Medium pressure high temperature steam control system

A high-temperature steam and control system technology, applied in pipeline systems, lighting and heating equipment, tubular components, etc., can solve the problems of increased production costs and expensive natural gas, and achieve low cost, low price, and avoid smog effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

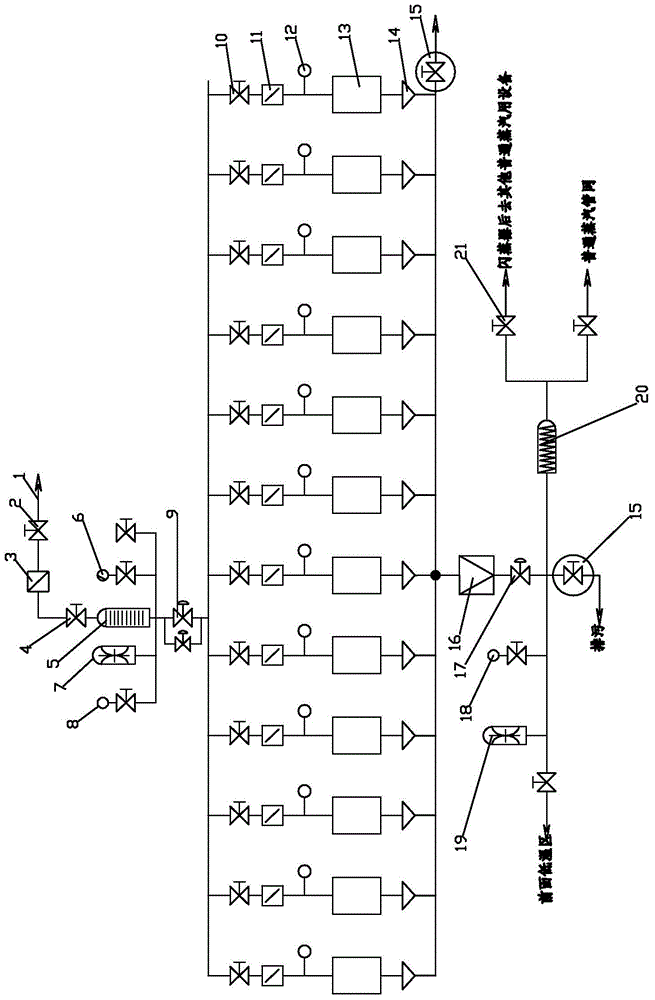

[0032] Such as figure 1 As shown, the medium-pressure high-temperature steam control system of the present invention includes a medium-pressure high-temperature pipe network 1, and the medium-pressure high-temperature pipe network 1 is sequentially installed with a first manual valve 2, a filter screen 3, a second manual valve 4 and a measuring instrument 5 , the first safety valve 7 and the thermometer 6 are respectively installed on both sides of the meter 5, the first pressure gauge 8 is installed on one side of the first safety valve 7, the automatic valve 9 is installed under the meter 5, the automatic valve 9 There are two parallel ones. Several heat exchange components are installed under the automatic valve 9. A pressure reducing valve 16 and an automatic intelligent valve 17 are installed in sequence under the heat exchange components. A third pressure gauge is respectively installed on both sides of the automatic intelligent valve 17. 18 and steam trap 20, a second s...

Embodiment 2

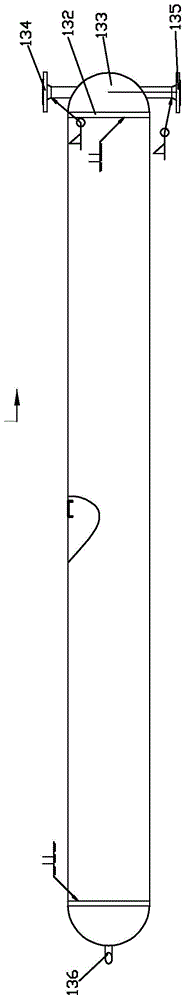

[0038] Such as Figure 4 As shown, several heat-conducting tube-connected heat exchanger fins 131 in this embodiment 2 are installed in parallel, the inlet flange 134, outlet flange 135 and water outlet 136 are installed on the same head 133, and the inlet flange 134 is located at the outlet Above the flange 135 , the water outlet 136 is installed at the bottom of the sealing head 133 .

[0039] Other structures and connection methods of Embodiment 2 are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

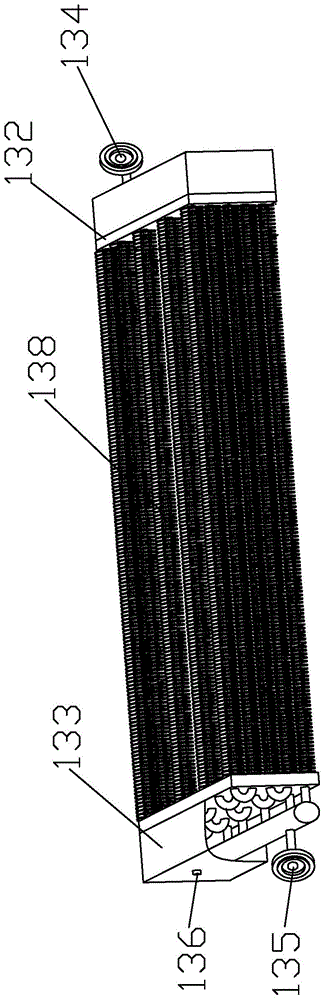

[0041] Such as Figure 5 As shown, the medium-pressure high-temperature steam heating heat exchanger 13 in Embodiment 3 is the first horizontal type, and several heat-conducting tube-connected heat exchanger fins 131 are arranged horizontally and left and right, and the inlet flange 134, outlet flange 135 and water outlet 136 is installed on the same head 133, and the inlet flange 134 is located above the outlet flange 135, and the water outlet 136 is installed at the bottom of the head 133.

[0042] Other structures and connection methods of Embodiment 3 are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com