Mixed stewed pork essence and making method thereof

A pork flavoring and blending technology, applied in food preparation, application, food science and other directions, can solve the problems of impure aroma, low flavor simulation, unnatural flavor, etc., to achieve rich and delicate aroma, good application effect, and realistic aroma Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

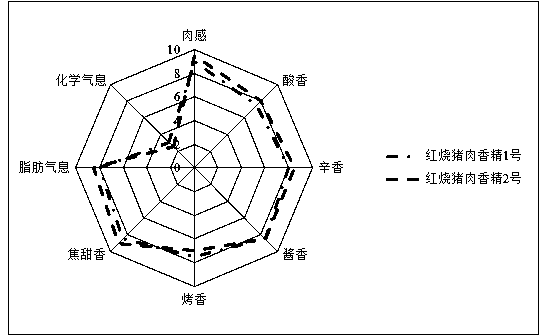

Image

Examples

Embodiment 1

[0040] Embodiment 1 A kind of deployment type braised pork essence of the present invention, is made up of the following composition of mass percentage:

[0041] 10% concentration of furanone 1.2-1.5%

[0042] 10% ethyl maltol 1.2-1.5%

[0043] 2-Acetylpyrazine at 10% concentration 0.3-0.5%

[0044] Methylcyclopentenolone at 10% concentration 0.7-1.0%

[0045] Difurfuryl sulfide at 1% concentration 0.1-0.15%

[0046] 3-Mercapto-2-butanol at 10% concentration 0.8-1.2%

[0047] 2-Methyl-3-furanthiol at 10% concentration 0.3-0.5%

[0048] 1% bis(2-methyl-3-furanthiol)-disulfide 0.8-1.0%

[0049] Methyl(2-methyl-3-furanthiol)-disulfide at 10% concentration 0.1-0.2%

[0050] Acetic acid at 10% concentration 0.08-0.1%

[0051] 3-Mercapto-2-butanone at a concentration of 1% 0.8-1.2%

[0052] 10% concentration of 3-methylthiopropanal 1.0-1.5%

[0053] Tetrahydrothiophen-3-one at 10% concentration 0.2-0.25%

[0054] 2,3,5-trimethylpyrazine at 1% concentration 0.4-0.6%

[005...

Embodiment 2

[0074] The raw material formula is shown in Table 1

[0075] Mass percent concentration is 10% furanone 1.20% Mass percent concentration is 10% ethyl maltol 1.20 % The mass percent concentration is 10% 2-acetylpyrazine 0.40 % Mass percent concentration is 10% methylcyclopentenolone 0.80 % The mass percent concentration is 10% bisfurfuryl sulfide 0.10 % Mass percentage concentration is 10% 3-mercapto-2-butanol 1.00 % The mass percent concentration is 10% 2-methyl-3-furanthiol 0.35% The mass percent concentration is 1% bis(2-methyl-3-furanthiol)-disulfide 0.85 % The mass percent concentration is 10% methyl (2-methyl-3-furanthiol)-disulfide 0.15 % The mass percent concentration is 10% acetic acid 0.10 % The mass percent concentration is 10% 3-mercapto-2-butanone 1.00 % Mass percent concentration is 10% 3-methylthiopropionaldehyde 1.00 % Mass percent concentration is 10% tetrahydrothiophene-3-one 0.20 ...

Embodiment 3

[0078] The raw material formula is shown in Table 2

[0079] Mass percent concentration is 10% furanone 1.50% Mass percent concentration is 10% ethyl maltol 1.50 % The mass percent concentration is 10% 2-acetylpyrazine 0.50 % Mass percent concentration is 10% methylcyclopentenolone 1.00 % The mass percent concentration is 10% bisfurfuryl sulfide 0.15 % Mass percentage concentration is 10% 3-mercapto-2-butanol 1.00 % The mass percent concentration is 10% 2-methyl-3-furanthiol 0.50 % The mass percent concentration is 1% bis(2-methyl-3-furanthiol)-disulfide 1.00 % The mass percent concentration is 10% methyl (2-methyl-3-furanthiol)-disulfide 0.15 % The mass percent concentration is 10% acetic acid 0.10 % The mass percent concentration is 10% 3-mercapto-2-butanone 1.20 % Mass percent concentration is 10% 3-methylthiopropionaldehyde 1.25 % Mass percent concentration is 10% tetrahydrothiophene-3-one 0.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com