High-energy welding-cutting gas

A high-energy welding and cutting gas technology, used in welding and cutting gas. It can solve the problems of high energy consumption, environmental pollution of acetylene gas, and high cost, and achieve the effect of reducing environmental pollution, improving cutting quality, and reducing gas and oxygen consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Specific embodiment one: this embodiment is that a kind of high-energy welding and cutting gas is mixed by nano-combustion accelerator and natural gas, wherein the volume ratio of the quality of nano-combustion accelerator and natural gas is (1kg~2kg): 100m 3 .

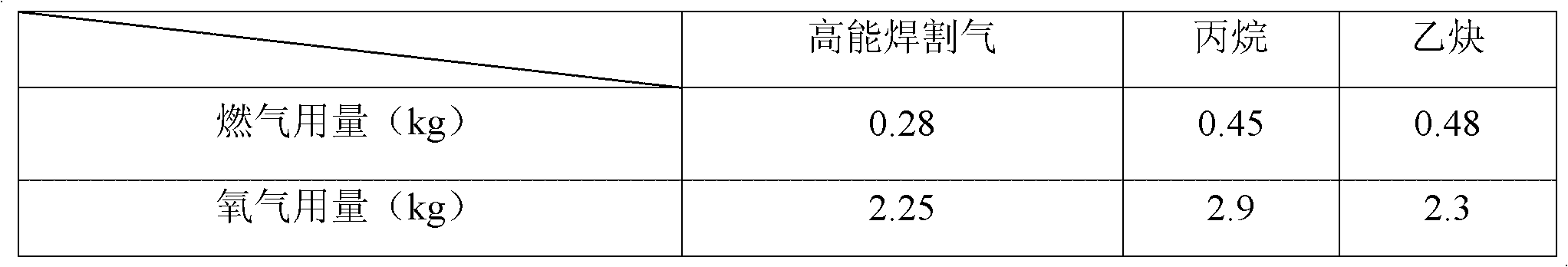

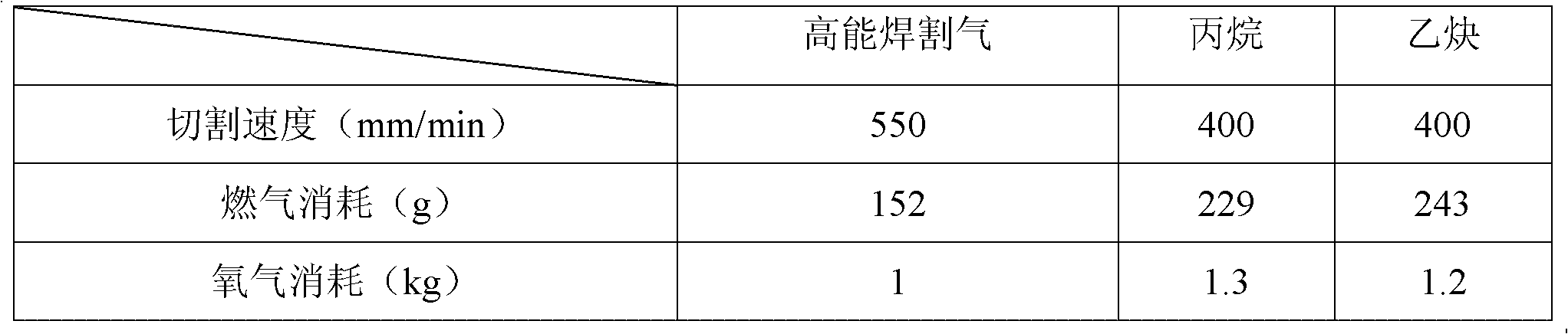

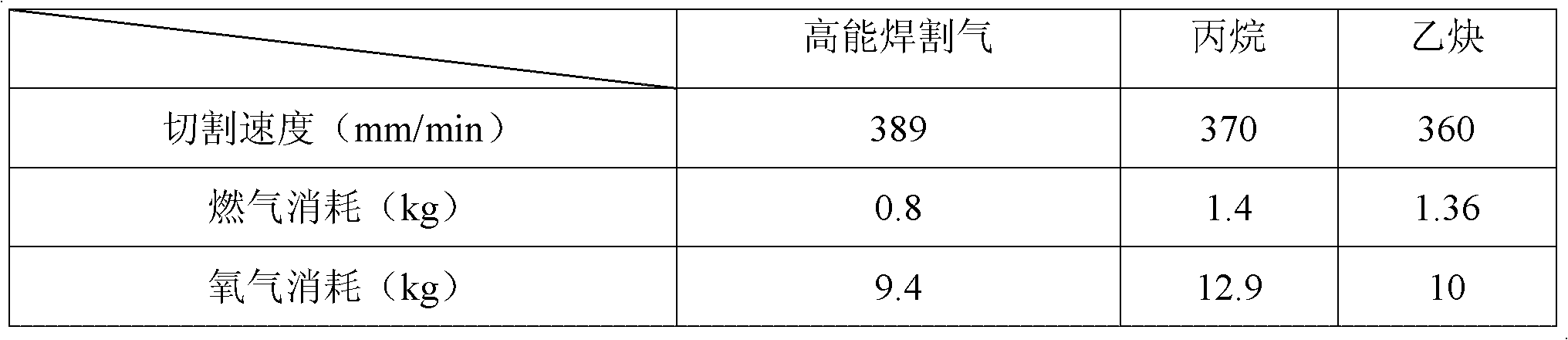

[0008] The invention uses a nano-combustion accelerator to concentrate the natural gas flame, raise the flame temperature, achieve the use effect of acetylene gas, improve the cutting quality of the workpiece, ensure safety without tempering, and greatly reduce the consumption of gas and oxygen. A bottle of 3 cubic meters of high-energy welding and cutting Gas can replace a bottle of 3 kg acetylene gas, the cost is only 1 / 5 of acetylene gas, and the high-energy welding and cutting gas only needs to be natural gas, which reduces environmental pollution compared with acetylene gas.

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nano-combustion accelerator consists of 20 to 30 parts of aviation kerosene, 10 to 15 parts of ethanol, 10 to 25 parts of n-butanol, 12-15 parts of ethyl acetate, 10-15 parts of ethylene glycol monobutyl ether, 5-10 parts of tert-butyl hydroperoxide, 1.8-2.2 parts of 2-pentanone, 0.4-0.6 parts of nano-alumina, 0.4-0.6 It is prepared by mixing one part of nano iron oxide and 1.8 to 2.2 parts of borane-pyridine complex. Others are the same as in the first embodiment.

[0010] The combustion process is a typical non-isothermal reaction, and the reactants at room temperature change into products immediately after entering the flame. Since the process is completed instantaneously, it can be approximately considered that the reaction is completed under adiabatic conditions, and all the heat released by the reaction is used to heat the product and the inert gas doped in the rea...

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the nano-combustion accelerator is composed of 28 parts of aviation kerosene, 15 parts of ethanol, 12 parts of n-butanol, 15 parts of Ethyl acetate, 15 parts ethylene glycol monobutyl ether, 10 parts tert-butyl hydroperoxide, 2 parts 2-pentanone, 0.5 parts nano-alumina, 0.5 parts nano-iron oxide, and 2 parts borane-pyridine complex mixed. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com