Chemical cleaning method of hollow fiber membrane and device thereof

A chemical cleaning, fiber membrane technology, applied in the field of cleaning, can solve the problems of membrane material damage, large consumption of drugs, difficult long-term storage, etc., to achieve the effect of improving stability, improving automation control level, and maintaining membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

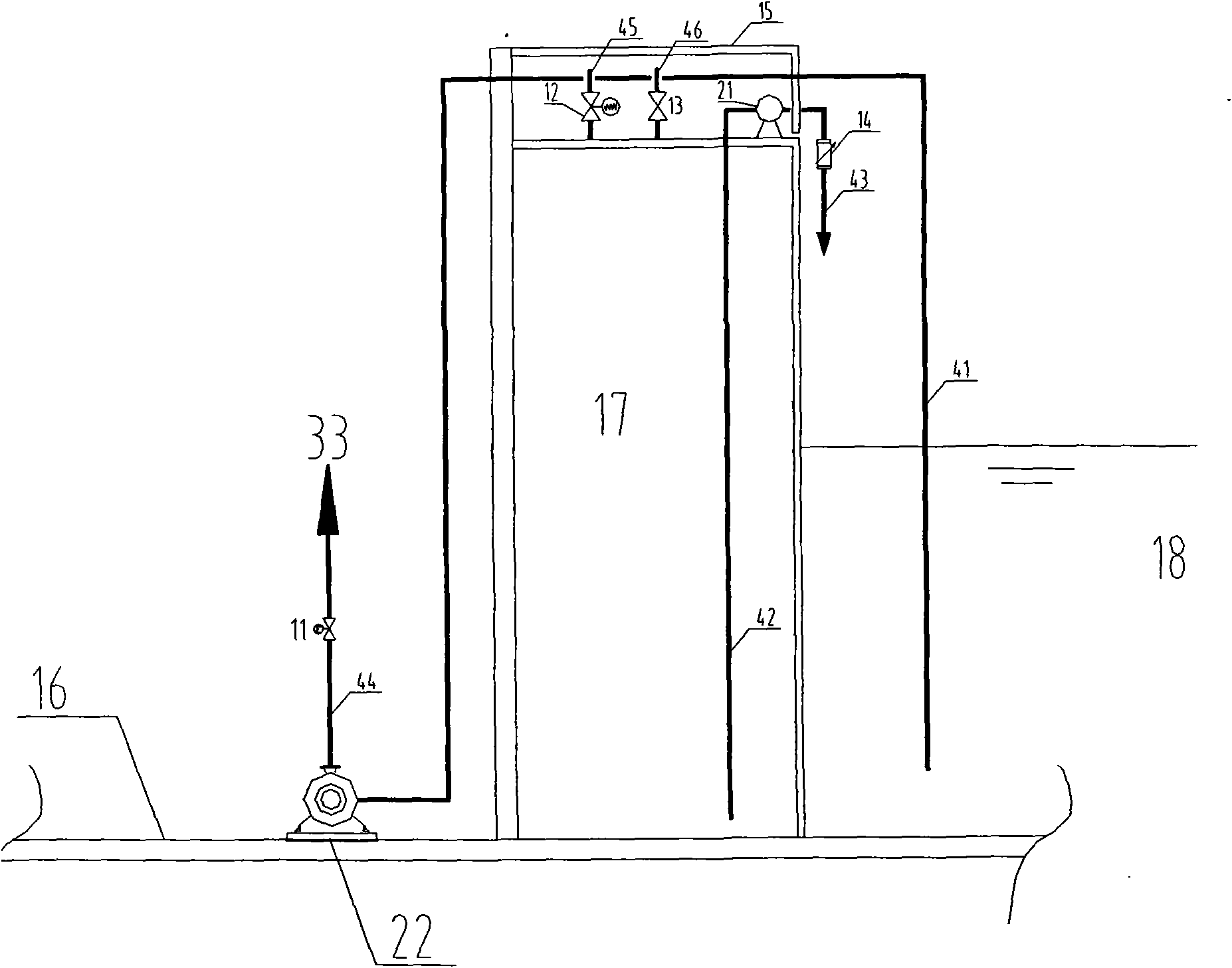

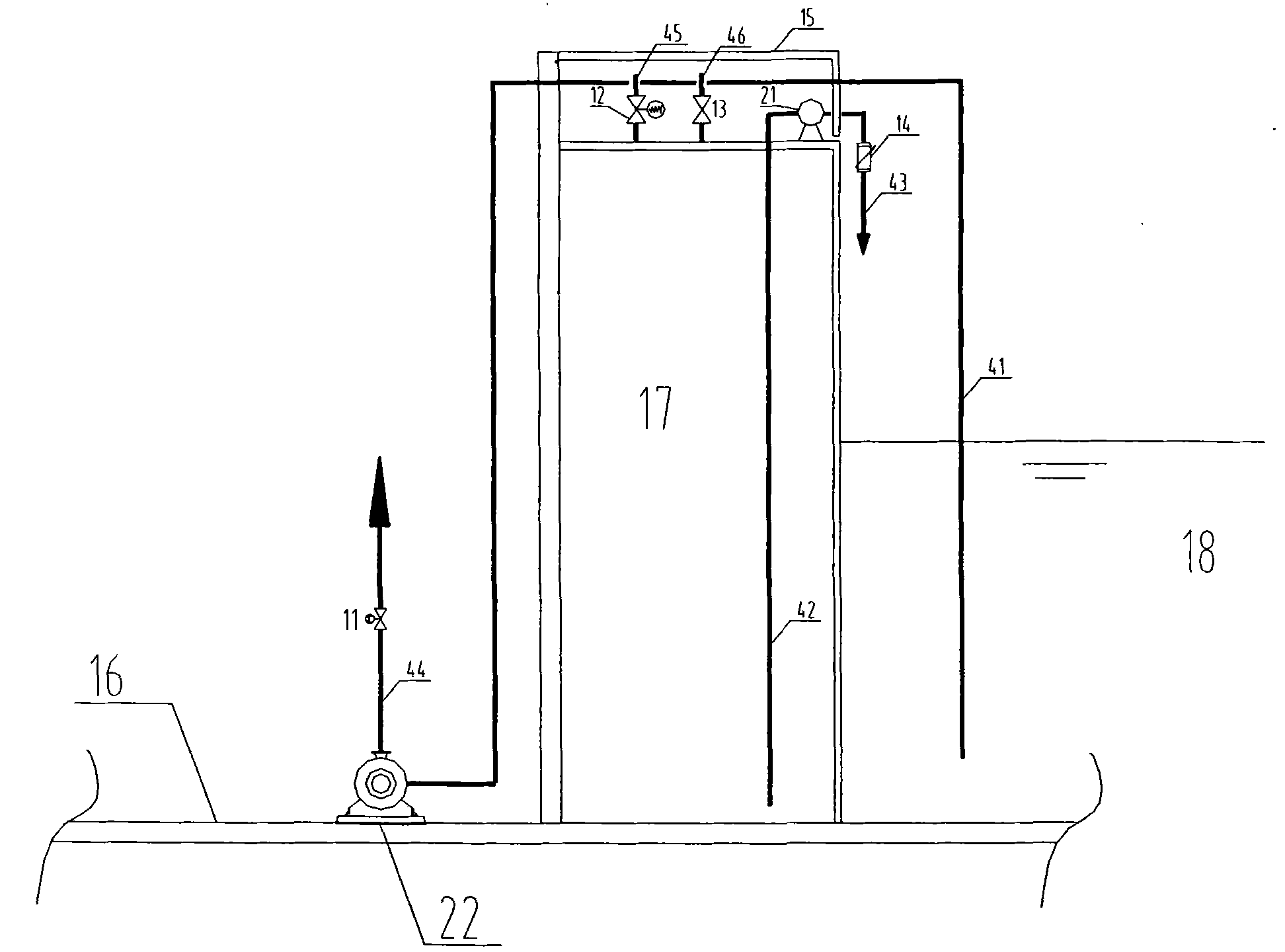

[0038] The present invention will be further described below with reference to the accompanying drawings and in conjunction with specific embodiments.

[0039] A chemical cleaning method for a microfiltration membrane of a membrane bioreactor has the following steps in sequence:

[0040] Step 1) preparing the composite chemical cleaning agent whose available chlorine concentration is 10-13%, the components and contents thereof of the composite chemical cleaning agent are as follows:

[0041] Industrial sodium hypochlorite with effective chlorine concentration of 10-13% 98.0%;

[0042] Lauryl polyoxyethylene 1.8%;

[0043] Sodium hydroxide balance.

[0044] The pH value of the compound chemical cleaning agent prepared by adjusting the available chlorine concentration of 10-13% with sodium hydroxide is greater than 13, and the addition amount of sodium hydroxide is determined according to the initial pH value of the purchased industrial sodium hypochlorite;

[0045] Step 2) u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com