Patents

Literature

36results about How to "Meet the arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

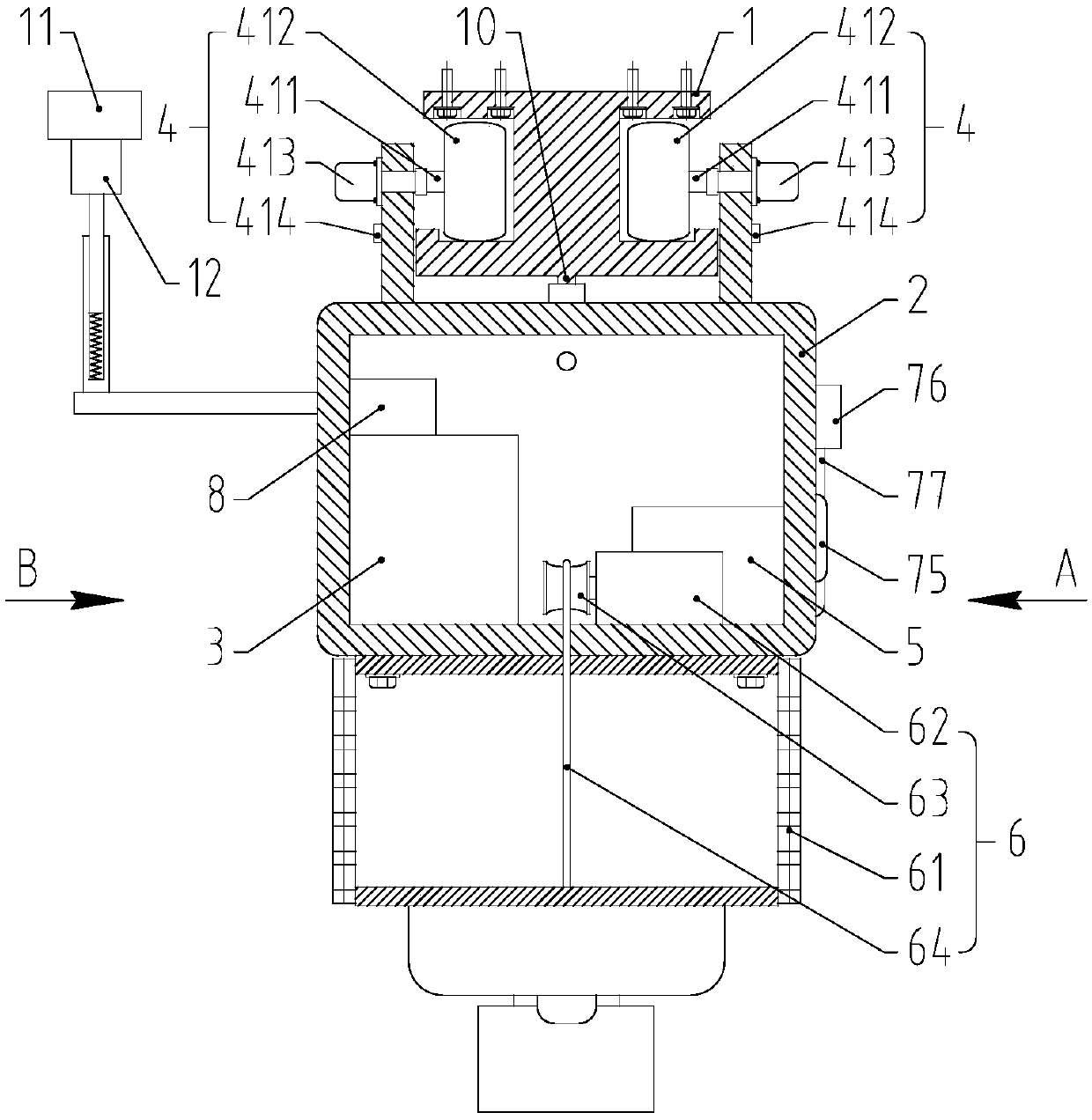

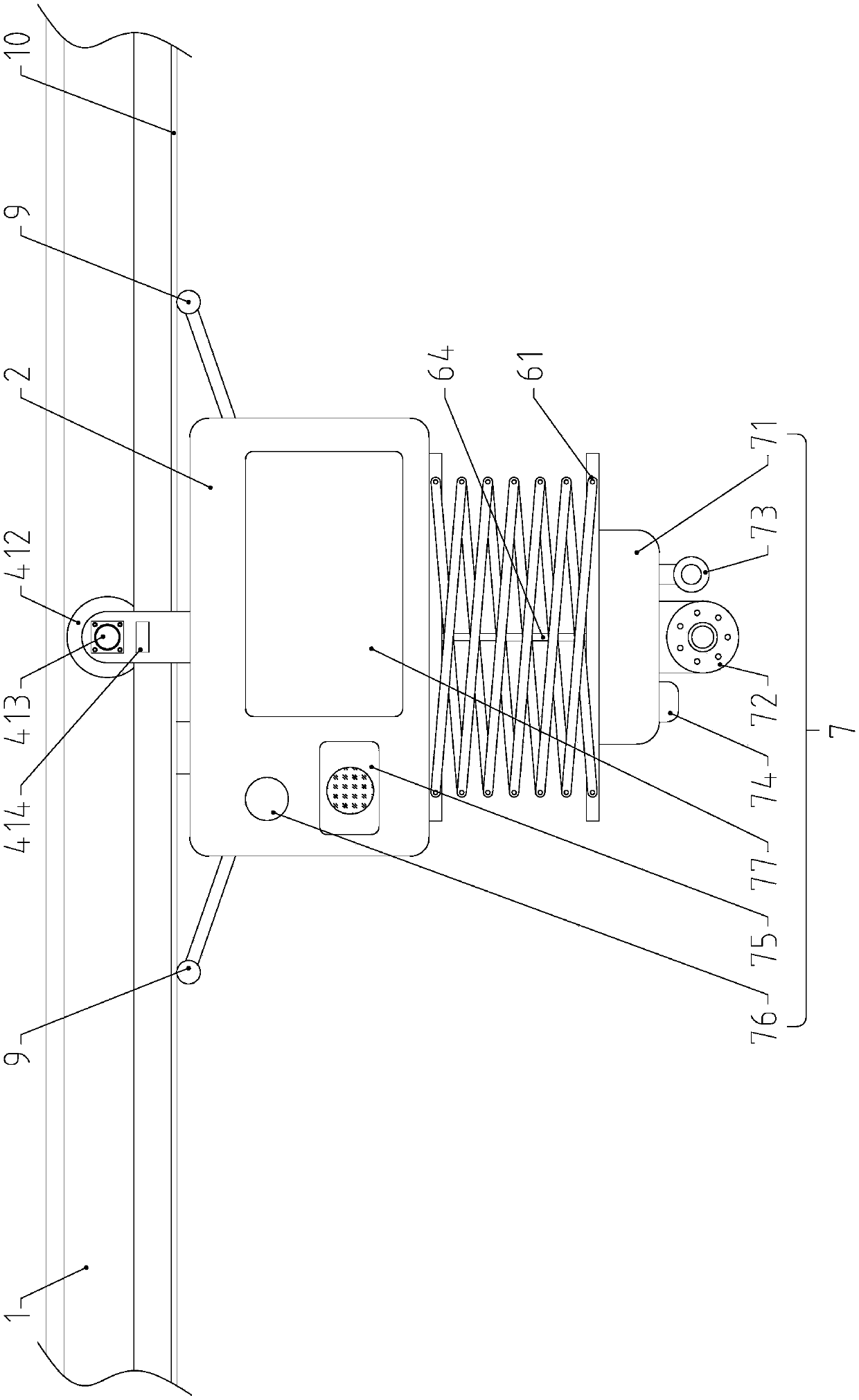

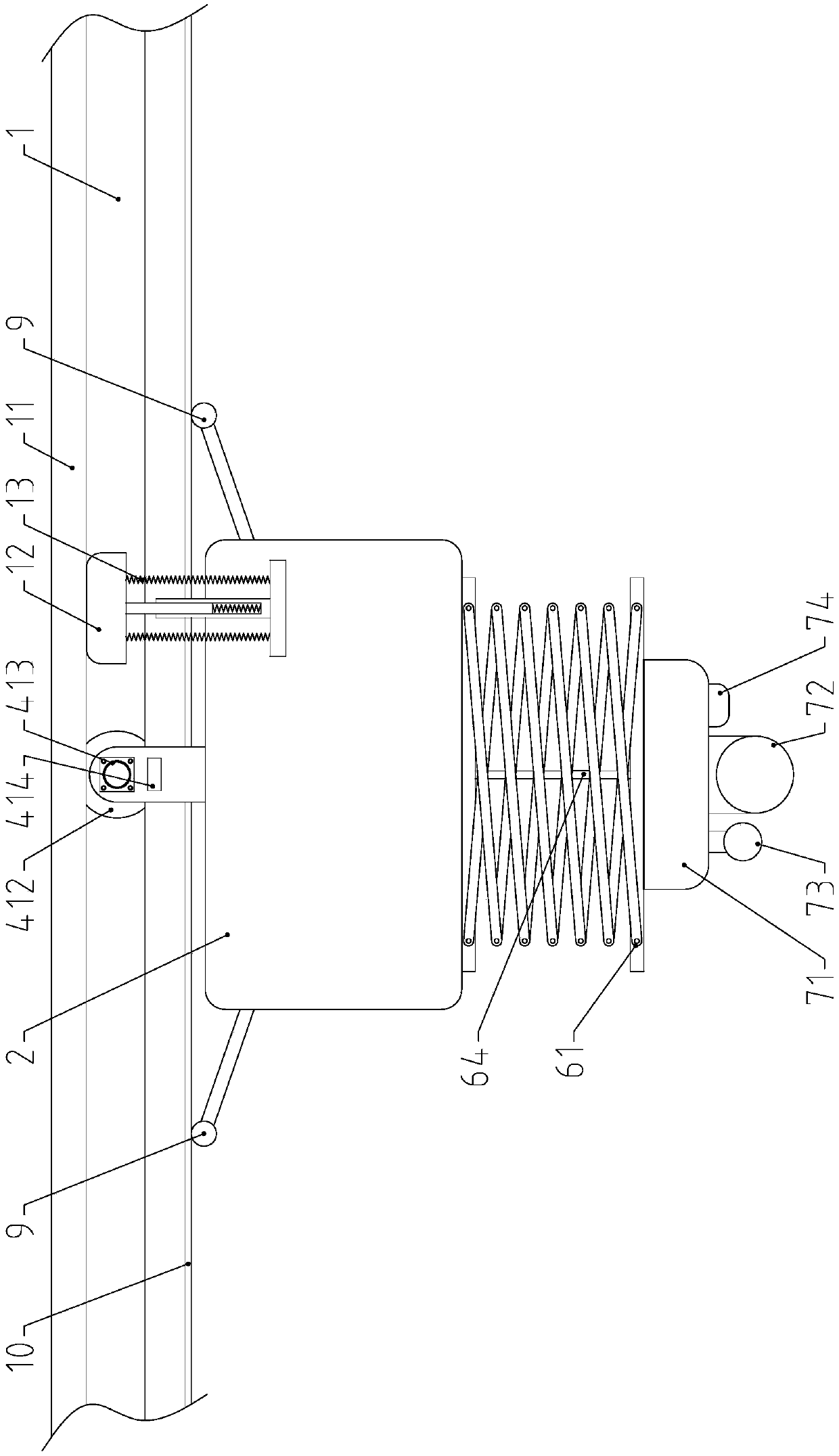

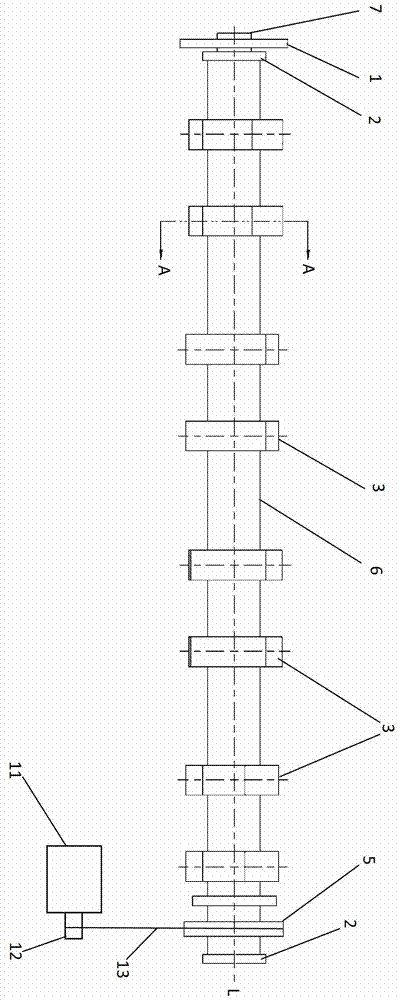

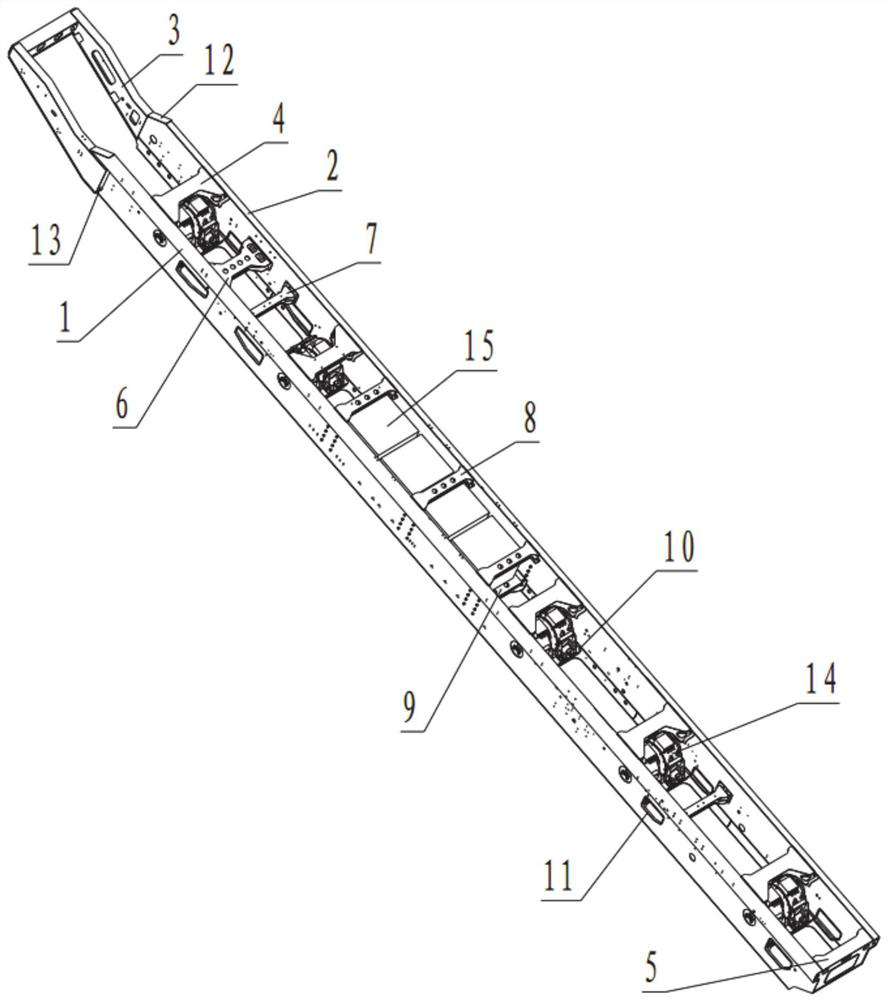

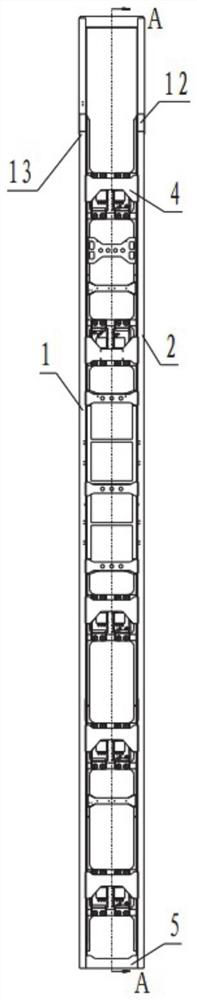

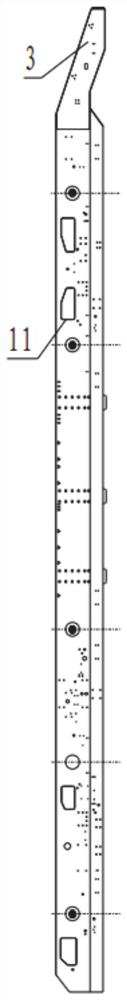

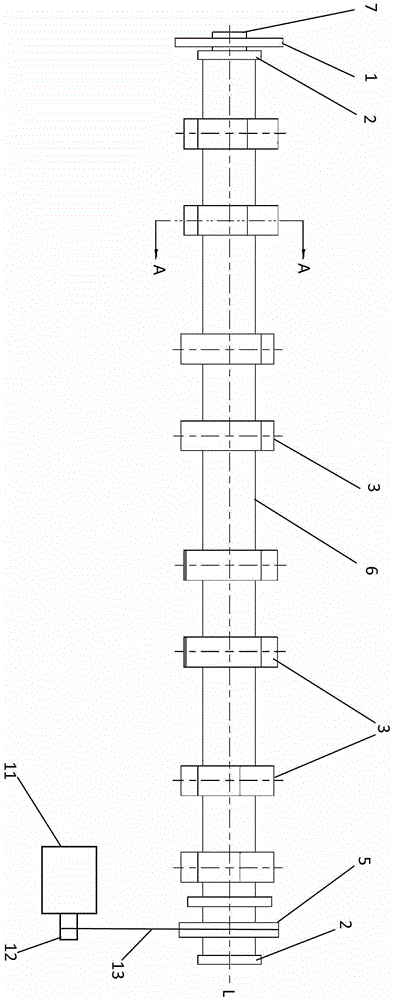

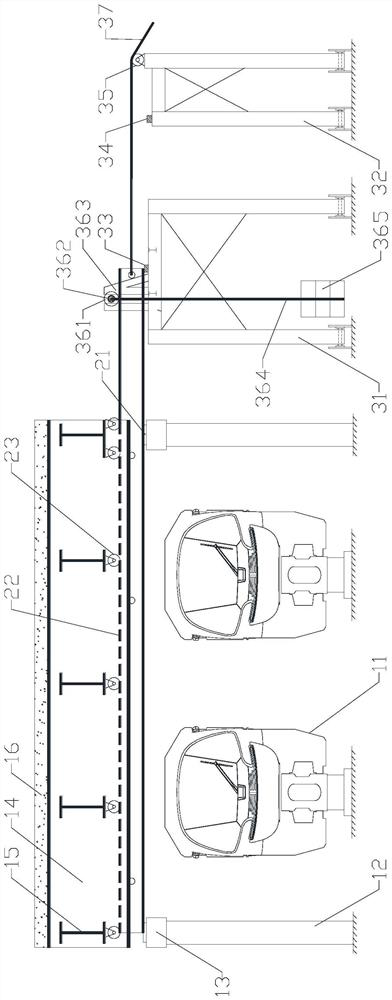

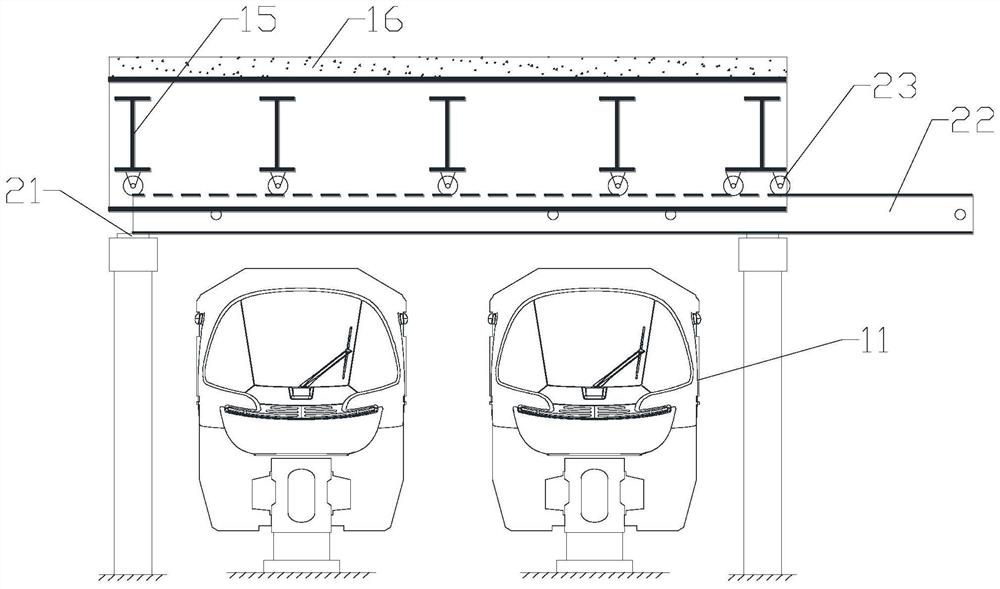

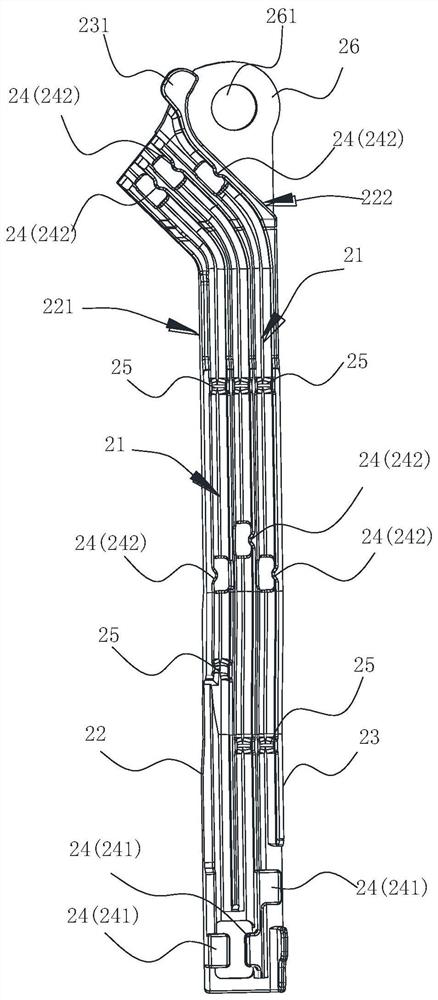

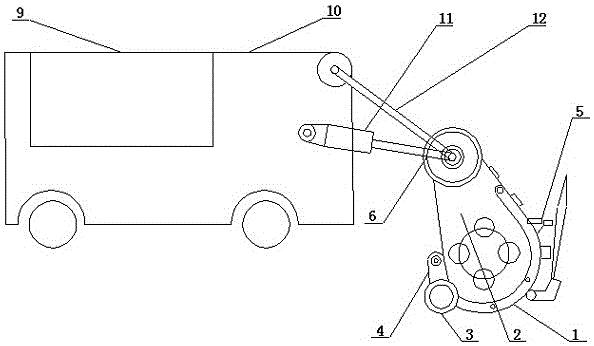

Rail type intelligent routing inspection robot

InactiveCN109514572AEfficient inspection operationsMeet the arrangementManipulatorElectricityDrive wheel

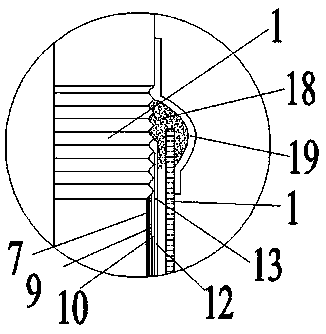

The invention discloses a rail type intelligent routing inspection robot. The robot is installed on a guide rail and comprises a main body, a storage battery, a moving mechanism, a control device, a lifting mechanism, a routing inspection mechanism and a battery controller, wherein the lifting mechanism comprises a shear-fork type lifting platform, a rope winding motor installed inside the main body, a rope winding wheel and a rope, the routing inspection mechanism comprises an electric cloud deck, a camera, an auxiliary lighting spotlight and a probe assembly, the electric cloud deck and theprobe assembly are fixedly installed to the bottom of the shear-fork type lifting platform, and the camera and the auxiliary lighting spotlight are installed on the electric cloud deck. According to the rail type intelligent routing inspection robot, two sets of driving wheel sets are adopted to be installed on the left and right two sides of the main body to be used for coordinating with rails onthe two sides of the guide rail, more flexible left and right turning is realized, and arrangement of the guide rail in sites with limited spaces is met; and in addition, the rail type intelligent routing inspection robot is further provided with an electricity fetching rail parallel to the guide rail, electricity fetching is performed by an electricity collecting shoe making contact with the electricity fetching rail, power supplying is guaranteed, and the routing inspection robot is made to perform efficient routing inspection operations.

Owner:HANGZHOU SHENHAO TECH

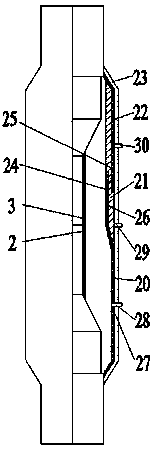

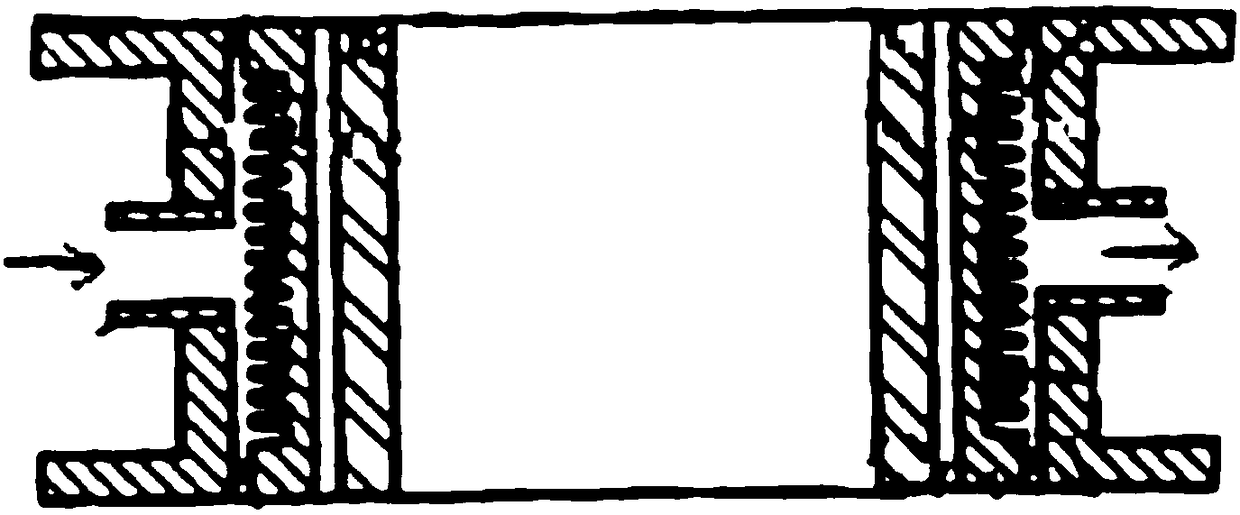

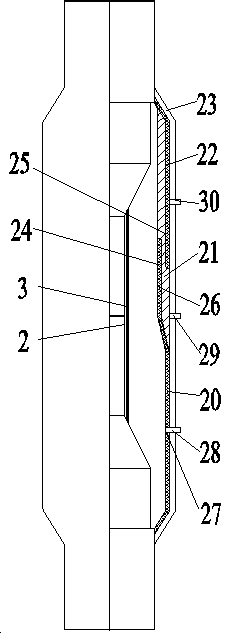

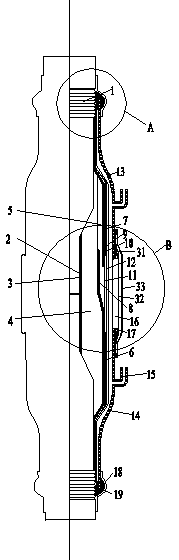

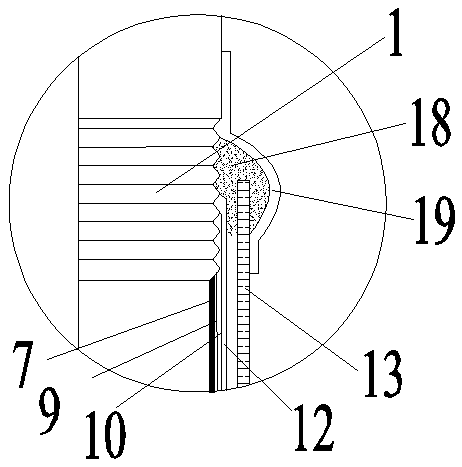

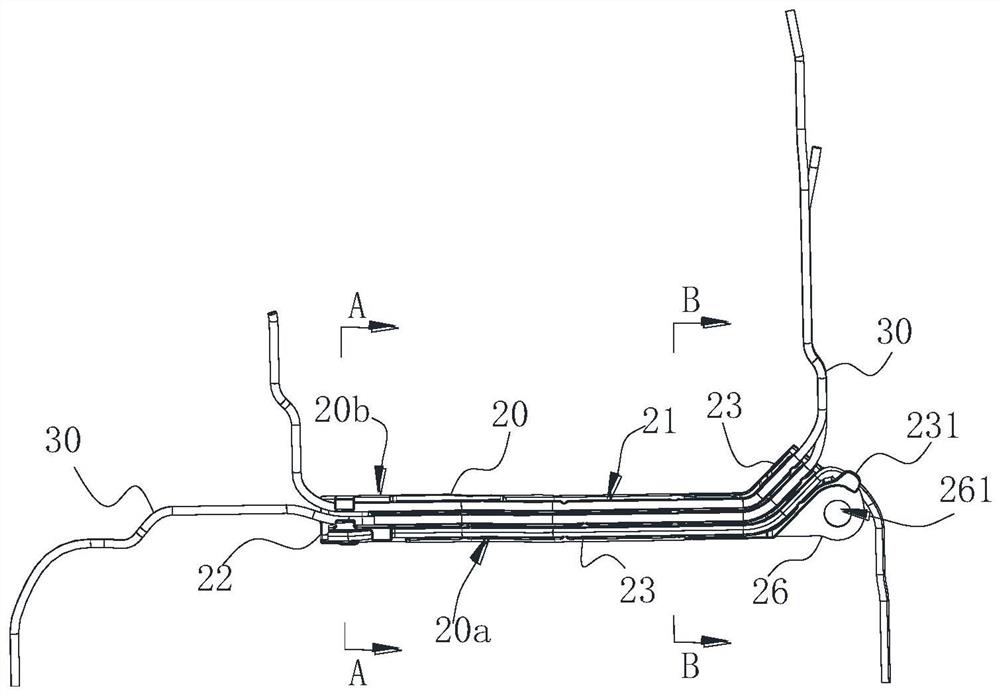

Manufacturing method for molding-type insulation connector of high-voltage cross-linked polyethylene insulated cable

ActiveCN110350451ACompact structureSmall sizeApparatus for joining/termination cablesElectrical conductorInsulation layer

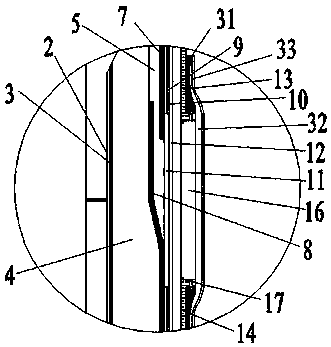

The invention discloses a manufacturing method for a molding-type insulation connector of a high-voltage cross-linked polyethylene insulated cable. The manufacturing method comprises the steps of 1) stripping and pre-processing the cable; 2) welding a conductor; 3) performing shielding and molding on the conductor; 4) molding an I segment of an insulation main body of the connector by a template method; 5) molding an I segment of insulation shielding of the connector by the template method; 6) molding an II segment of the insulation main body of the connector by the template method; 7) moldingan II segment of insulation shielding of the connector by the template method; 8) performing vulcanization; 9) degassing; 10) wrapping a belt material; and 11) installing an insulation copper shell.According to the manufacturing method for the molding-type insulation connector of the high-voltage cross-linked polyethylene insulated cable, an original integrated pre-fabricated connector is abandoned, a molding recovery conductor shielding layer, an insulation layer and an insulation shielding layer with materials same as a cable body are employed, no physical interface exists, integration ofconnector main insulation and cable main insulation is achieved, so that the cable is free from influence of thermal expansion and cold shrinkage, good water prevention performance is achieved, and electric field and hot field are uniform and stable in distribution.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

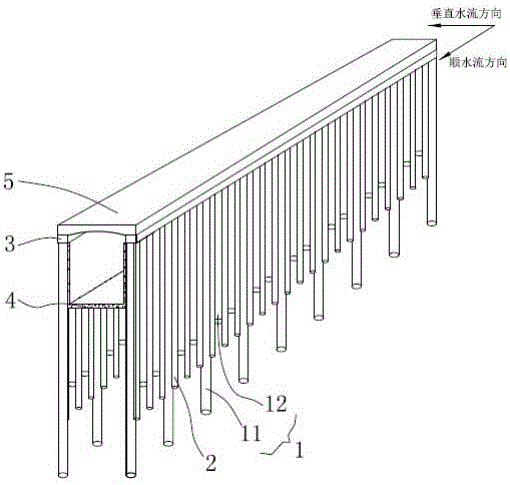

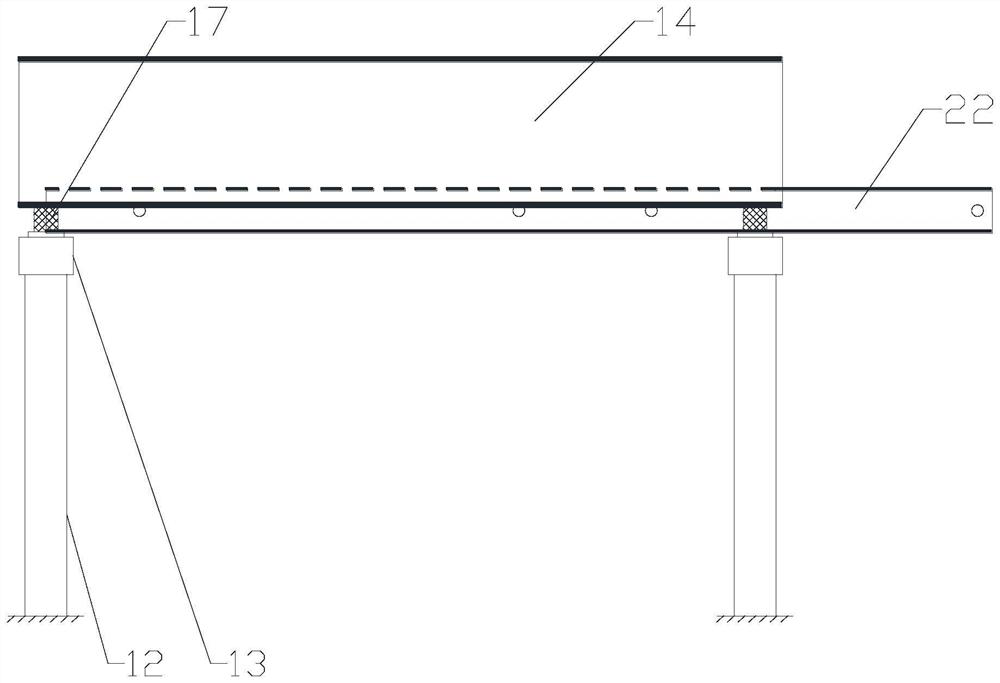

Rowed pile box culvert structure and construction method thereof

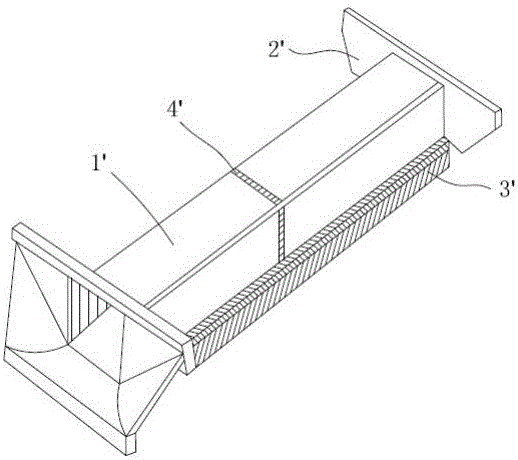

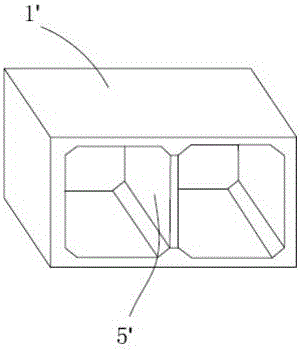

The invention discloses a rowed pile box culvert structure and a construction method thereof. The rowed pile box culvert structure comprises side column rowed piles, high pressure jet grouting piles, side crown beams, U-shaped base plates and top plates, wherein the side column rowed piles are divided into two groups and are symmetrically distributed on two sides, high pressure jet grouting piles are arranged between two side column rowed piles on each side to form a water stopping curtain, the number of the side crown beams is two, the side crown beams are located above the two groups of side column rowed piles, the U-shaped base plates are cast between the groups of side column rowed piles, side walls of the U-shaped base plates are connected with the inner walls of the side column rowed piles, and the upper portions of the side column rowed piles are cast with the top plates integrally. The construction method of the structure comprises the steps that the row piles are supported, then the base plates and the top plates are cast by adopting inverse excavation construction, construction links are decreased, an original temporary structure for rowed pile supporting is changed into a perpetual structure, engineering structure waste is avoided, a constriction period is effectively shortened, and construction cost is reduced.

Owner:XIAMEN MUNICIPAL ENGINEERING DESIGN INSTITUTE CO LTD

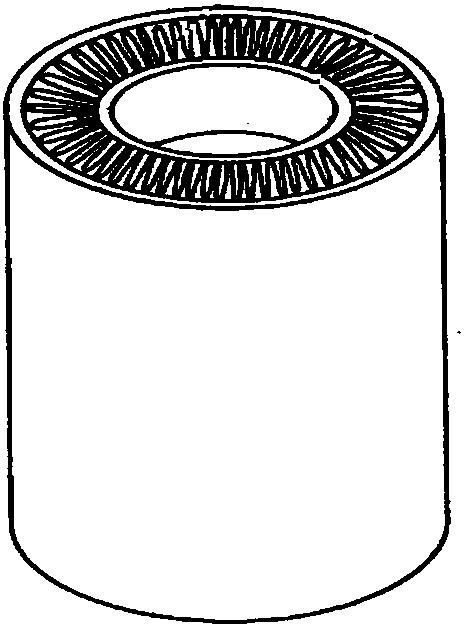

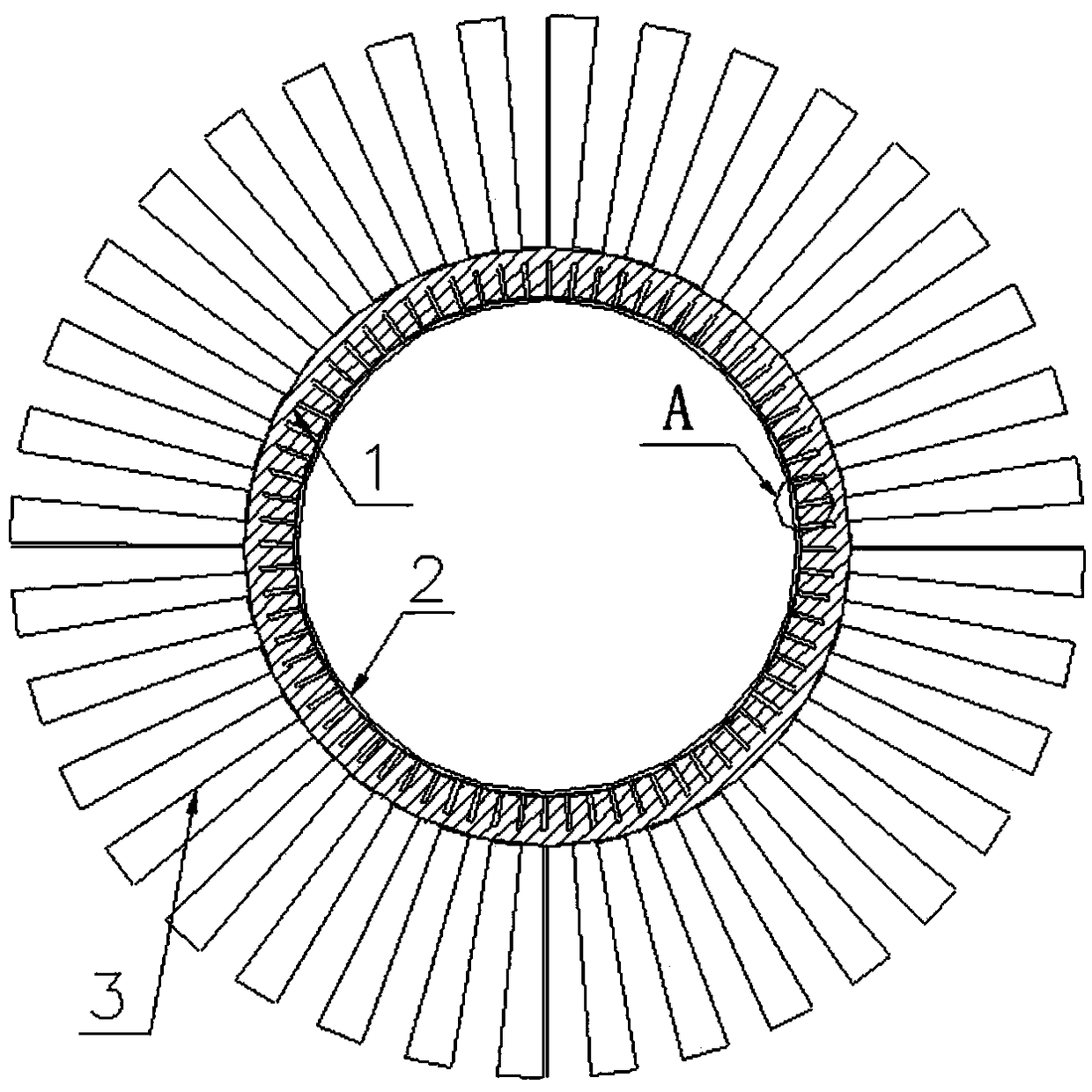

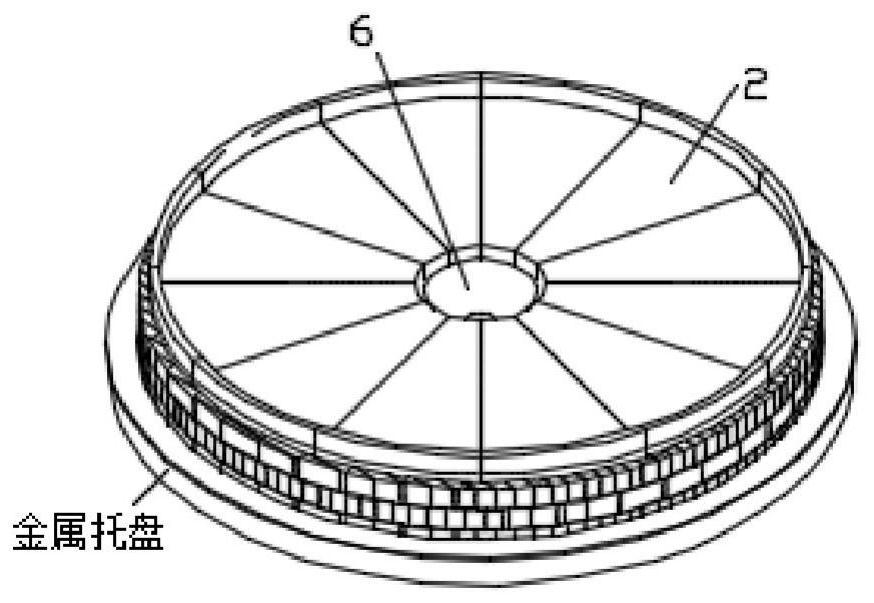

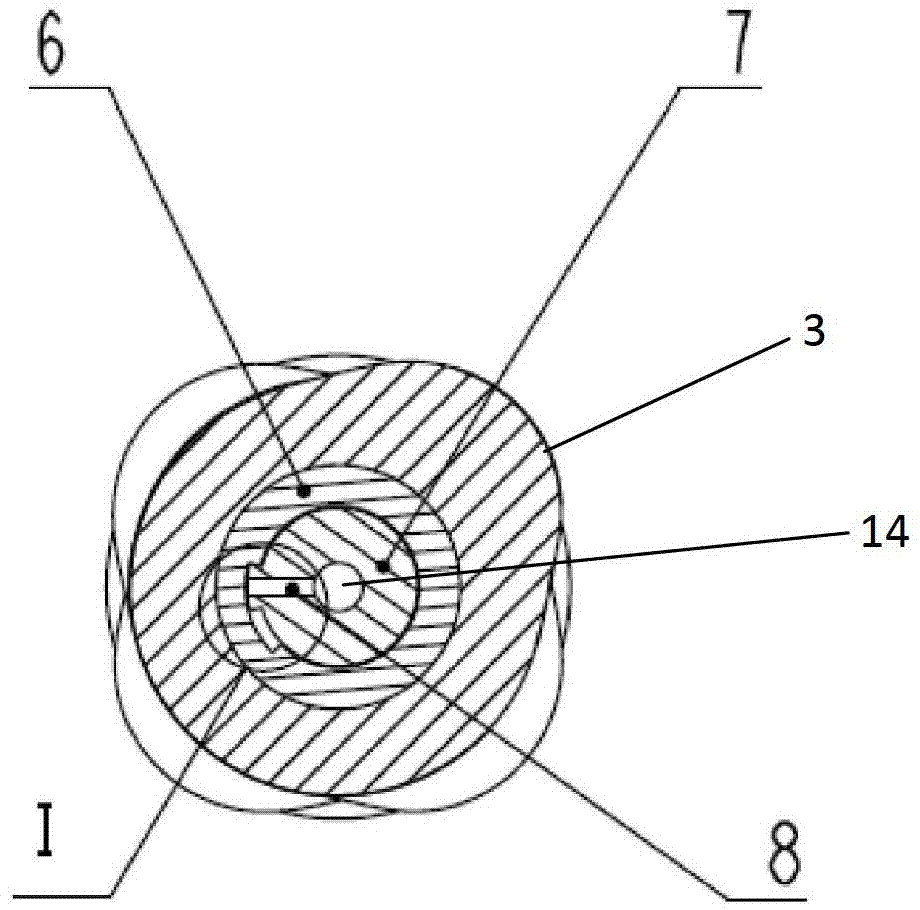

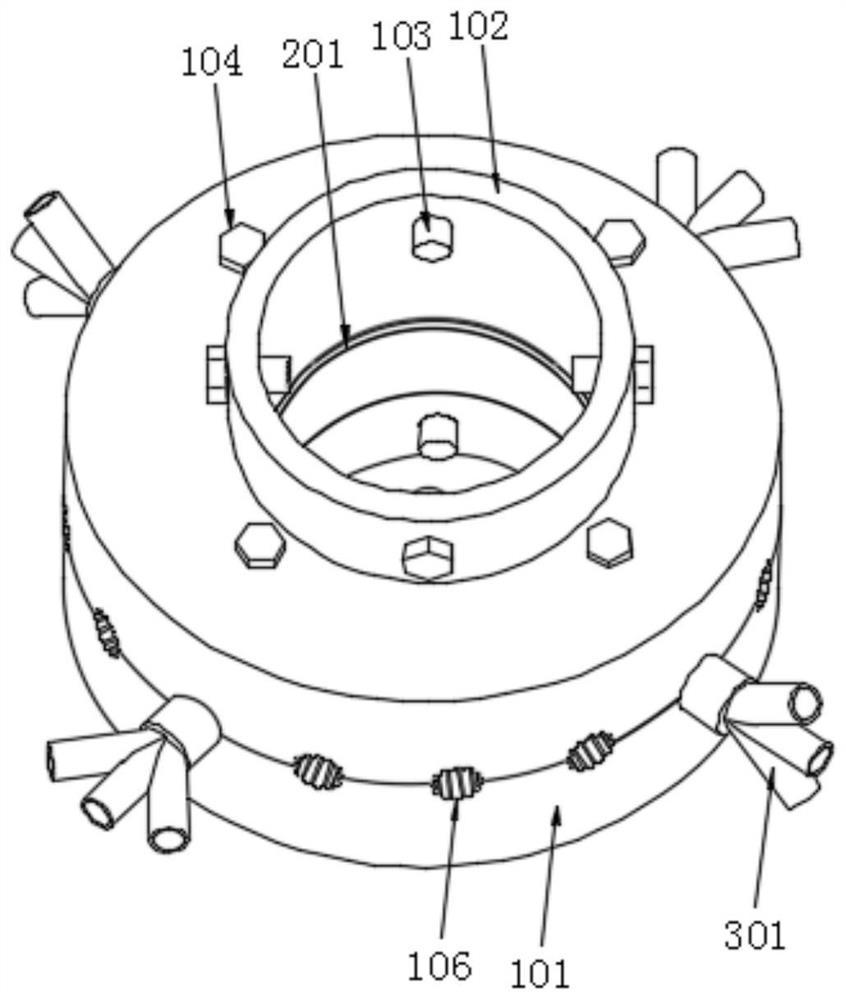

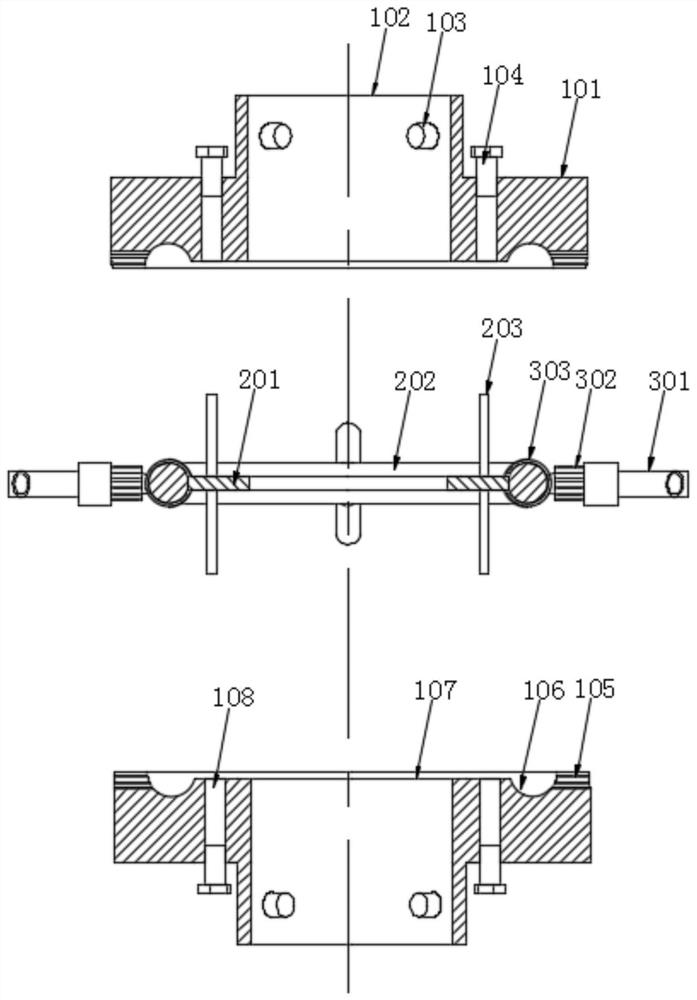

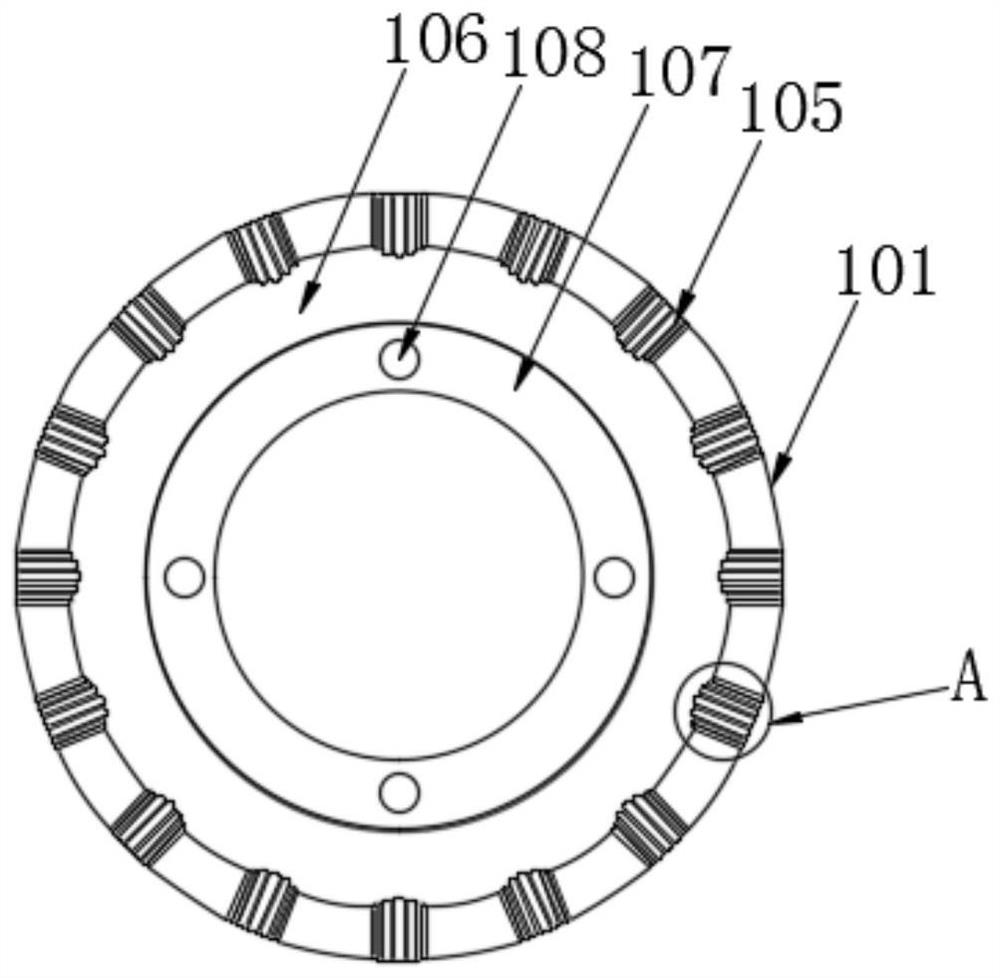

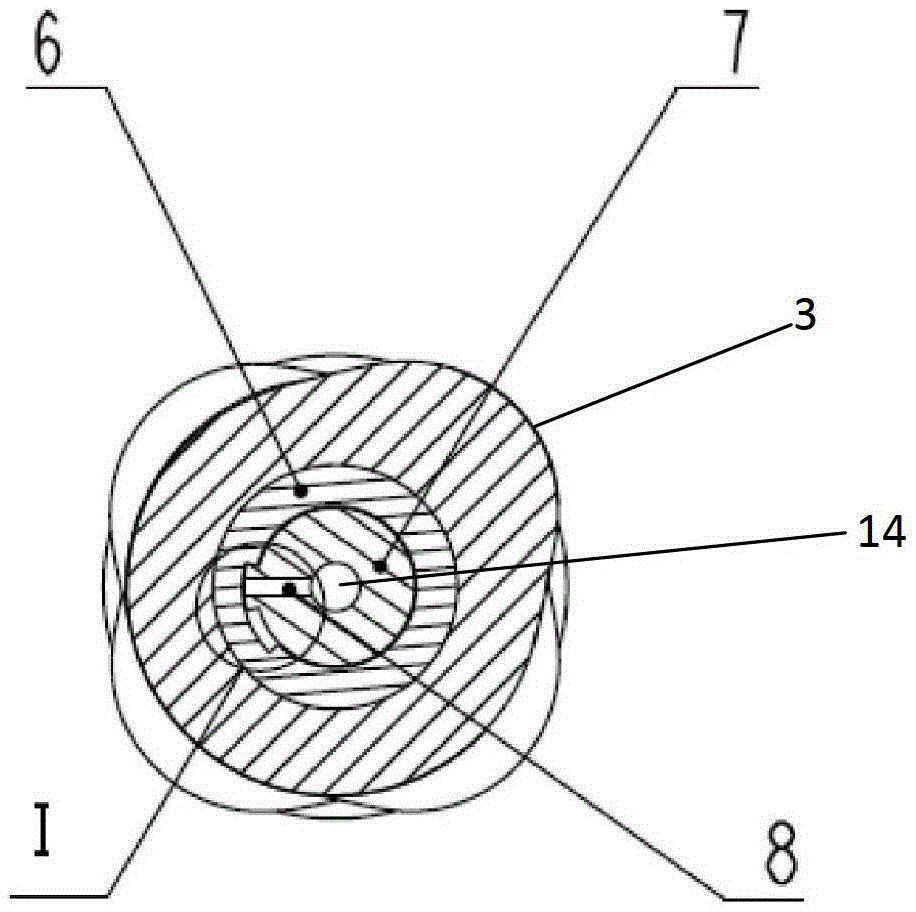

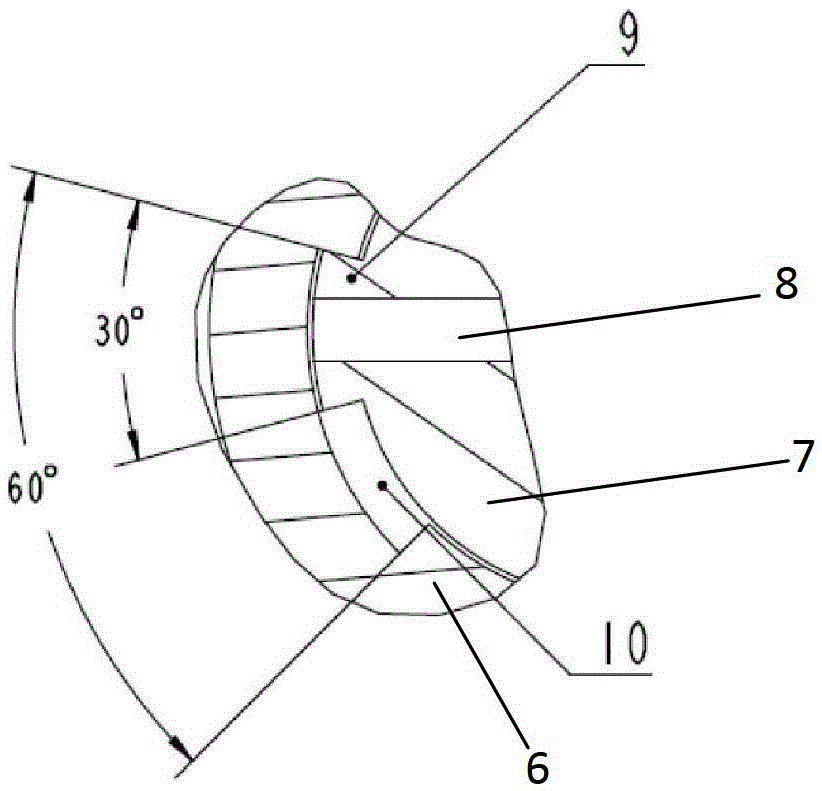

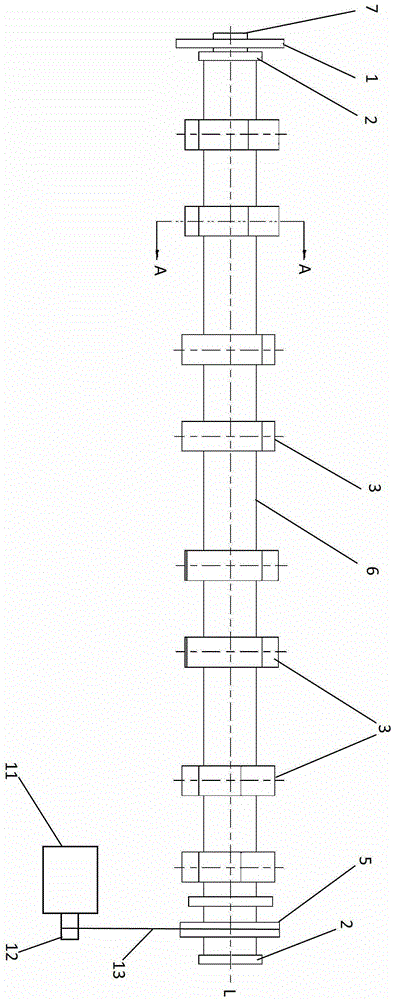

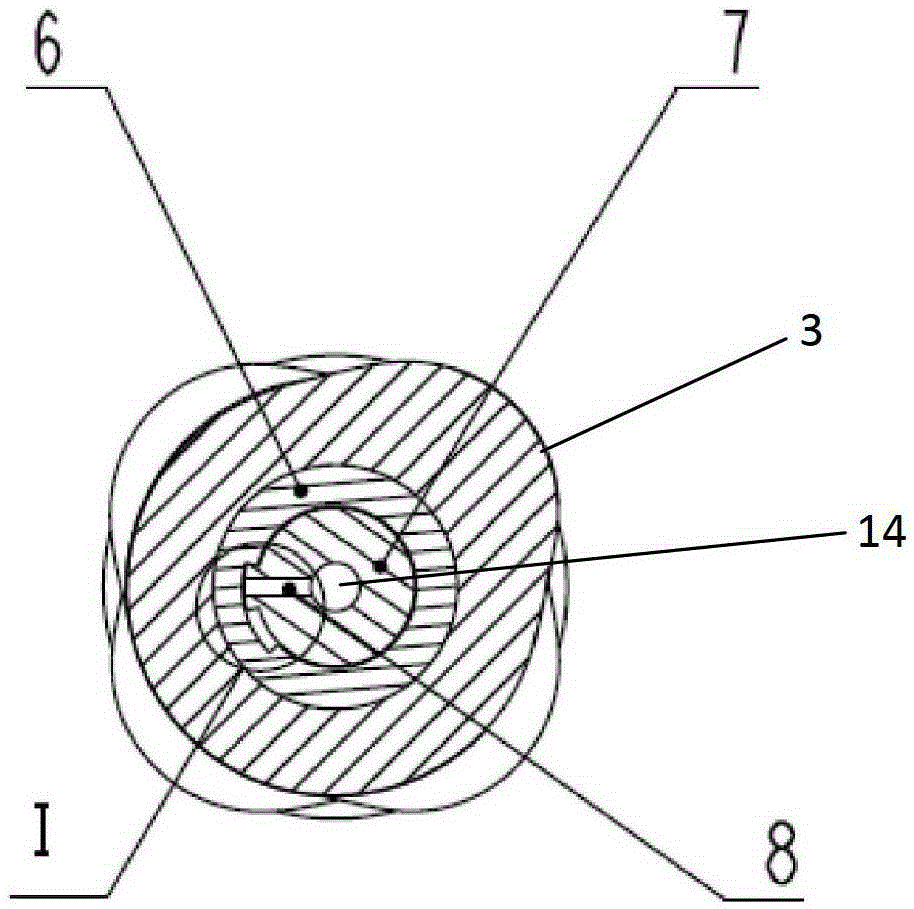

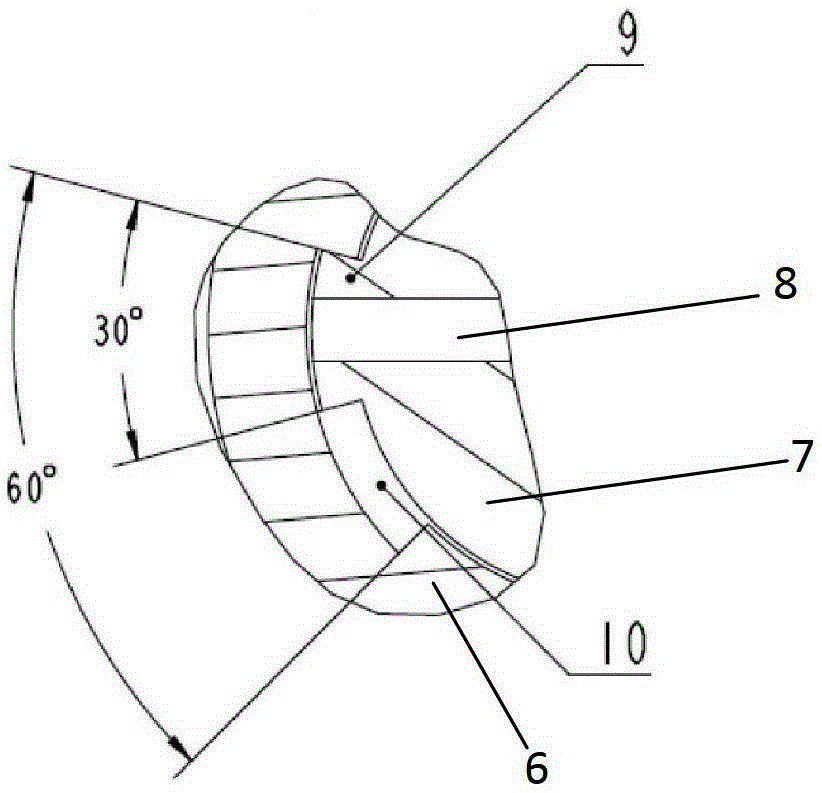

Heat exchanger provided with annular slots and used for sound-energy refrigerating machine

PendingCN108195214AImprove cooling effectImprove heat transfer coefficientCompression machinesIndirect heat exchangersInterference fitSound energy

The invention discloses a heat exchanger provided with annular slots and used for a sound-energy refrigerating machine, and belongs to the technical field of heat exchangers. The heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine comprises an inner rib body and an inner sleeve. The inner rib body is an annular cylinder with the inner annular surfaceopen towards the outer annular surface. The inner sleeve is arranged in the inner rib body in a sleeved mode and is in interference fit with the inner rib body. The multiple slots are formed in the inner annular surface of the inner rib body at intervals, so that a slot channel allowing air to flow therein is formed between the inner rib body and the inner sleeve. According to the heat exchanger provided with the annular slots and used for the sound-energy refrigerating machine, forced-convection heat change between alternately-flowing working medium gas and the inner wall of the heat exchanger is achieved, and the heat exchange coefficient is large; in the heat conduction direction towards the outside, through interference fit between the inner rib body and the inner sleeve as well as a welding structure of the inner rib body and outer fins, contact heat resistance is eliminated; and in addition, the inner rib body is made of red copper with small heat conduction resistance, and thusthe heat exchanger provided with the annular slots in the hot end has a good cooling effect.

Owner:陕西仙童科技有限公司

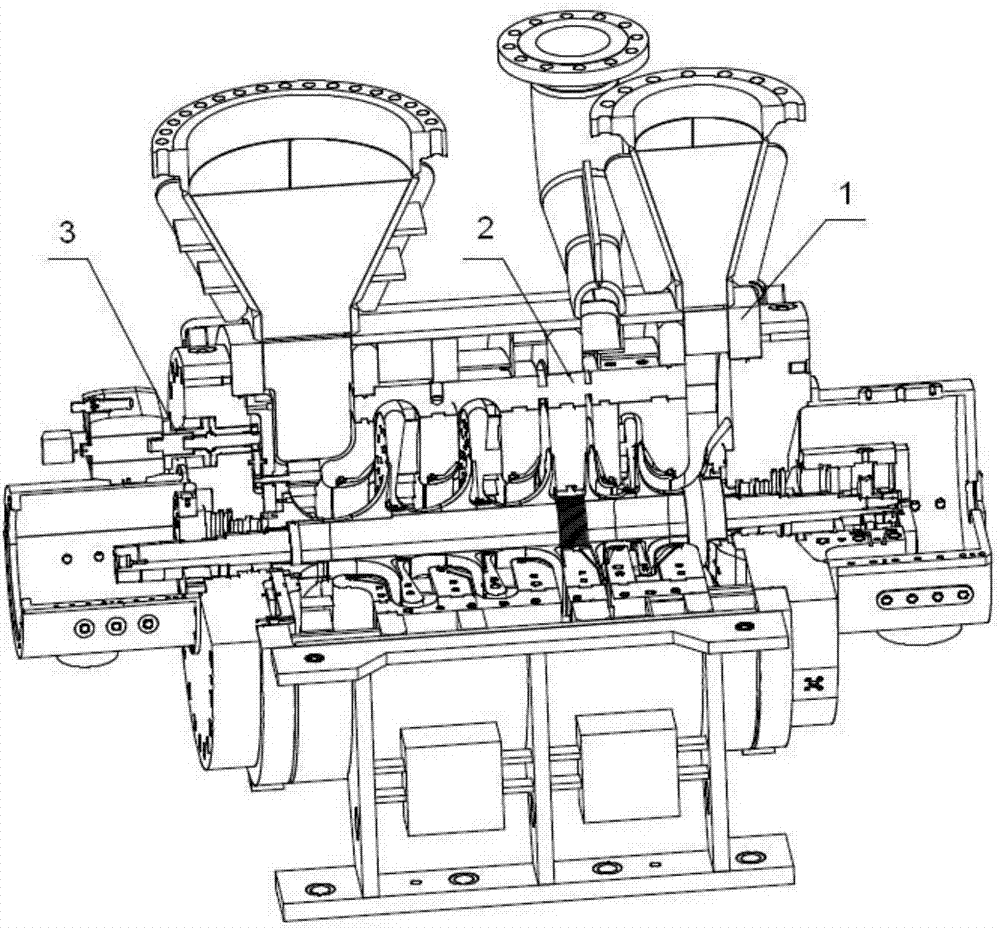

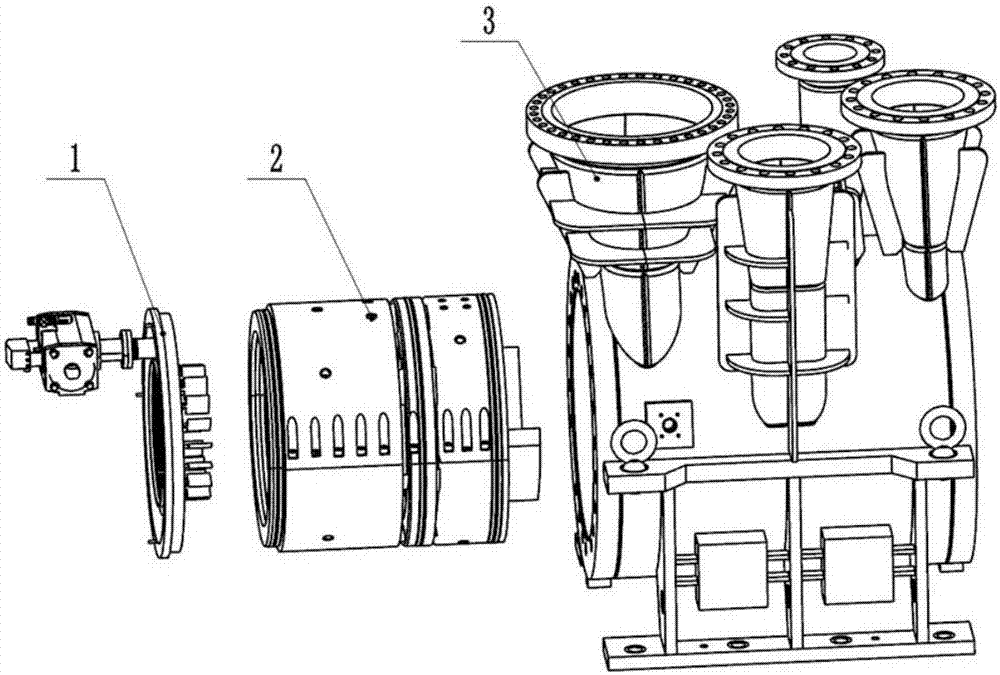

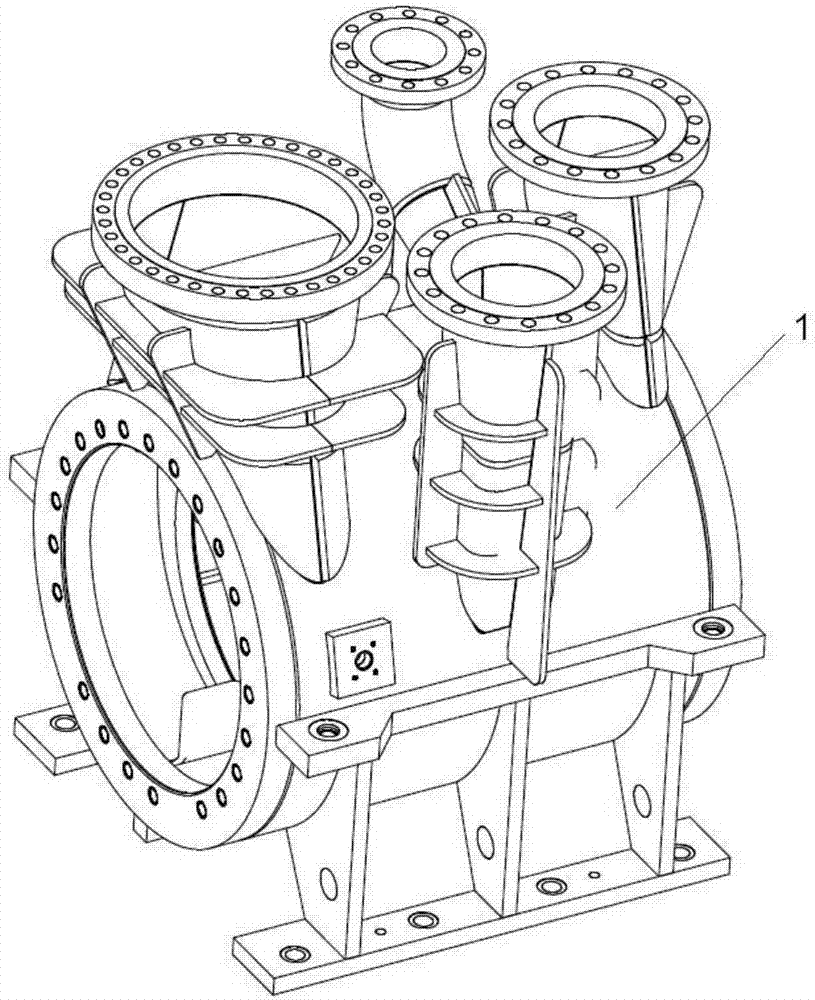

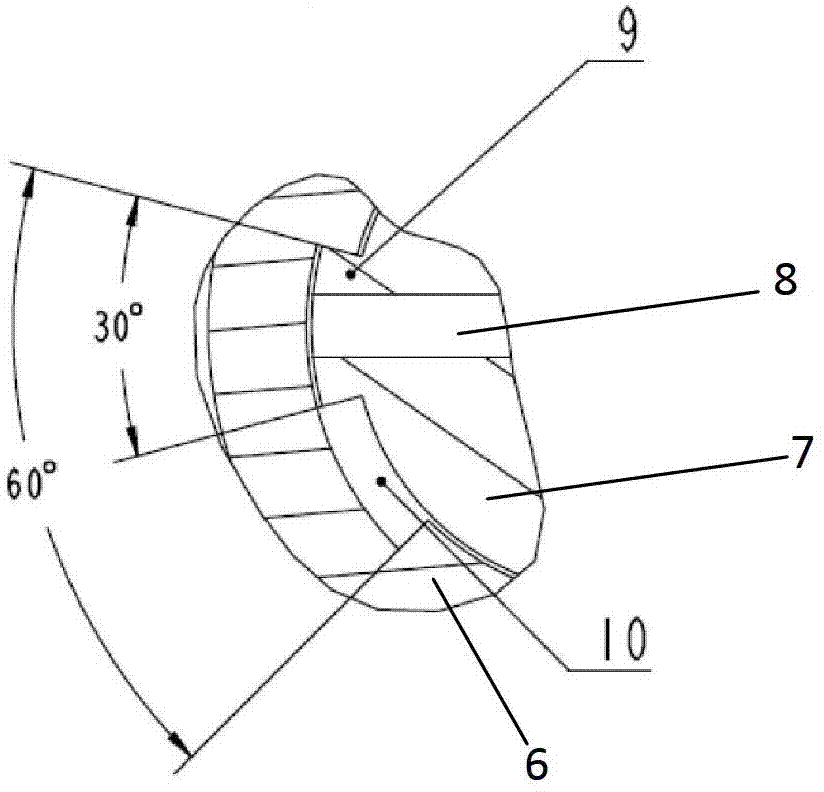

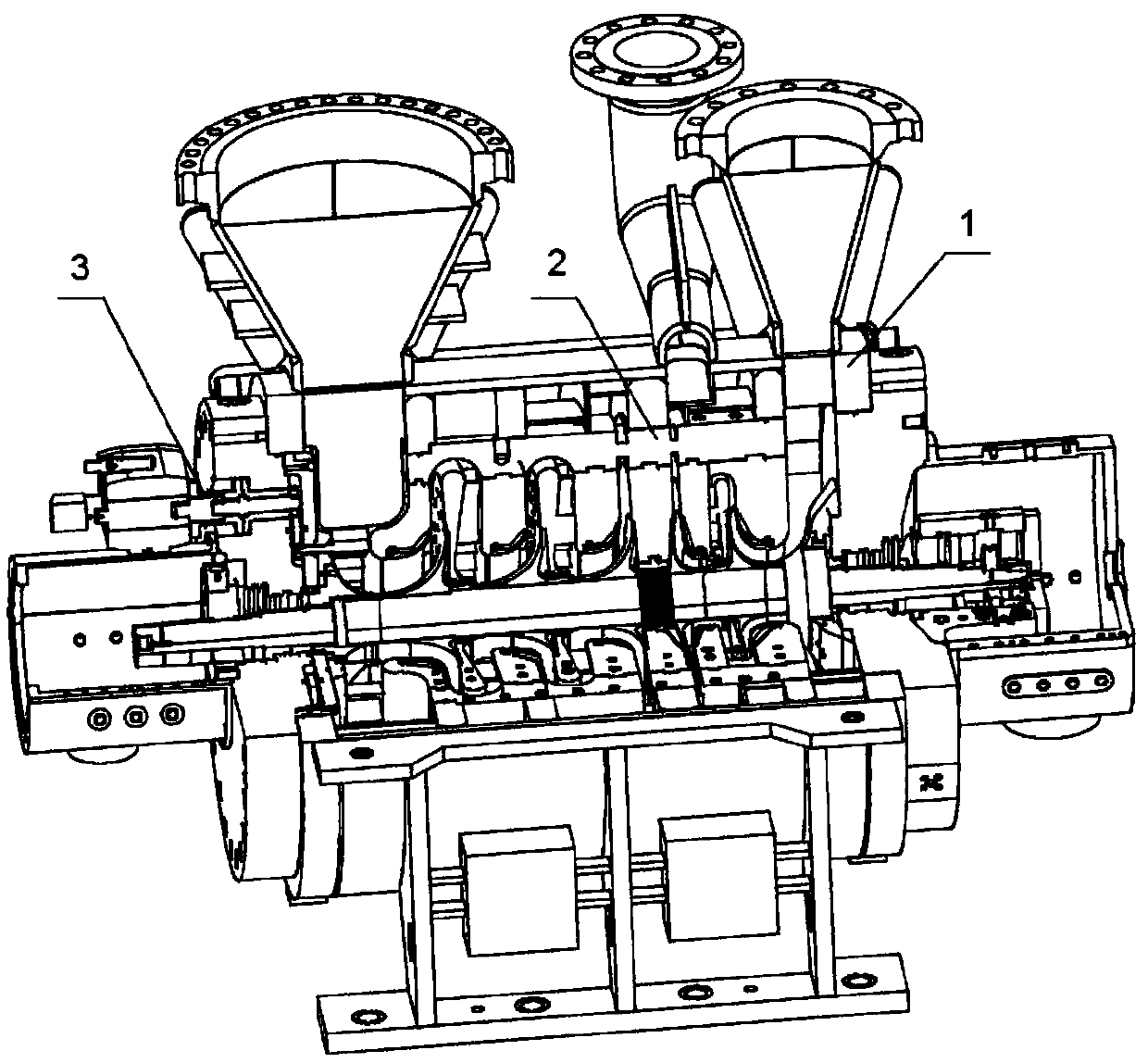

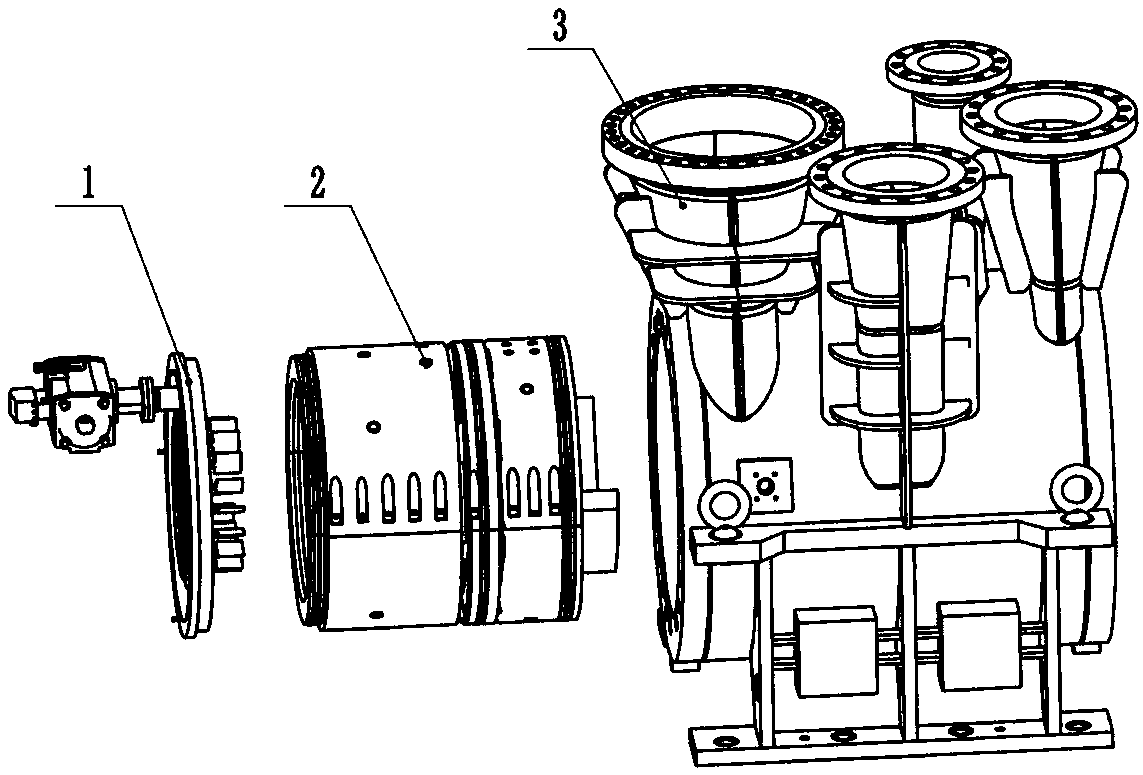

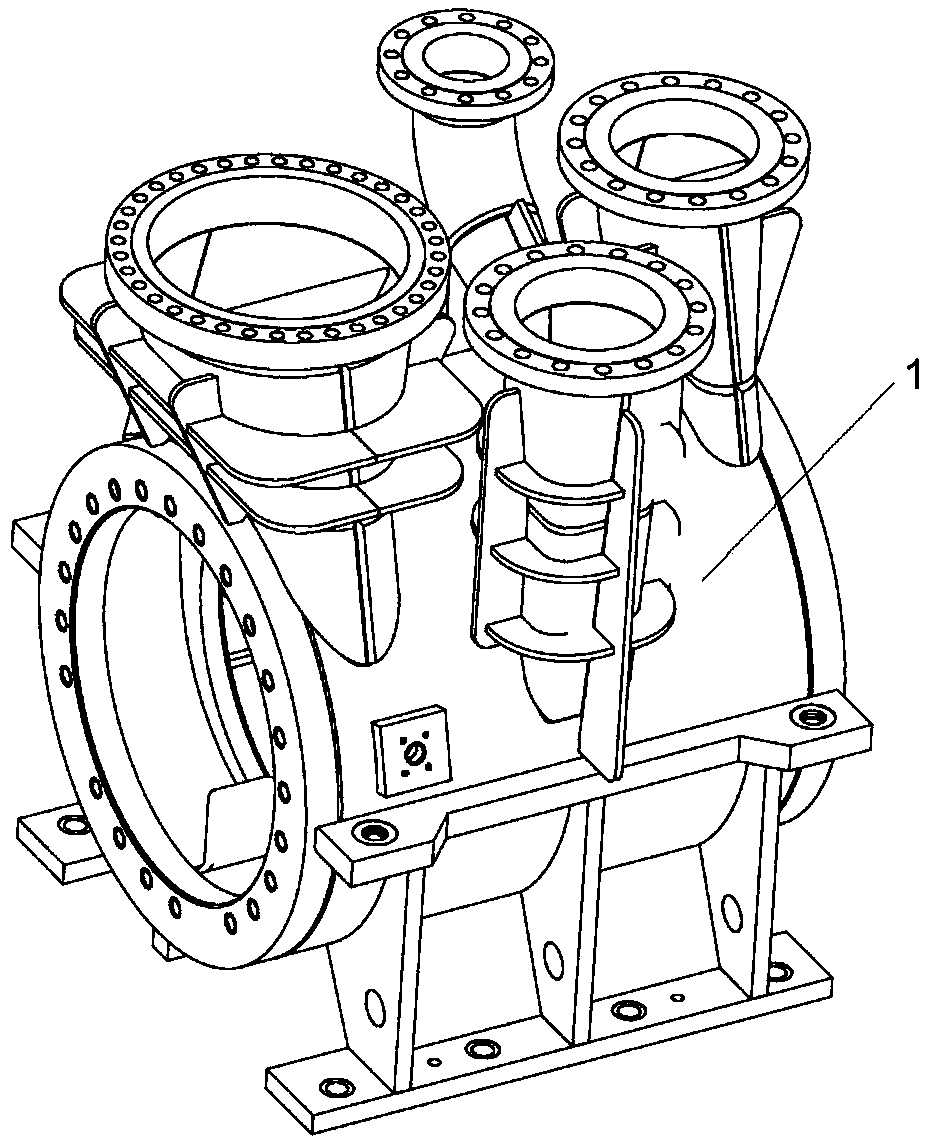

Barrel type refrigerant compressor

ActiveCN107956745AGood high pressure sealingMeet the arrangementPump componentsPumpsEngineeringHigh pressure

The invention relates to a barrel type refrigerant compressor. The compressor comprises a barrel type welding machine shell, an inner machine shell and an adjustable guide blade execution mechanism, wherein a volute chamber is arranged inside the barrel type welding machine shell; the inner machine shell is arranged inside the barrel type welding machine shell, and a connecting rib set is arrangedin the circumferential direction of the shell wall of the inner machine shell and is used for dividing the inner machine frame into at least two units of inner machine frame bodies; and the inner machine shell is arranged in the part, close to one side of the inner machine shell, of the barrel type welding machine shell. The barrel type refrigerant compressor has the advantages of being light inunit weight and low in unit cost, and the refrigerant compressor can also achieve high-pressure sealing performance and the single-layer arrangement of the unit.

Owner:SHENYANG TURBO MASCH CORP

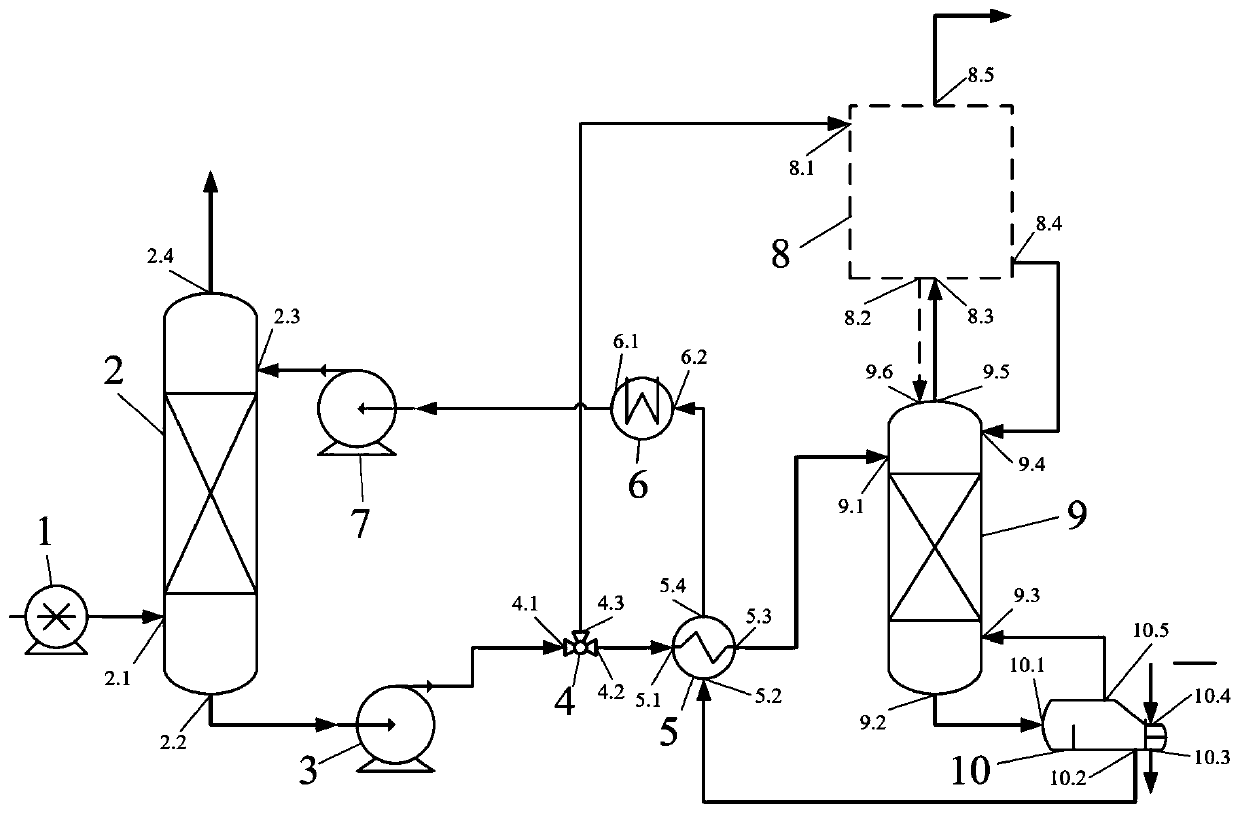

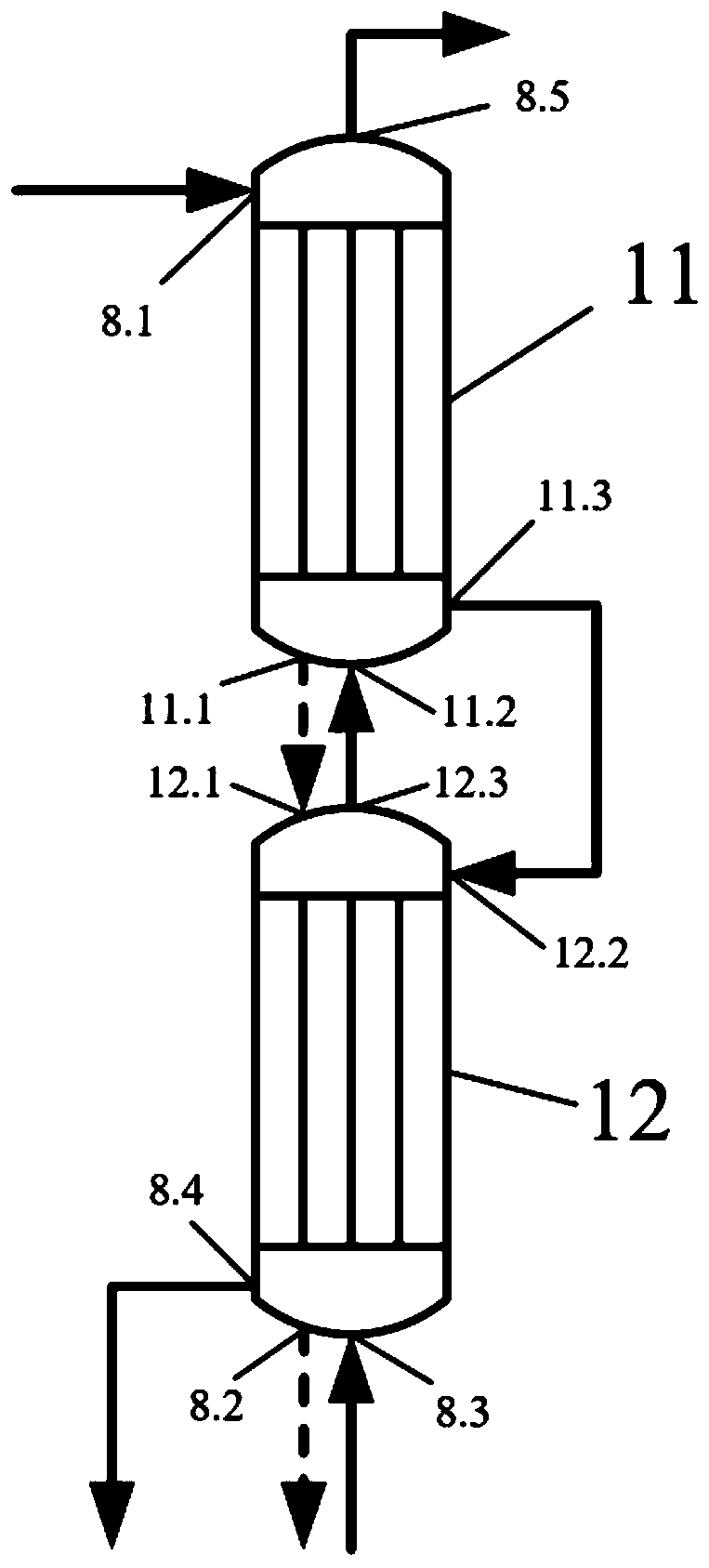

CO2 chemical absorption system and method for reinforcing waste heat recovery of hydrophilic and hydrophobic double-membrane heat exchangers

PendingCN110170235AEnhanced total water mass transferImprove waste heat recovery efficiencyDispersed particle separationWaste heat recovery unitCo2 absorption

The invention discloses a CO2 chemical absorption system and method for reinforcing waste heat recovery of hydrophilic and hydrophobic double-membrane heat exchangers. The CO2 chemical absorption system for reinforcing waste heat recovery of the hydrophilic and hydrophobic double-membrane heat exchangers comprises CO2 absorption equipment, CO2 recovery equipment, a rich solution pump, a lean solution pump, a lean solution cooler, a diverging three way valve, a rich and lean solution heat exchanger, a booster fan and a regenerated gas waste heat recovery unit. The CO2 chemical absorption systemfor reinforcing waste heat recovery of the hydrophilic and hydrophobic double-membrane heat exchangers, disclosed by the invention, has the advantages that water vapor and liquid water can be correspondingly and effectively recovered for different working conditions by combining the hydrophilic-membrane heat exchanger and the hydrophobic-membrane heat exchanger as a heat exchanging medium betweenthe regenerated gas and a cold rich solution; convective heat exchange reinforcing from the regenerated gas to the cold rich solution is realized from two aspects of sufficiently utilizing water vapor latent heat and promoting water vapor / liquid water transfer enhancement convective heat exchange. Therefore, the waste heat recovery efficiency of the regenerated gas is greatly enhanced; moreover,multiple combination modes are also suitable for waste heat recovery demands in large-scale industrial application.

Owner:HUAZHONG AGRI UNIV

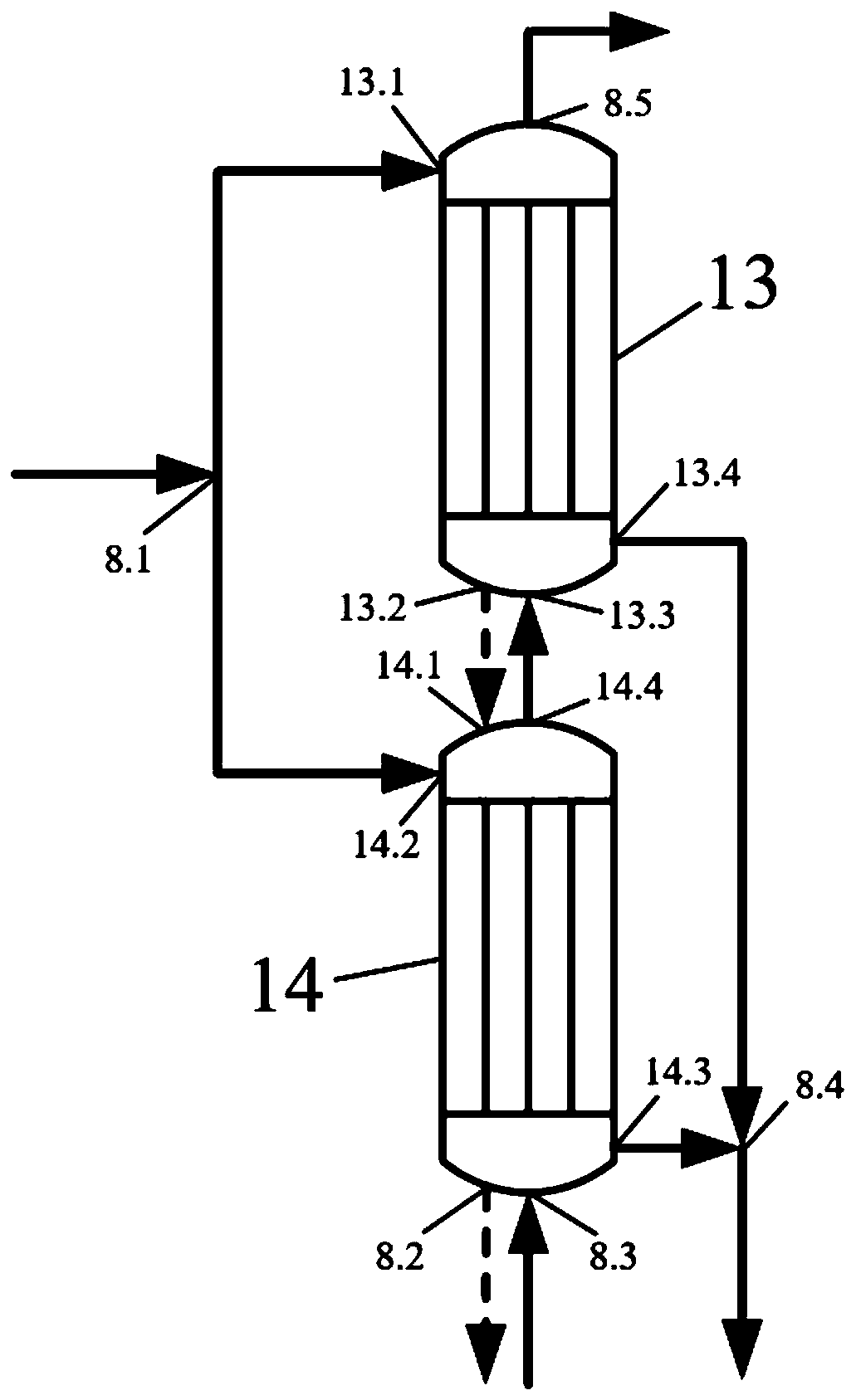

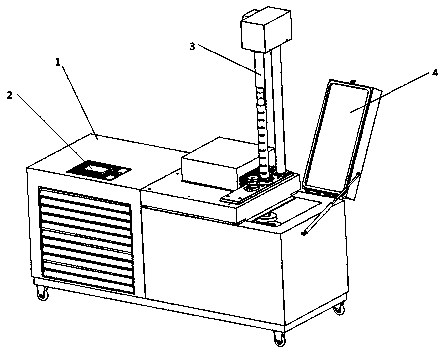

Low-temperature falling ball impact testing machine

According to a low-temperature falling ball impact testing machine, a placing part comprises an experiment table of a disc structure, and a plurality of sample seats arranged around the circle centerare arranged on the experiment table. The impact part comprises a fixed plate mounted at the upper end of the freezing box, and an impact column and a supporting column are arranged on the fixed plate. A lifting motor table is fixedly arranged at the top ends of the impact column and the supporting column, a lifting motor is arranged on the lifting motor table, a rotating shaft of the lifting motor is horizontally arranged, and two driven wheels parallel to the rotating shaft of the lifting motor are arranged on the two sides of the rotating shaft of the lifting motor. The impact column and the supporting column are both hollow and are of an up-down penetrating structure, and a traction rope is arranged in the supporting column. An electromagnet and a steel ball are arranged in the impactcolumn, and a placing hole for placing the steel ball is formed in the impact column. The traction rope bypasses the driven wheel and a rotating shaft of the lifting motor to be connected with the upper end of the electromagnet. A punched hole for communicating the fixed plate with the upper wall of the freezing box is formed in the lower end of the fixed plate, and is over against the upper end of the sample seat.

Owner:重庆世通仪器检测服务有限公司

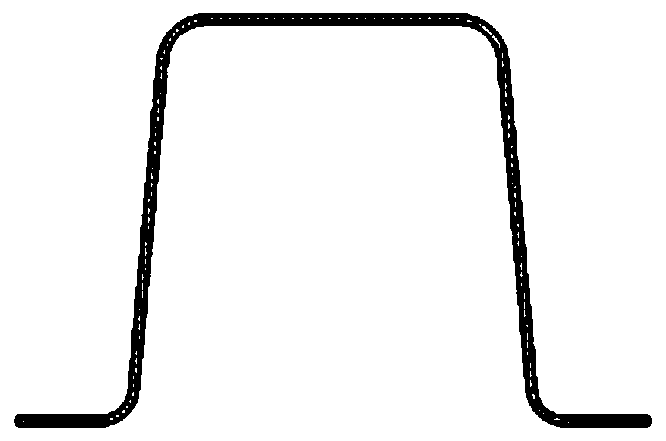

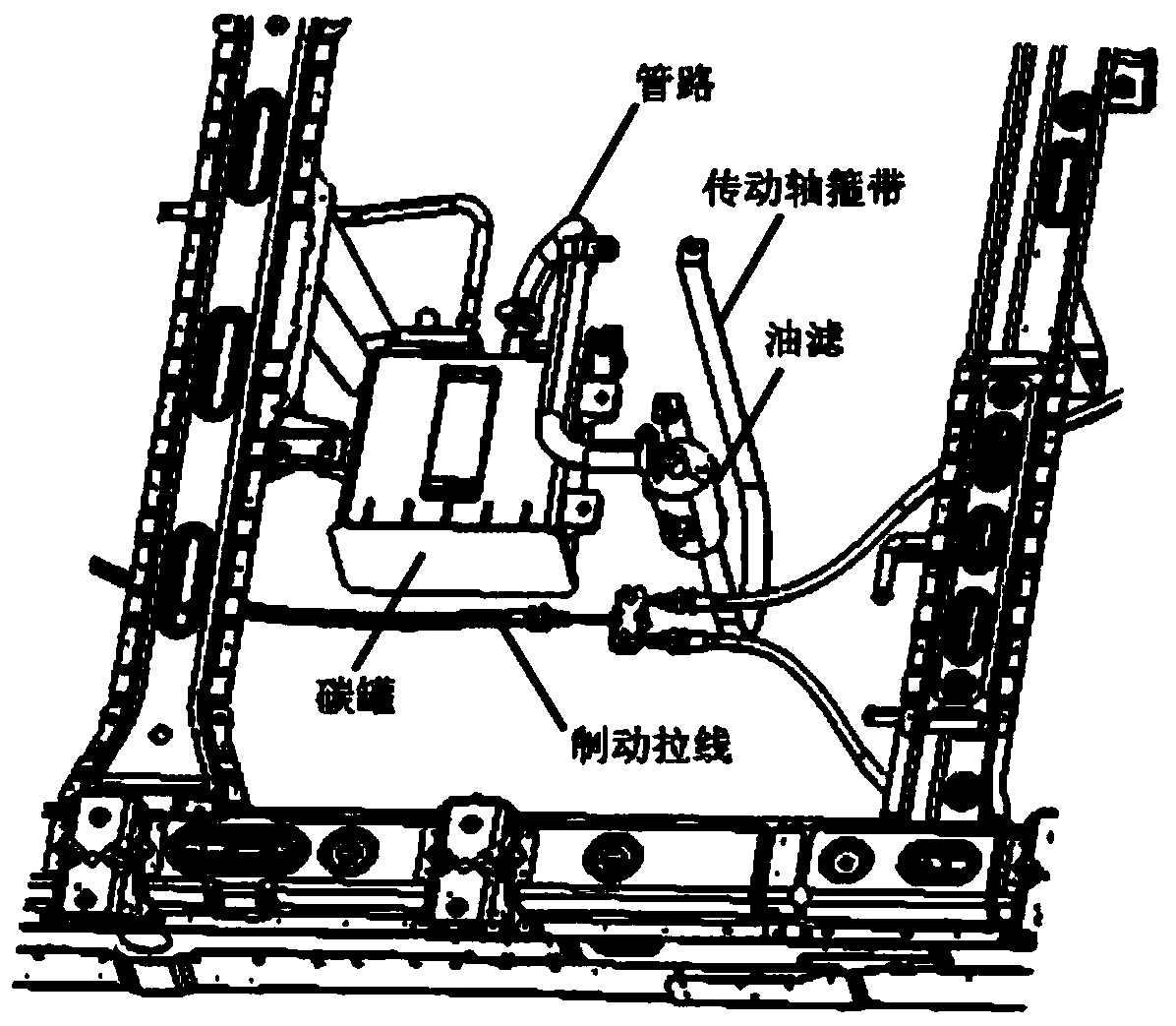

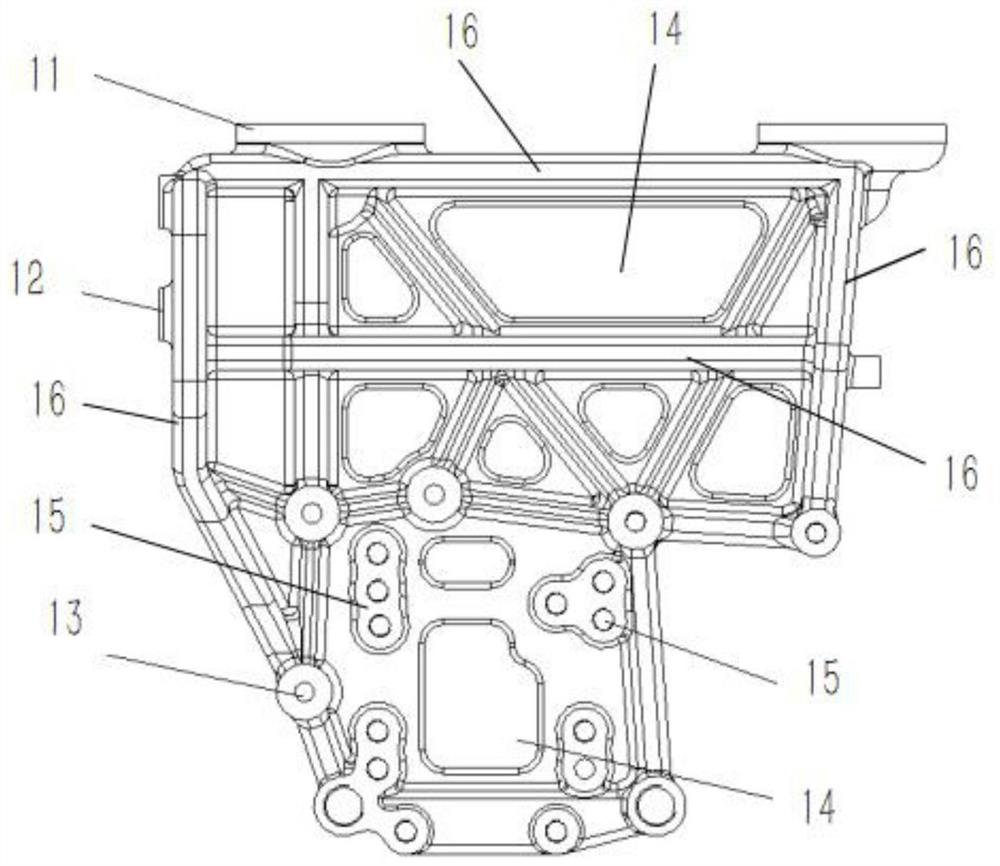

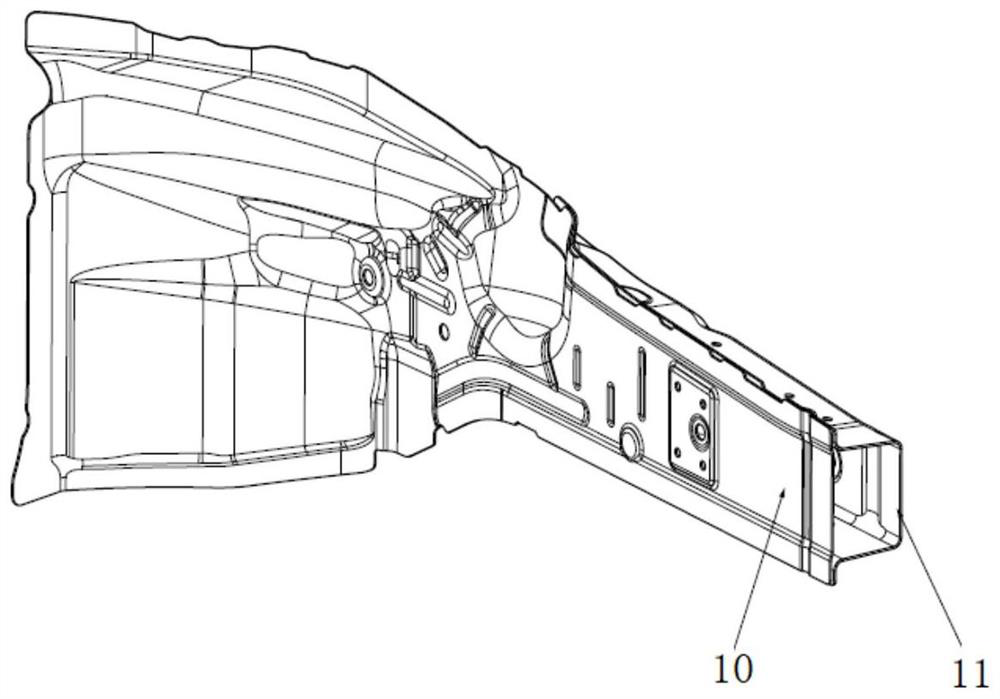

Lower body cross beam structure of micro-truck, and machining process thereof

InactiveCN111361640AMeet the arrangementSatisfy the direction space requirementUnderstructuresBrakeDrive shaft

The invention discloses a lower vehicle body cross beam structure of a micro-truck. The cross beam structure comprises a longitudinal beam, the longitudinal beam is composed of a rear longitudinal beam front section reinforcing plate, a longitudinal beam rear section body connecting plate, a longitudinal beam lower reinforcing plate, a longitudinal beam lower reinforcing plate rear portion and a rear longitudinal beam cover plate. The rear longitudinal beam front section reinforcing plate is welded with the inner wall of the longitudinal beam rear section body connecting plate, the longitudinal beam lower reinforcing plate is welded to the outer wall of the lower end of the longitudinal beam rear section body connecting plate, the rear portion of the longitudinal beam lower reinforcing plate is welded to the longitudinal beam lower reinforcing plate, the cross beam structure further comprises a cross beam, the cross beam is an n-shaped circular tube beam, a cross beam penetrating holeis formed in the longitudinal beam rear section body connecting plate, and the two ends of the cross beam penetrate through the cross beam penetrating hole respectively and are welded to the longitudinal beam rear section body connecting plate. The cross beam is divided into a welding section and a bent bearing section, and a brake cable support, a carbon tank support, a transmission shaft strap support and an oil filter support are welded to the welding section, so that the space requirement of the longitudinal beam in the Z direction is met to the maximum extent, installation of newly-addedparts is facilitated, the change amount of the longitudinal beam is reduced, the number of dies is reduced, and cost is reduced.

Owner:ZHEJIANG UFO AUTOMOBILE MFG CO LTD +1

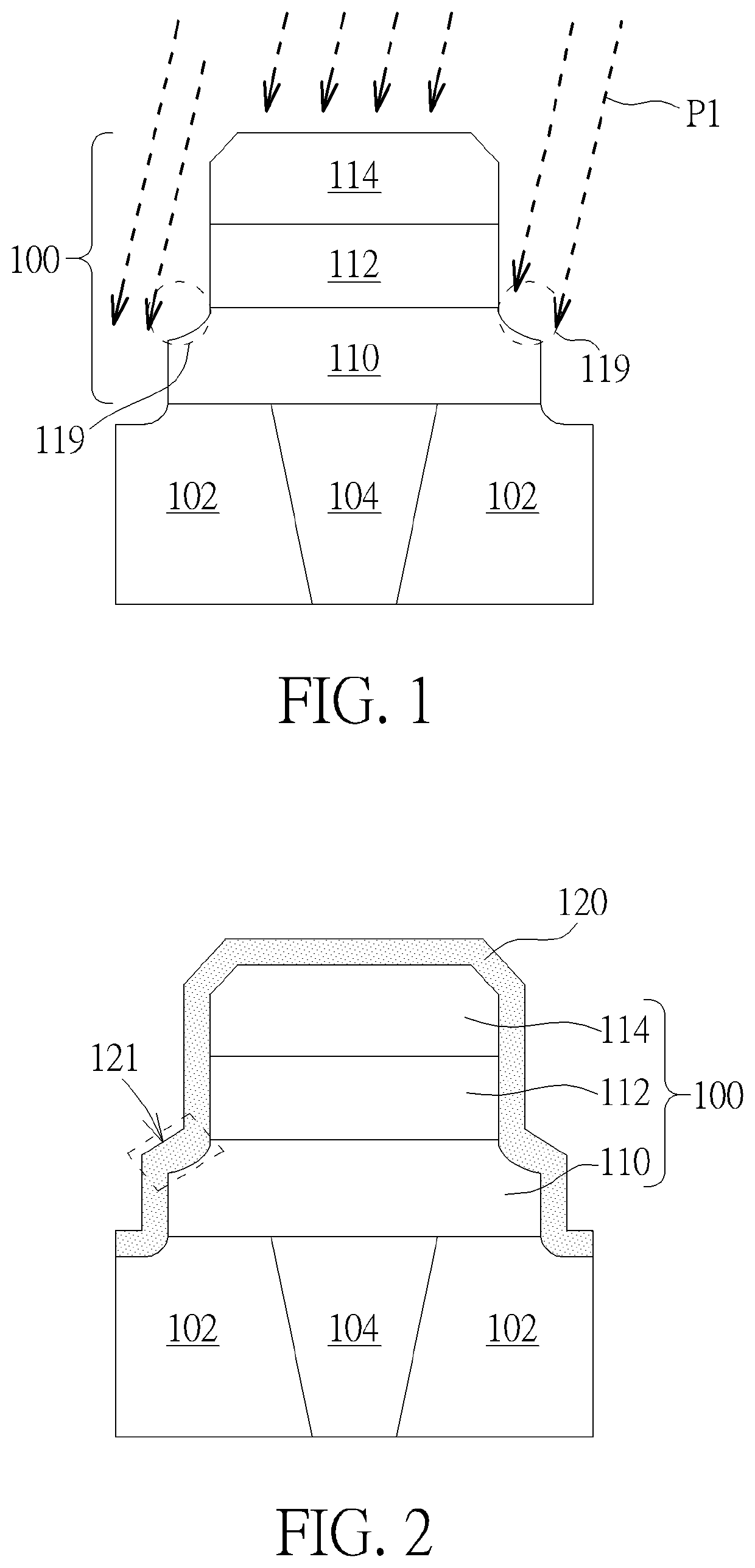

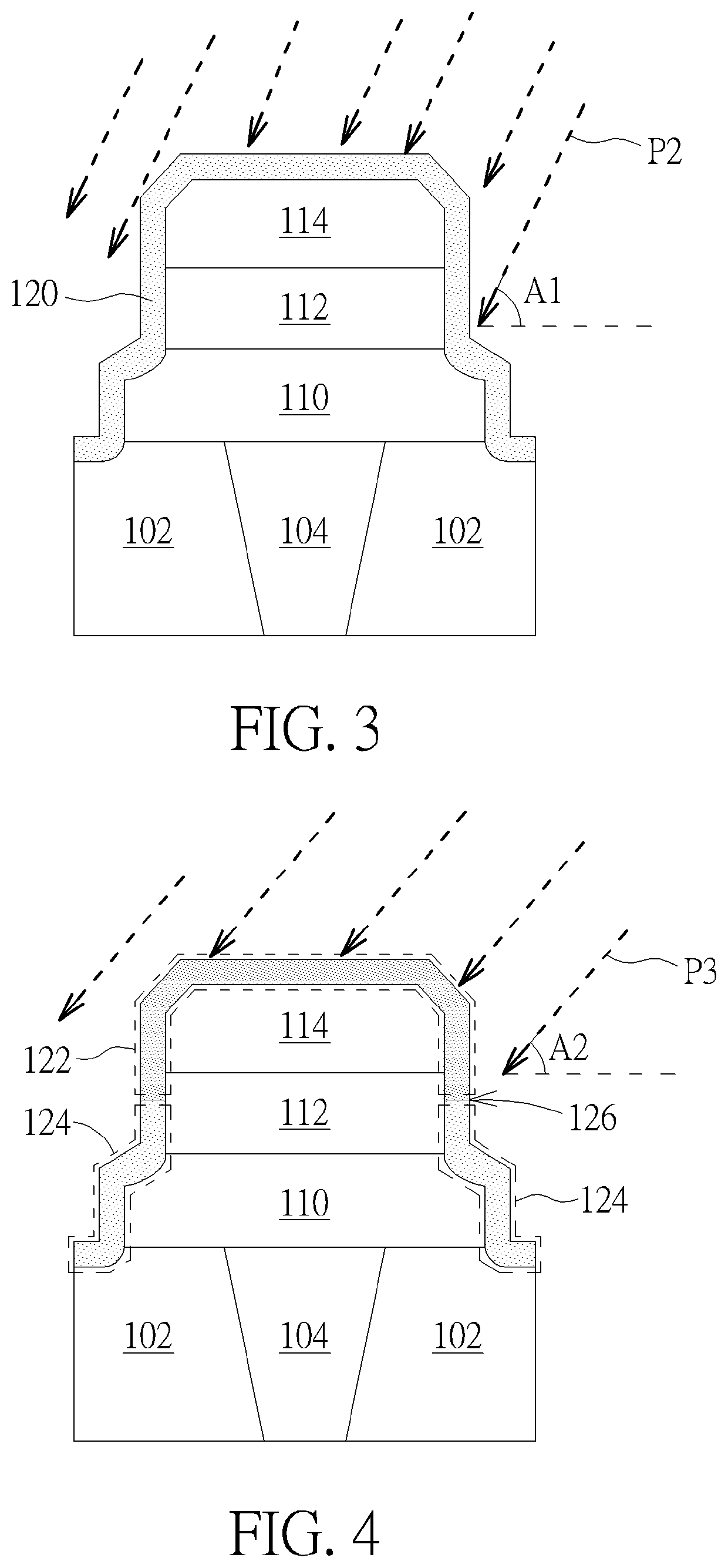

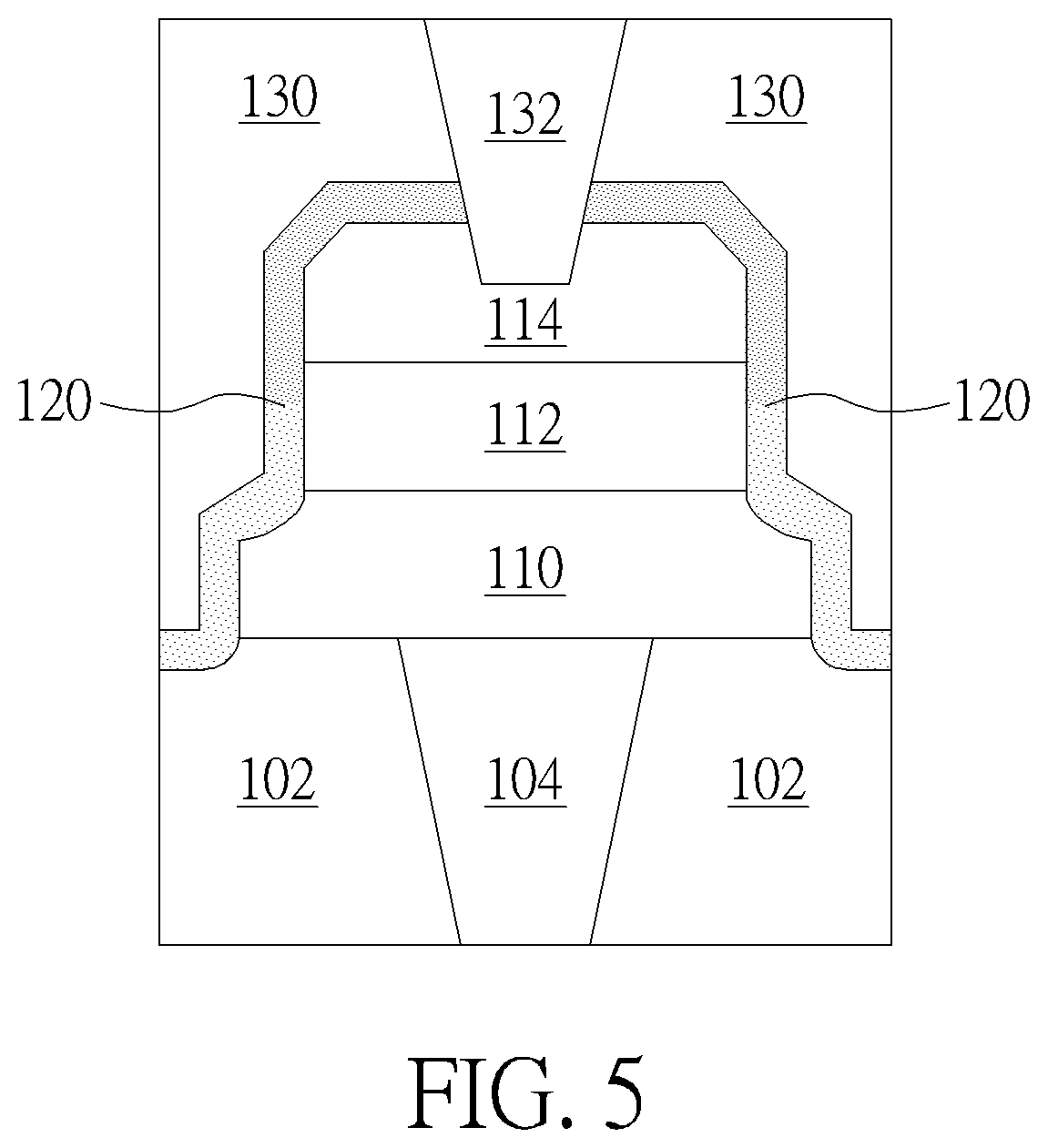

Semiconductor structure and manufacturing method thereof

PendingUS20220140239A1Weaken energyIncreased carrier mobilitySolid-state devicesSemiconductor devicesSemiconductor structureRandom access memory

The invention provides a semiconductor structure, the semiconductor structure includes a substrate, a resistance random access memory on the substrate, an upper electrode, a lower electrode and a resistance conversion layer between the upper electrode and the lower electrode, and a cap layer covering the outer side of the resistance random access memory, the cap layer has an upper half and a lower half, and the upper half and the lower half contain different stresses.

Owner:UNITED MICROELECTRONICS CORP

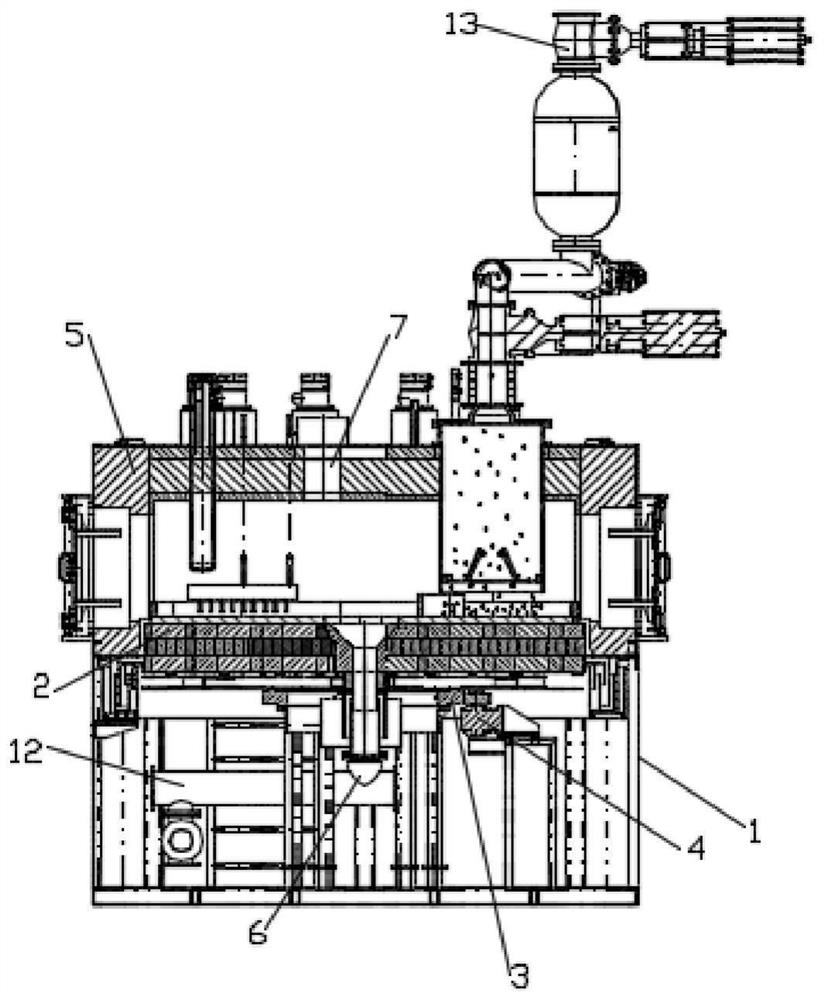

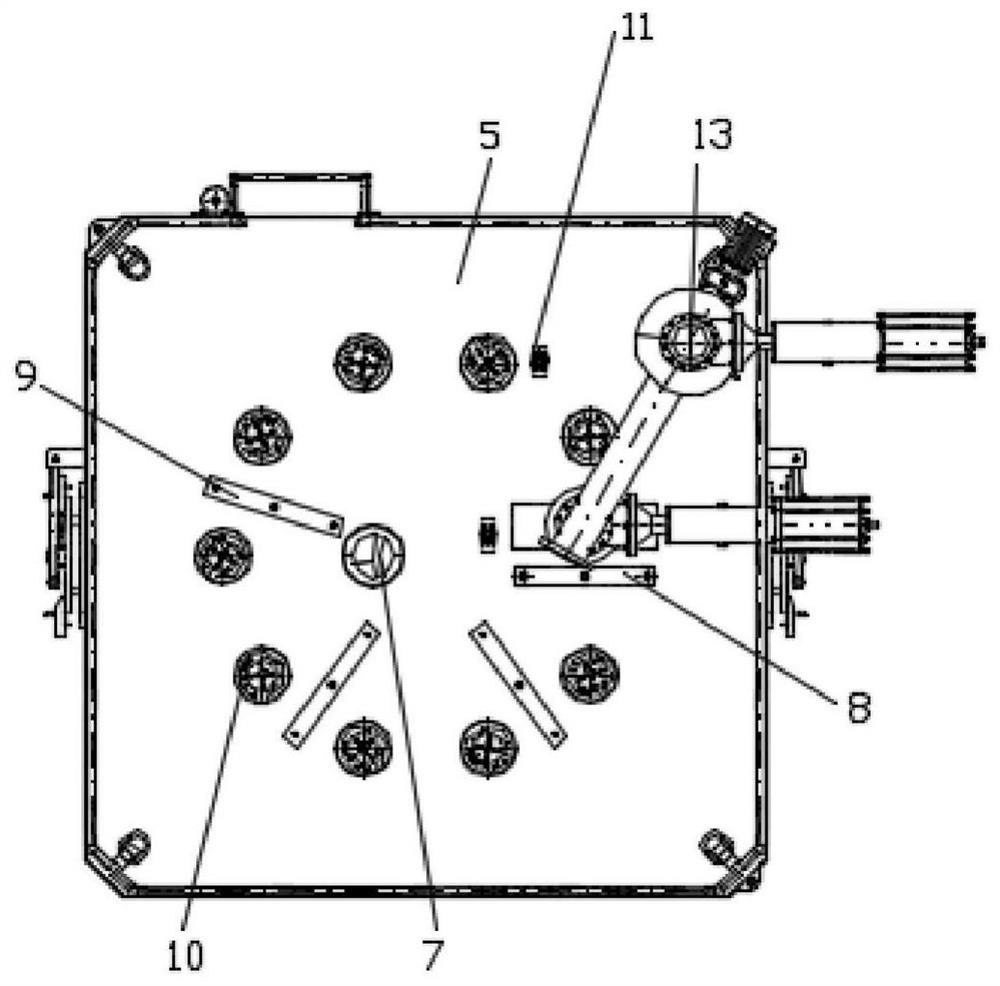

Furnace platform rotary type thermal cracker

PendingCN112646591AGood pyrolysis effectUniform thermal crackingIndirect heating destructive distillationSpecial form destructive distillationProcess engineeringMechanical engineering

The invention discloses a furnace platform rotary type thermal cracker in the technical field of environment-friendly solid waste (hereinafter referred to as 'solid waste') treatment. The thermal cracker comprises a fixed bracket, a rotary furnace platform, a toothed turntable bearing and the like; the surface of the rotary furnace platform adopts a high-temperature-resistant material resistant to corrosion at a high temperature; the rotary furnace platform can bear solid waste subjected to thermal cracking treatment in the thermal cracker; and a driving device drives the toothed turntable bearing to rotate, the toothed turntable bearing rotates to drive the rotary furnace platform to rotate, the rotary furnace platform contains the solid waste in the rotating process, and a space formed between a cover type shell and the rotary furnace platform is a thermal cracker furnace cavity. Solid waste enters the rotary furnace platform through a feeding mechanism and is arranged and turned over through a material distributing mechanism and a material turning mechanism, it is guaranteed that the solid waste is evenly heated and cracked, the thermal cracking effect is good, meanwhile, conveying and arrangement of the solid waste are met, high-temperature resistance and corrosion resistance are achieved, the solid waste thermal cracking effect is good, and meanwhile the service life is long.

Owner:伊勉特(上海)环境技术有限公司

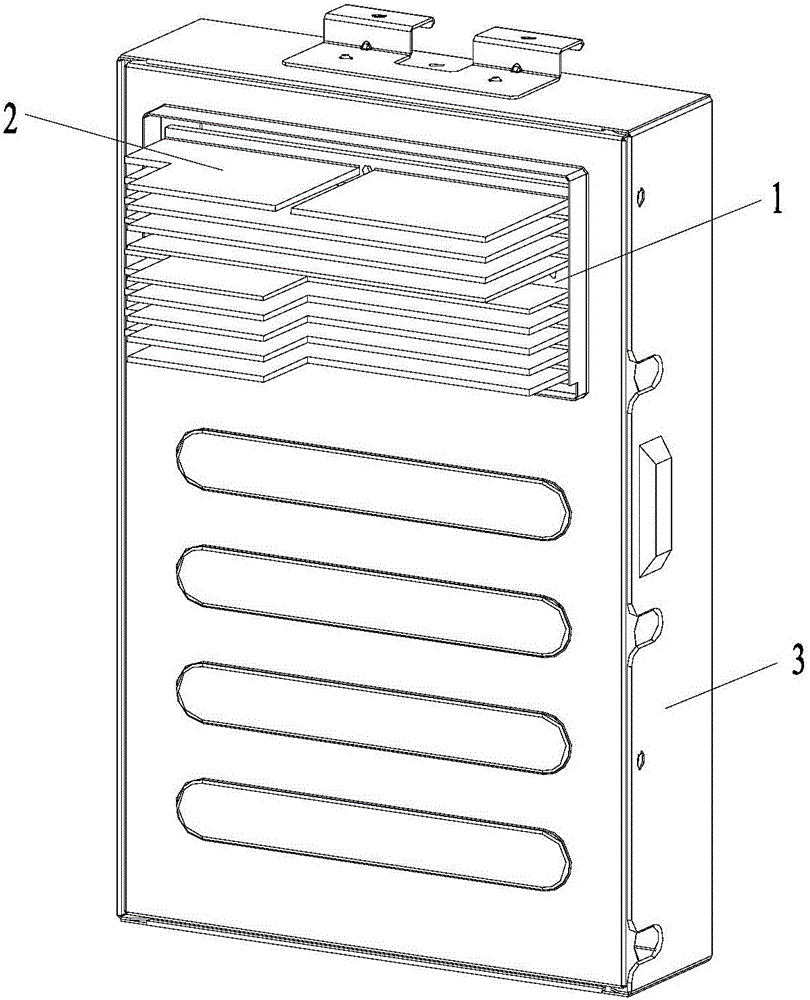

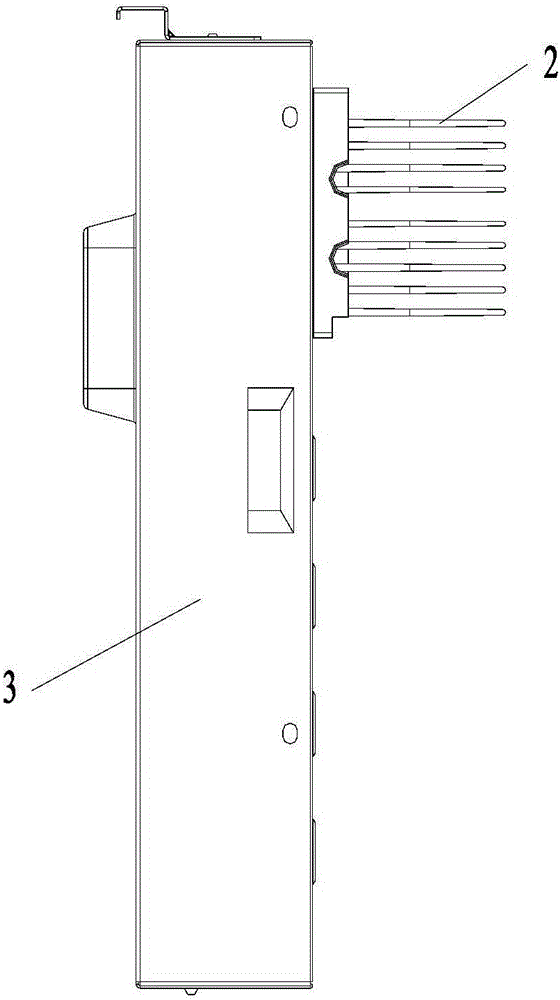

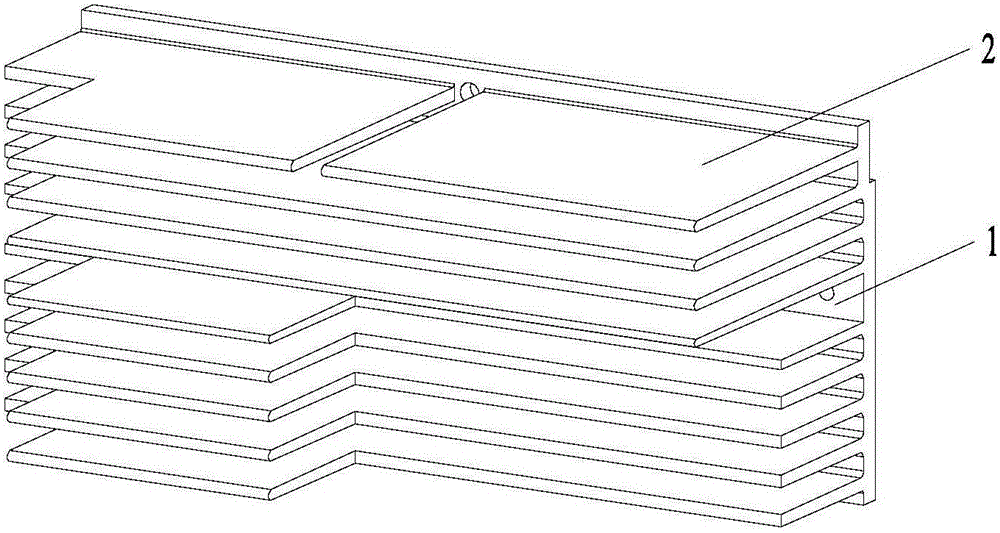

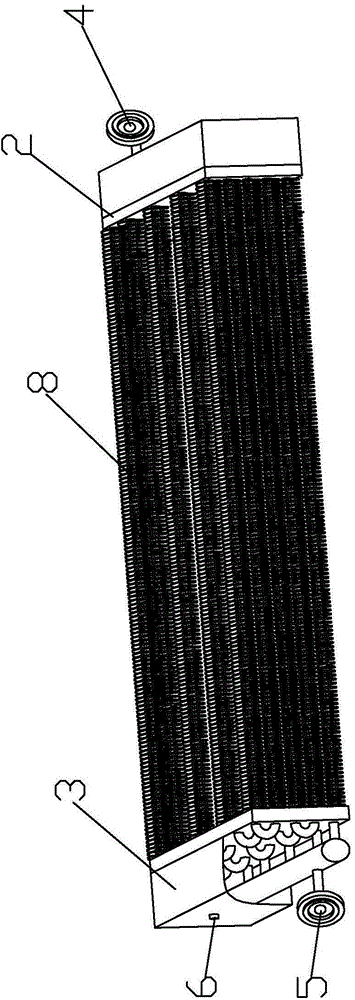

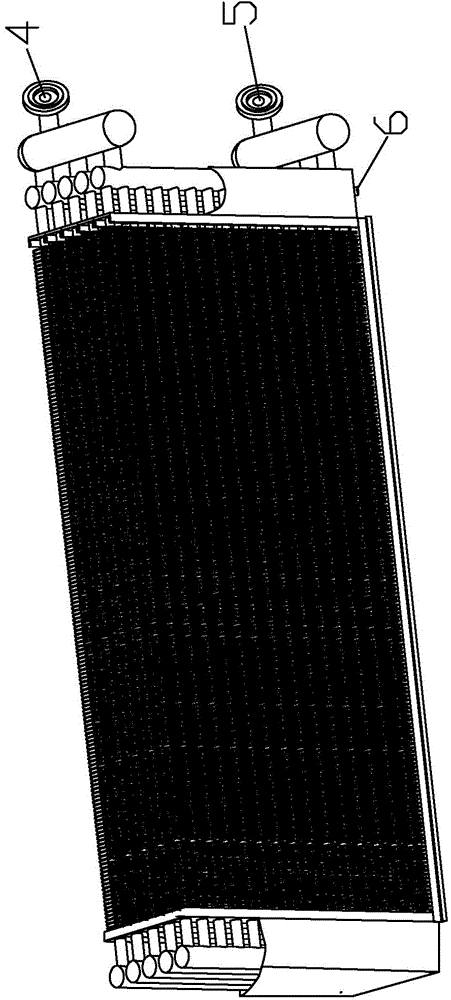

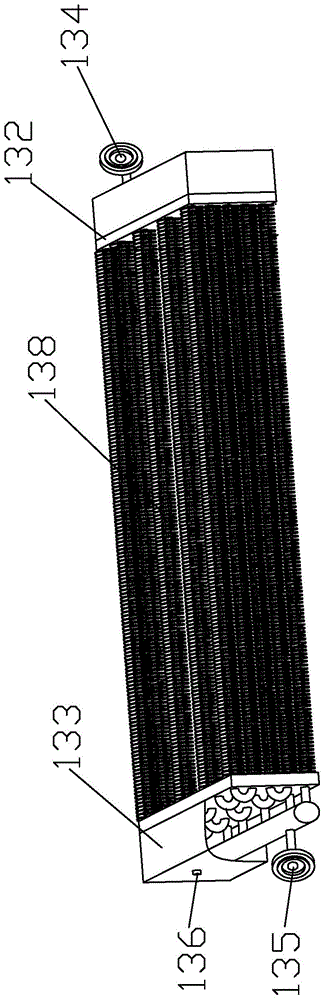

Radiator, controller and air conditioner

InactiveCN106091169ACompact structureSolve the volume increaseLighting and heating apparatusAir conditioning systemsEngineeringRefrigerant

The invention provides a radiator, a controller and an air conditioner. The radiator comprises a heated plate, a radiating part and connecting pipes, wherein the heated plate makes contact with an element and is internally provided with a first pipeline; a second pipeline is arranged in the radiating part; and the radiating part and the heated plate are connected through the connecting pipes in a position-adjustable mode, the connecting pipes communicate with the first pipeline and the second pipeline to form a circulating loop, and a refrigerant is arranged in the circulating loop. By the application of the technical scheme, the problem that the size of the air conditioner in the prior art is increased due to the non-flexible radiator structure can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Variable valve timing method

ActiveCN102852582AChange on durationRealize timing controlValve arrangementsMachines/enginesVariable valve timingEngineering

The invention discloses a variable valve timing method used for controlling opening and closing timing of a valve of a vehicular engine. When the valve needs to be opened in advance, a phase adjusting mechanism drives a camshaft to rotate forwards relative to a rotary driving part; when the camshaft rotates to a position enabling the valve to be maximum in lift basically, the phase adjusting mechanism keeps the camshaft at the current position, so that the valve is kept at the maximum lift basically; and after the camshaft is kept at the current position for a period of preset time, the rotary driving part drives the camshaft to rotate continuously. The valve can be opened continuously by the variable valve timing method, and the variable valve timing method is larger in air inflow as compared with that in the prior art under the high-rotational-speed high-load working condition.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

A method for manufacturing high-voltage cross-linked polyethylene insulated cable molded insulating joint

ActiveCN110350451BCompact structureSmall sizeApparatus for joining/termination cablesInsulation layerElectrical conductor

The invention discloses a manufacturing method for a molding-type insulation connector of a high-voltage cross-linked polyethylene insulated cable. The manufacturing method comprises the steps of 1) stripping and pre-processing the cable; 2) welding a conductor; 3) performing shielding and molding on the conductor; 4) molding an I segment of an insulation main body of the connector by a template method; 5) molding an I segment of insulation shielding of the connector by the template method; 6) molding an II segment of the insulation main body of the connector by the template method; 7) moldingan II segment of insulation shielding of the connector by the template method; 8) performing vulcanization; 9) degassing; 10) wrapping a belt material; and 11) installing an insulation copper shell.According to the manufacturing method for the molding-type insulation connector of the high-voltage cross-linked polyethylene insulated cable, an original integrated pre-fabricated connector is abandoned, a molding recovery conductor shielding layer, an insulation layer and an insulation shielding layer with materials same as a cable body are employed, no physical interface exists, integration ofconnector main insulation and cable main insulation is achieved, so that the cable is free from influence of thermal expansion and cold shrinkage, good water prevention performance is achieved, and electric field and hot field are uniform and stable in distribution.

Owner:HENGTONG SUBMARINE POWER CABLE CO LTD +1

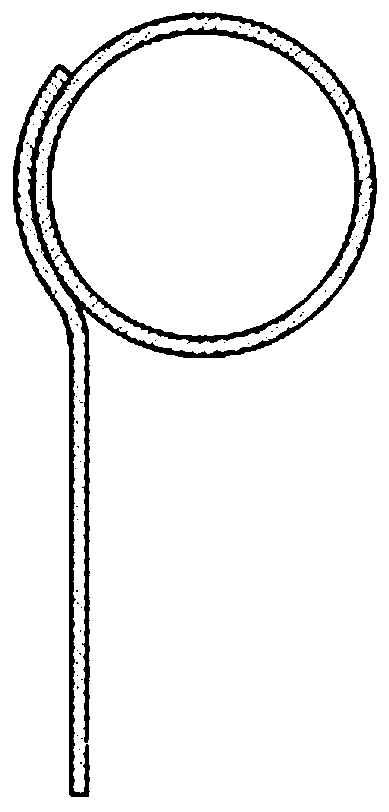

Connecting joint device of fabricated homestay hotel spatial structure

InactiveCN111997187AMeet the construction needs of the layoutMeet construction needsBuilding constructionsSpatial structureStructural engineering

The invention discloses a connecting joint device of a fabricated homestay hotel spatial structure, and relates to the technical field of fabricated buildings. According to the technical scheme, the connecting joint device is characterized by comprising a circular connecting rod and two annular bases symmetrically arranged on the two sides of the circular connecting rod, and a connecting plate isannularly arranged on the inner side of the circular connecting rod; and the surfaces of the annular bases are provided with annular grooves in clamping fit with the circular connecting rod. The surfaces of the annular bases are provided with annular bosses located on the inner sides of the annular grooves. The connecting plate can be in contact with the annular bosses. The circular connecting rodis slidably connected with an opening type sliding sleeve. The outer side wall of the sliding sleeve is rotatably connected with a connector. The annular bases are provided with a plurality of clamping grooves in the outer sides of the annular grooves. The connector can be in clamping fit with the clamping grooves. The two annular bases are fixedly connected through a fixing part. The connector can be flexibly adjusted to be in different positions in the same plane. Meanwhile, the connection direction of the connector in a corresponding plane can be flexibly adjusted, and the construction requirement for arranging complex spatial structure bodies in buildings of different artistic styles can be met.

Owner:HUBEI POLYTECHNIC UNIV

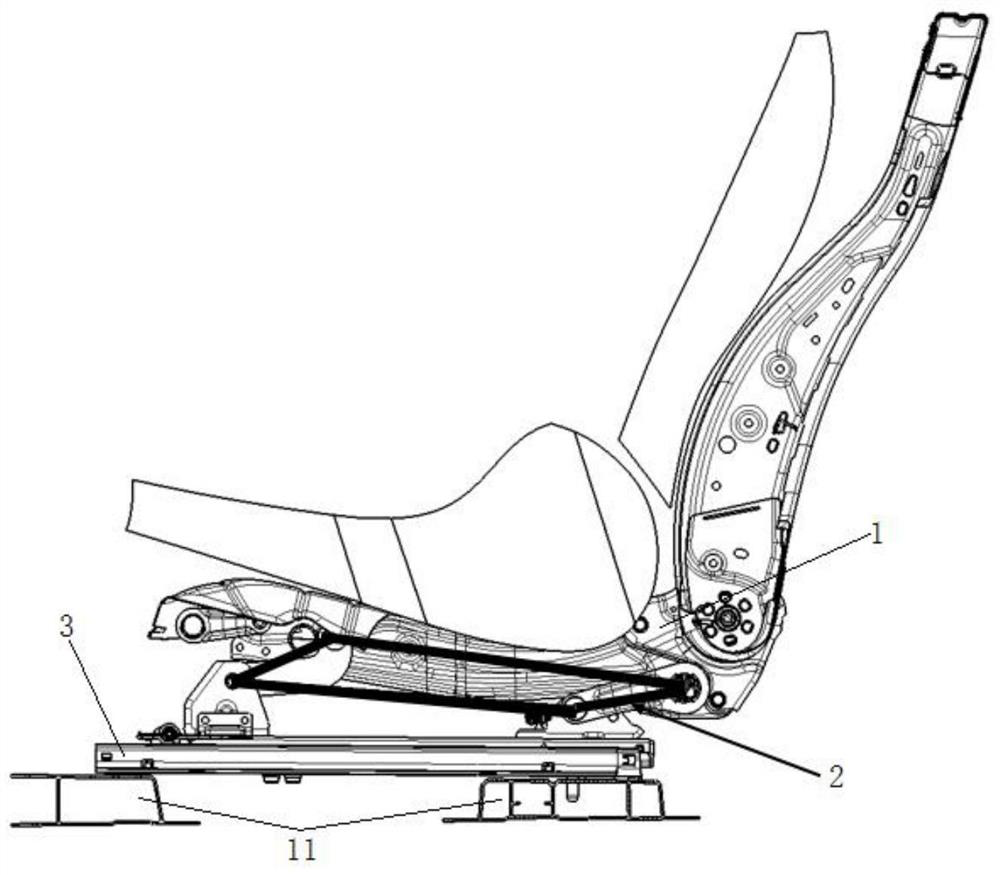

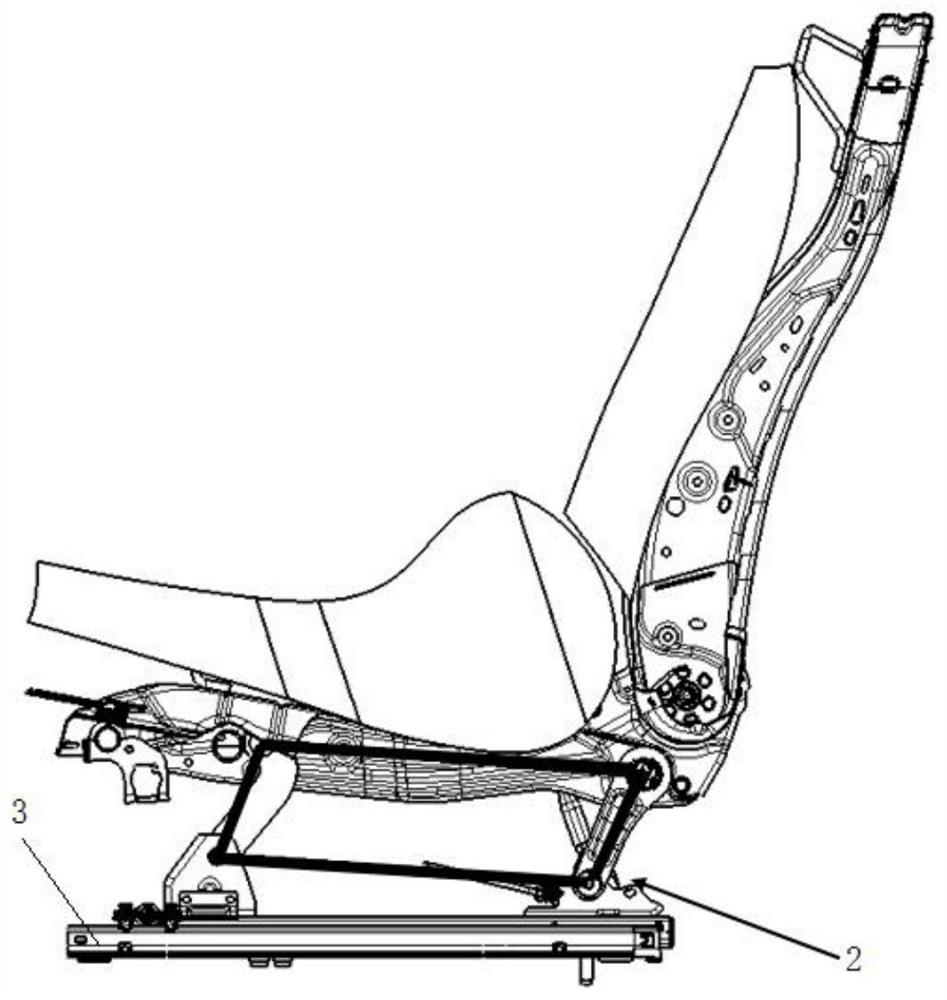

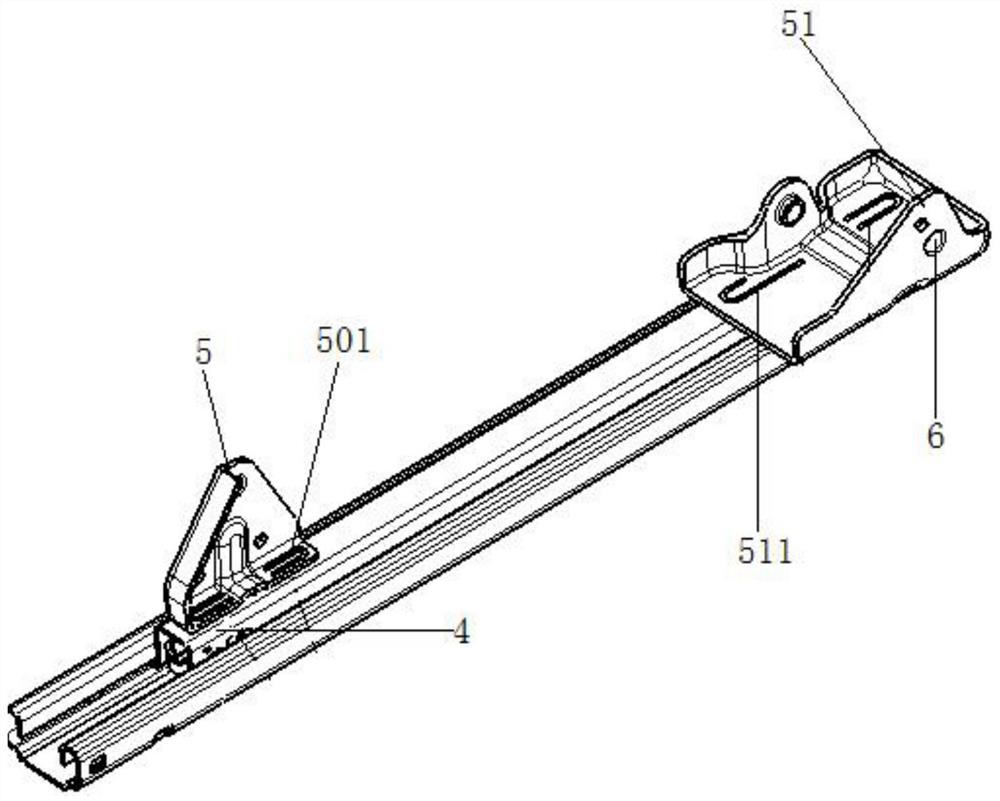

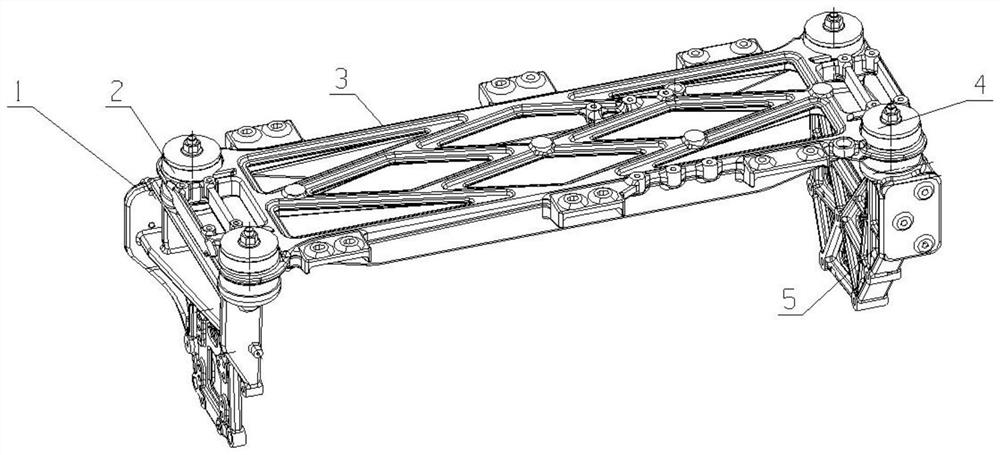

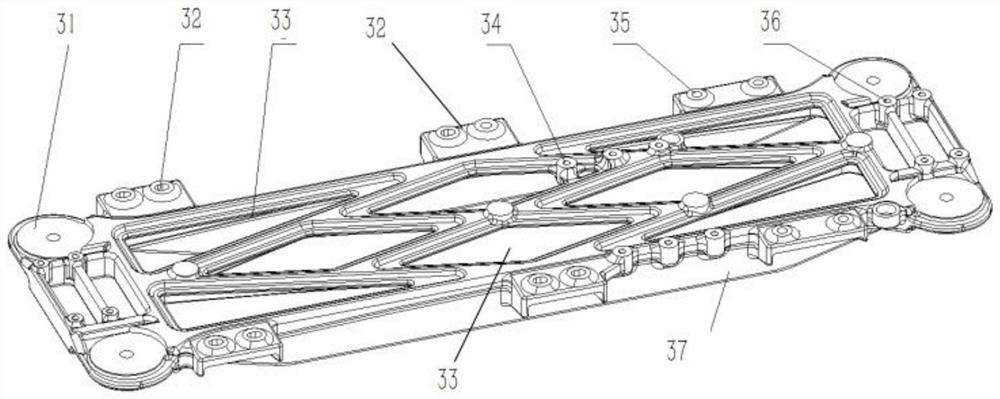

Low-sitting-posture seat framework platform and automobile seat

InactiveCN113581033AIncrease share rateMeet the arrangementMovable seatsCar seatPhysical medicine and rehabilitation

Owner:上海国琻汽车科技有限公司

Frame structure suitable for heavy electric drive special vehicle chassis

ActiveCN113879400ALarge installation spaceImprove maintainabilityUnderstructuresElectric driveElectric machinery

The invention discloses a frame structure suitable for a heavy electric drive special vehicle chassis. The frame structure comprises a left longitudinal beam and a right longitudinal beam which are symmetrically arranged, a front end is connected with the left longitudinal beam and the right longitudinal beam through a front beam, and the middle of the left longitudinal beam and the middle of the right longitudinal beam are supported by a plurality of beam welding parts, a plurality of tail beam welding parts, a plurality of motor supporting seat welding parts and a plurality of steering reinforcing beam welding parts. A power unit upper supporting beam welding part and a power unit lower supporting beam welding part serve as a middle supporting beam, and support is provided for installation of a battery pack and a controller. According to the novel frame structure, all system interfaces can follow the traditional vehicle type structure, the arrangement space of the upper system interfaces is sufficient, the novel frame structure can serve as a universal frame, the frame structure is reasonable in design, novel in form and high in bearing capacity, the good cross-country performance and passing performance of a chassis can be guaranteed, and the novel frame structure is quite suitable for a novel full-electric-drive heavy special vehicle.

Owner:泰安航天特种车有限公司

variable valve timing device

ActiveCN102852581BChange on durationRealize timing controlMachines/enginesNon-mechanical valveAir volumeVariable valve timing

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Protection system, dismounting device and construction method for existing traffic of composite beam upper cover

PendingCN114737479AFirmly connectedAvoid the risk of fallingClimate change adaptationBridge erection/assemblyArchitectural engineeringBlock and tackle

The invention discloses a composite beam upper cover existing traffic protection system, a dismounting device and a construction method, and is applied to the technical field of composite beam construction protection, the composite beam upper cover existing traffic protection system comprises composite beam longitudinal beams, a beam plate structure with the height smaller than or equal to 50 cm, blocking pieces and a high-strength steel wire mesh, and the two sides of the beam plate structure are clamped to the adjacent side edges of the bottoms of the adjacent composite beam longitudinal beams through the blocking pieces correspondingly; strip-shaped areas between the adjacent composite beam longitudinal beams are vertically sealed and separated through the beam plate structures and the blocking pieces, and the high-strength steel wire meshes are arranged below the composite beam longitudinal beams; the dismounting device comprises a first movable support, a second movable support, a second support fixed pulley, a traction rope and a pulley assembly for ballasting. The construction method comprises protection construction and disassembly construction. The protection structure of the protection system is small in occupied space height, high-reliability protection is provided, the protection system can still be applied even when the clearance between the existing traffic building clearance and the composite beam is very limited, meanwhile, the difficulty of the construction method is reduced, the construction process is convenient, and the protection and dismantling speed is high.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

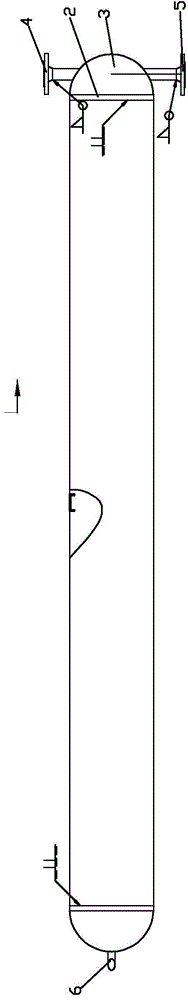

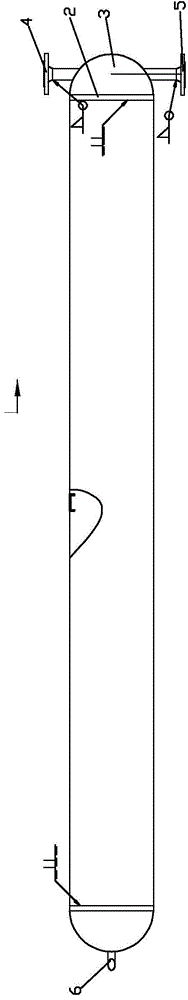

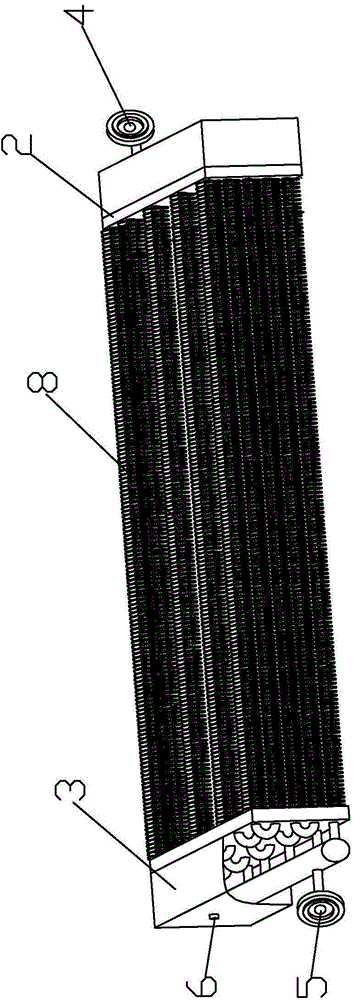

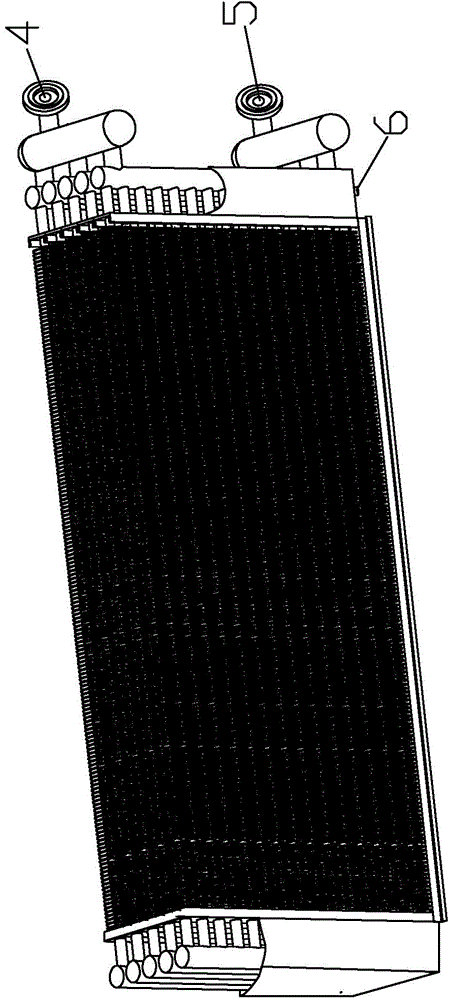

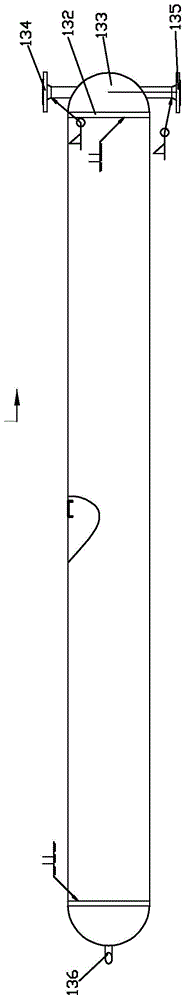

Medium-pressure high-temperature steam heating heat exchanger

InactiveCN103954148BMeet the needs of medium pressure and high temperatureRealize cascade waste heat utilizationStationary conduit assembliesTubular elementsNew energyEngineering

The utility model relates to a medium-pressure high-temperature steam heating heat exchanger, comprising a plurality of heat conduction pipe connection heat exchange pieces; the heat conduction pipe connection heat exchange pieces are of metal seamless heat conduction pipe connection heat exchange pieces; radiating pieces wrap the outer parts of the heat conduction pipe connection heat exchange pieces; heat conduction pipe connection plates are arranged at two ends of the heat conduction pipe connection heat exchange pieces; seal ends are arranged at the outer parts of the heat conduction pipe connection plates; the heat exchanger is also provided with an inlet flange, an outlet flange and a water emptying outlet, which are all arranged on the seal ends. The heat exchanger can bear the weight of about 30Kg, the maximal pressure of 36Kg and the highest temperature of 320 DEG C and can meet the medium-pressure high-temperature needs in the industrial production. Steam heating is adopted, and industrial waste heat steam can be adopted as a heat exchange source to realize the step utilization of waste heat, thus making great contribution to use of new resources, effectively avoiding haze generated in the burning of a boiler and eliminating the haze source. The heat exchanger accords with the topic of environment protection, and is low in price, low in cost and simple in operation.

Owner:ZHEJIANG JINGBAO MACHINERY

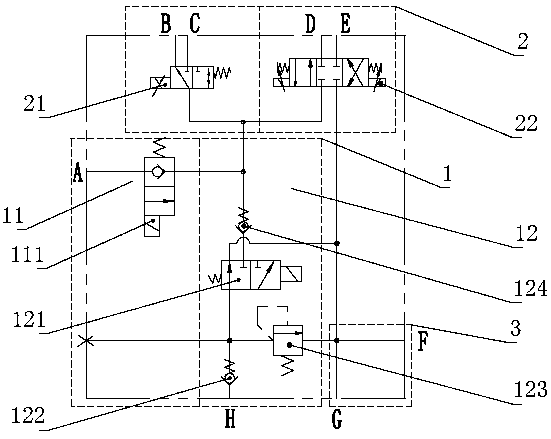

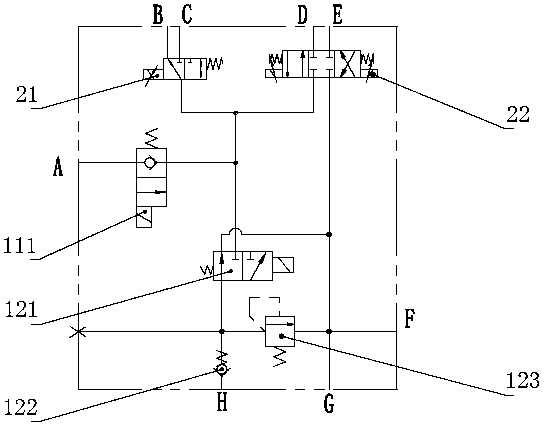

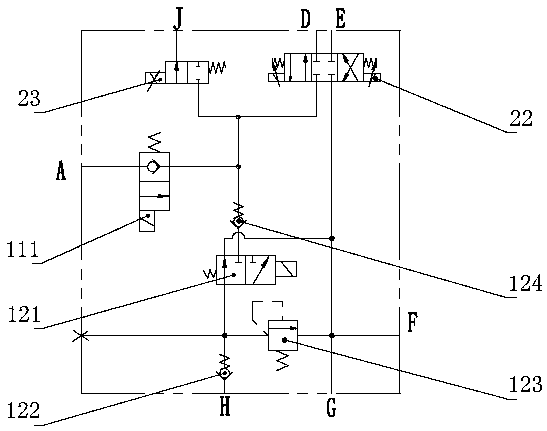

Hydraulic combination valve

PendingCN110486345AMeet the control requirementsCompact structureServomotor componentsSolenoid valveControl system

A hydraulic combination valve comprises an oil source switching system and an auxiliary combined control system which are connected with each other in series, and the oil source switching system comprises a first oil source switching system and a second oil source switching system which are connected with each other in parallel. The first oil source switching system comprises a first oil source switching valve which is a two-position two-way solenoid valve; and the second oil source switching system comprises a second oil source switching valve which is a two-position three-way solenoid valve.The hydraulic combination valve is compact in structure, and safe and reliable, and can meet hydraulic circuit arrangement with different flow requirements.

Owner:LIUGONG CHANGZHOU MACHINERY

Medium-pressure high-temperature steam heating heat exchanger

InactiveCN103954148AMeet the needs of medium pressure and high temperatureRealize cascade waste heat utilizationStationary conduit assembliesTubular elementsNew energyEngineering

The utility model relates to a medium-pressure high-temperature steam heating heat exchanger, comprising a plurality of heat conduction pipe connection heat exchange pieces; the heat conduction pipe connection heat exchange pieces are of metal seamless heat conduction pipe connection heat exchange pieces; radiating pieces wrap the outer parts of the heat conduction pipe connection heat exchange pieces; heat conduction pipe connection plates are arranged at two ends of the heat conduction pipe connection heat exchange pieces; seal ends are arranged at the outer parts of the heat conduction pipe connection plates; the heat exchanger is also provided with an inlet flange, an outlet flange and a water emptying outlet, which are all arranged on the seal ends. The heat exchanger can bear the weight of about 30Kg, the maximal pressure of 36Kg and the highest temperature of 320 DEG C and can meet the medium-pressure high-temperature needs in the industrial production. Steam heating is adopted, and industrial waste heat steam can be adopted as a heat exchange source to realize the step utilization of waste heat, thus making great contribution to use of new resources, effectively avoiding haze generated in the burning of a boiler and eliminating the haze source. The heat exchanger accords with the topic of environment protection, and is low in price, low in cost and simple in operation.

Owner:ZHEJIANG JINGBAO MACHINERY

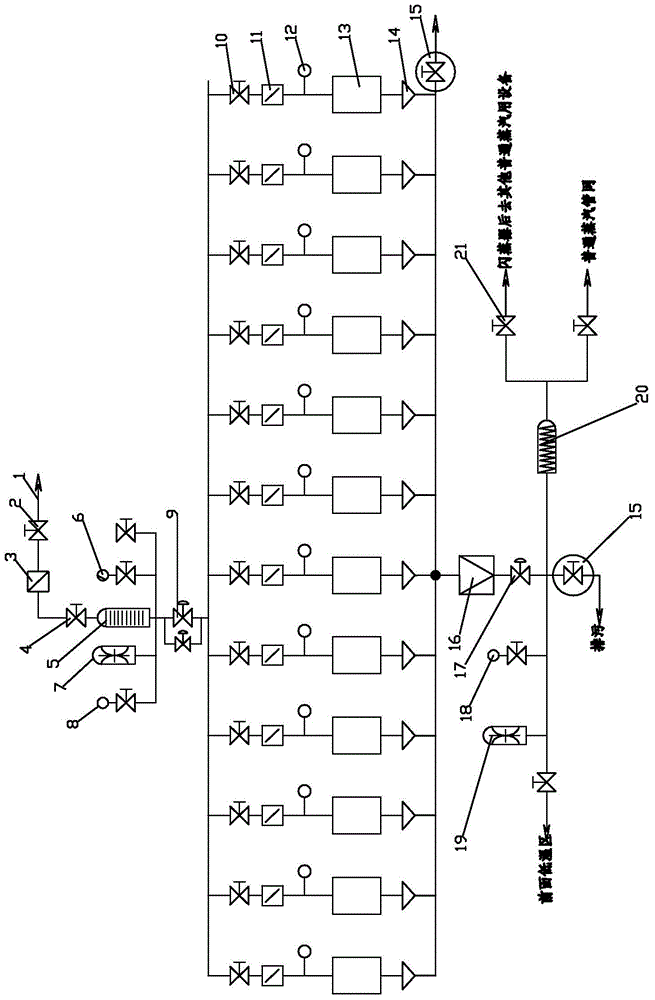

Medium pressure high temperature steam control system

InactiveCN103953851BMeet the needs of medium pressure and high temperatureRealize comprehensive utilizationPipeline systemsStationary conduit assembliesControl systemWastewater

The invention relates to a medium-pressure high-temperature steam control system, comprising a medium-pressure and high-temperature pipe network, wherein a first manual valve, a filter screen, a second manual valve and a meter are installed in sequence on the medium-pressure and high-temperature pipe network. A first safety valve and a temperature gauge are installed, a first pressure gauge is installed on one side of the first safety valve, an automatic valve is installed below the measuring instrument, and a number of heat exchange components are installed below the automatic valve. A pressure reducing valve and an automatic intelligent valve are installed, a third pressure gauge and a steam trap are installed on both sides of the automatic intelligent valve, a second safety valve is installed on one side of the third pressure gauge, and one side of the second safety valve is connected with a In the low temperature zone, one side of the trap is connected with a flasher and a common steam pipe network. The invention meets the requirements of medium pressure and high temperature in industrial production, the generated waste water is applied to other equipment, and the waste gas is discharged in the low temperature area, so as to realize the comprehensive utilization of energy, and is suitable for application in the fields of tanning tenter machines, hot needle spinning and setting machines, etc. .

Owner:ZHEJIANG JINGBAO MACHINERY

Multifunctional postprocessing support system

PendingCN112160824ACompact structureMeet fixedExhaust apparatusNon-rotating vibration suppressionSupporting systemAir filter

The invention discloses a multifunctional postprocessing support system. Three postprocessing supports, rubber anti-vibration pads and steel plate cushion blocks are combined into a main body, and a post-processor, a fuel filter and an air filtering system can be arranged in various positions by using one set of postprocessing support system, i.e., through mounting holes in a postprocessing support II and different mounting modes of the postprocessing support II, arrangement modes of various parts such as a postprocessing system, an air filtering system and a fuel filter can be achieved. In addition, through the mounting holes in the postprocessing support III, the arrangement mode of a fuel filtering system can be supplemented, the arrangement structural form is more diversified, the arrangement requirement of a whole machine is met, and an internal combustion engine is safer and has fewer troubles in the using process through the structure. Besides, according to the postprocessing supports, suspension anti-vibration pad mounting surfaces are arranged on the supports in advance, so that a flexible connection mode is formed between postprocessing parts and the supports, and damageto the strength of a postprocessing device due to vibration of an engine and a whole vehicle is reduced.

Owner:GUANGXI YUCHAI MASCH CO LTD

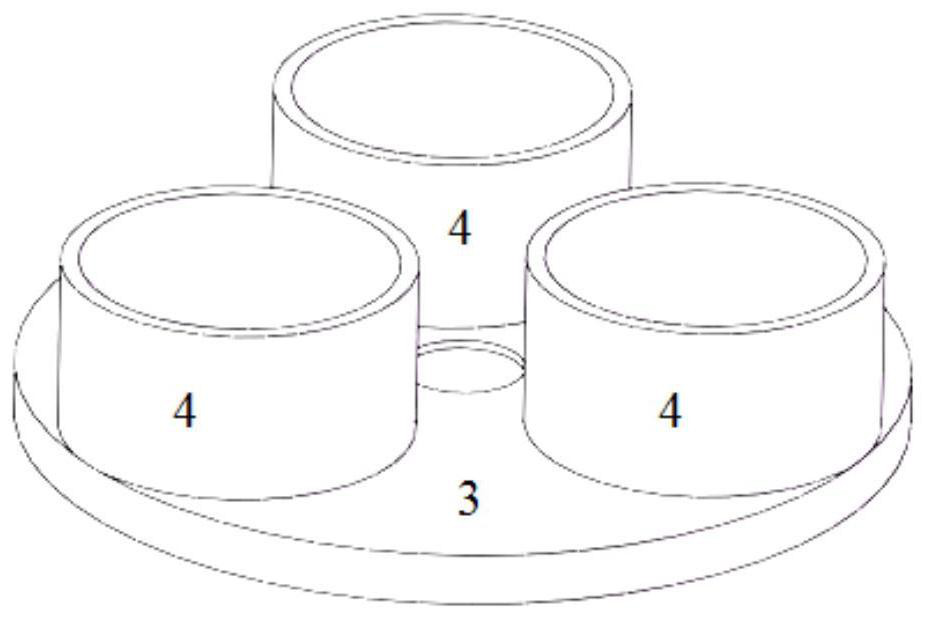

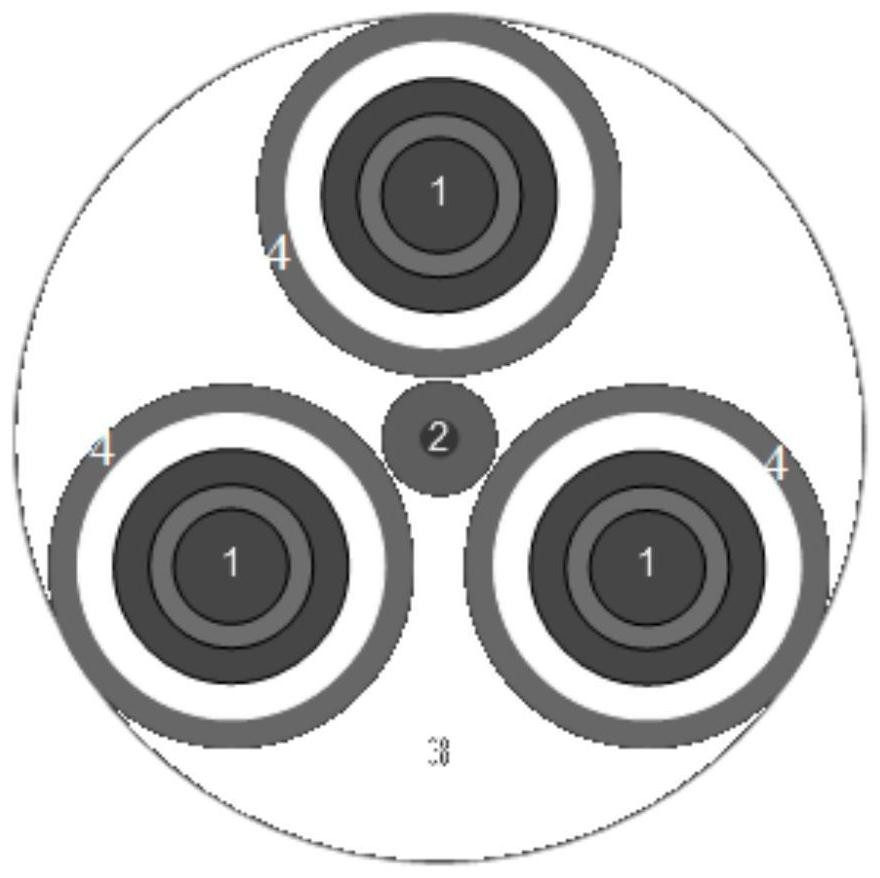

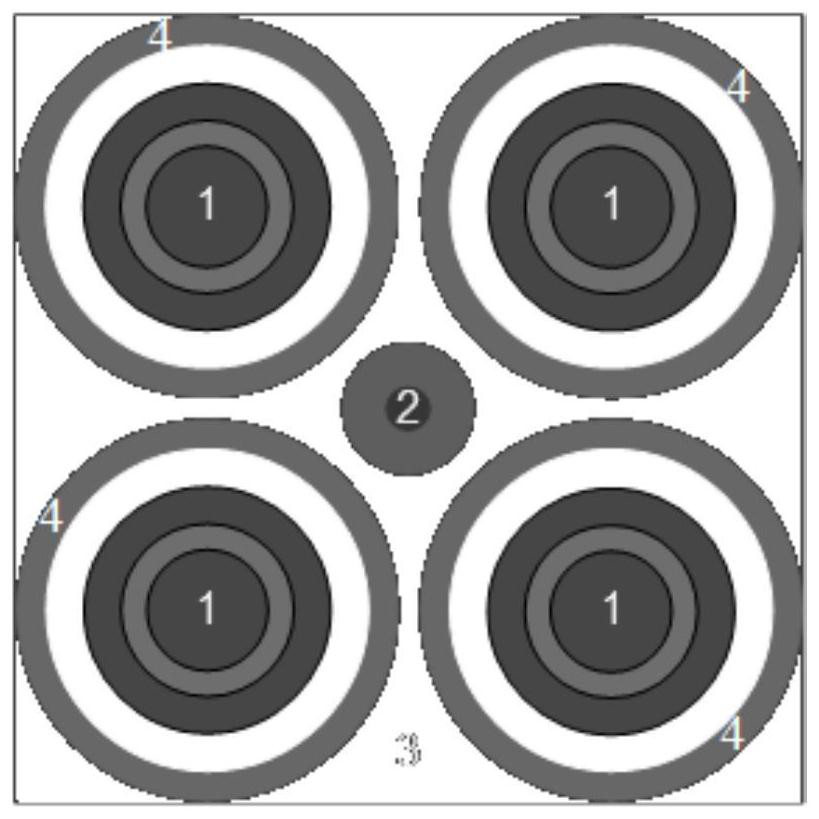

An Anti-magnetic Interference Bracket Applied to Hall Thruster Cluster

ActiveCN110894823BReduce Space Flux LeakageReduce distractionsMachines/enginesUsing plasmaMagnetic disturbanceMechanical engineering

The invention provides an anti-magnetic interference bracket applied to Hall thruster clusters, which includes a magnetically conductive bottom plate and a plurality of magnetically conductive sleeves evenly arranged on the magnetically conductive bottom plate, and the magnetically conductive bottom plate and the plurality of magnetically conductive sleeves are integrated Forming setting, a thruster unit of the Hall thruster cluster is placed in each magnetic sleeve, each magnetic sleeve completely covers the thruster unit inside, and there are gaps between each magnetic sleeve, multiple The center of the area enclosed by the magnetic sleeve is the center of the magnetic bottom plate, and the cathode is arranged in the center of the area enclosed by multiple magnetic sleeves, and the cathode is the shared cathode of each thruster unit of the Hall thruster cluster. The anti-magnetic interference support of the present invention can effectively reduce the spatial magnetic flux leakage of the thruster while fixing each thruster unit, so as to ensure that each thruster unit is free from external magnetic field interference. At the same time, a cathode can be arranged in the center of the bracket, and a cathode sharing strategy can be adopted to provide electrons required for the ionization process and ion neutralization process for several thrusters at the same time.

Owner:HARBIN INST OF TECH

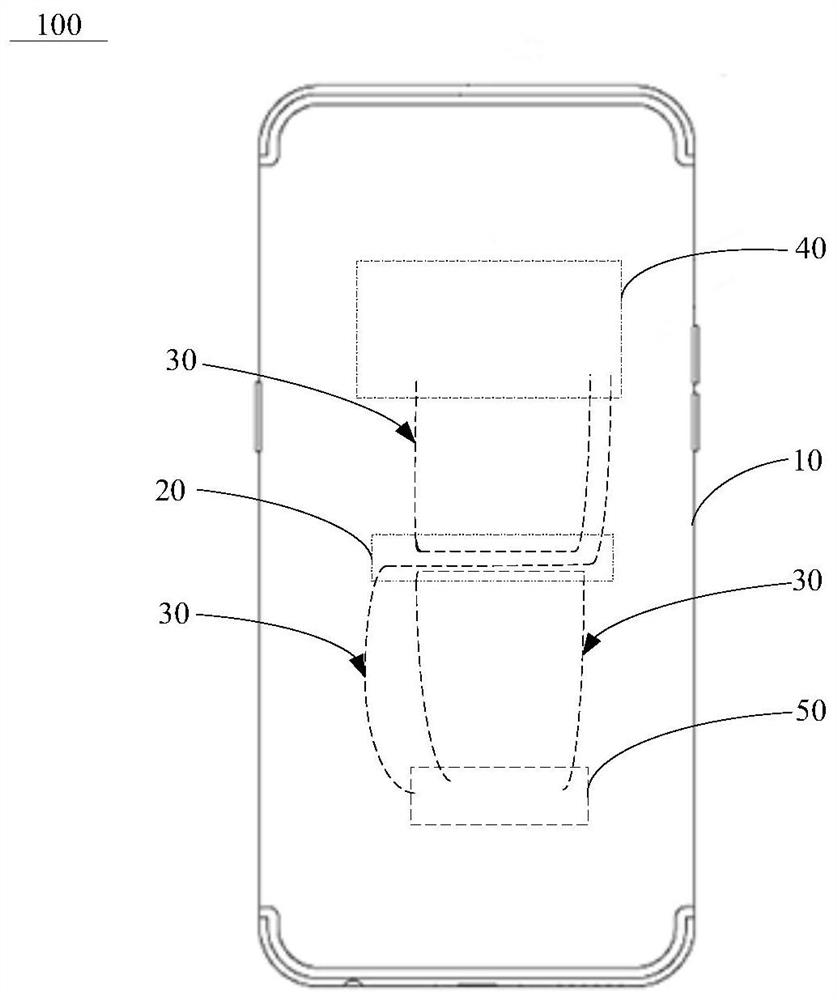

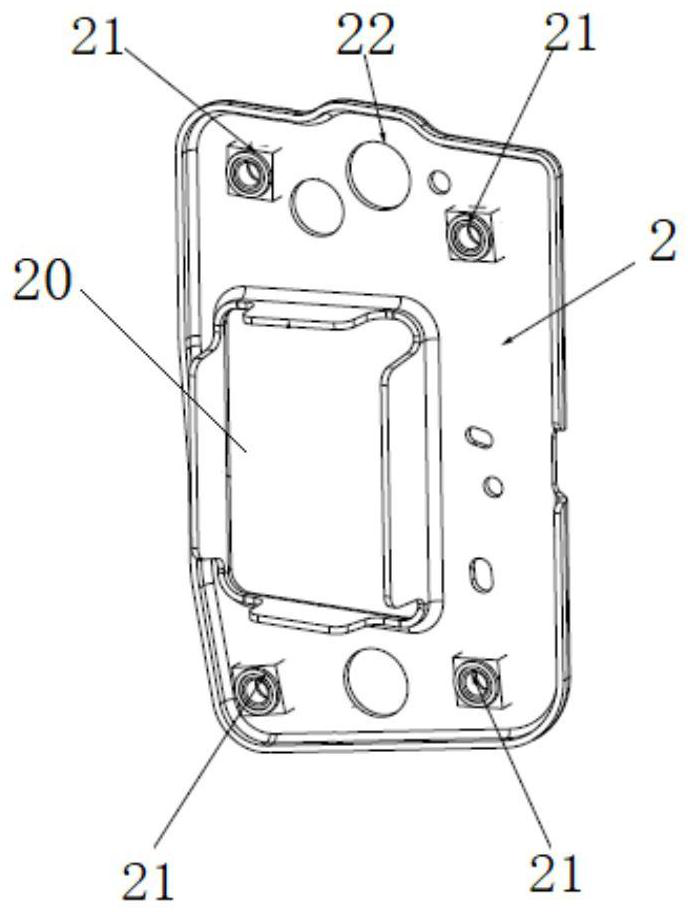

mobile terminal

ActiveCN110324466BFast data transferMeet the arrangementTelephone set constructionsRadio frequency signalCoaxial line

The invention provides a mobile terminal, which includes a shell, a bracket and a coaxial line, the bracket is arranged inside the shell; the mounting surface of the The extending direction of the groove is consistent with the length direction of the bracket, and the two ends of the installation groove are open and pass through the fixing surface of the bracket; multiple coaxial cables are arranged inside the housing, and each coaxial cable is correspondingly arranged in an installation groove, so that The mounting grooves guide the coaxial cables to bend in different directions. The installation groove on the bracket can meet the arrangement of multiple coaxial cables inside the housing. The two ends of the coaxial cables protrude from the opening of the installation groove, and are guided in different directions under the guidance of the installation groove, so that the movement The small boards at different positions inside the terminal can be connected to the main board, so as to realize the transmission of radio frequency signals between the parts with a large span inside the mobile terminal, so that the mobile terminal can meet the transmission requirements of various radio frequency signals, thereby improving the data transmission of the mobile terminal speed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

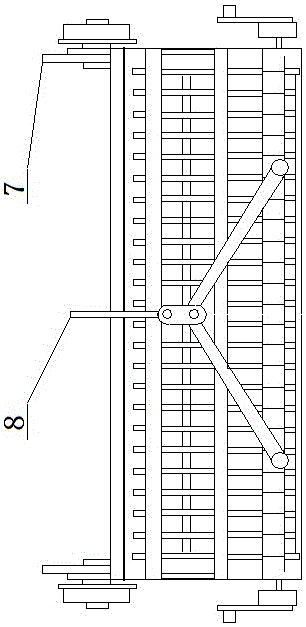

Trash remover with movable scraper bucket

The invention relates to a trash remover with a movable scraper bucket. The trash remover comprises a storage bin and a frame. The storage bin is arranged on the frame. A telescopic rod and a lifting arm are arranged at the right end of the frame. The right end of the telescopic rod and the right end of the lifting arm are hinged together. An upper running wheel is arranged in the hinge position of the right end of the telescopic rod and the right end of the lifting arm. The upper running wheel is connected with an inner bucket and an outer bucket. A locking hook is arranged at the right end of the inner bucket. A lower running wheel and a connecting lever are arranged at the left end of the inner bucket. A handle is arranged on the right side of the locking hook. A scraper bucket lifting rope is arranged on the outer side of the upper running wheel. A scraper bucket opening and closing rope is arranged in the center of the upper running wheel. A V-type frame is connected to the rear end of the scraper bucket opening and closing rope. The trash remover has the advantages of being simple in structure, convenient to adjust and install, low in cost, safe and reliable.

Owner:HENAN HUANGHE WATER ENG MACHINERY

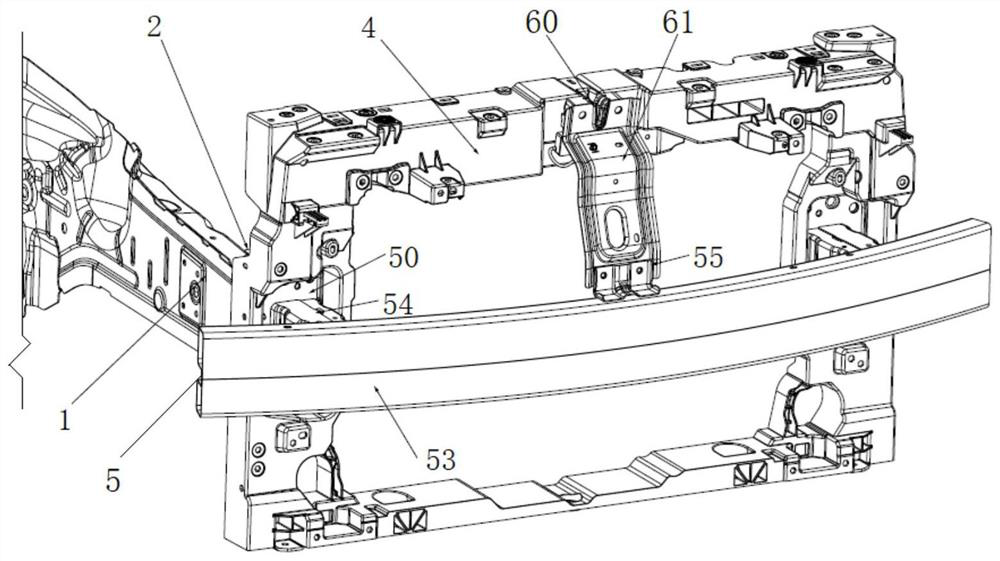

Positioning and mounting structure and mounting method of automobile front-end module

InactiveCN113276948AGuaranteed cooling effectCorrect position errorUnderstructuresBumpersStructural engineeringHorizontal orientation

The invention relates to a positioning installation structure and method for an automobile front-end module, and relates to the field of automobile front structure design. A first connecting plate is arranged at the end, away from a cab, of each front longitudinal beam in the positioning and mounting structure, an auxiliary positioning plate is arranged on the side, away from the corresponding front longitudinal beam, of each first connecting plate, a first connecting part is arranged in each vertical frame of a front end frame, and second connecting plates are arranged at the two ends of an anti-collision beam correspondingly; the first connecting part is used for being fixed to the first connecting plate and the second connecting plate so that the length of a horizontal frame of the front end frame can be not smaller than the preset length, and the auxiliary positioning plate is used for correcting the positioning error generated by the position error of the two front longitudinal beams when the front end frame is fixed to the first connecting plate, and enabling the positioning errors of the front-end frame in the vertical direction and the horizontal direction not to be greater than a preset error. According to the positioning and mounting structure, the problems that the length of the front-end frame is limited and the positioning precision of the front-end assembly is poor in the prior art are solved.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Cartridge refrigerant compressor

ActiveCN107956745BGood high pressure sealingMeet the arrangementPump componentsRadial flow pumpsEngineeringHigh pressure

Owner:SHENYANG TURBO MASCH CORP

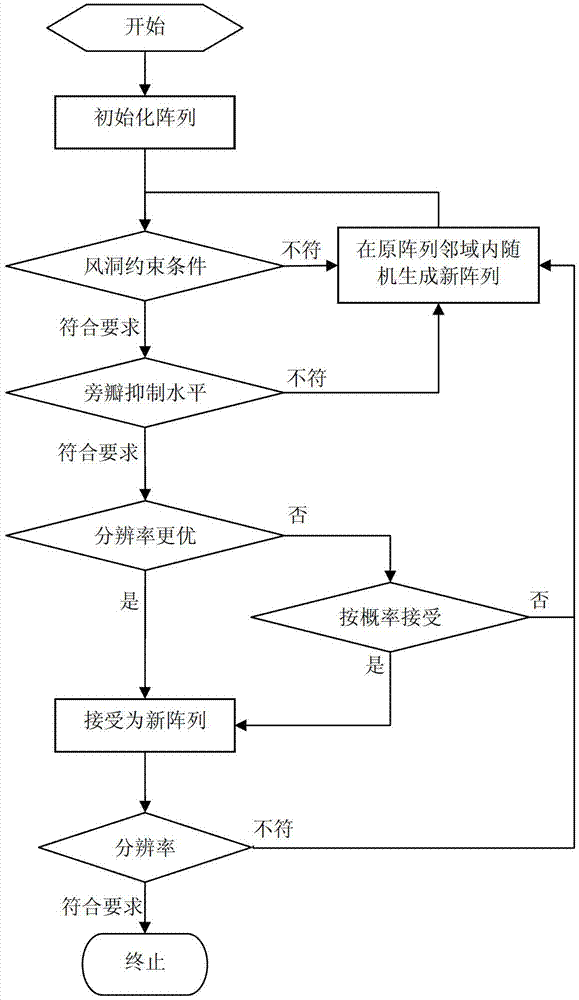

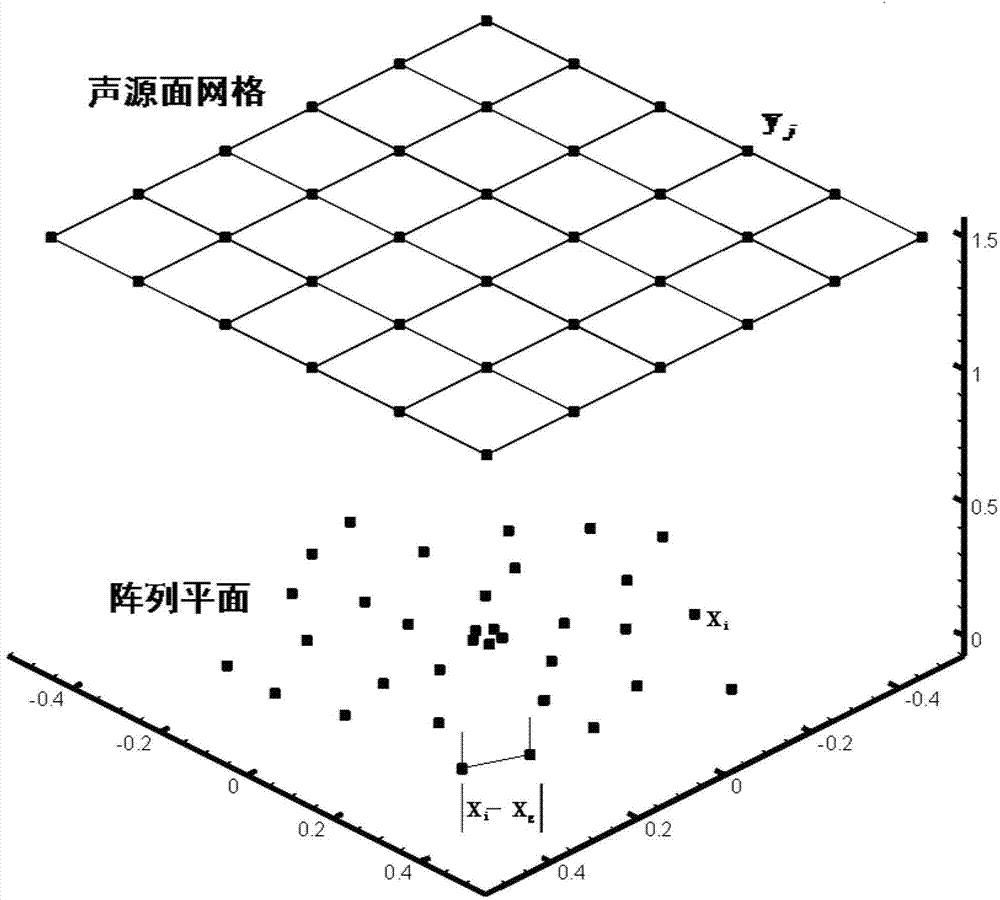

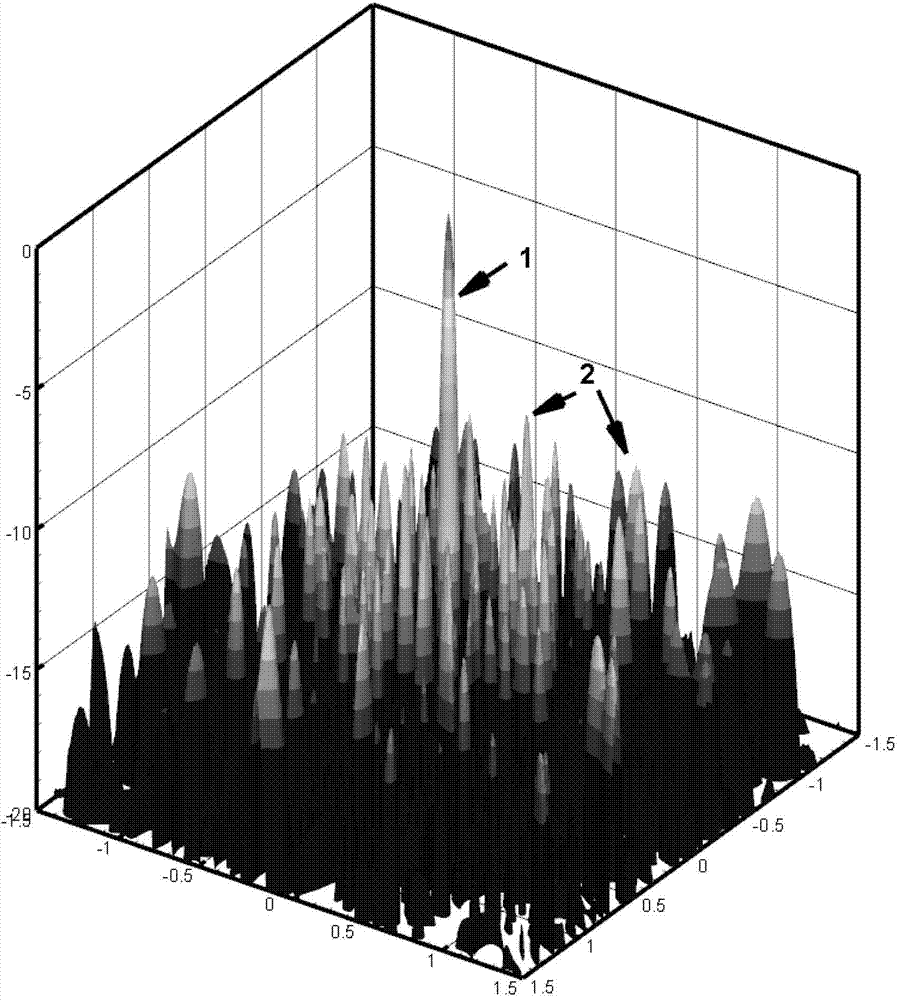

Microphone array optimum design method for closed wind channel aerodynamic noise measurement

ActiveCN103487135BMeet the arrangementOptimize coordinatesSubsonic/sonic/ultrasonic wave measurementImage resolutionDesign methods

Provided is a microphone array optimum design method for closed wind channel aerodynamic noise measurement. According to the method, aiming at the demand for a microphone array of closed wind channel aerodynamic noise measurement, under the condition that array installation conditions of a closed wind channel are met, with requirements of array sidelobe suppression levels as constraint conditions and with the array resolution ratio as an objective function, array unit coordinates are optimized in a simulated annealing method. The microphone array optimum design method overcomes defects in existing methods, and array unit arrangement adaptive to closed wind channel installation can be achieved, wherein the sidelobe suppression levels and the resolution ratio of the array unit arrangement can meet demands.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

variable valve timing method

ActiveCN102852582BChange on durationRealize timing controlValve arrangementsMachines/enginesVariable valve timingCamshaft

The invention discloses a variable valve timing method used for controlling opening and closing timing of a valve of a vehicular engine. When the valve needs to be opened in advance, a phase adjusting mechanism drives a camshaft to rotate forwards relative to a rotary driving part; when the camshaft rotates to a position enabling the valve to be maximum in lift basically, the phase adjusting mechanism keeps the camshaft at the current position, so that the valve is kept at the maximum lift basically; and after the camshaft is kept at the current position for a period of preset time, the rotary driving part drives the camshaft to rotate continuously. The valve can be opened continuously by the variable valve timing method, and the variable valve timing method is larger in air inflow as compared with that in the prior art under the high-rotational-speed high-load working condition.

Owner:HANGZHOU BRANCH ZHEJIANG GEELY AUTOMOBILE RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com