Lithium-ion battery electrode prepared by water-based binder

A lithium ion battery, water-based binder technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of accelerating lithium ion conduction rate, polyvinylidene fluoride can not be used as high specific capacity electrode binder, etc. problems, to achieve excellent rate performance and cycle performance, low price, and maintain stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

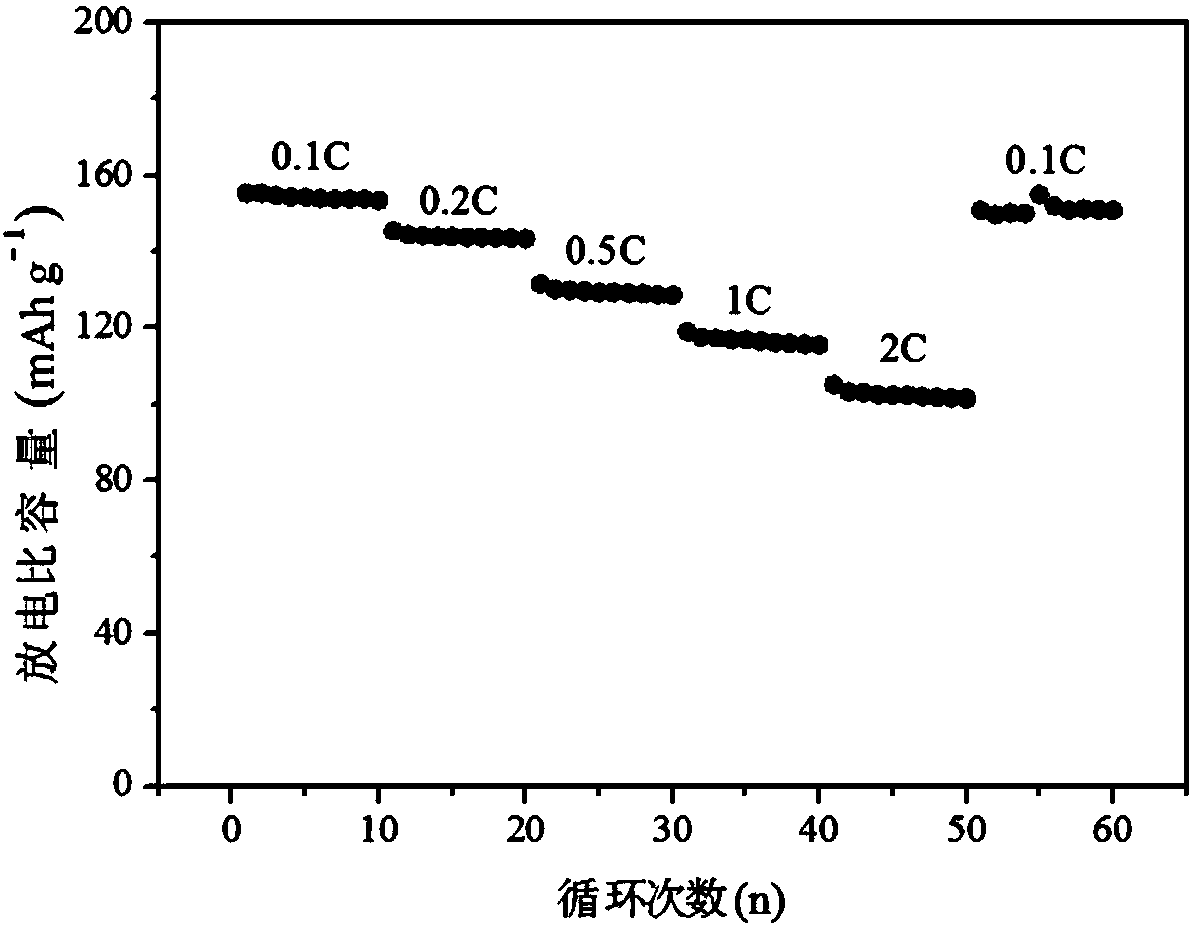

[0023] Coating the positive electrode slurry of the lithium ion battery on an aluminum foil to prepare the positive electrode of the lithium ion battery has a thickness of 50 microns. The weight ratio formula of each raw material in the slurry is: 60 parts by weight of lithium iron phosphate, 15 parts by weight of SP-Li, 7.5 parts by weight of binder, 7.5 parts by weight of sodium carboxymethyl cellulose, and 30 parts by weight of dispersion medium. Among them, the theoretical specific capacity of lithium iron phosphate is 170mAh / g; the binder is styrene / methyl acrylate / styrene block copolymer, and the structure of the block copolymer is R-AA 10 -b-St 15 -b-MA 8000 -b-St 15 ; The dispersion medium is deionized water.

[0024] The lithium-ion battery positive electrode slurry is prepared by the following processing technology: ①Add water to sodium carboxymethyl cellulose and magnetically stir for 60 minutes, put SP-Li and lithium iron phosphate particles into a planetary hig...

Embodiment 2

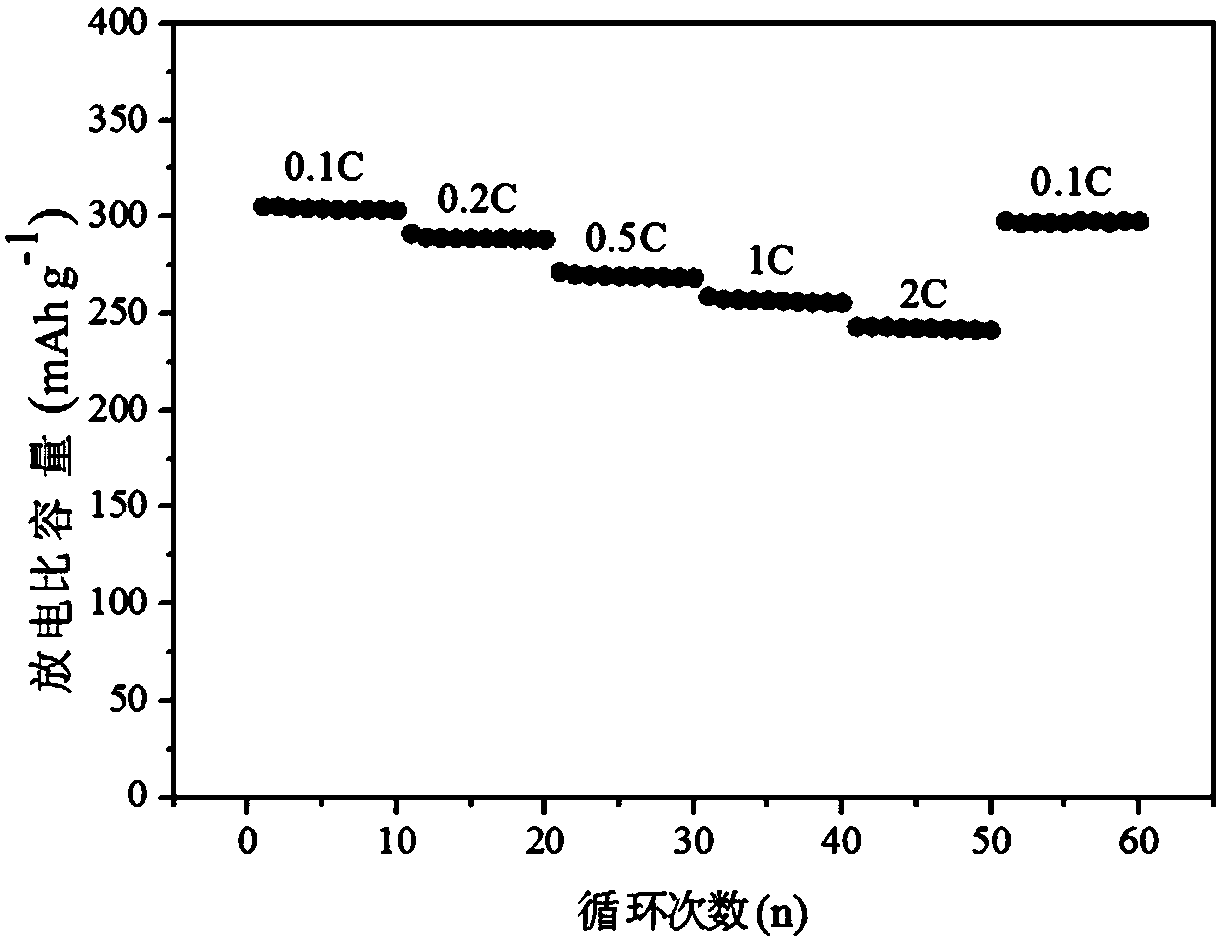

[0027] Coating the negative electrode slurry of the lithium ion battery on the copper foil to prepare the negative electrode of the lithium ion battery has a thickness of 50 microns. The weight ratio formula of each raw material in the slurry is: 60 parts by weight of graphite, 15 parts by weight of Ketjen black, 7.5 parts by weight of binder, 7.5 parts by weight of sodium carboxymethyl cellulose, and 30 parts by weight of dispersion medium. Among them, the theoretical specific capacity of graphite is 372mAh / g; the binder is styrene / methyl acrylate / styrene block copolymer, and the structure of the block copolymer is R-AA 10 -b-St 15 -b-MA 8000 -b-St 15 ; The dispersion medium is distilled water.

[0028]The lithium-ion battery negative electrode slurry is prepared by the following processing technology: ① Add water to sodium carboxymethyl cellulose and magnetically stir for 60 minutes, put Ketjen black and graphite particles into a planetary high-energy ball mill for dry gr...

Embodiment 3

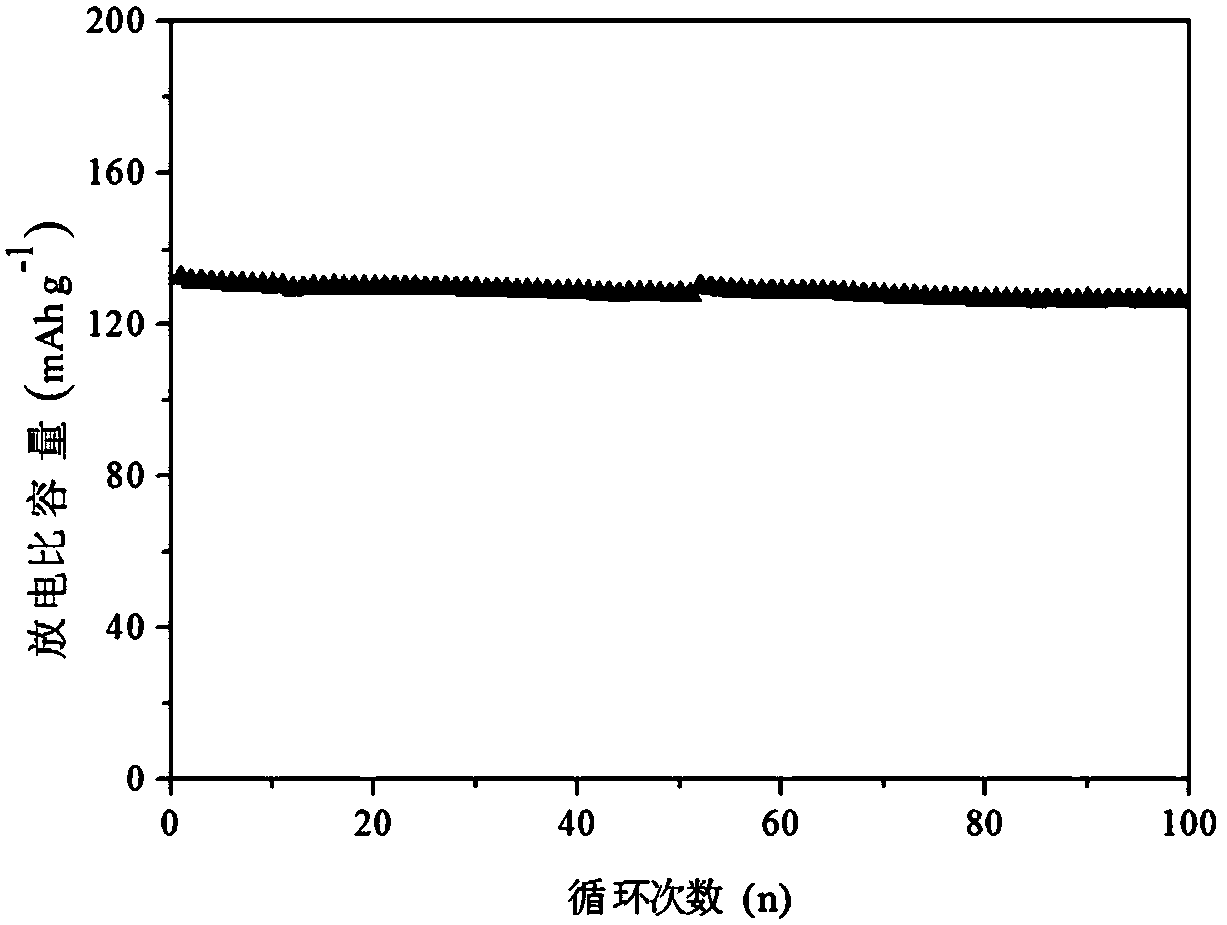

[0031] Coating the positive electrode slurry of the lithium ion battery on an aluminum foil to prepare the positive electrode of the lithium ion battery has a thickness of 300 microns. The weight ratio formula of each raw material in the slurry is: 96 parts by weight of lithium iron phosphate, 1 part by weight of conductive graphite, 7.5 parts by weight of binder, 1 part by weight of polyacrylic acid, and 400 parts by weight of dispersion medium. Among them, the theoretical specific capacity of lithium iron phosphate is 170mAh / g; the binder is styrene / methyl acrylate / styrene block copolymer, and the structure of the block copolymer is R-AA 40 -b-St 8000 -b-MA 50 -b-St 8000 ; The dispersion medium is pure water.

[0032] The lithium ion battery positive electrode slurry is prepared by the following processing technology: ① Add water to polyacrylic acid and magnetically stir for 120 minutes, put conductive graphite and lithium iron phosphate into a planetary high-energy ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com