Nisiloy bronze alloy material and processing technique thereof

A bronze alloy and processing technology, applied in metal rolling, temperature control, etc., can solve problems such as high technical and quality requirements, long procurement cycle, complex process, etc., and achieve high technical content, short procurement cycle and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

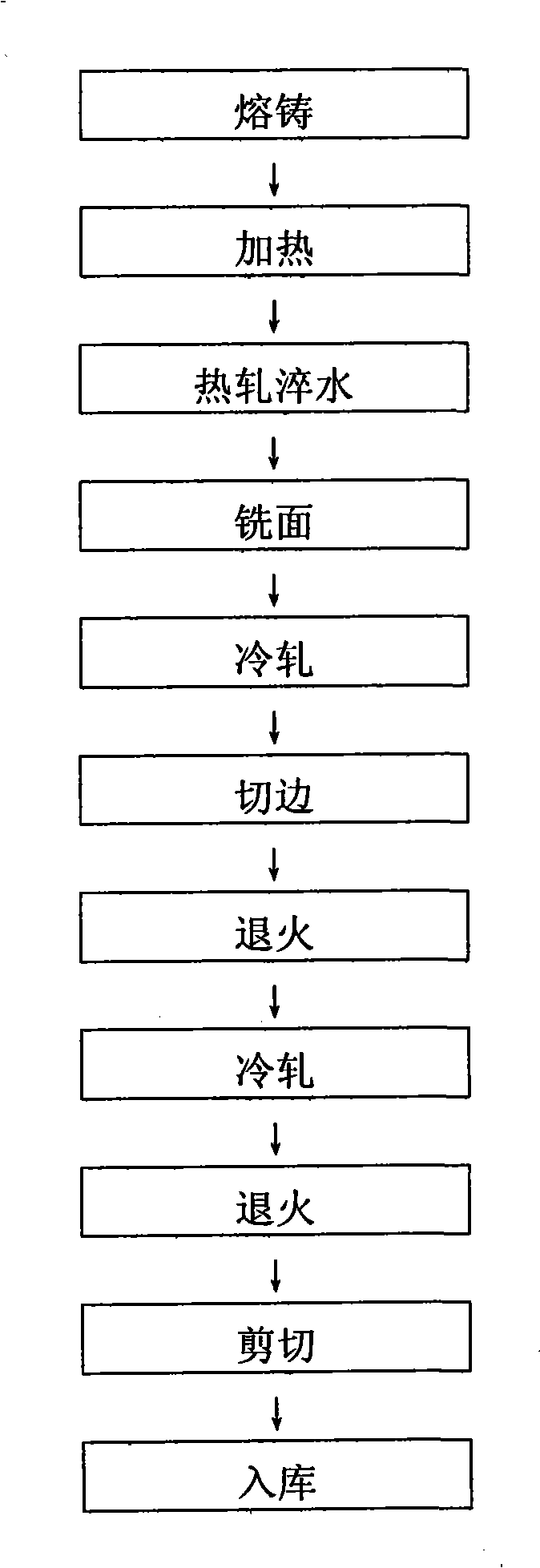

[0010] The CuNi2Si nickel-silicon bronze alloy plate of Y state 2X600X85.14mm is produced by rolling, and the process method adopts:

[0011] Melting and casting: Nickel-silicon bronze material components are weighed separately by weight: copper balance, nickel 1.6-3.4%, silicon 0.15-1.1%, manganese ≤ 1.0%, iron ≤ 0.6%, and unavoidable impurities ≤ 0.3% are weighed separately The ingredients are put into the smelting furnace one after another, and cast into ingots;

[0012] Heating: use a heating furnace to heat the ingot, heating temperature: 850-980°C, holding time: 2-3h;

[0013] Hot-rolling and quenching: use a hot-rolling mill to carry out billet hot-rolling on the heated ingot, and use normal temperature water to quench on-line for solid solution treatment, rolling rate: 90-95%;

[0014] Face milling: double-sided milling is used to mill the hot-rolled slab;

[0015] Cold rolling: the first cold rolling is carried out on the milled slab by the rough rolling mill, the r...

Embodiment 2

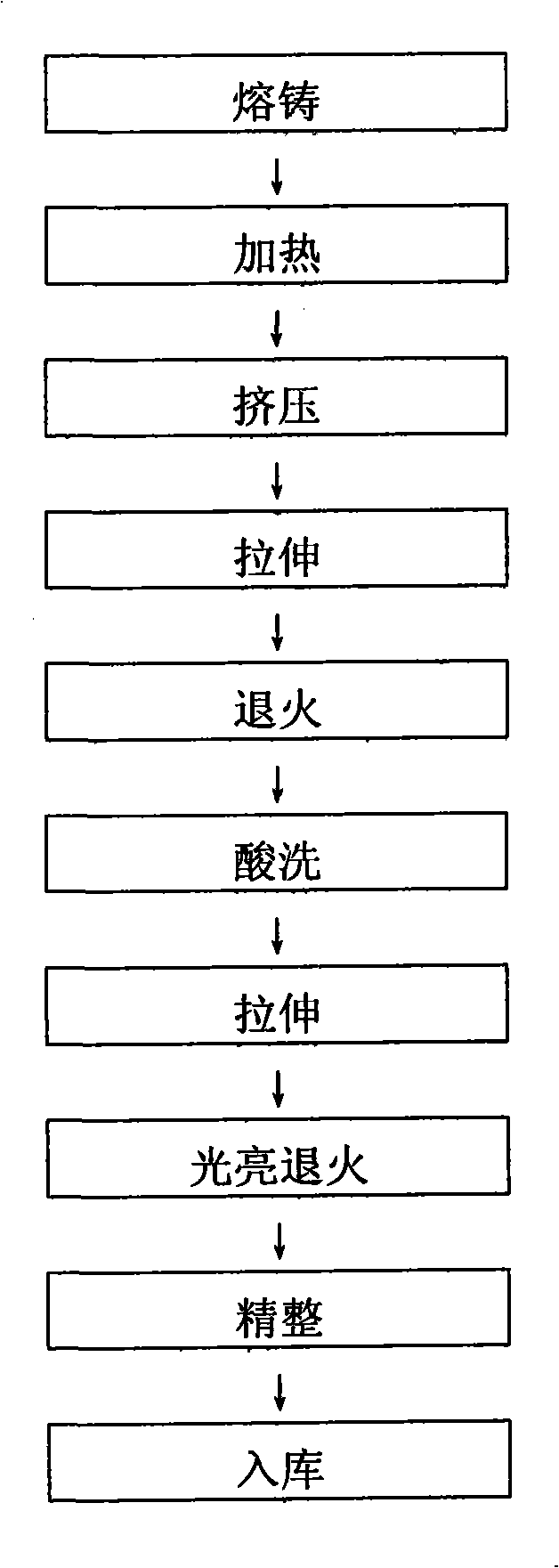

[0022] The CuNi2Si alloy bar of M state φ18X3000mm is produced by extrusion and stretching, and the process method adopts:

[0023] Melting and casting: Nickel-silicon bronze material components are weighed separately by weight. Ingredients: copper balance, nickel 1.6-3.4%, silicon 0.15-1.1%, manganese ≤ 1.0%, iron ≤ 0.6% and unavoidable impurities ≤ 0.3%, respectively The weight is successively put into the smelting furnace and melted into ingots;

[0024] Heating: use induction heating furnace to heat the ingot, heating temperature: 850~900℃, heating time: 3~6min;

[0025] Extrusion: use hydraulic press to extrude the heated ingot into billet, extrusion ratio: 26-45;

[0026] Stretching: use a stretching machine to perform the first stretching process on the extruded billet, and the stretching processing rate: 38-45%;

[0027] Annealing: Use an annealing furnace to perform intermediate annealing on the stretched billet, annealing temperature: 650℃~700℃, annealing time: 2~4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com