Process for preparing cyclopropyl methyl ketone

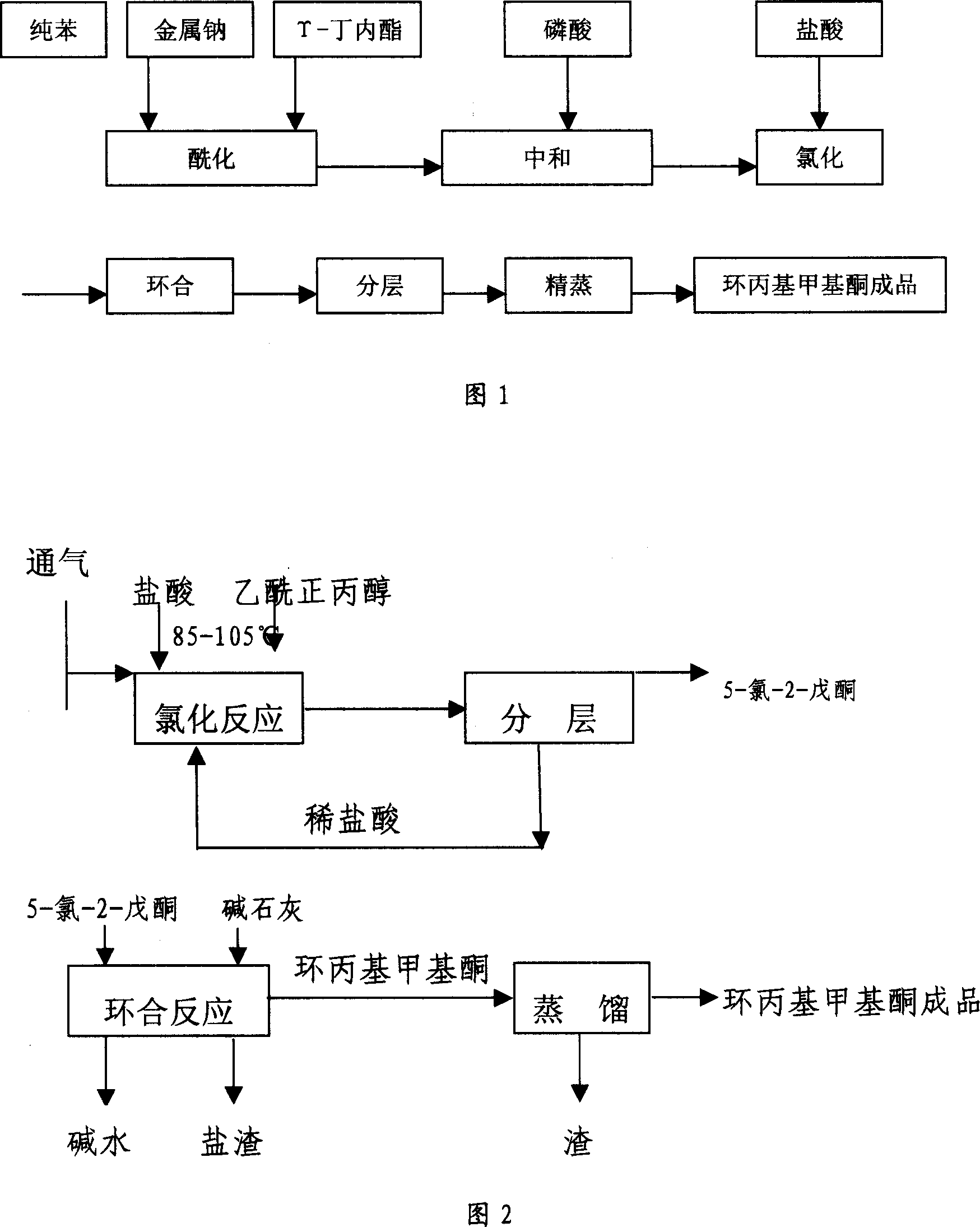

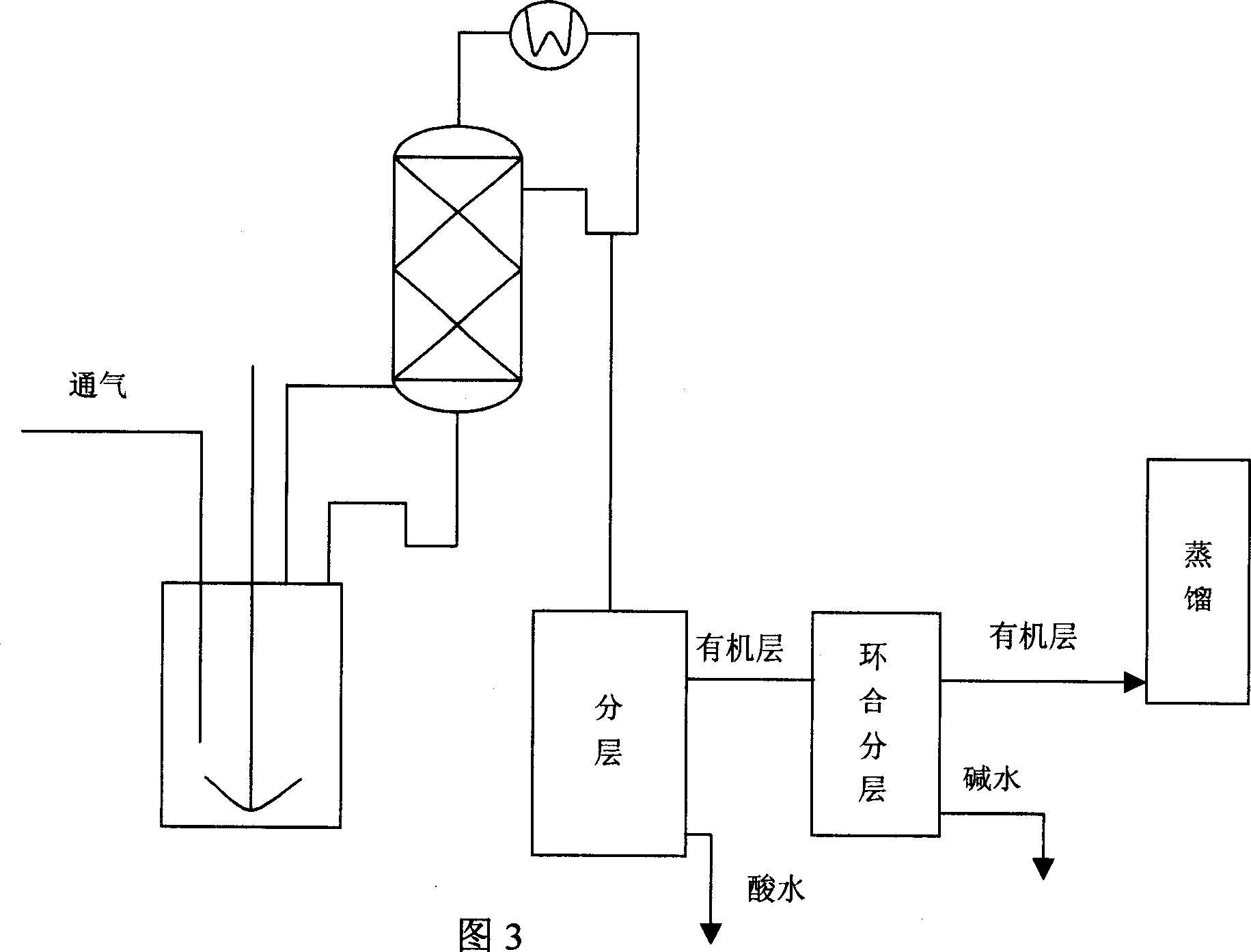

A technology of cyclopropyl methyl ketone and pentanone, which is applied in the field of preparation of cyclopropyl methyl ketone, can solve the problems of difficult control of side reactions, low raw material utilization rate, large material consumption, etc., and achieve easy control of reactions, Effects of improving utilization rate and shortening production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

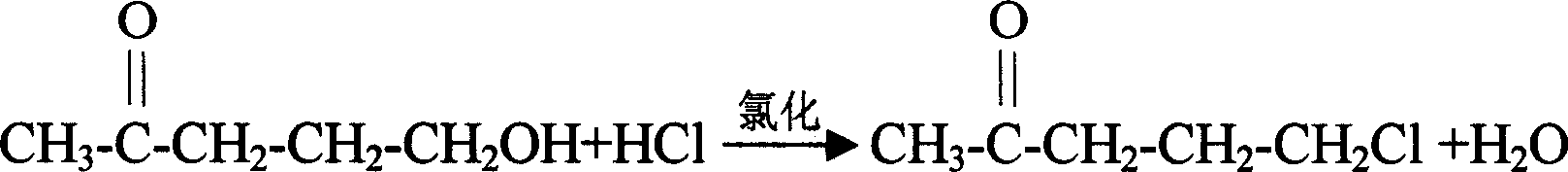

[0027] Example 1: Synthesis of 5-chloro-2-pentanone

[0028] Add 193g of 30% HCl (the amount of HCl is 1.5mol) into a 1000ml three-necked flask, stir and heat to 90°C, start to add 102g (1mol) of acetyl n-propanol dropwise, and complete the dropwise addition within one hour. Continue to keep the temperature for 2 hours, cool, separate the organic layer, and vacuum distill to obtain 105 g (yield: 87.4%) of a light yellow transparent liquid product, with a purity of 98.2% by GC analysis.

example 2

[0029] Example 2: Synthesis of Cyclopropyl Methyl Ketone

[0030] Add 120.6g (purity 98.2%, 1mol) of 5-chloro-2-pentanone to a solution composed of 70.6g soda lime and 50g water, heat to 65-75°C (preferably 70°C), and stir for 1 hour, Insulated for 2 hours, separated into layers, 90 g of the crude product in the organic layer was separated, 86 g was processed, and 72 g of pure product was obtained by distillation (yield 86.6%). The purity by GC analysis was 99.4%, and it was a colorless transparent liquid. Soda lime is composed of 5-10% NaOH and 90-95% CaO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com