Method for processing automobile rear torsion beam on horizontal boring machine

A horizontal boring machine and torsion beam technology, applied in the field of auto parts processing, can solve the problems of high processing cost, large investment in equipment configuration, and inability to meet sample processing in time, so as to meet the demand of sample processing and reduce the pressure of processing investment , The effect of shortening the equipment procurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

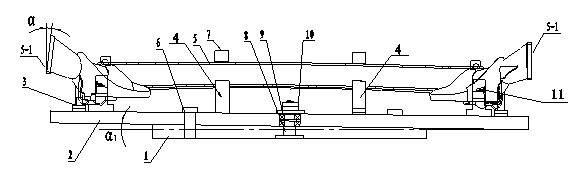

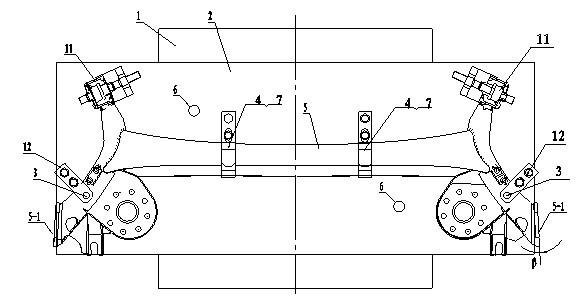

[0019] The present invention uses a ∮200 disc milling cutter to process the outer surfaces of the two hub brackets of the rear torsion beam of an automobile on an ordinary horizontal boring machine. The method utilizes the combined action of the rotary table of the horizontal boring machine, the bottom plate of the tooling, and the rotary plate to make the surface to be processed correspond to the cutting surface of the disc milling cutter, thereby realizing the machining of the outer surface of the hub bracket.

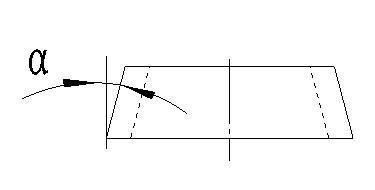

[0020] image 3 , Figure 4 The inclination angle α and the toe angle β of the outer surfaces of the two wheel hub brackets of the rear torsion beam of the automobile are schematically represented by a simplified diagram.

[0021] see Figure 5-9 , the inventive method process is as follows:

[0022] a. Install the tool: install a ∮200 disc milling cutter on the spindle of the horizontal boring machine;

[0023] b. Installation tooling: Fix the rear torsion beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com