Axial-flow type adjusting valve

A regulating valve, axial flow technology, applied in sliding valves, valve details, safety valves, etc., can solve problems such as slow response speed, output pressure, output flow fluctuation, and low level of automation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

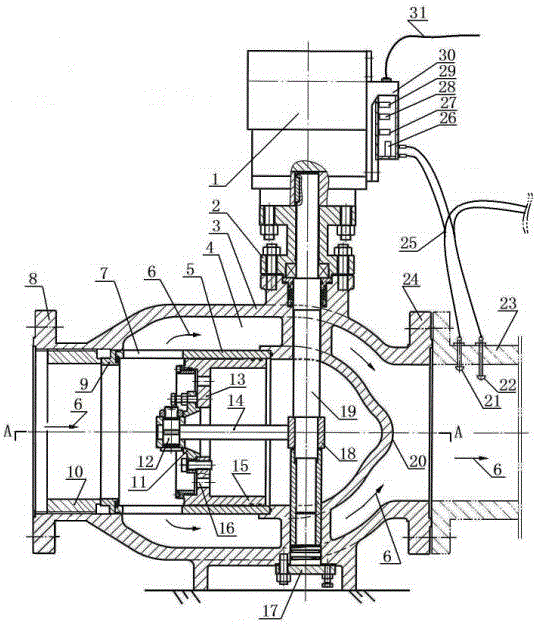

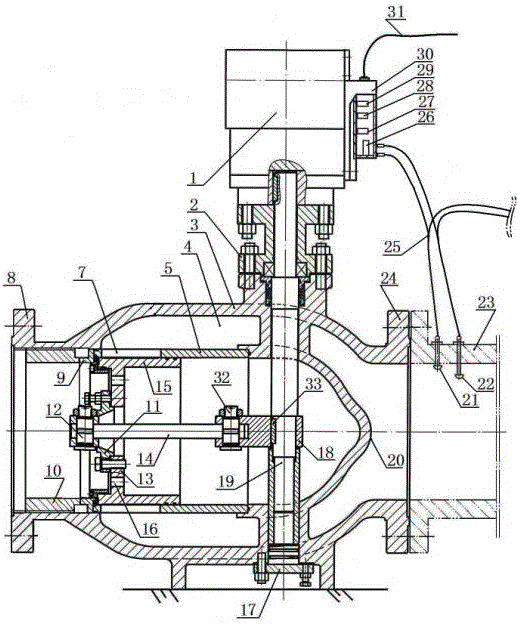

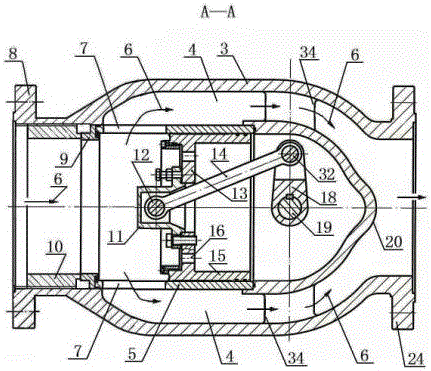

[0023] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0024]An axial flow regulating valve proposed by the present invention is mainly composed of a valve body 3, a support seat 2 installed on the valve body 3, an electric head 1, a locking coil 10 fitted in the valve body 3, a valve seat 9. The regulating valve sleeve 5, the valve core 15, the pull rod 14, the regulating rotating shaft 19, the pressure sensor 21 and the flow sensor 22 installed in the output pipe 23 behind the valve are formed. In the valve body 3, a streamlined inner cone head 20 is supported and connected by a group of integrally cast supporting ribs 34, and the valve body 3 and the streamlined inner cone head 20 set in the valve body 3 and the two ends of the valve body 3 are set The inlet flange 8 and the outlet flange 24 are integral structures made of one-time casting. The adjusting shaft 19 vertically passes through the streamlined inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com