Treatment method of waste water produced by adopting castor oil to prepare decanedioic acid

A treatment method, sebacic acid technology, applied in the field of sebacic acid production wastewater treatment, can solve the problems of low solubility, limited application, strong taste, etc., achieve high treatment efficiency, improve treatment efficiency, and speed up the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in further detail by the following examples.

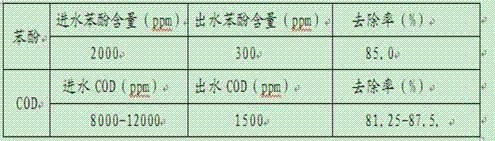

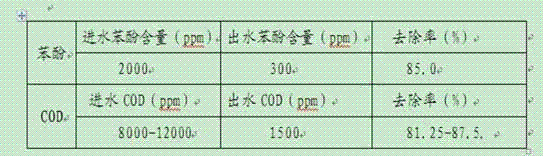

[0026] Firstly, iron filings are added to the oxidation pool, piled up to a certain height (no more than the height of the oxidation pool) to form a fixed bed of solids; then the waste water after removing solid impurities through plate and frame filtration is discharged into the oxidation pool, the inflow of waste water, The effluent is continuous; at the same time, 30% hydrogen peroxide oxidant is added to the oxidation tank, the volume ratio of hydrogen peroxide to waste water is 1:125; the air is sent into the oxidation tank by the fan, and the air accelerates the waste water and hydrogen peroxide on the fixed bed of iron filings and make the mixing uniform and sufficient; finally add sulfuric acid and adjust the pH value to 3.5, iron scraps and sulfuric acid react to generate ferrous sulfate, ferrous sulfate is the active component of the catalyst, and at the same time, the oxygen cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com