Formula and preparing method of thermistor insulating protection material

A technology of insulation protection and thermistor, which is applied in the direction of epoxy resin coating, coating, etc., to prevent the entry of moisture, reduce the possibility of malfunction, and improve the effect of environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment combines figure 1 with figure 2 , the material is made of the following components by mass: 100 parts of E-51 epoxy resin, 50 parts of light calcium carbonate, 10 parts of yellow paste, 20 parts of imidazole adduct curing agent, 5 parts of fumed silica, 0.05 part of defoamer.

[0031] The preparation method of this embodiment is:

[0032] 1) Weigh 100 parts of E-51 epoxy resin, 10 parts of yellow paste, and 0.05 parts of defoamer in proportion, and stir evenly;

[0033] 2) A small amount of 50 parts of light calcium carbonate was added several times, and stirred at high speed for 1.5 hours;

[0034] 3) Natural cooling to below 50°C;

[0035] 4) Add 10 parts of imidazole adduct curing agent and 5 parts of fumed silica in proportion, and stir for 10 minutes until uniform;

[0036] 5) After the three-roll machine disperses twice, stir for 10 minutes until uniform;

[0037] 6) Vacuum defoaming for 60 minutes.

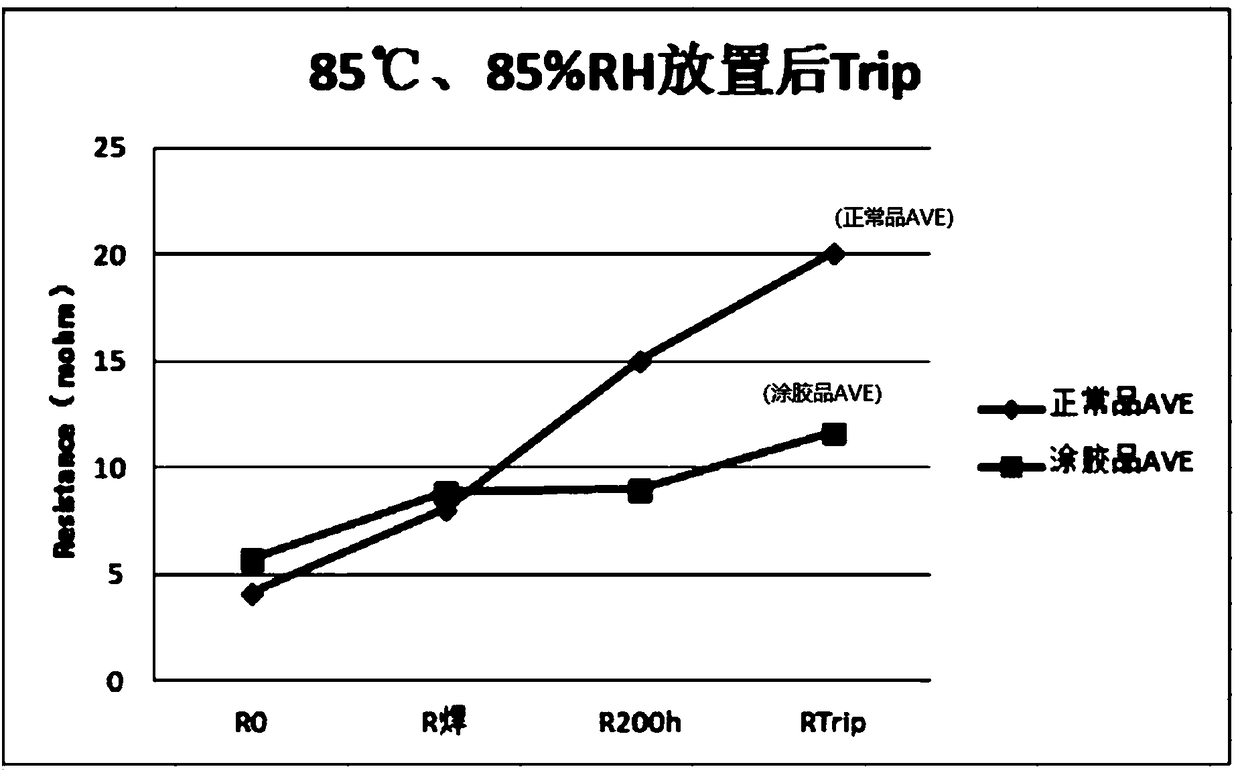

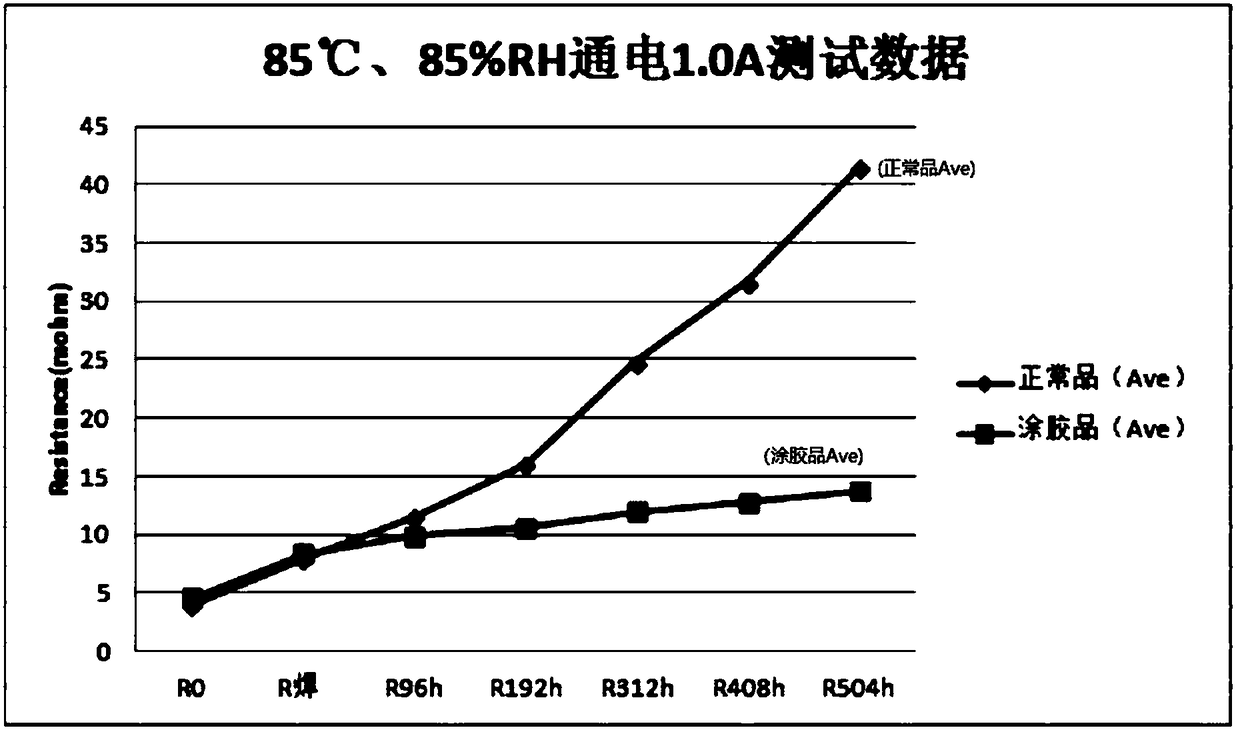

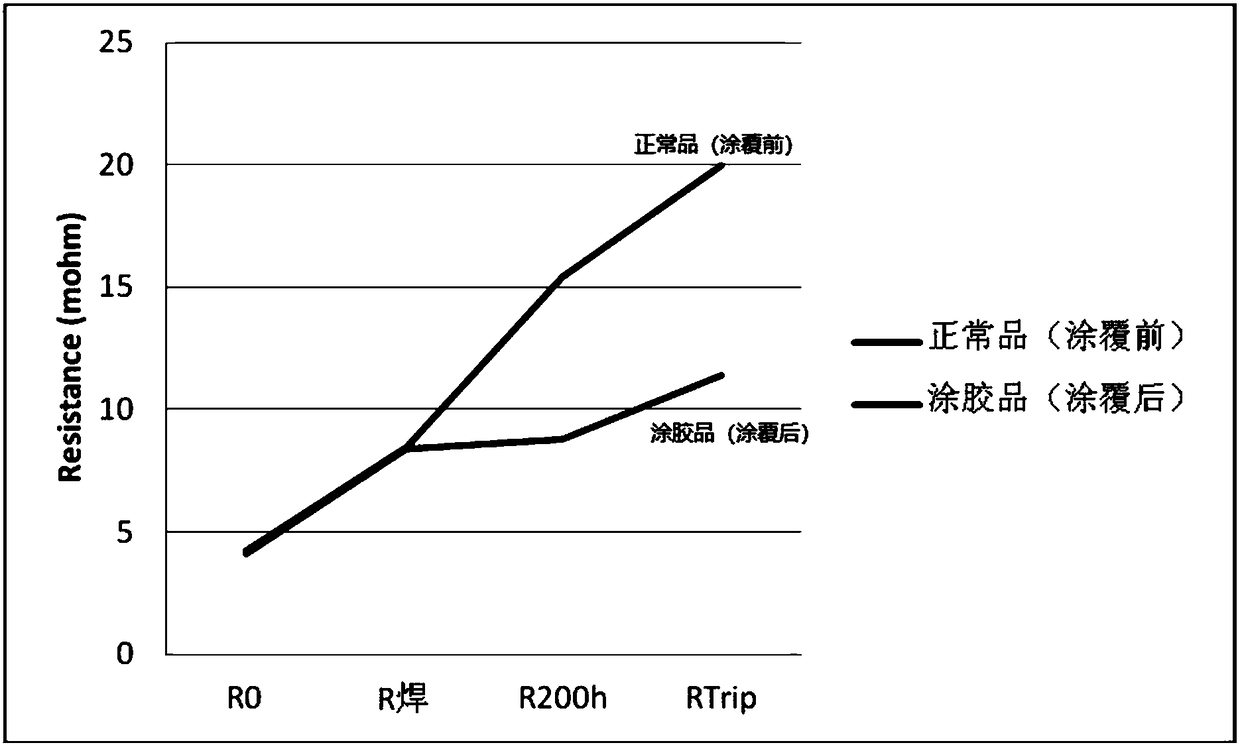

[0038] Apply this insulating protection...

Embodiment 2

[0045] This embodiment combines image 3 with Figure 4 , the material is made of the following components by mass: 100 parts of liquid bisphenol F epoxy resin, 80 parts of heavy calcium carbonate, 20 parts of blue paste, 10 parts of imidazole adduct curing agent, 1 part of fumed silica part, 0.5 part of defoamer.

[0046] The preparation method of this embodiment is:

[0047] 1) Weigh 100 parts of liquid bisphenol F epoxy resin, 20 parts of blue paste, and 0.5 parts of defoamer in proportion, and stir evenly;

[0048] 2) Add 80 parts of heavy calcium carbonate several times in small amounts, and stir at high speed for 1.5 hours;

[0049] 3) Natural cooling to below 50°C;

[0050] 4) Add 10 parts of imidazole adduct curing agent and 1 part of fumed silica in proportion, and stir for 5 minutes until uniform;

[0051] 5) After the three-roll machine disperses for 3 times, stir for 20 minutes until uniform;

[0052] 6) Vacuum defoaming for 30 minutes.

[0053] Apply this i...

Embodiment 3

[0060] The material of this example is made of the following components by mass: 100 parts of liquid bisphenol F epoxy resin, 50 parts of heavy calcium carbonate, 10 parts of cyan paste, 15 parts of imidazole adduct curing agent, fumed silica 3 parts, 0.3 parts of defoamer.

[0061] The preparation method of this embodiment is:

[0062] 1) Weigh 100 parts of liquid bisphenol F epoxy resin, 10 parts of cyan paste, and 0.3 parts of defoamer in proportion, and stir evenly;

[0063] 2) Add 50 parts of heavy calcium carbonate several times in small amounts, and stir at high speed for 1.5 hours;

[0064] 3) Natural cooling to below 50°C;

[0065] 4) Add 15 parts of imidazole adduct curing agent and 3 parts of fumed silica in proportion, and stir for 5 minutes until uniform;

[0066] 5) After the three-roll machine disperses twice, stir for 20 minutes until uniform;

[0067] 6) Vacuum defoaming for 40 minutes.

[0068] Apply this insulating protection material evenly around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com