Horizontal high-pressure heat exchanger applicable to cleaning medium evaporation

A technology for cleaning media and heat exchangers, which is applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc. To achieve the effect of good high pressure sealing, eliminating thermal stress and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings.

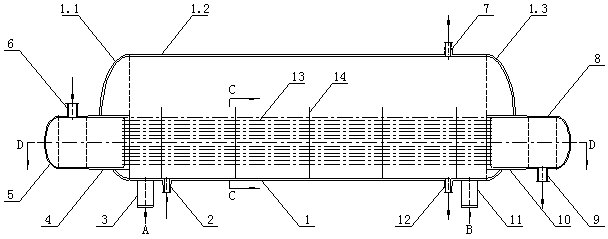

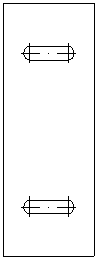

[0026] Such as figure 1 As shown, it includes a shell side composed of a shell 1, a baffle 14, a tube side composed of a left tube box 5, a right tube box 8, a left shaped tube plate 4, a right shaped tube plate 10, and a heat exchange tube bundle 13, and The sliding saddle 3 and the fixed saddle 11; the two sides of the lower part of the housing 1 are respectively installed with a left shaped tube plate 4 and a right shaped tube plate 10, the end faces of the extending cylinder of the left shaped tube plate 4 and the right shaped tube plate 10 are respectively Connected with the left tube box 5 and the right tube box 8. A row of baffles 14 are arranged evenly spaced between the left shaped tube plate 4 and the right shaped tube plate 10 in the housing 1, such as Figure 4 As shown, the baffle 14 is in the shape of a circle with a crown cut off, and the side of each baffle 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com