Concrete aggregate automatic bin-searching and feeding system

A concrete aggregate and concrete technology, applied in batching storage, clay preparation equipment, mixing operation control, etc., can solve the problems of inability to realize continuous conveying of aggregates, high labor intensity, and large dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0043] In conjunction with the accompanying drawings.

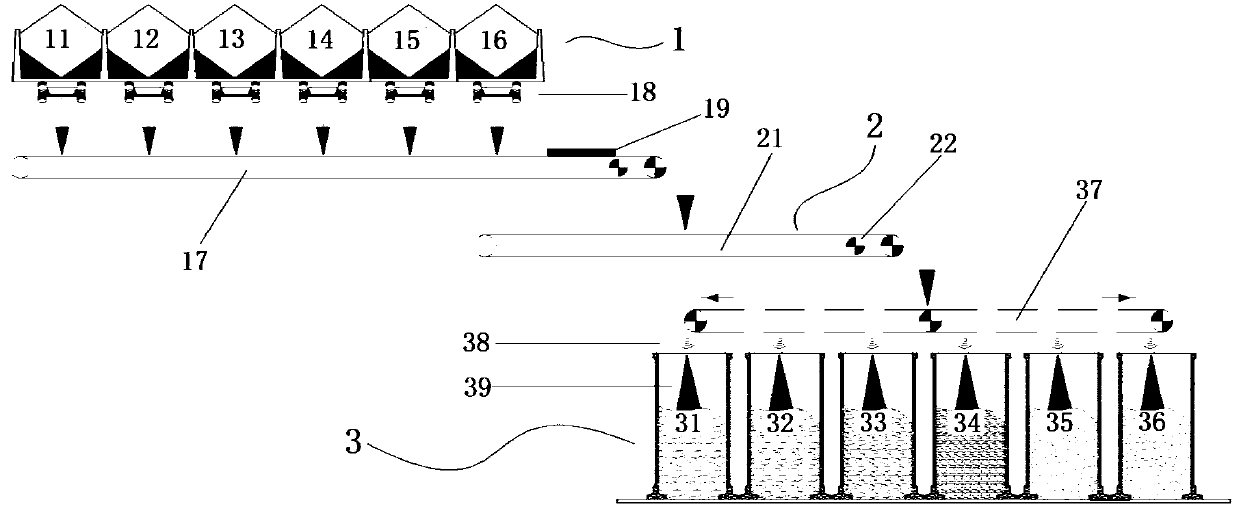

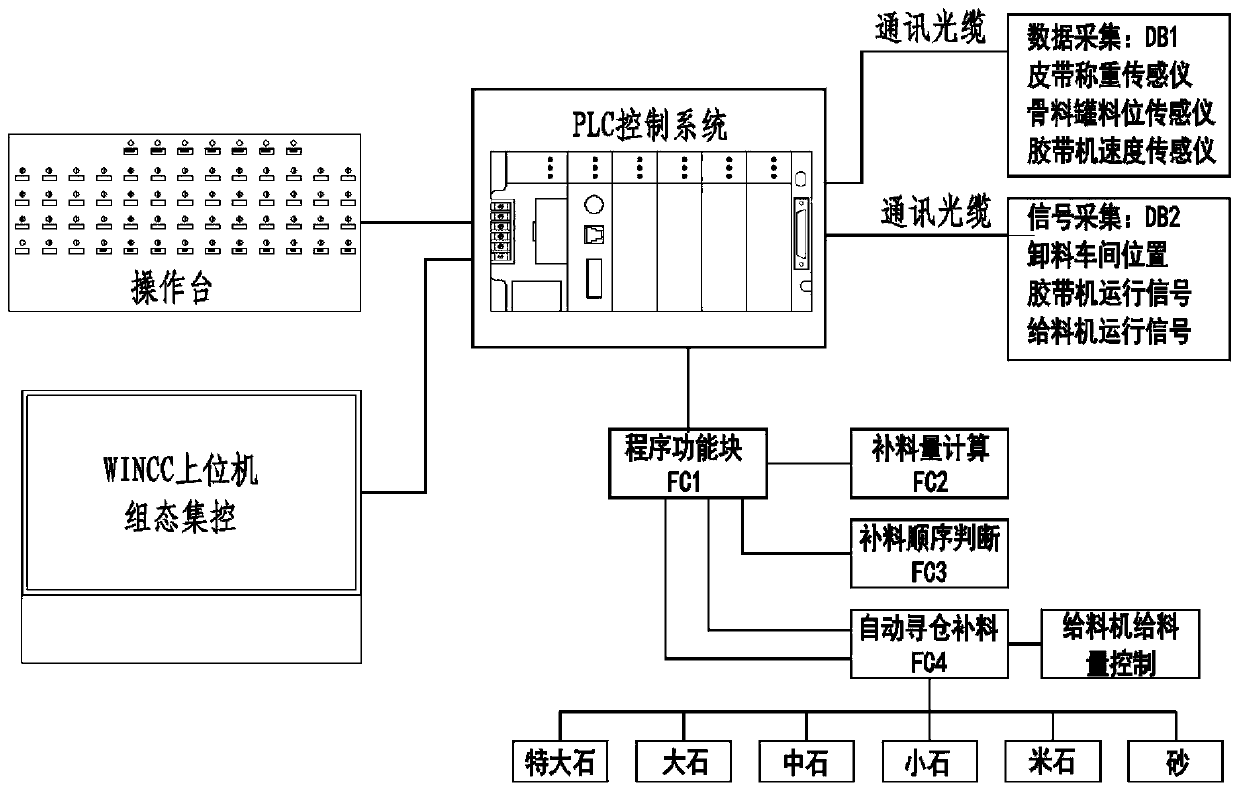

[0044] As shown in the figure, the aggregate intelligent bin search and replenishment system is composed of on-site production facilities and control systems. Production facilities include concrete production system raw material warehouse, sand and gravel system finished product yard, ridge feeding device, belt conveyor, mobile trolley and other equipment. The control system includes data signal acquisition system, on-site PLC and central control PLC control system. Data acquisition is used to detect on-site production data and raw material storage vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com