Method of preparing 2-pentanone from ethanol

A technology of ethanol and pentanone, which is applied in the field of 2-pentanone preparation, can solve the problems of complex catalyst components and difficult regulation, and achieve the effect of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

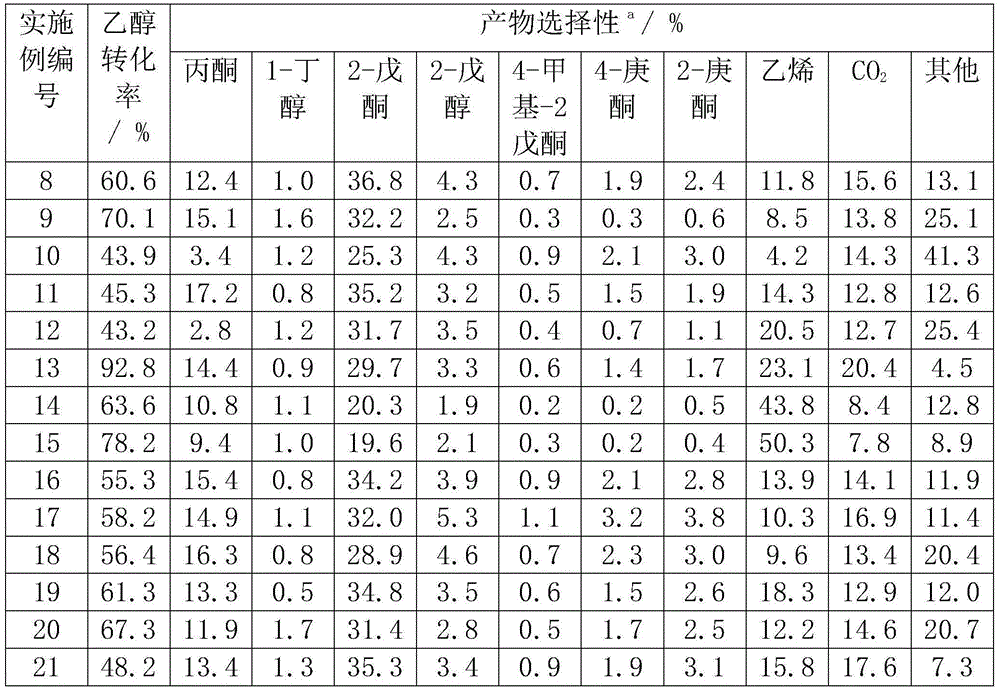

Examples

Embodiment 1

[0023] Example 1: Using cerium nitrate as the precursor of cerium and ammonia water as the precipitating agent, the catalyst was prepared by precipitation method, the specific process is as follows. Accurately formulated to contain 0.5mol·L -1 200mL of cerium nitrate solution, ammoniacal liquor (26wt%) was added dropwise in the cerium nitrate solution under vigorous stirring, and the pH of the solution was adjusted to 11. Wash and dry overnight. Catalyst 1 was then prepared by calcining (550° C., Air, 4 h), tableting, crushing, and sieving (40-60 mesh). Using Micromeritics ASAP2010 physical adsorption instrument to measure the specific surface area of the sample, the nitrogen adsorption and desorption experiment shows that the specific surface area of the material is 48m 2 g -1 .

Embodiment 2

[0024] Embodiment 2: The precursor of adjusting cerium is ammonium cerium nitrate, and the concentration of ammonium cerium nitrate is 2.0mol L -1 , the pH of the system was 10, the calcination temperature was 500° C., and other conditions were the same as in Example 1 to prepare catalyst 2. Nitrogen adsorption and desorption experiments show that the specific surface of the material is 39m 2 g -1 .

Embodiment 3

[0025] Embodiment 3: The precursor of adjusting cerium is cerium sulfate, and the concentration of cerium sulfate is 1.0mol L -1 Precipitating agent is potassium hydroxide, and other conditions are with example 1, make catalyst 3. Nitrogen adsorption and desorption experiments show that the specific surface of the material is 43m 2 g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com