Control method and system of lithium battery pole piece rolling mill based on digital twin technology

A rolling mill control and lithium battery technology, which is applied in the general control system, electrode rolling/rolling, control/regulation system, etc., can solve the problem of poor information integration ability of the control system, dependence on human observation and judgment, and limited information acquisition ability of the control system and other issues, to achieve the effect of optimizing processing parameters, realizing control methods, and improving the degree of visualization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The design scheme of the control system of the present invention will be further described in conjunction with the accompanying drawings and embodiments.

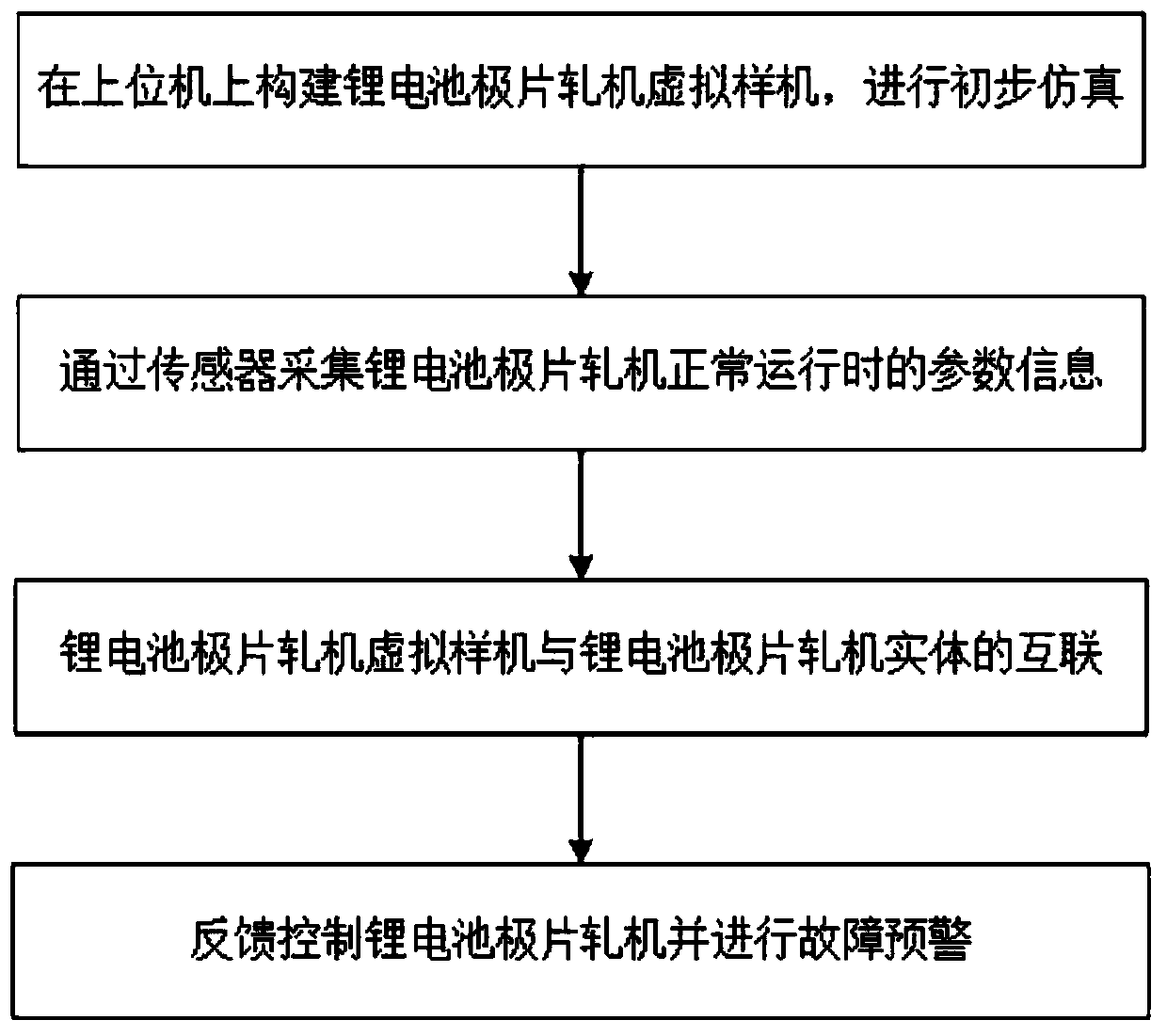

[0035] The present invention provides a lithium battery pole piece rolling mill control method based on digital twin technology (control method for short, see figure 1 ), the method includes the following steps:

[0036] (1) Construct a virtual prototype of a lithium battery pole piece rolling mill on the host computer for preliminary simulation

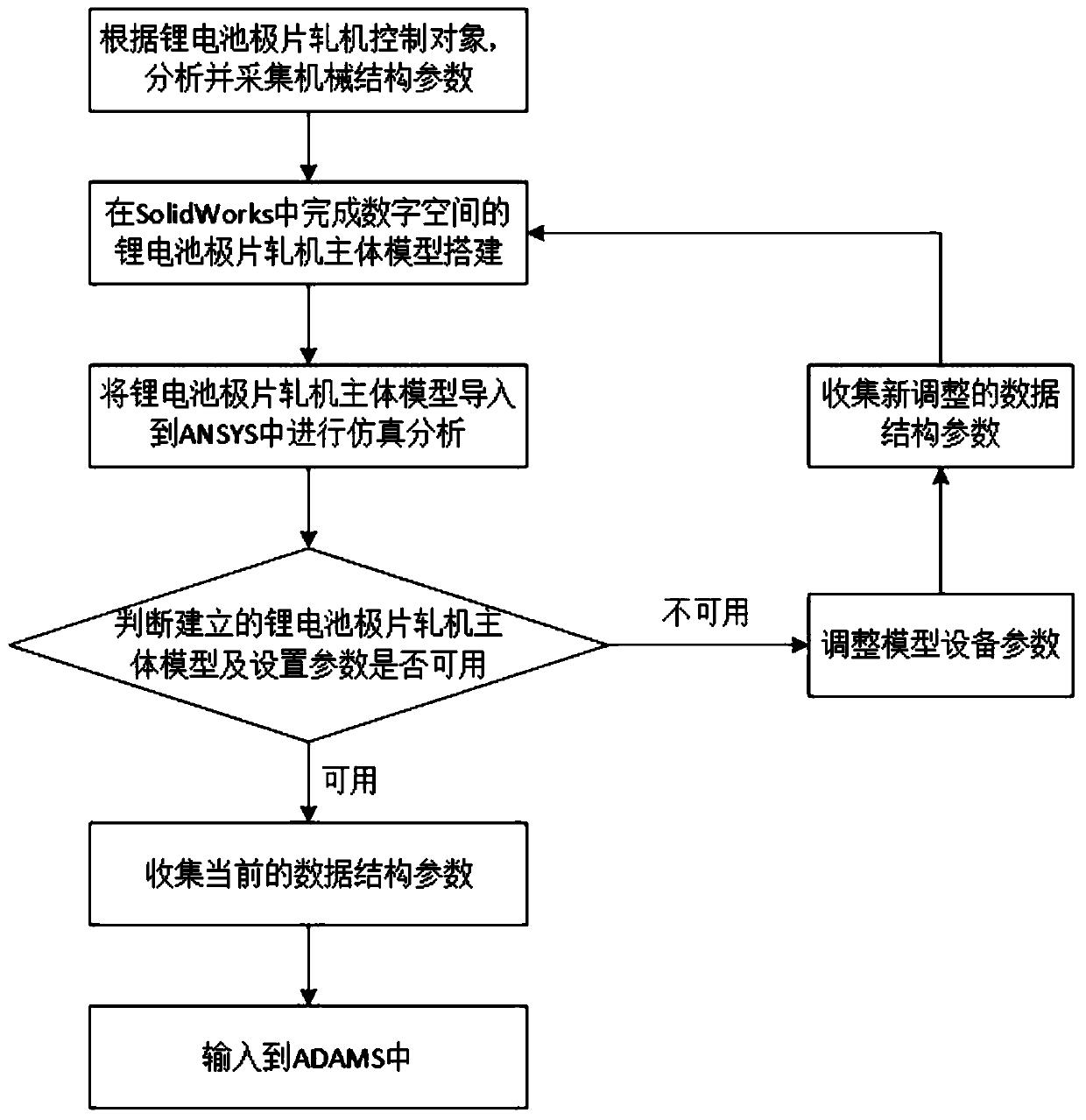

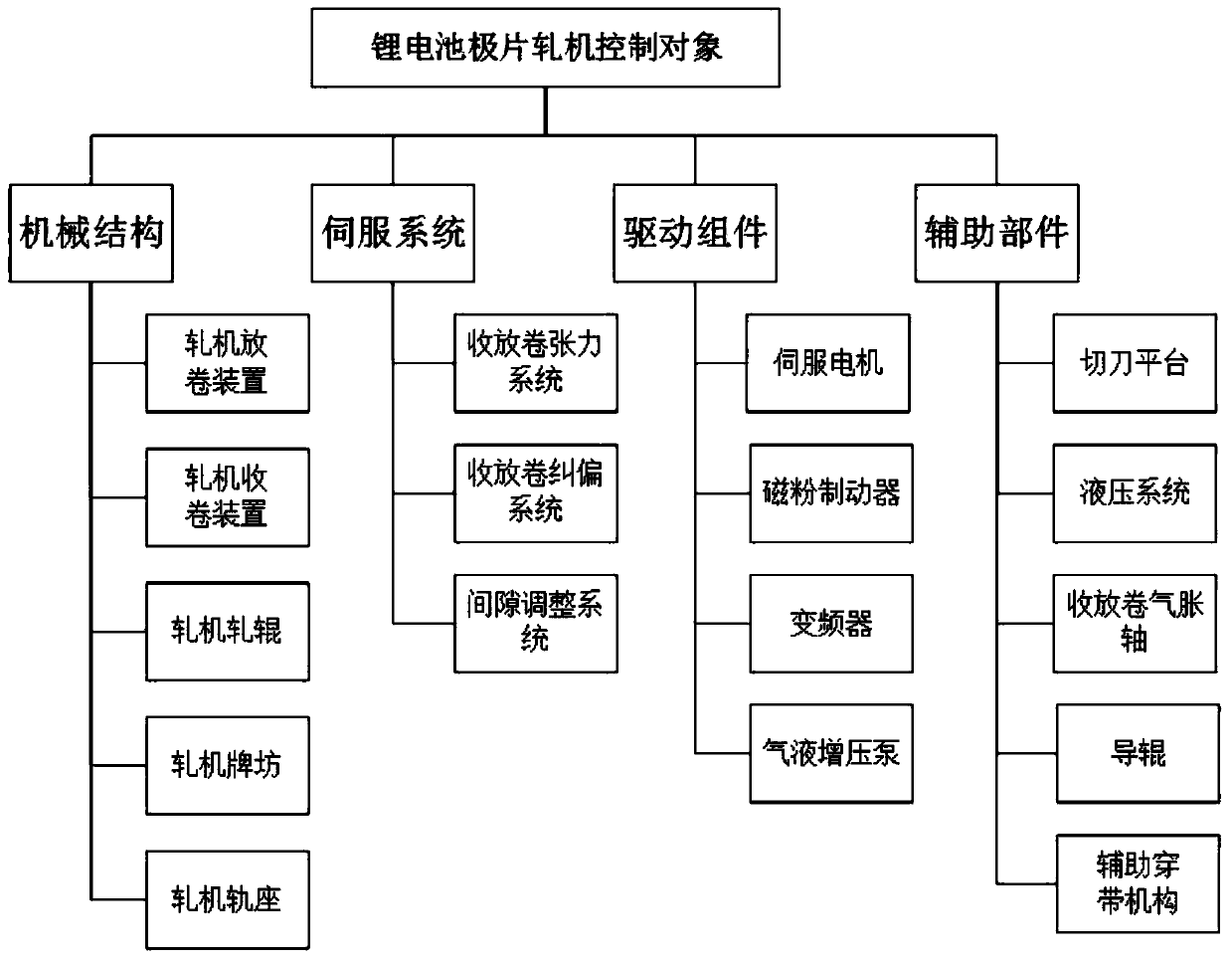

[0037] First, classify the control objects of the lithium battery pole piece rolling mill, and divide it into four parts: mechanical structure, servo system, drive components and auxiliary components, laying the foundation for the establishment of the model of the lithium battery pole piece rolling mill in the subsequent digital space. Among them, the mechanical structure part covers rolling mill unwinding device, rolling mill winding device, rolling mill roll, rolling mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com