Protection system, dismounting device and construction method for existing traffic of composite beam upper cover

A technology of protection system and dismantling device, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of small occupied space, cumbersome protection procedures, low protection reliability, etc., so as to improve reliability and reduce equipment. The effect of high investment and labor costs, and high protection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

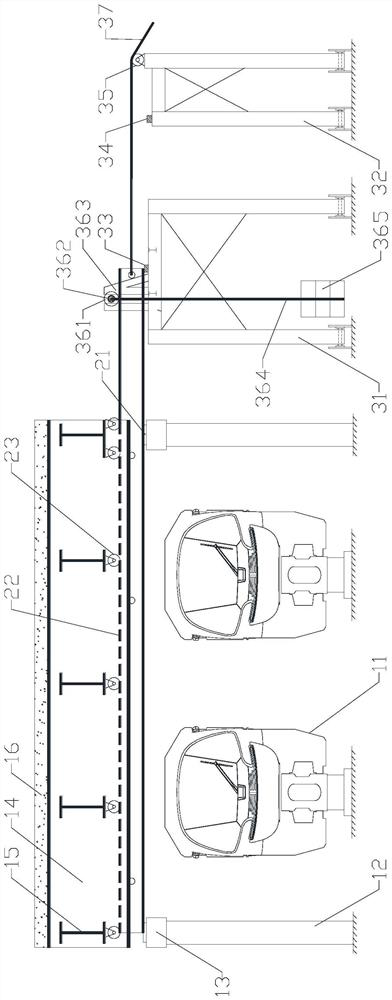

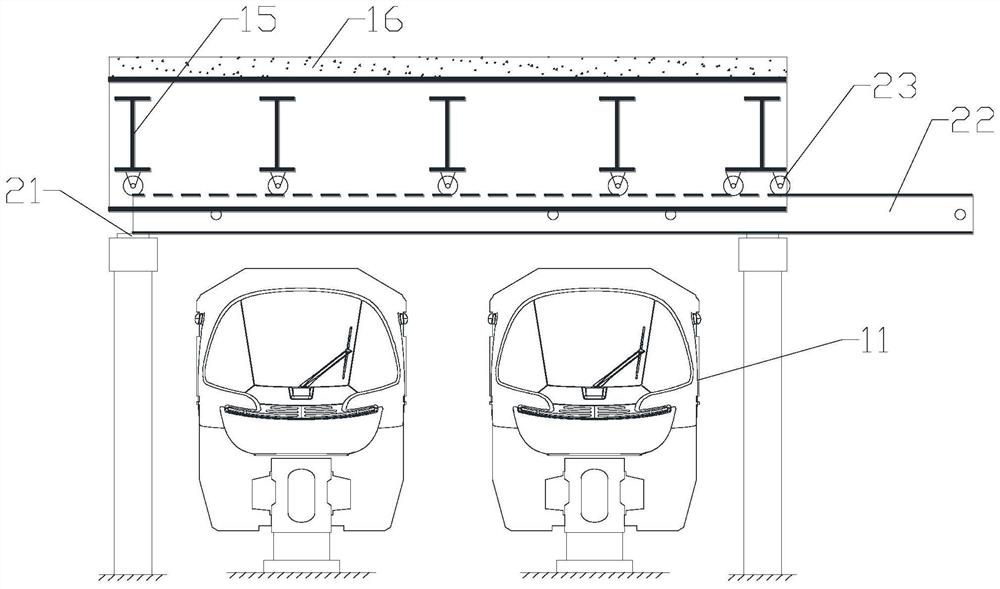

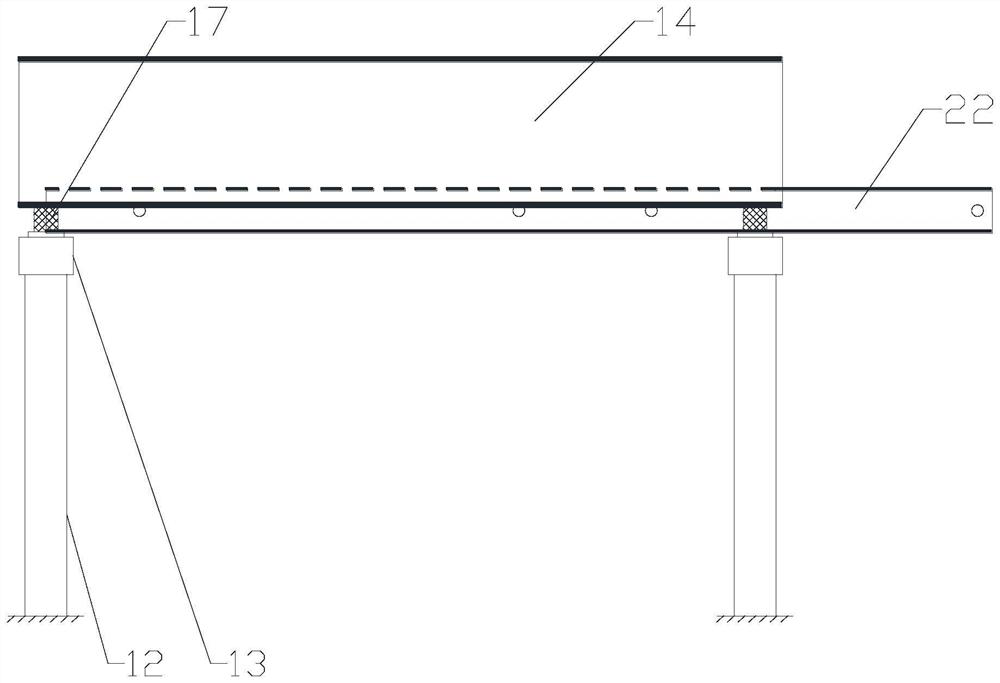

[0056] Please refer to figure 1 , This embodiment provides a protection system for the existing traffic on the composite beam. The protection system is applied to an existing straddle type monorail in an urban area. The protection system includes a composite beam longitudinal beam 14, a composite beam cross beam 15, and a composite beam roof. Panel 16, composite beam support 17, sliding cushion 21, beam plate structure 22, beam fixed pulley 23, high-strength steel wire mesh 24, stopper 25 and locking member 26, wherein several composite beam longitudinal beams 14 are equally spaced Set up, and vertically weld several equidistantly spaced composite beam beams 15 between adjacent composite beam longitudinal beams 14, thus forming a composite beam structure, and the above-mentioned protective structure is erected on the existing piers 12 and cover beams 13, the protective structure is under the limited clearance of 50-100cm between the lower edge of the composite beam and the up...

Embodiment 2

[0063] This embodiment provides a disassembly device for the existing traffic protection system on the upper cover of the composite beam. The disassembly device is applied to the protection system of the first embodiment, and the protection system of the first embodiment is dismantled, which includes a first movable bracket 31, a second The movable bracket 32, the first sliding support 33, the second sliding support 34, the second bracket fixed pulley 35, the ballast pulley assembly 36, the traction rope 37 and the traction equipment; the first movable bracket 31 and the second movable bracket 32 It is constructed by using the existing steel structure bracket. The first movable bracket 31 is arranged beside the cover beam 13 and the protection system. The first movable bracket 31 cantilevered outside the cover beam 13 through the beam-slab structure 22, which is convenient for dismantling in the later construction. , the second movable bracket 32 is arranged next to the first...

Embodiment 3

[0068] Please refer to Figure 7 and Figure 8 , the present embodiment provides the construction method of the protection system of the existing traffic on the composite beam, adopts the protection system of the existing traffic on the composite beam in the embodiment 1, the construction method includes the protection construction, and the protection construction comprises the following steps:

[0069] S1. Concrete the pier column 12 and the cover beam 13. After the structural construction of the pier column 12 and the cover beam 13 is completed, a sliding cushion 21 is set between the composite beam supports 17 on the top of the cover beam 13. The beam-slab structure 22 is prefabricated. The parts of the beam-slab structure 22 can be connected by bolting or welding. During the non-operation period of the track and the vehicle 11, the beam-slab structure 22 is lifted and placed on the top of the sliding cushion 21. Pay attention to the beam-slab structure 22 There is a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com