Special sealing ring for pressure container

A pressure vessel and sealing ring technology, which is applied in the container filling method, container discharge method, gas/liquid distribution and storage, etc., can solve problems such as unsuitable pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

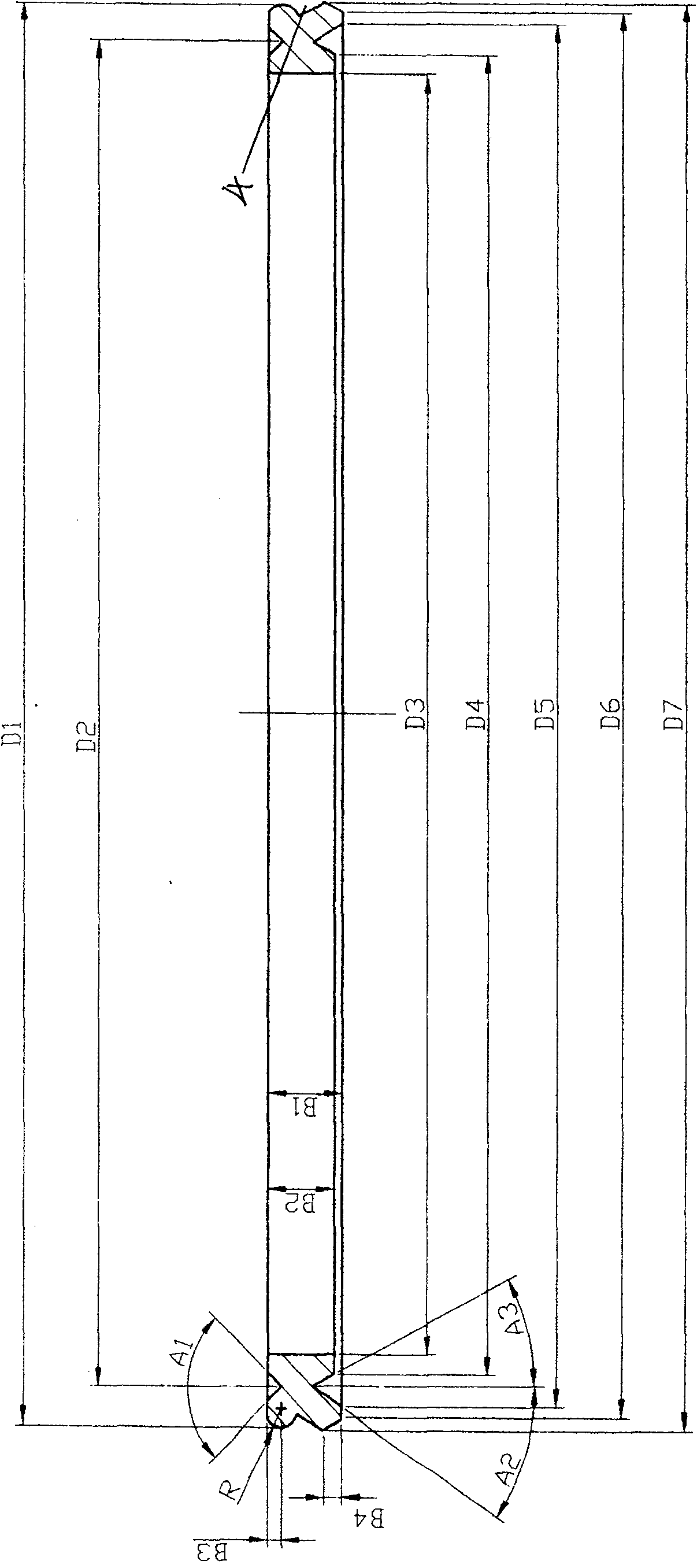

[0006] Embodiment 1. A special rubber sealing ring for a pressure vessel of the present invention is a combined sealing ring, which combines the shapes of the U-shaped sealing ring and the O-shaped sealing ring, and is improved on this basis. The outer corner of the upper part of the annular body of the sealing ring is an O-ring shape R, that is, the outer corner of the annular body and the upper surface are rounded. The lower part of the annular body of the sealing ring is provided with a circle of V-shaped grooves A2 and A3, which are the part of the V-shaped groove. In this way, a rubber sealing ring similar to a V-shaped pressure vessel can be formed, and the direction of the V-shaped notch is toward the pressure-bearing part of the pressure vessel during assembly. In the case of low pressure, the O-ring part of the sealing ring can normally exert the good low-pressure sealing performance of the ordinary O-ring sealing ring. In the case of high pressure, the V-shaped notc...

Embodiment 2

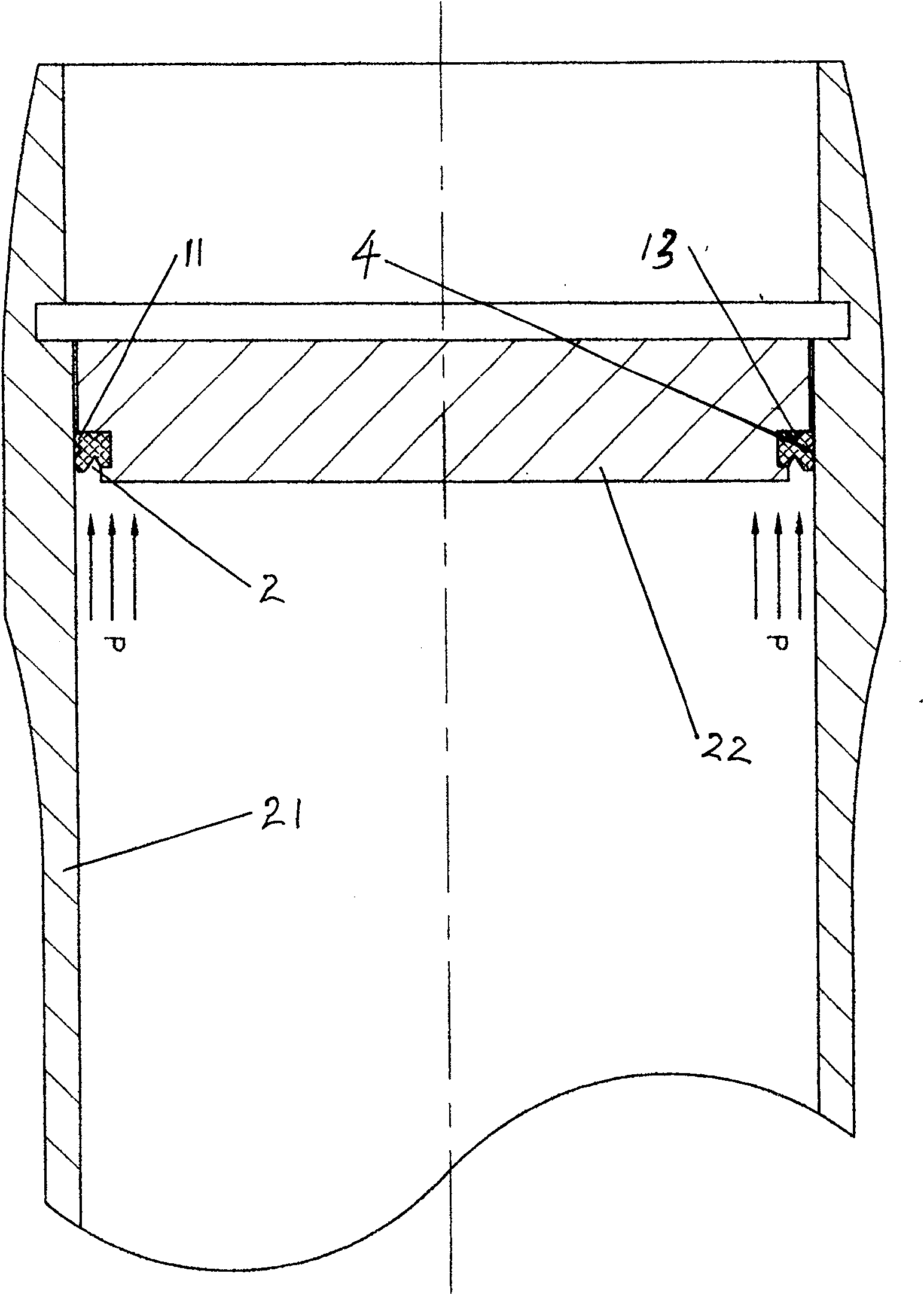

[0009] Embodiment 2. A special sealing ring for a pressure vessel of the present invention is an elastic plastic annular body, and the outer side and the upper surface of the annular body are rounded, forming a part 11 similar to an O-shaped sealing ring; There is a right-angled triangular notch 13 in place. The lower part of the annular body of the sealing ring is provided with a V-shaped groove, and a V-shaped ring groove 2 is formed under the annular body. There is also a V-ring groove 4 in the middle of the outer surface. In this way, the elastic plastic sealing ring of the present invention is assembled in the annular groove between the main body 21 and the end cover 22 of the pressure vessel. The sealing performance makes up for the defect of insufficient sealing of these two kinds of sealing rings under high pressure and low pressure respectively. In addition, since the upper and lower parts of the sealing ring are provided with a triangular notch, the deformation spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com