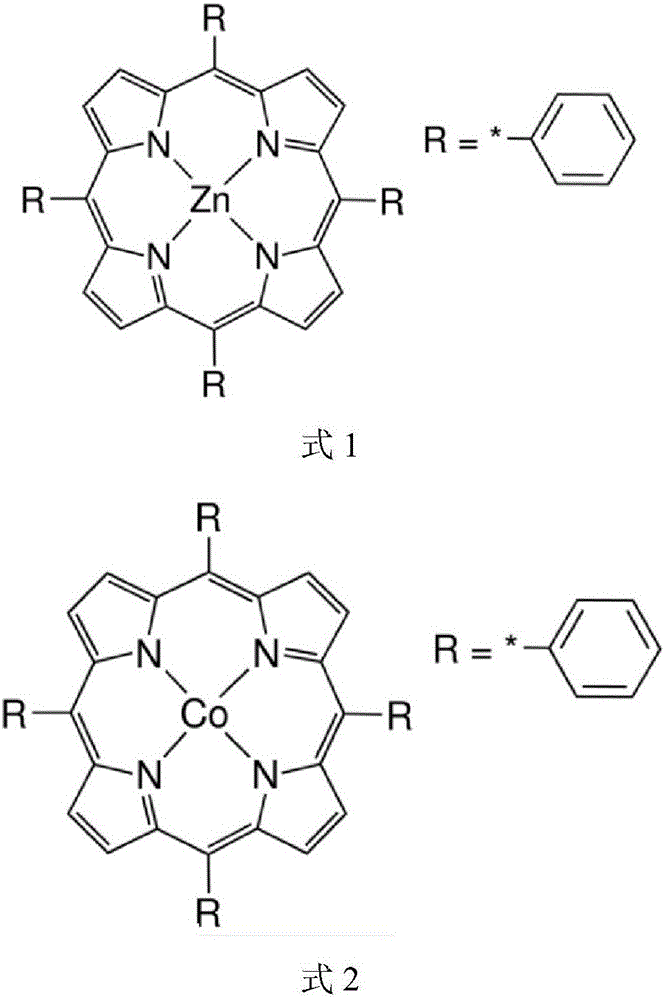

Visual array chip for gas analysis and application thereof

ActiveCN106198797AHigh selectivityHigh detection sensitivityComponent separationEthylenediamineGas analysis

The invention provides a visual array chip for gas analysis and application thereof. According to the visual array chip, functional modules from No.1 to No.36 are arranged on a substrate according to an array distribution mode, and the functional modules are prepared by coating the substrate with porphyrin and dye modified by gold nano-particles, porous organic silicate, plasticizer and materials having specific response to aldehyde volatile organic compounds. The visual array chip can be used for detecting and analyzing at least one volatile gas in benzene, methylbenzene, p-xylene, trimethylbenzene, trichlorofluoromethane, propyl aldehyde, hexanal, acetaldehyde, heptanal, acetone, 2-pentanone, tetrahydrofuran, heptane, decane, undecane, 1-hexene, isoprene, styrene, acetic acid, propionic acid, ethylenediamine, tetramethylethylenediamine, acetonitrile, propyl alcohol, thiol and butyl acetate compounds. The chip can be used for detecting multiple gas ingredients, has high sensitivity for detected objects with low detection limit, and can reach the ppbv detection level.

Owner:CHONGQING UNIV

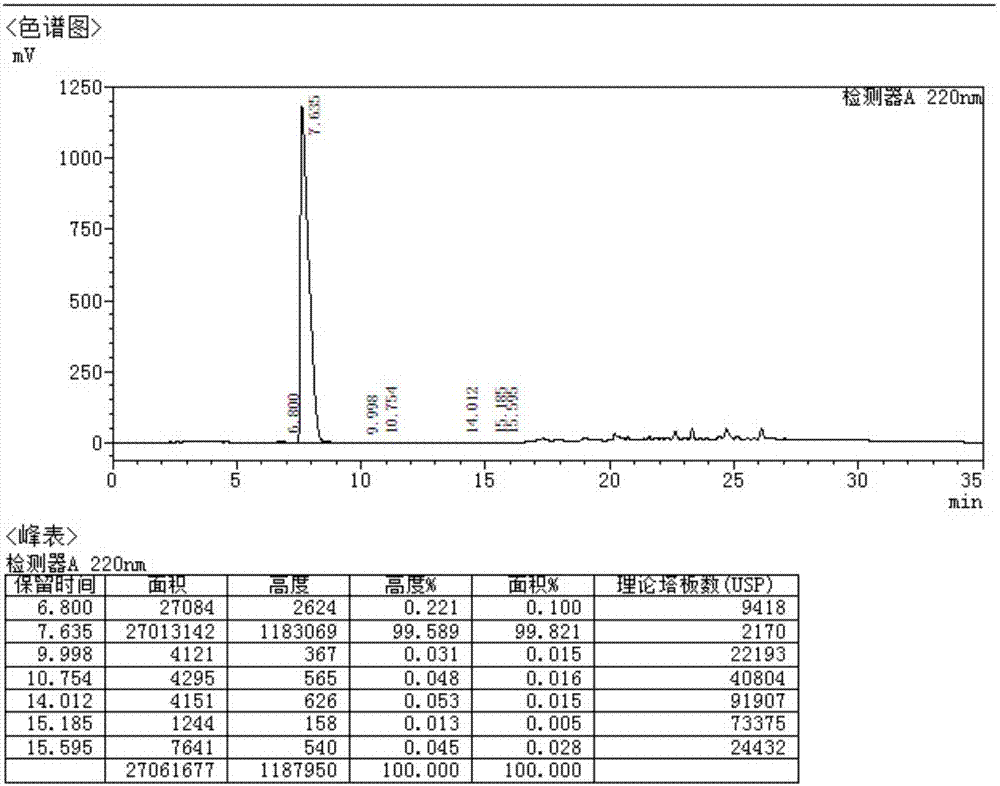

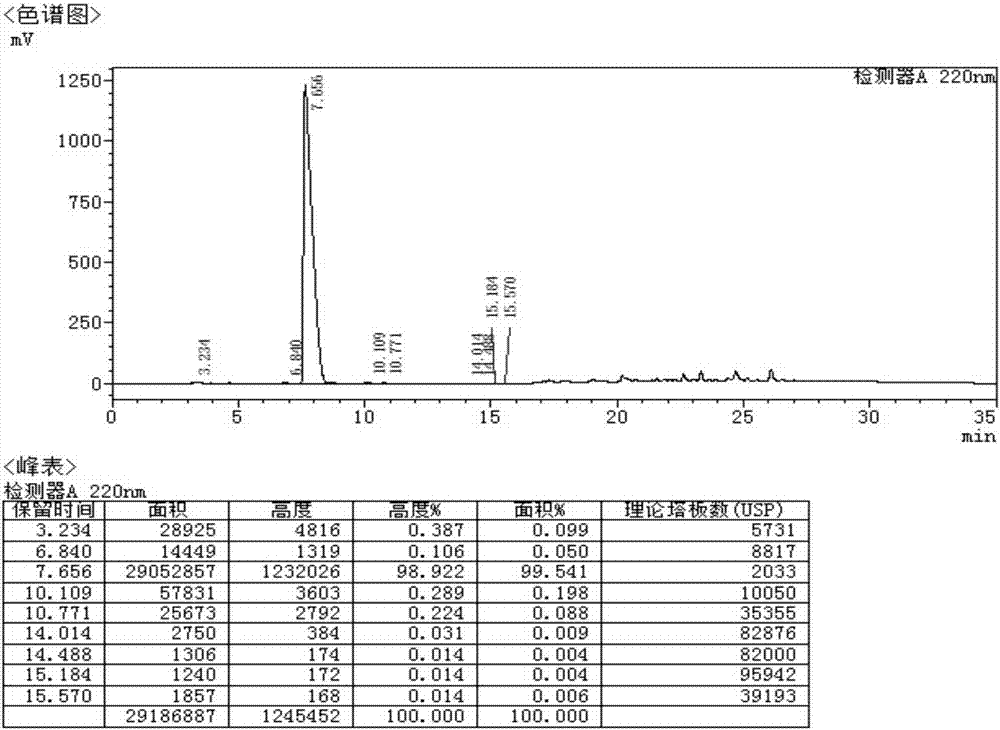

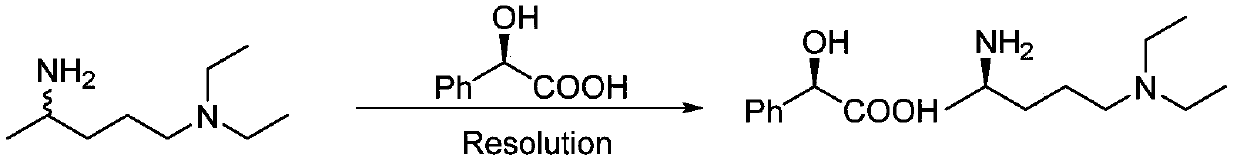

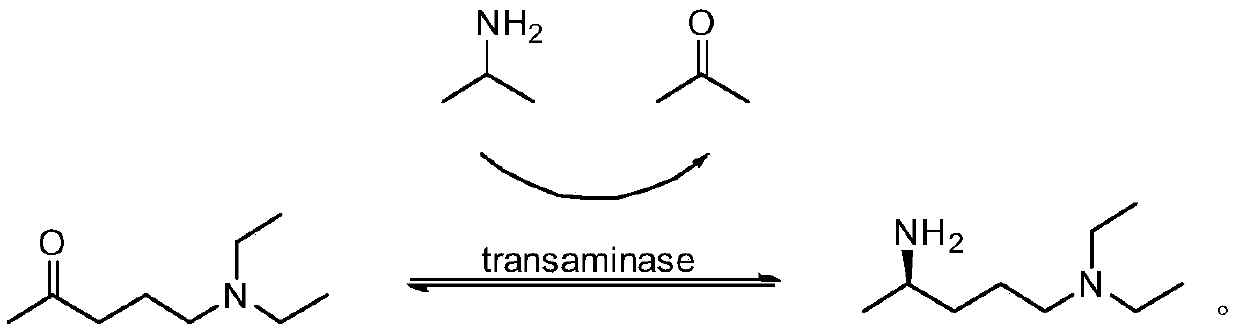

Preparation method of (R)-N1,N1-diethyl-1,4-pentanediamine

The present invention belongs to the technical field of chiral amine preparations and particularly relates to a preparation method of chiral amine (R)-N1,N1-diethyl-1,4-pentanediamine. A synthesis ofthe (R)-N1,N1-diethyl-1,4-pentanediamine comprises the following steps: using 5-diethylamino-2-pentanone as a raw material and catalyzing the 5-diethylamino-2-pentanone with an amino group donor isopropylamine to conduct a transamination reaction under catalysis of omega-transaminase ATA-117 and coenzyme pyridoxal phosphate to produce the(R)-N1,N1-diethyl-1,4-pentanediamine. The product prepared by the provided method is good in stereoselectivity and produced enantiomer by-products are less than 0.5%; after purification by distillation, purity reaches 99.3% or more and single impurity reachesstarting raw material indexes of raw material medicines; and a total yield can reach as high as 70-85%, the yield is obviously higher than that of traditional process, and the preparation method has avery good industrial application prospect.

Owner:暨明医药科技(苏州)有限公司

Processes for Producing Optically Active 1-Substituted 2-Methylpyrrolidine and Intermediate Therefor

InactiveUS20070292926A1Easy to produceLow costOrganic compound preparationOxygen compounds preparation by reductionCompound (substance)Agrochemical

The present invention relates to a process for producing an optically active 1,4-pentanediol by asymmetrically reducing 5-hydroxy-2-pentanone, which is easily available at low cost. The present invention also relates to a process for producing an optically active 1-substituted 2-methylpyrrolidine including sulfonylating the optically active 1,4-pentanediol to convert it to an optically active sulfonate compound, and reacting the compound with an amine. According to the processes of the present invention, an optically active 1,4-pentanediol and an optically active 1-substituted 2-methylpyrrolidine, which are useful as an intermediate for medicines and an intermediate for agricultural chemicals, can be simply produced from an inexpensive starting material.

Owner:KANEKA CORP

Process for producing optically active alcohol and carboxylic acid

It is an object of the present invention to provide a low-cost and efficient industrial process for producing (S)-2-pentanol, (S)-2-hexanol, 1-methylalkylmalonic acid and 3-methylcarboxylic acid with high optical purity. There is provided a process for producing (S)-2-pentanol and (S)-2-hexanol, comprising causing a certain type of microbe or transformed cells, a treatment mixture from the microbe or cells, a culture solution of the microbe or cells and / or a product of crude purification or purification of a carbonyl reductase fraction obtained from the microbe or cells to act on 2-pentanone and 2-hexanone, respectively.

Owner:API CO LTD

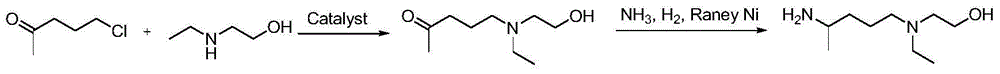

Synthetic method of 5-(N-ethyl-N-2-ethylol amine)-2-amylamine

InactiveCN104803859AImprove conversion rateSimple and fast operationOrganic compound preparationAmino-hyroxy compound preparationHydrogen pressureSolvent

The invention discloses a synthetic method of 5-(N-ethyl-N-2-ethylol amine)-2-amylamine. The method comprises the following steps: (1) the preparation of a catalyst, to be specific, dispersing and dissolving nitrate into an organic solvent, adding oxide or nanopowder of carbonate into the organic solvent, after ultrasonic stirring, evaporating the organic solvent to dryness, carrying out vacuum drying and grinding the dried solvent into fine powder to obtain the catalyst; (2) adding xylene, 5-chlorine-2-pentanone and N-ethylethanolamine in a reaction flask in sequence, stirring the materials, adding the prepared catalyst, heating the flask to increase the temperature till reflux occurs, cooling the heated materials to room temperature, filtering the materials to obtain a filtrate, fractionating the filtrate to obtain 5-(N-ethyl-N-2-ethylol amine)-2-pentanone; (3) putting 5-(N-ethyl-N-2-ethylol amine)-2-pentanone in a hydrogenation flask, adding aminomethanol and raney nickel to perform reaction under hydrogen pressure; after the reaction, displacing the hydrogen and ammonia in the system with nitrogen, filtering the reaction liquid to obtain a filtrate, fractionating the filtrate to obtain 5-(N-ethyl-N-2-ethylol amine)-2-amylamine. The method is high in conversion rate, simple and convenient to operate, high in yield, low in cost, easy for industrial production, safe and environment-friendly.

Owner:WUHAN RUIKAIXING SCI & TECH

Method for preparing 4-methyl-4-hydroxyl-2-pentanone by using solid base as catalyst

InactiveCN101659604AAddress governance issuesImprove conversion ratePhysical/chemical process catalystsOrganic compound preparationDistillationSolid base

The invention discloses synthesis of a novel catalyst and an application method thereof in catalyzing condensation of acetone and hydroxyaldehyde. The method comprises the following steps: adding acetone into a distillation kettle connected with a reactor and an apparatus for refluxing to remove water; then adding little catalyst into the reactor, carrying out reflux reaction for a certain time ata certain temperature when mixing, sampling to analyze; when the reaction is balanced, ending the reaction to obtain the product in the reaction kettle. The substance in the reactor is material acetone that is not adequately reacted and can be used as the reactant of next batch of reaction.

Owner:NANJING INST OF TECH

Preparation method of 2-chloro-1-(1-chlorocyclopropyl) acetone

InactiveCN109748783AShort reaction pathShort reaction cycleOrganic compound preparationCarbonyl compound preparationChemical synthesisChloride

The invention relates to the technical field of chemical synthesis, and particularly discloses a preparation method of 2-chloro-1-(1-chlorocyclopropyl) acetone. The preparation method comprises the following steps: enabling alpha-acetyl-gamma butyrolactone and hydrochloric acid to have an open-loop decarboxylic reaction to obtain 5-chloro-2-pentanone; adding the 5-chloro-2-pentanone and a catalystinto an alkaline solution, implementing a cyclization reaction, obtaining cyclopropyl methyl ketone; implementing a chlorination reaction with a chloride agent to obtain the 2-chloro-1-(1-chlorocyclopropyl) acetone. The reaction steps of the provided method are less, the reaction period is short, the yield is more than 70%, and the content of the 2-chloro-1-(1-chlorocyclopropyl) acetone in a product is more than 95%.

Owner:HEBEI CHENGXIN

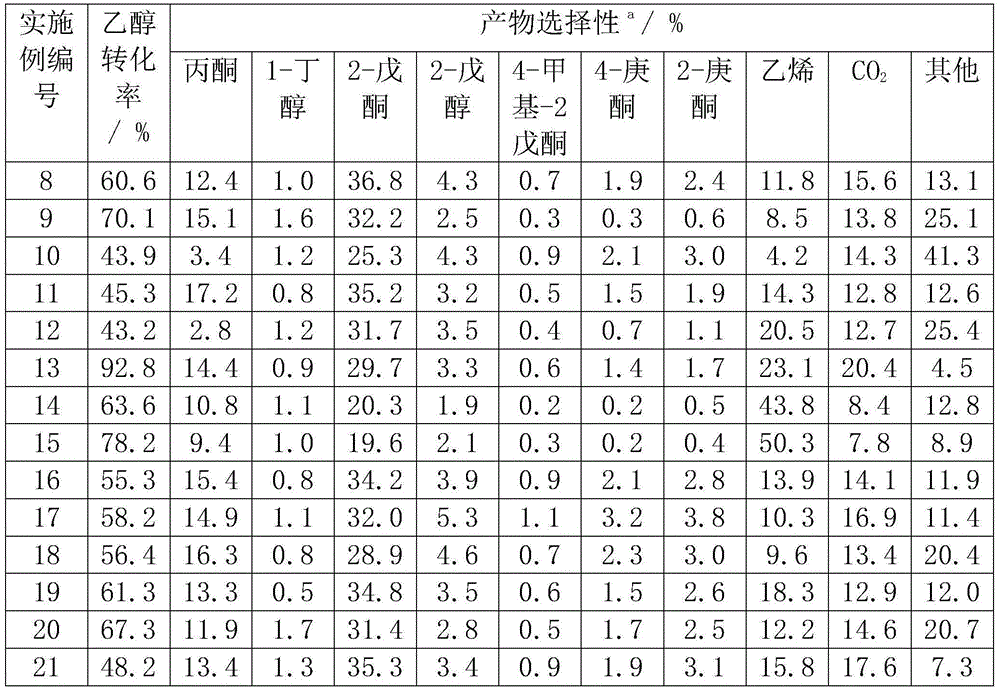

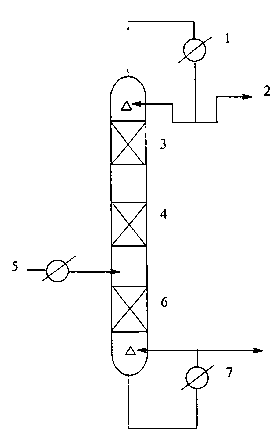

Method of preparing 2-pentanone from ethanol

ActiveCN106478386ARaw materials are cheap and easy to getEasy to prepareOrganic compound preparationCarbonyl compound preparationFixed bedReaction temperature

The invention relates to a method of preparing 2-pentanone from ethanol. According to the method, CeO2 is taken as the catalyst, in a fixed bed reactor, in an inert gas atmosphere, ethanol is taken as the raw material, reactions are carried out at a temperature of 200 to 600 DEG C under a normal pressure; the liquid hourly space velocity (LHSV) of the reactions is 0.1-6.0 g<cat><-1>h<-1>, and the gas space velocity of the reactions is 2000 to 8000 mL.g<cat><-1>h<-1>. The method can efficiently convert cheap ethanol into 2-pentanone in one step. The ethanol conversion rate can reach 92.8%. The selectivity of 2-pentanone is 36.8%. Moreover, the used catalyst raw materials are cheap and easily-available, the preparation method is simple, a normal pressure reaction technology is adopted, the operation is easy, and the method can be applied to the industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Synthetic method of 3, 5-dichloro-2-pentanone

ActiveCN105461533AProcess safety and environmental protectionEasy to industrializeCarbonyl compound separation/purificationPreparation from heterocyclic compoundsRetention timeEthyl Chloride

The invention discloses a synthetic method of 3, 5-dichloro-2-pentanone. Under the action of salt and a phase transfer catalyst, alpha-chloro-alpha'-acetyl-gamma-butyrolactone, which is used as a raw material, reacts with hydrochloric acid; and then, 3, 5-dichloro-2-pentanone is synthesized through a continuous steam distillation method. According to the characteristic of great boiling point difference between the raw material and the product, the technical scheme of reacting while separating is adopted. Therefore, purity of the product is raised, yield is greatly increased, and the hydrochloric acid solution in the reaction can be recycled. By adding the phase transfer catalyst, reaction speed of the raw material can be raised, and accumulation of the raw material in the reaction system is reduced. By adding salt, reaction distillation temperature can be increased, product separation speed is accelerated, and retention time of the raw material and the product in the reaction system is shortened. Thus, side reaction is minimized, and selectivity is enhanced.

Owner:大连科铎环境科技有限公司

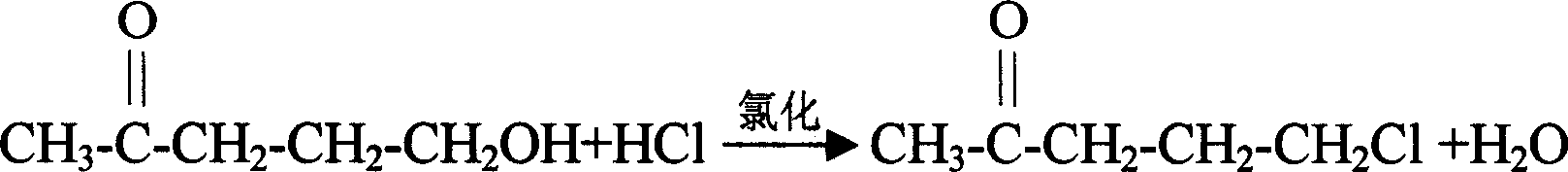

Preparation method of cyclopropyl acetylene important intermediate cyclopropylmethyl ketone

ActiveCN103232333AReduce generationImprove responseOrganic compound preparationChemical industryReaction temperatureReactive distillation

The invention relates to a preparation method of a cyclopropyl acetylene important intermediate cyclopropylmethyl ketone. The invention adopts a technical scheme that: 5-chloro-2-pentanone is adopted as an initial raw material; under an alkaline condition and in a multistage reactor, a reaction is carried out with a reactive distillation technology, wherein a reaction temperature is controlled at 90-150 DEG C; and cyclopropylmethyl ketone is obtained in the multistage reactor. According to the invention, the reaction is carried out with the reactive distillation technology. Reaction and distillation are carried out simultaneously, such that the reaction process is simplified. Therefore, the operation is simple, and reaction can be continuously carried out. A cyclization reaction is carried out in the multistage reactor, such that space-time yield and selectivity of the reaction are improved. The reaction is carried out with the reactive distillation technology, such that reaction product is continuously removed, and reaction conversion rate is greatly improved. Because reaction selectivity and conversion rate are improved, three-waste production is greatly reduced, original steps of stratification and extraction are eliminated, and cost is reduced. The method is a green synthesizing process.

Owner:JIANGSU YUXIANG CHEM

Efficient synthesizing method of prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride

InactiveCN108794313ANothing producedShort reaction timeOrganic compound preparationCarbonyl compound preparationAlkalinitySodium methoxide

The invention discloses an efficient synthesizing method of prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride and relates to the technical field of the synthesis of the prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride. The method has the advantages that the strong alkalinity of sodium methoxide is utilized to allow raw material 3,5-dichloro-2-pentanone to have ring-closing reaction, the reaction process can be completed under normal temperature and normal pressure, the mole yield of the prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride can reach 95%,the synthesized prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride is pure, basically no tar is generated, the prothioconazole intermediate 1-acetyl-1-cyclopropanoyl chloride can be usedfor next-step reaction after direct layering, the method is short in reaction time, complete reaction only needs five minutes, and catalyst adding is not needed.

Owner:YANGZHOU TIANCHEN FINE CHEM

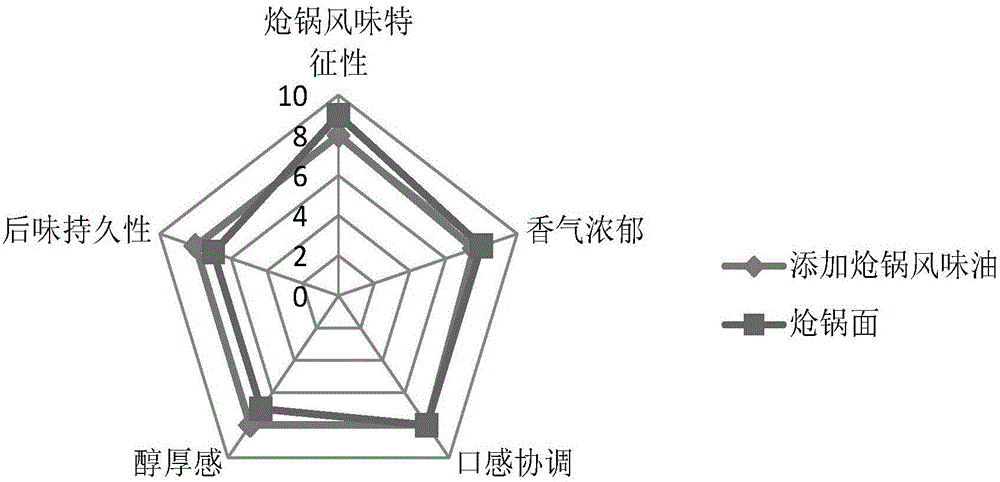

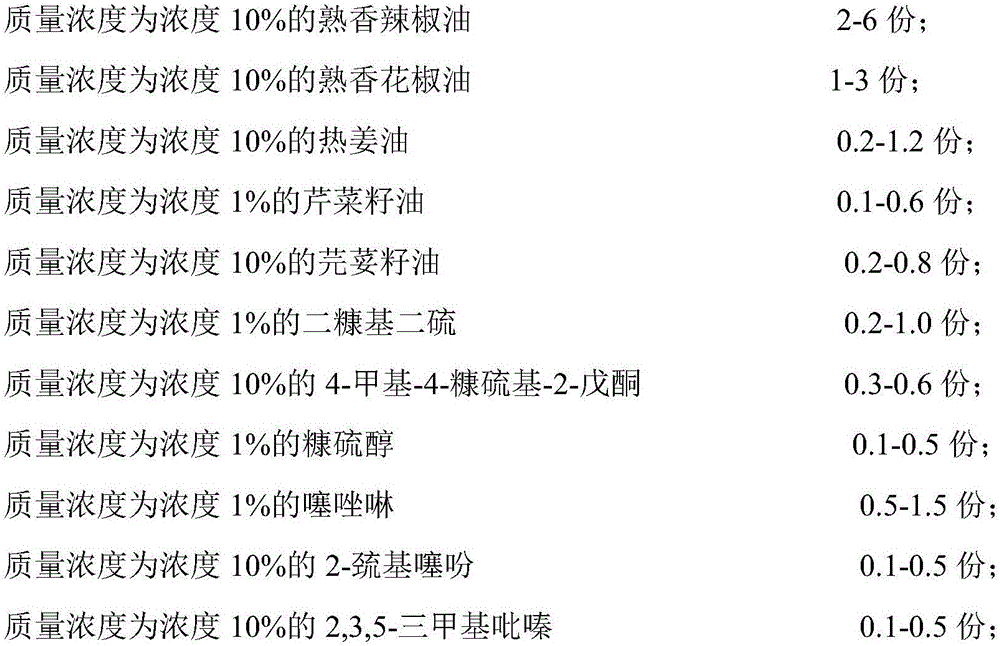

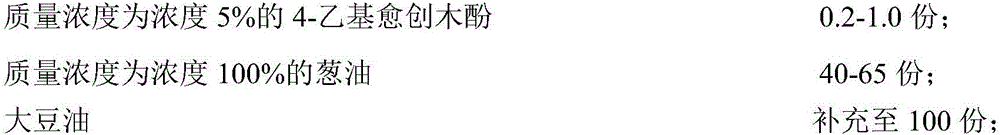

Stir-frying flavor oil and preparation method thereof

InactiveCN106343044AStrong sense of food conditioningMeet food needsEdible oils/fatsCoriander seedPyrazine

The invention relates to stir-frying flavor oil, which is prepared from the following components in parts by weight: 2-6 parts of cooked spicy chilli oil, 1-3 parts of cooked spicy zanthoxylum oil, 0.2-1.2 parts of hot ginger oil, 0.2-0.8 part of coriander seed oil, 0.3-0.6 part of 4-methyl-4-furfurylthio-2-pentanone, 0.1-0.5 part of 2-thiol thiophene, 0.1-0.5 part of 2, 3, 5-trimethyl pyrazine, 0.1-0.6 part of celery seed oil, 0.2-1.0 part of difurfuryl disulfide, 0.1-0.5 part of furfuryl mercaptan, 0.5-1.5 parts of thiazoline, 0.2-1.0 part of 4-ethyl guaiacol, 40-65 parts of scallion oil and the balance of soybean oil, wherein the sum of the parts by weight is 100 parts. The stir-frying flavor oil has a unique flavor, produced by stir-frying food materials by using high-temperature hot oil, of stir-frying, has spicy, sauce aroma and burnt fragrance at the same time, is rich and permeant in fragrance and natural in flavor, and has strong catering regulation feeling, thus being capable of meeting the eating demand of consumers.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com