Novel loose-item-free chip-type optical divider

An optical splitter and chip-type technology, which is applied in the field of new-type chip-free splitters without spare parts, can solve problems such as long production cycle, high cost, and signal transmission failure, so as to reduce the unit price of transportation and save raw materials , the effect of reducing product weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

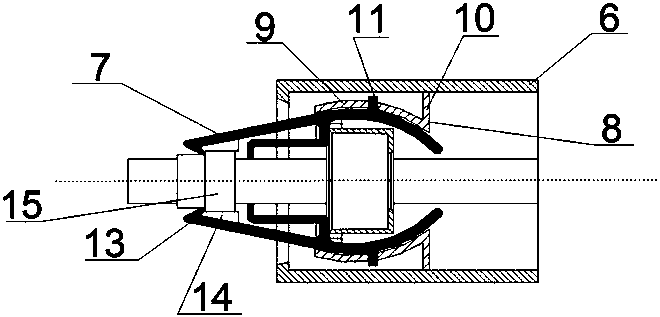

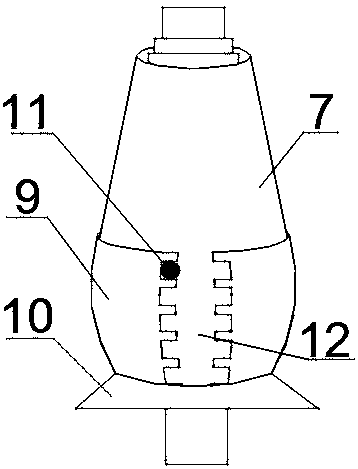

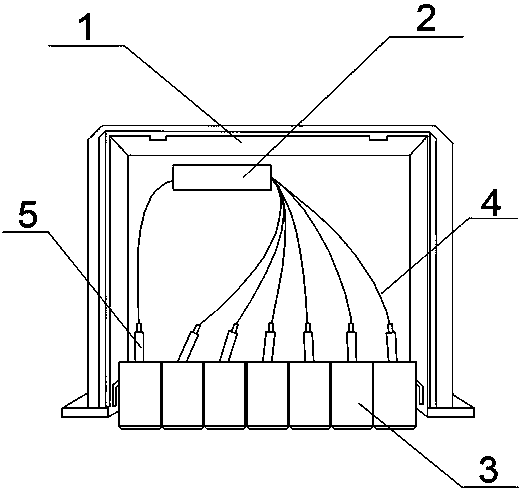

[0019] A new type of plug-in optical splitter without loose parts, including a plug-in bottom box 1, a miniature optical splitter 2, and a flange 3, the miniature optical splitter 2 is installed in the plug-in bottom box 1, The input end and the output end 4 of the miniature optical splitter 2 are penetrated into the ceramic ferrule 5 and fixed, and the ceramic ferrule 5 connected with the splitter is put into the end of the flange plate 3 without loose parts, and the flange plate 3 It includes an outer shell 6 and an inner core member 7 matched with the outer shell. A fixed mounting part 8 is embedded on the inner wall of the outer shell 6. The fixed mounting part 8 consists of a spherical shell-shaped rotating fixing part 9 and an outer sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com