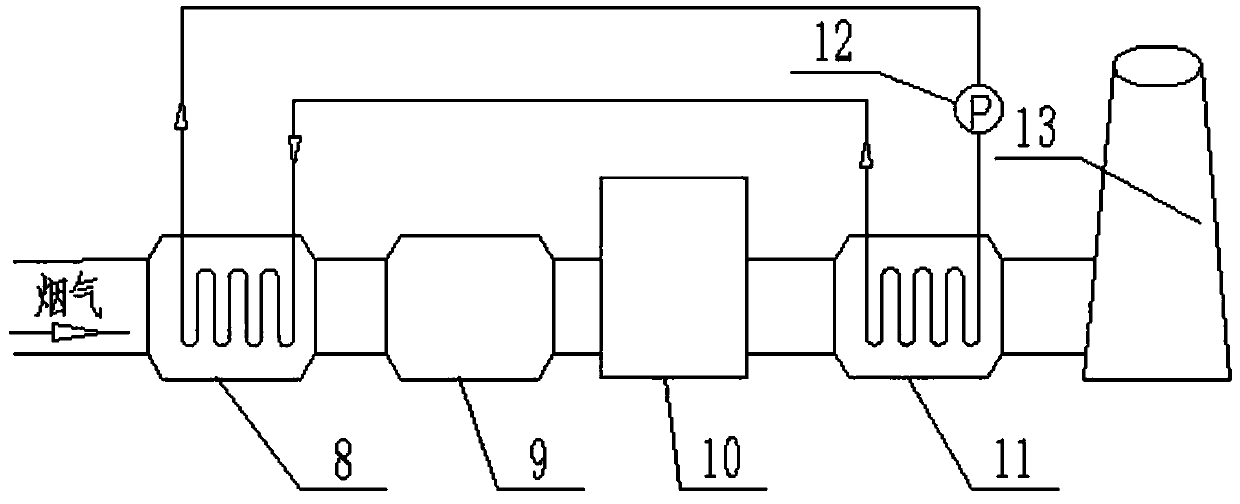

White smoke heating eliminating device and method for smoke of fossil-fuel power station

A flue gas heating, thermal power plant technology, applied in lighting and heating equipment, etc., can solve the problems of high operating cost, high investment, large system, etc., to prevent equipment damage or safety accidents, reduce investment costs, and improve heat exchange efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

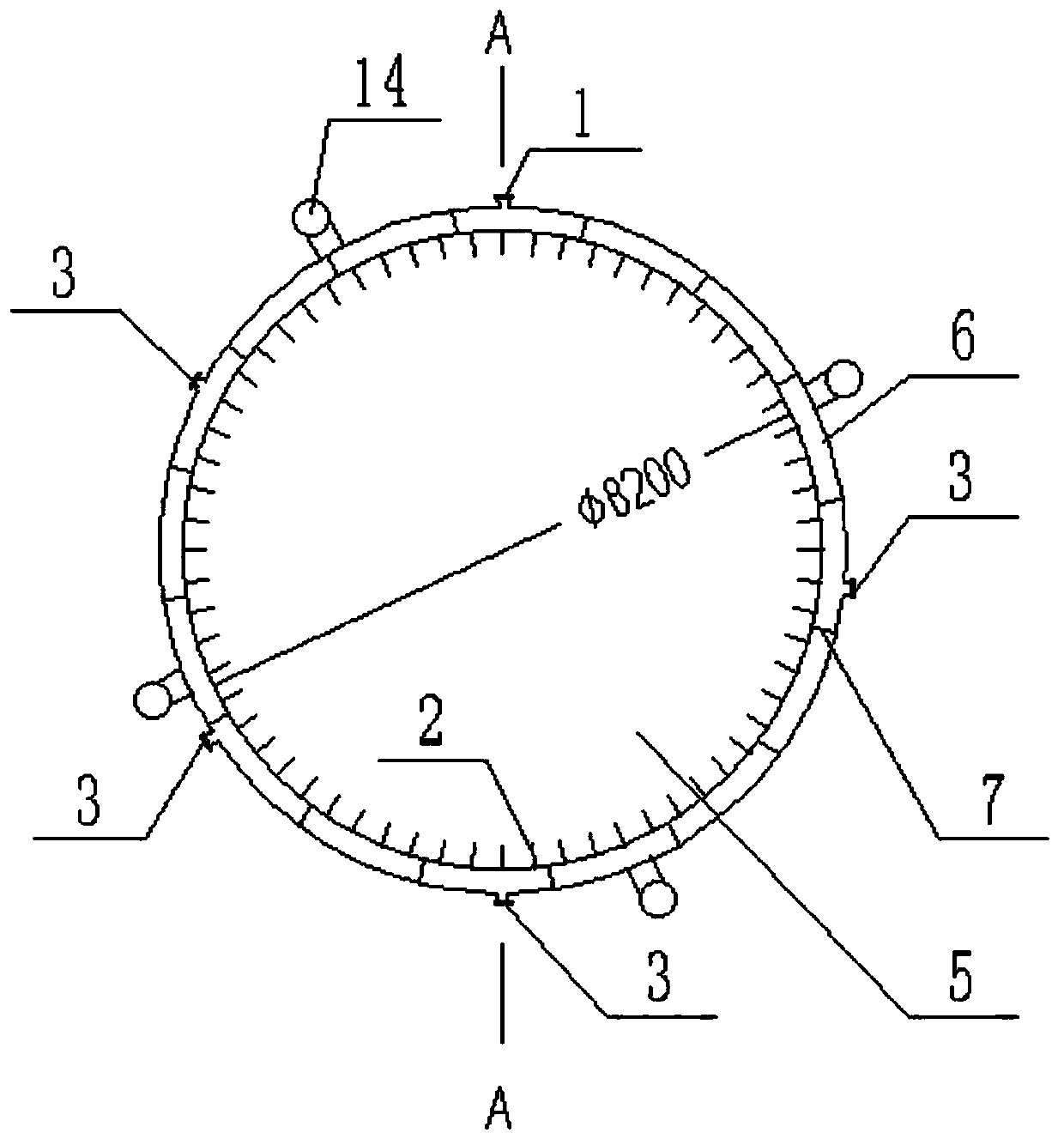

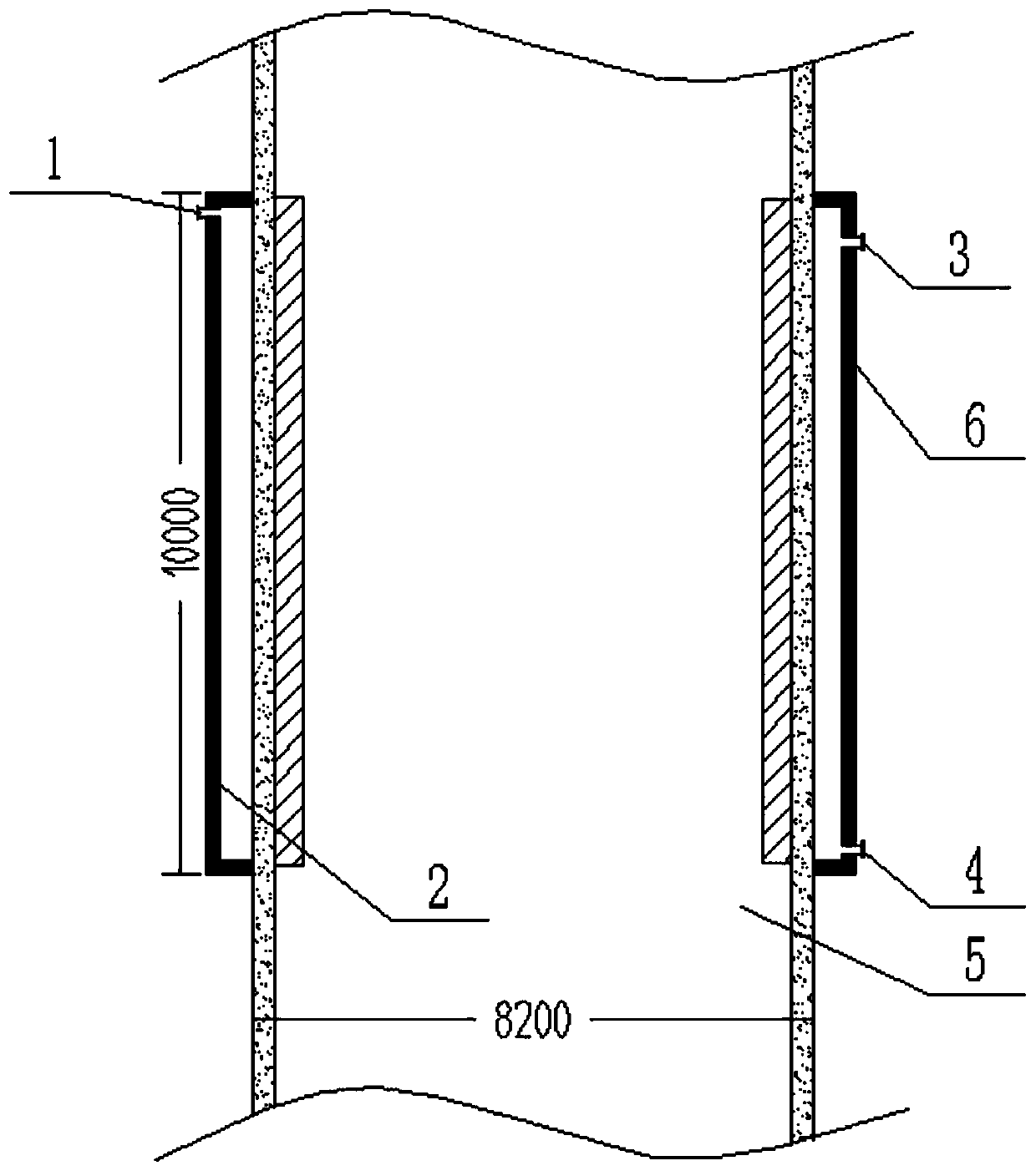

[0025] Such as Figure 2-3 As shown, a device for heating and eliminating white smoke of flue gas in a thermal power plant includes a flue 5 for discharging flue gas after desulfurization. The diameter of the flue 5 is 8.2m. Sheet 2 is made of a titanium plate with a thickness of 1 mm, and there are 250 sheets in total.

[0026] The flue gas heating and white smoke elimination device also includes a sleeve heater 6 with a height of 10m arranged on the outer wall of the flue 5. The sleeve heater 6 is made of 8mm Q235 steel plate. The sleeve heater 6 The distance between the outer wall and the outer wall of the flue 5 is 150 mm, and a reinforcement plate 7 is arranged at an interval of about 1 m in the cavity formed by the inner wall of the sleeve heater 6 and the outer wall of the flue 5 .

[0027] The rated pressure of the sleeve heater 6 is 0.6 MPa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com