Medium-pressure high-temperature steam heating heat exchanger

A technology of high-temperature steam and heat exchangers, applied in the types of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of high production costs, high natural gas prices, and impossibility of popularization, and achieve low cost and low price , good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

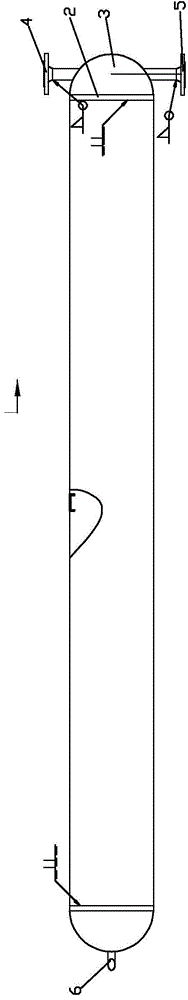

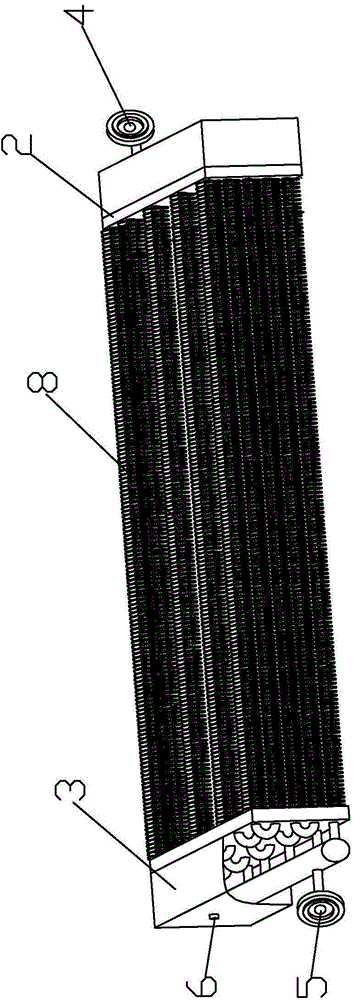

[0031] like figure 1 and 2 As shown, the medium-pressure high-temperature steam heating heat exchanger of the present invention includes several heat-conducting tube-connected heat-exchanging fins 1, and the heat-conducting tube-connected heat-exchanging fins 1 are metal seamless heat-conducting tube-connected heat exchangers, which can withstand 30 kg or more The pressure of the heat transfer tube can also withstand high temperature. The outside of the heat transfer tube-connected heat exchange fin 1 is covered with a heat sink 8, and both ends of the heat transfer tube-connected heat transfer fin 1 are equipped with a heat transfer tube connection plate 2, and the outside of the heat transfer tube connection plate 2 A sealing head 3 is installed, and the heat exchanger of the present invention is also equipped with an inlet flange 4, an outlet flange 5 and a water outlet 6, and the inlet flange 4, the outlet flange 5 and the water outlet 6 are all installed on the sealing he...

Embodiment 2

[0034] like image 3 As shown, in this embodiment 2, several heat-conducting tube-connected heat exchanger fins 1 are installed in parallel, the inlet flange 4, outlet flange 5 and water outlet 6 are installed on the same head 3, and the inlet flange 4 is located at the outlet Above the flange 5, the water outlet 6 is installed at the bottom of the head 3.

[0035] Other structures and connection methods of Embodiment 2 are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

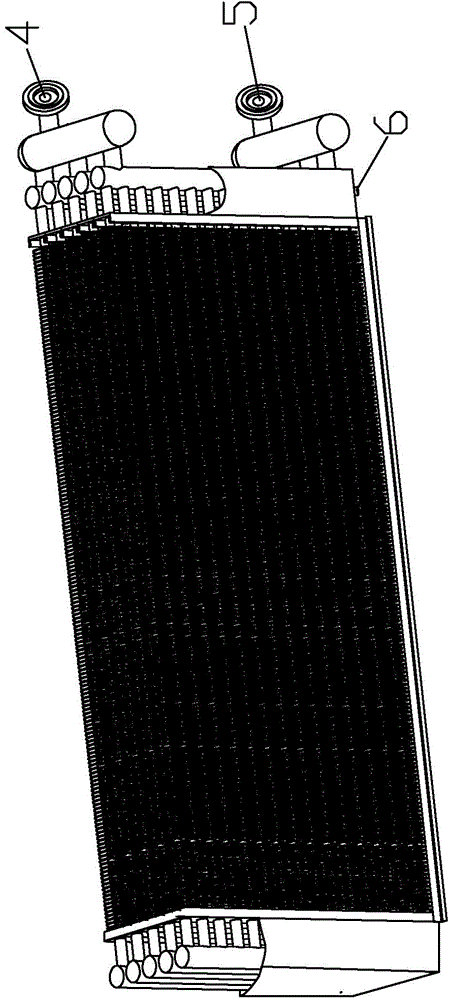

[0037] like Figure 4 As shown, the heat exchanger in this embodiment 3 is the first horizontal type, and several heat-conducting tube-connected heat-exchanging fins 1 are arranged horizontally and left and right, and the inlet flange 4, outlet flange 5 and water outlet 6 are installed in the same seal. On the head 3, and the inlet flange 4 is located above the outlet flange 5, and the water outlet 6 is installed at the bottom of the head 3.

[0038] Other structures and connection methods of Embodiment 3 are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com