Barrel type refrigerant compressor

A compressor and barrel-type technology, applied in the field of refrigerant compressors, can solve the problems of single-layer layout of the unit, failure to meet high-pressure sealing, and heavy unit weight, etc., to achieve shortened procurement cycle, light weight, and low cost input Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

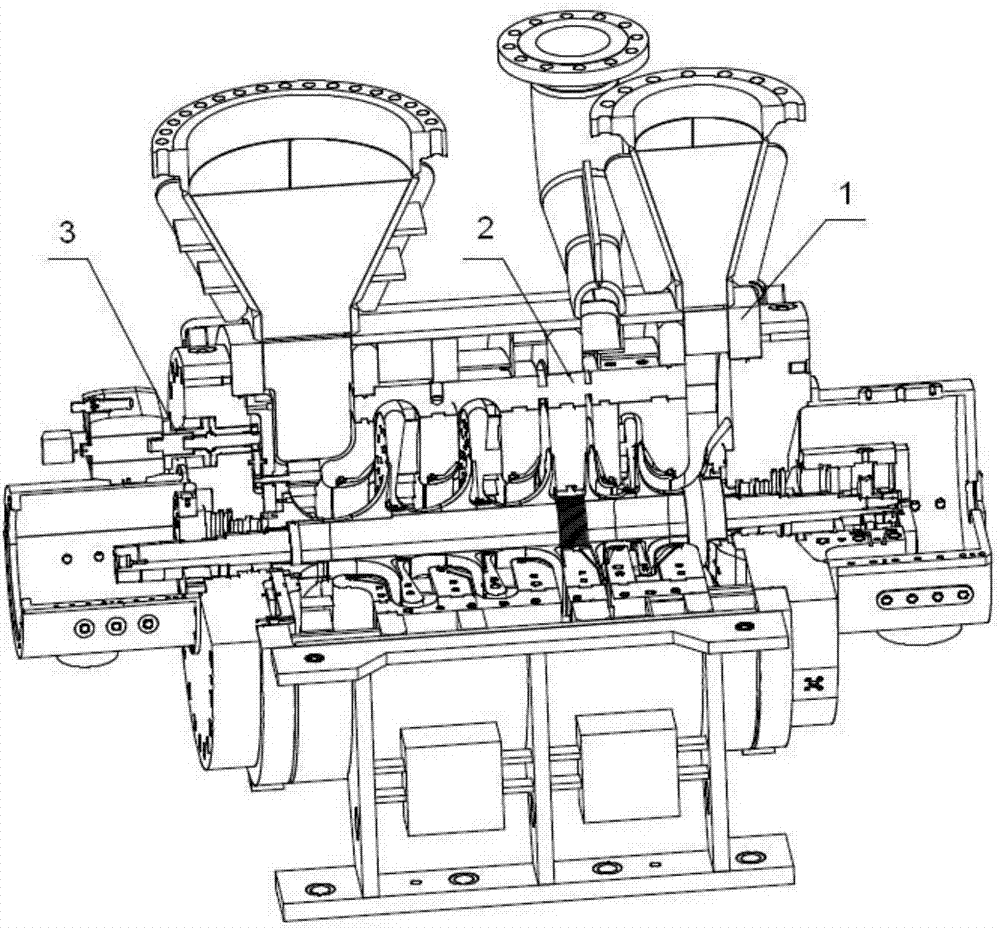

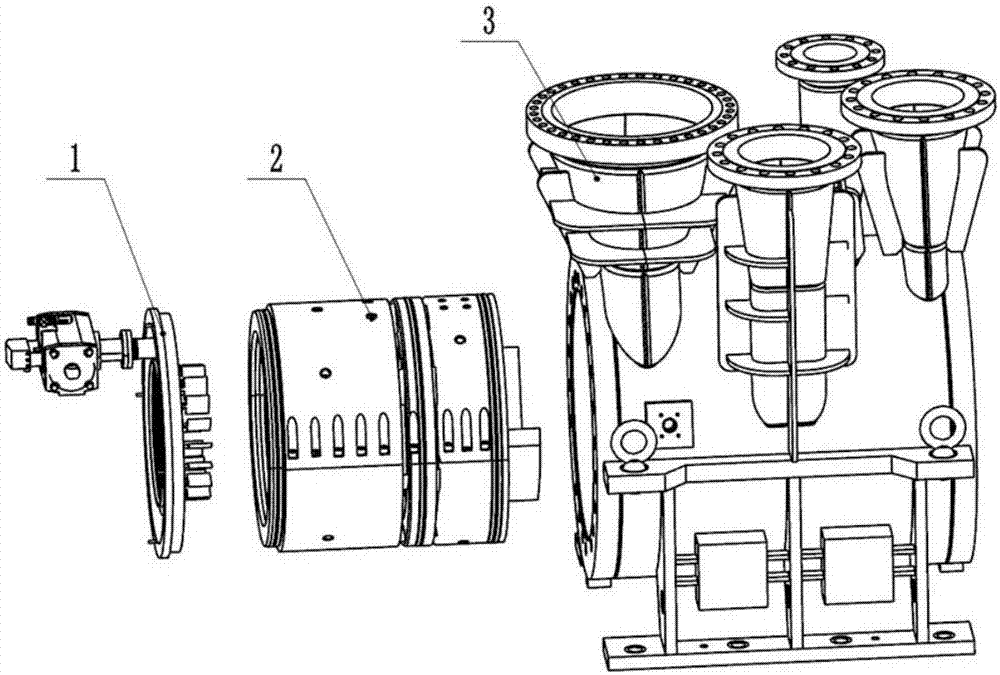

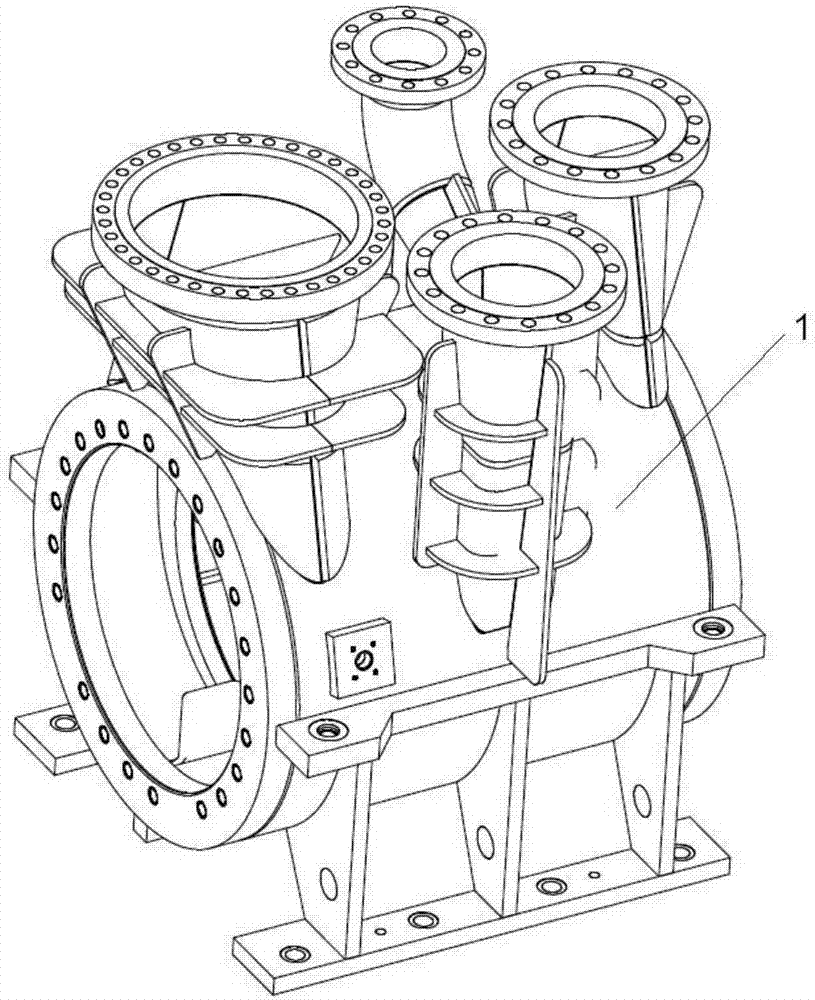

[0035] like Figures 1 to 4 As shown, the cylindrical refrigerant compressor includes a cylindrical welded casing 1, an inner casing 2 and an adjustable guide vane actuator 3. A support ring and a baffle are welded on the inner wall of the cylindrical welded casing 1, and the support ring and the baffle form a volute inside the cylindrical welding casing 1, the inner casing 2 is arranged inside the cylindrical welding casing 1, and a connecting rib group 4 is arranged along the circumferential direction of the shell wall of the inner casing 2 to connect The rib group is used to divide the inner casing 2 into at least two unit inner casings; the adjustable guide vane actuator 3 is arranged in the cylindrical welding casing 1 on the side close to the inner casing 2 .

[0036] The cylindrical welded casing 1 is welded by the Q345R plate, and the Q345R plate is composed of the following chemical composition in weight percentage: C 0.02%, Si 0.3%, Mn 1.2%, P 0.002%, S 0.015% , CaO...

Embodiment 2

[0044]Referring to Example 1, the cylindrical refrigerant compressor provided in this embodiment is different in that the cylindrical welded casing 1 is welded by the Q345R plate, and the Q345R plate consists of the following weight percentages: Chemical composition: C0.2%, Si 0.5%, Mn 1.3%, P 0.01%, S 0.01%, CaO 0.003%, Co 0.16%, Cu 0.03%, Alt 0.02%, V 0.01%, and the balance of Fe and unavoidable impurities.

Embodiment 3

[0046] Referring to Example 1, the cylindrical refrigerant compressor provided in this embodiment is different in that the cylindrical welded casing 1 is welded by the Q345R plate, and the Q345R plate consists of the following weight percentages: Chemical composition: C0.1%, Si 0.2%, Mn 1.6%, P 0.02%, S 0.013%, CaO 0.0025%, Ni 0.4%, Co 0.18%, Cu0.2%, Al t 0.01%, V 0.025% , and the balance of Fe and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com