Preparation method of cyclopropyl acetylene important intermediate cyclopropylmethyl ketone

A technology of cyclopropyl methyl ketone and cyclopropyl acetylene is applied in the field of preparation of cyclopropyl methyl ketone, an important intermediate of cyclopropyl acetylene, and can solve the problems of low yield, difficult to obtain raw materials, high cost of raw materials, etc. The effect of improving reaction selectivity and conversion rate, improving space-time yield and selectivity, and improving reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

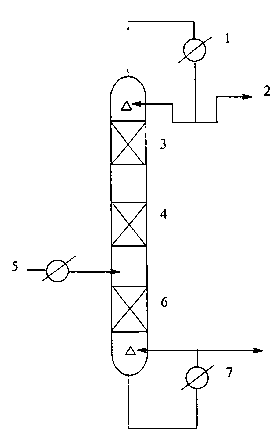

Embodiment 1

[0027] See the attached figure: After the preheated 5-chloro-2-pentanone and alkaline aqueous solution (5) enter the tower from the middle of the tower, they pass through the reaction separation section (6) and the reaction section (4), and a ring closure reaction occurs to form a ring Propyl methyl ketone. Since the generated cyclopropylmethyl ketone has a boiling point (110°C) lower than that of 5-chloro-2-pentanone, it is distilled out of the reaction section (4), so that the balance of the cyclization reaction shifts towards the generation of cyclopropylmethyl The direction of the ketone moves. As the reaction proceeds, the cyclopropyl methyl ketone is continuously distilled off, then passes through the separation section (3), and is collected from the top 2 of the tower to obtain the cyclopropyl methyl ketone product. The raw materials that have not been completely converted through the reaction section are separated by the reaction separation section (6), and then heate...

Embodiment 2

[0031] In a tower reactor with a length of 1m, the separation section (3) and the reaction section (4) are filled with 40g of glass spring rectification tower packing respectively, and the reaction separation section (6) is filled with 25g of glass spring rectification tower packing. 5-Chloro-2-pentanone and 30% KOH solution are mixed in a 1:2 mol ratio and then fed at a certain flow rate in the middle of the tower, staying at 150°C for 1 hr, and can be collected at the top of the tower to obtain cyclopropyl methyl ketone , content 99.2%, yield 95.6%.

[0032]

Embodiment 3

[0034] In a tower reactor with a length of 1m, the separation section (3) and the reaction section (4) are filled with 40g of glass spring rectification tower packing respectively, and the reaction separation section (6) is filled with 25g of glass spring rectification tower packing. 5-Chloro-2-pentanone and 30% NaOH solution are mixed in a 1:1 mol ratio and then fed at a certain flow rate in the middle of the tower, staying at 90°C for 2 hours, and can be collected at the top of the tower to obtain cyclopropyl methyl ketone , content 99.4%, yield 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com