Stir-frying flavor oil and preparation method thereof

A technology for flavor oil and cooking pot, which is applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of no aroma, blackening, affecting taste, etc., achieving a simple preparation method, improving production efficiency, and being widely used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

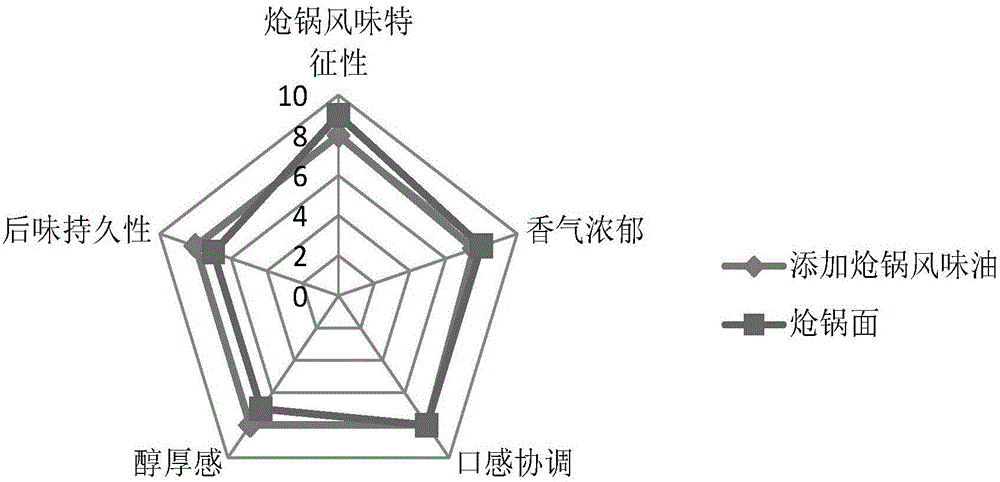

Image

Examples

Embodiment 1

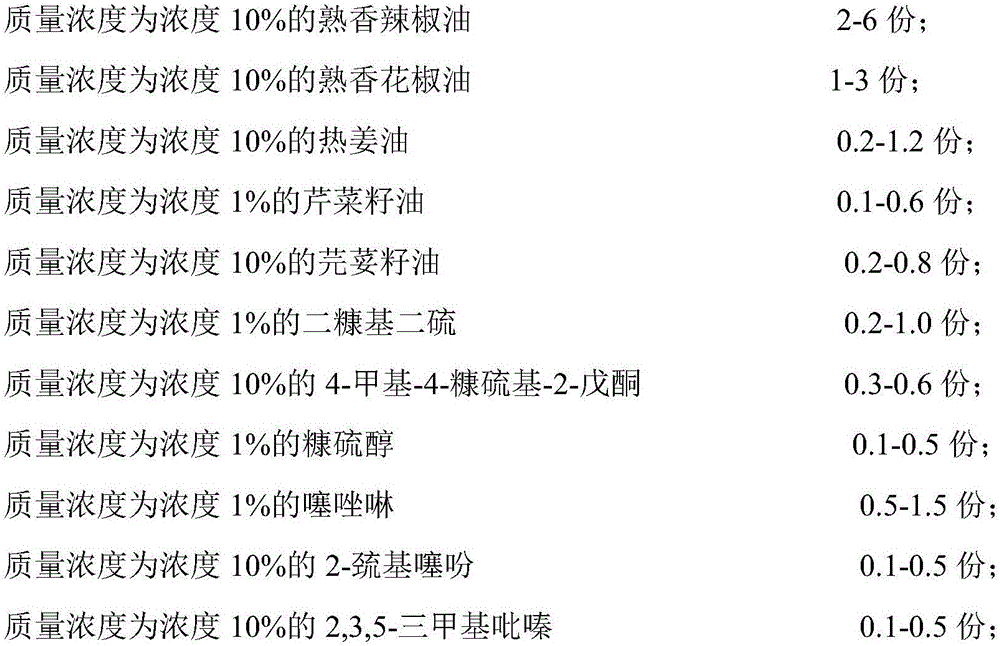

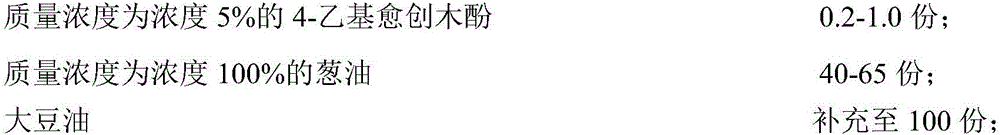

[0023] A hot pot flavor oil, its composition and parts by weight are as follows:

[0024]

[0025] Among them, the cooked fragrant chili oil, cooked fragrant pepper oil, hot ginger oil, celery seed oil, coriander seed oil, difurfuryl disulfide, 4-methyl-4-furfurylsulfanyl-2-pentanone, bran The solvents of mercaptan, thiazoline, 2-mercaptothiophene, 2,3,5-trimethylpyrazine and 4-ethylguaiacol are all soybean oil, and the soybean oil is first grade soybean oil.

[0026] The preparation method of described scallion oil is as follows:

[0027] ⑴Wash shallots, green onions, and onions, chop them, and mix them evenly according to the mass ratio of shallots: green onions: onions: 6:1:0.1, and set aside;

[0028] (2) Add the mixture of chives, green onions and onions in step (1) to soybean salad oil, the mass ratio of the mixture to soybean salad oil is 1:1, stir evenly, heat to 140°C-150°C, then naturally cool to room temperature, Pass through a 200-mesh filter cloth to get scal...

Embodiment 2

[0032] A hot pot flavor oil, its composition and parts by weight are as follows:

[0033]

[0034] Among them, the cooked fragrant chili oil, cooked fragrant pepper oil, hot ginger oil, celery seed oil, coriander seed oil, difurfuryl disulfide, 4-methyl-4-furfurylsulfanyl-2-pentanone, bran The solvents for mercaptan, thiazoline, 2-mercaptothiophene, 2,3,5-trimethylpyrazine and 4-ethylguaiacol were soybean oil.

[0035] The preparation method of described scallion oil is as follows:

[0036] ⑴ Clean shallots, shallots and onions, chop them, and mix them evenly according to the mass ratio of shallots: shallots: onions: 7:2:0.6, and set aside;

[0037] ⑵Add the mixture of shallots, green onions and onions in step ⑴ to soybean salad oil, the mass ratio of the mixture to soybean salad oil is 1:3, stir evenly, heat to 150°C-160°C, then naturally cool to room temperature, Pass through a 200-mesh filter cloth to get scallion oil.

[0038] A method for preparing the above-mention...

Embodiment 3

[0041] A hot pot flavor oil, its composition and parts by weight are as follows:

[0042]

[0043] Among them, the cooked fragrant chili oil, cooked fragrant pepper oil, hot ginger oil, celery seed oil, coriander seed oil, difurfuryl disulfide, 4-methyl-4-furfurylsulfanyl-2-pentanone, bran The solvents of mercaptan, thiazoline, 2-mercaptothiophene, 2,3,5-trimethylpyrazine and 4-ethylguaiacol are all soybean oil, and the soybean oil is first grade soybean oil.

[0044] The preparation method of described scallion oil is as follows:

[0045] ⑴ Clean shallots, shallots and onions, chop them, and mix them evenly according to the mass ratio of shallots: shallots: onions: 8:3:1, and set aside;

[0046] (2) Add the mixture of chives, green onions and onions in step (1) to the soybean salad oil, the mass ratio of the mixture to the soybean salad oil is 1:5, stir evenly, heat to 160°C-170°C, then naturally cool to room temperature, Pass through a 200-mesh filter cloth to get scall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com