Angle grinder adjusting rack capable of being installed on machine tool

An angle grinding and machine tool technology, applied in the direction of grinding machine parts, grinding frames, grinding machines, etc., can solve problems such as unfavorable long-term development of enterprise production and school research, occupying a large space, increasing workpiece costs, etc., to improve the workpiece. The effect of quality and finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

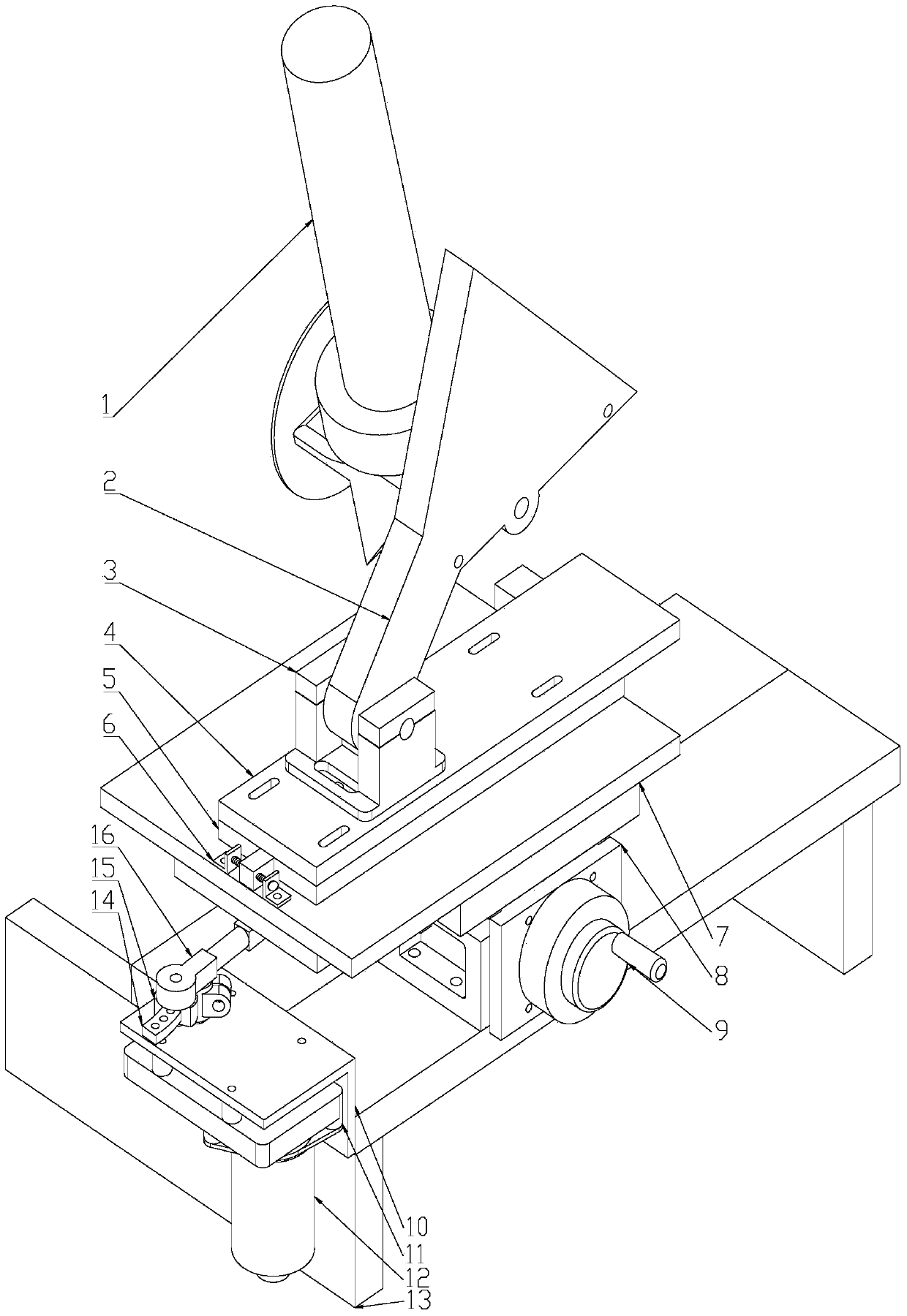

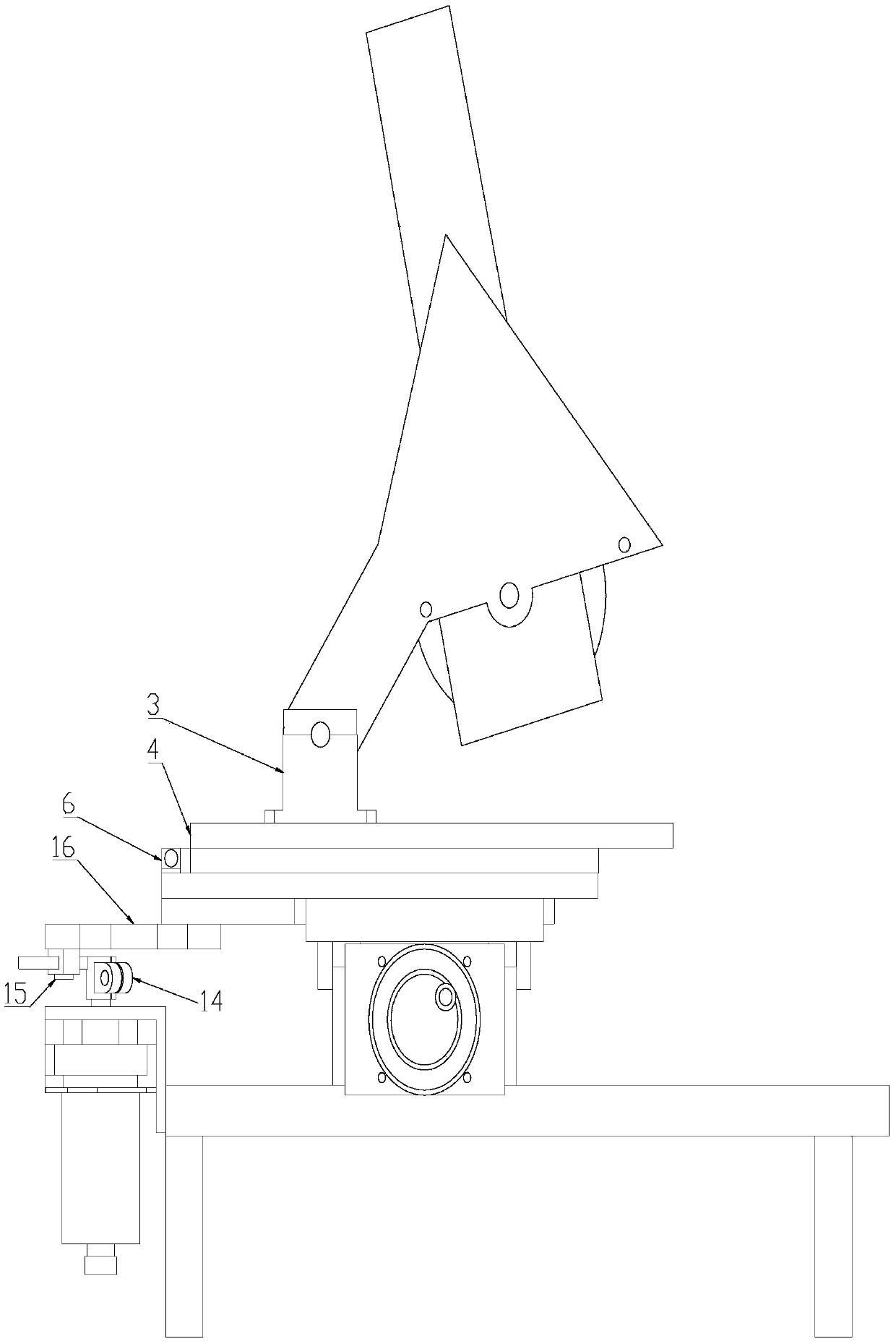

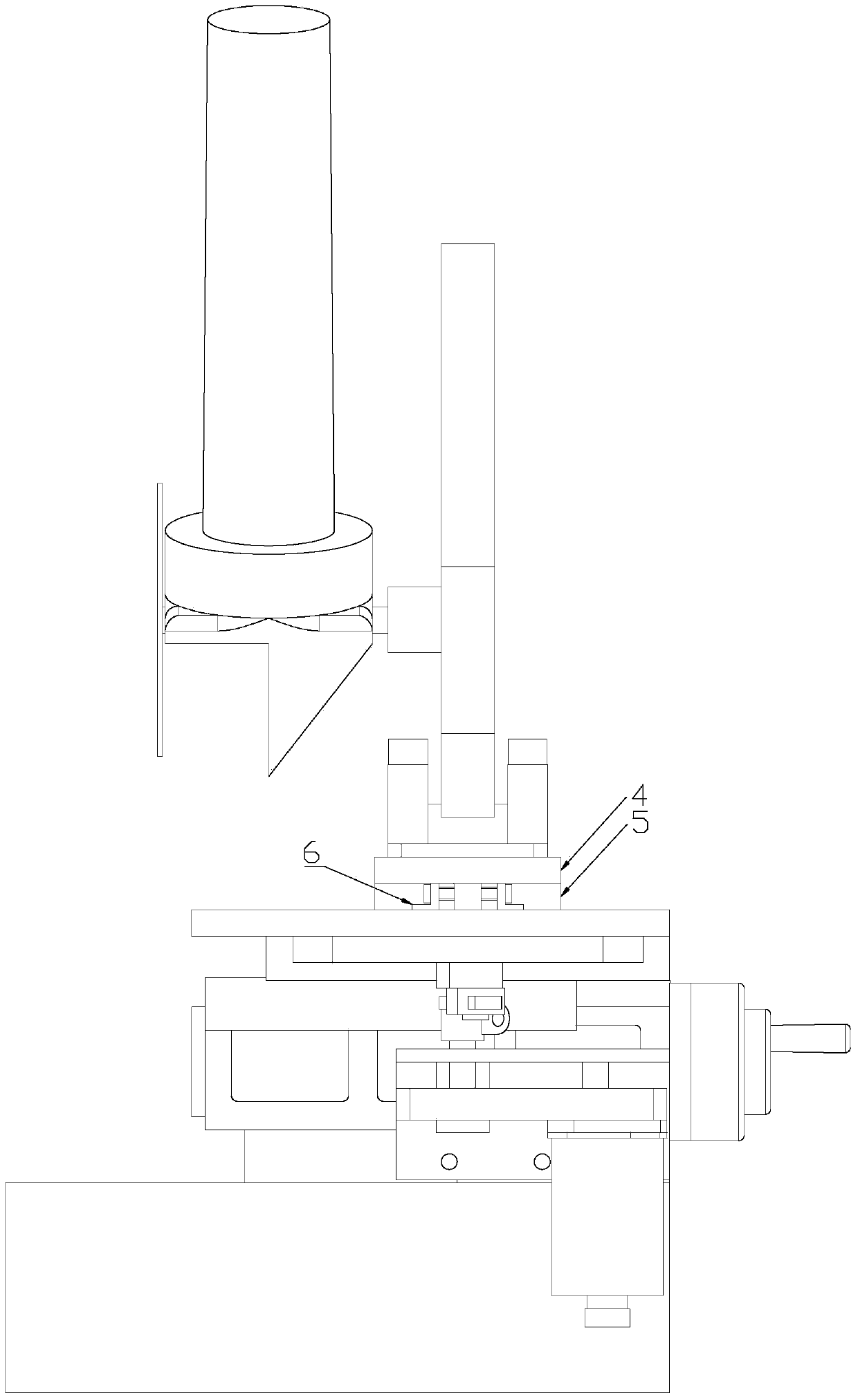

[0014] like figure 1 , figure 2 and image 3 As shown, an angle grinder adjustment stand that can be installed on a machine tool includes a base for fixed support, a power device and a power transmission device for supporting the reciprocating motion of the angle grinder, and is used as an angle grinder for reciprocating motion and The cross slide device for the moving body, the rotation control device for adjusting the working angle of the angle grinder, the displacement control device for adjusting the left and right working positions of the angle grinder, the angle grinder fixing device for fixing and supporting the angle grinder and the angle grinder; The power device is fixed on the left side plate of the base, and is connected with the cross slide device through the power transmission device. The cross slide device is fixed directly above the base, and the rotation control device is fixed on the cross slide through a shaft connection. The cover plate of the table devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com